IBM Solid Logic Technology

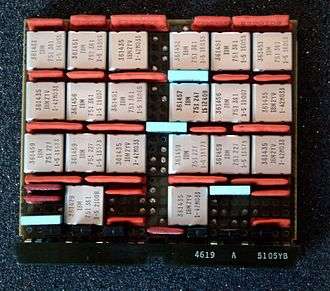

Solid Logic Technology (SLT) was IBM's method for packaging electronic circuitry introduced in 1964 with the IBM System/360 series and related machines.[1] IBM chose to design custom hybrid circuits using discrete, flip chip-mounted, glass-encapsulated transistors and diodes, with silk screened resistors on a ceramic substrate, forming an SLT module. The circuits were either encapsulated in plastic or covered with a metal lid. Several of these SLT modules (20 in the image on the right) were then mounted on a small multi-layer printed circuit board to make an SLT card. Each SLT card had a socket on one edge that plugged into pins on the computer's backplane (the exact reverse of how most other companies' modules were mounted).

SLT was a revolutionary technology for 1964 with the reliability improvements over other assembly techniques helping propel the IBM/360 mainframe family to overwhelming success during the 1960s. SLT research produced ball chip assembly, wafer bumping, trimmed thick film resistors, printed discrete functions, chip capacitors and one of the first volume uses of hybrid thick film technology.

SLT replaced the earlier Standard Modular System, although some SMS cards held SLT modules.

Details

SLT used silicon planar glass-encapsulated transistors and diodes.[2]

SLT uses dual diode chips and individual transistor chips each approx 0.025 inch square.[3]:15 The chips are mounted on a 0.5 inch square substrate with screen resistors and printed connections. The whole is encapsulated to form a 0.5 inch square module. 6 to 36 modules are mounted on each card. Cards plug into boards which are connected to form gates which form frames.[3]:15

SLT voltages : > +2.08V is up, < 0.90 V is down.[3]:16

Later developments

The same basic packaging technology (both device and module) was also used for the devices that replaced SLT as IBM gradually transitioned from hybrid integrated circuits to monolithic integrated circuits:

- Solid Logic Dense (SLD) increased packaging density and circuit performance by mounting the discrete transistors and diodes on top of the substrate and the resistors on the bottom.[3]:15 SLD voltages were the same as SLT.

- Advanced Solid Logic Technology (ASLT) increased packaging density and circuit performance by stacking two substrates in the same package. ASLT is based on the Emitter-follower-coupled-switch used with current-switching logic.[3]:18 ASLT voltage levels were : > +235 mV is high, < -239 mV is low.[3]:16

- Monolithic System Technology (MST) increased packaging density and circuit performance by replacing discrete transistors and diodes with one to four monolithic integrated circuits (resistors now external from the package on the module). Each MST chip holds about 5 circuits and is the approx equivalent of an SLT card.[3]:18 Circuits used NPN transistors.

References

- ↑ System/360 Announcement

- ↑ Davis, E.M.; Harding, W.E.; Schwartz, R.S.; Corning, J.J. (April 1964). "Solid Logic Technology: Versatile, High-Performance Microelectronics". IBM Journal of Research and Development. 8 (2): 102–114. doi:10.1147/rd.82.0102.

- 1 2 3 4 5 6 7 Logic Blocks Automated Logic Diagrams SLT, SLD, ASLT, MST (PDF) 86 pages

External links

- Davis, E.M.; Harding, W.E.; Schwartz, R.S.; Corning, J.J. (April 1964). "Solid Logic Technology: Versatile, High-Performance Microelectronics". IBM Journal of Research and Development. 8 (2): 102–114. doi:10.1147/rd.82.0102.

- Logic Blocks Automated Logic Diagrams SLT, SLD, ASLT, MST (PDF)