Steam-electric power station

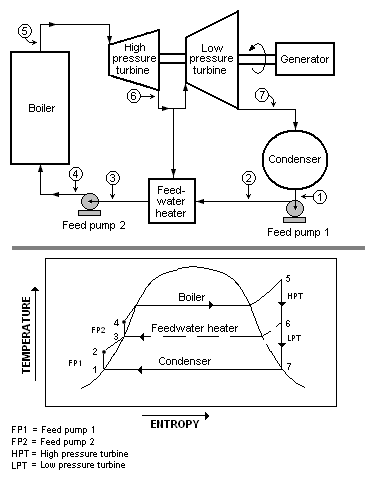

A steam-electric power station is a power station in which the electric generator is steam driven. Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenser. The greatest variation in the design of steam-electric power plants is due to the different fuel sources.

Almost all coal, nuclear, geothermal, solar thermal electric power plants, waste incineration plants as well as many natural gas power plants are steam-electric. Natural gas is frequently combusted in gas turbines as well as boilers. The waste heat from a gas turbine can be used to raise steam, in a combined cycle plant that improves overall efficiency.

Worldwide, most electric power is produced by steam-electric power plants, which produce about 86% of all electric generation. The only other types of plants that currently have a significant contribution are hydroelectric and gas turbine plants, which can burn natural gas or diesel. Photovoltaic panels, wind turbines and binary cycle geothermal plants are also non-steam electric, but currently do not produce much electricity.

History

Reciprocating steam engines have been used for mechanical power sources since the 18th Century, with notable improvements being made by James Watt. The very first commercial central electrical generating stations in New York and London, in 1882, also used reciprocating steam engines. As generator sizes increased, eventually turbines took over due to higher efficiency and lower cost of construction. By the 1920s any central station larger than a few thousand kilowatts would use a turbine prime mover.

Efficiency

The electric efficiency of a conventional steam-electric power plant, considered as saleable energy produced at the plant busbars compared with the heating value of the fuel consumed, is typically 33 to 48% efficient, limited as all heat engines are by the laws of thermodynamics (See: Carnot cycle). The rest of the energy must leave the plant in the form of heat. This waste heat can be disposed of with cooling water or in cooling towers. If the waste heat is instead utilized for e.g. district heating, it is called cogeneration. An important class of steam power plants are associated with desalination facilities; these are typically found in desert countries with large supplies of natural gas and in these plants, freshwater production and electricity are equally important co-products.

Since the efficiency of the plant is fundamentally limited by the ratio of the absolute temperatures of the steam at turbine input and output, efficiency improvements require use of higher temperature, and therefore higher pressure, steam. Historically, other working fluids such as mercury have been experimentally used in a mercury vapour turbine power plant, since these can attain higher temperatures than water at lower working pressures. However, the obvious hazards of toxicity, and poor heat transfer properties, have ruled out mercury as a working fluid.

Steam plant

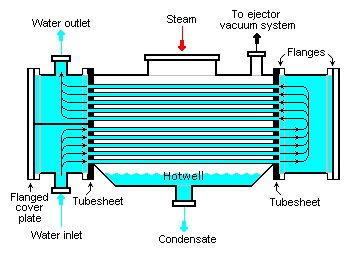

Condenser

Steam-electric power plants utilize a surface condenser cooled by water circulating through tubes. The steam which was used to turn the turbine is exhausted into the condenser. The steam is therefore condensed as it comes in contact with the cool tubes full of circulating water. This condensed steam is withdrawn from the bottom of the surface condenser. The condensed steam is now water, commonly referred to as condensate water.

The adjacent image is a diagram of one of the many typical surface condenser designs.[1][2][3][4]

For best efficiency, the temperature in the condenser must be kept as low as practical in order to achieve the lowest possible pressure in the condensing steam. Since the condenser temperature can almost always be kept significantly below 100 oC where the vapor pressure of water is much less than atmospheric pressure, the condenser generally works under vacuum. Thus leaks of non-condensable air into the closed loop must be prevented. Plants operating in hot climates may have to reduce output if their source of condenser cooling water becomes warmer; unfortunately this usually coincides with periods of high electrical demand for air conditioning. If a good source of cooling water is not available, cooling towers may be used to reject waste heat to the atmosphere. A large river or lake can also be used as a heat sink for cooling the condensers; temperature rises in naturally occurring waters may have undesirable ecological effects, but may also incidentally improve yields of fish in some circumstances.

Feedwater heater

In the case of a conventional steam-electric power plant utilizing a drum boiler, the surface condenser removes the latent heat of vaporization from the steam as it changes states from vapor to liquid. The heat content (btu) in the steam is referred to as Enthalpy. The condensate pump then pumps the condensate water through a feedwater heater. The feedwater heating equipment then raises the temperature of the water by utilizing extraction steam from various stages of the turbine.[1][2]

Preheating the feedwater reduces the irreversibilities involved in steam generation and therefore improves the thermodynamic efficiency of the system.[5] This reduces plant operating costs and also helps to avoid thermal shock to the boiler metal when the feedwater is introduced back into the steam cycle.

Boiler

Once this water is again inside the boiler or steam generator, the process of adding the latent heat of vaporization or Enthalpy is underway. The boiler transfers energy to the water by the chemical reaction of burning some type of fuel. The water enters the boiler through a section in the convection pass called the economizer. From the economizer it passes to the steam drum. Once the water enters the steam drum it goes down the downcomers to the lower inlet waterwall headers. From the inlet headers the water rises through the waterwalls and is eventually turned into steam due to the heat being generated by the burners located on the front and rear waterwalls (typically). As the water is turned into steam/vapor in the waterwalls, the steam/vapor once again enters the steam drum. The steam/vapor is passed through a series of steam and water separators and then dryers inside the steam drum. The steam separators and dryers remove the water droplets from the steam and the cycle through the waterwalls is repeated. This process is known as natural circulation.

Any droplets of liquid water carried over into the turbine can produce destructive erosion of the turbine blades.

Geothermal plants need no boiler since they use naturally occurring steam sources. Heat exchangers may be used where the geothermal steam is very corrosive or contains excessive suspended solids. Nuclear plants also boil water to raise steam, either directly passing the working steam through the reactor or else using an intermediate heat exchanger.

Superheater

As the steam is conditioned by the drying equipment inside the drum, it is piped from the upper drum area into an elaborate set up of tubing in different areas of the boiler. The areas known as superheater and reheater. The steam vapor picks up energy and its temperature is now superheated above the saturation temperature. The superheated steam is then piped through the main steam lines to the valves of the high-pressure turbine.

See also

References

- 1 2 Babcock & Wilcox Co. (2005). Steam: Its Generation and Use (41st ed.). ISBN 0-9634570-0-4.

- 1 2 Thomas C. Elliott, Kao Chen, Robert Swanekamp (coauthors) (1997). Standard Handbook of Powerplant Engineering (2nd ed.). McGraw-Hill Professional. ISBN 0-07-019435-1.

- ↑ Air Pollution Control Orientation Course from website of the Air Pollution Training Institute

- ↑ Energy savings in steam systems Figure 3a, Layout of surface condenser (scroll to page 11 of 34 pdf pages)

- ↑ Fundamentals of Steam Power by Kenneth Weston, University of Tulsa