Monocrystalline silicon

Monocrystalline silicon (or "single-crystal silicon", "single-crystal Si", "mono c-Si", or just mono-Si) is the base material for silicon chips used in virtually all electronic equipment today. Mono-Si also serves as photovoltaic, light-absorbing material in the manufacture of solar cells.

It consists of silicon in which the crystal lattice of the entire solid is continuous, unbroken to its edges, and free of any grain boundaries. Mono-Si can be prepared intrinsic, consisting only of exceedingly pure silicon, or doped, containing very small quantities of other elements added to change its semiconducting properties. Most silicon monocrystals are grown by the Czochralski process into ingots of up to 2 meters in length and weighing several hundred kilograms. These cylinders are then sliced into thin wafers of a few hundred microns for further processing.

Single-crystal silicon is perhaps the most important technological material of the last few decades—the "silicon era",[1] because its availability at an affordable cost has been essential for the development of the electronic devices on which the present-day electronics and IT revolution is based.

Monocrystalline silicon differs from other allotropic forms, such as the non-crystalline amorphous silicon—used in thin-film solar cells—and polycrystalline silicon, that consists of small crystals, also known as crystallites.

In electronics

The monocrystalline form is used in the semiconductor device fabrication since grain boundaries would bring discontinuities and favor imperfections in the microstructure of silicon, such as impurities and crystallographic defects, which can have significant effects on the local electronic properties of the material. On the scale that devices operate on, these imperfections would have a significant impact on the functionality and reliability of the devices. Without the crystalline perfection, it would be virtually impossible to build Very Large-Scale Integration (VLSI) devices (figure below), in which billions[2] of transistor-based circuits, all of which must be reliably working, are combined into a single chip to form a microprocessor, for example. Therefore, the electronics industry has invested heavily in facilities to produce large single crystals of silicon.

In solar cells

Monocrystalline silicon is used in the manufacturing of high performance solar cells; however, since solar cells are less demanding than microelectronics regarding structural imperfections, monocrystaline solar grade (Sog-Si) is often used.

Market-share

In 2013, monocrystalline solar cells had a market-share of 36 percent, which translated into the production of 12,600 megawatts of photovoltaic capacity,[3] and ranked second behind the somewhat cheaper sister-technology of polycrystalline silicon.[4]

Efficiency

Lab efficiencies of 26.6 percent for (heterojunction back-contact type) mono-Si cells are the highest in the commercial PV market, ahead of polysilicon with 21.3 percent and all established thin-film technologies namely, CIGS cells (22.6%), CdTe cells (22.1%), and a-Si cells (14.0%).[5] These high efficiencies can be combined with other technologies, such as multi-layer solar cells in applications where space and weight become an issue such as powering satellites.

Solar module efficiencies—which are always lower than those of their corresponding cells—crossed the 20 percent mark for mono-Si in 2012; an improvement of 5.5 percent over a period of ten years. The thickness of a silicon wafer used to produce a solar cell also decreased significantly, requiring less raw material and therefore less energy for its manufacture. Increased efficiency combined with economic usage of resources and materials was the main driver for the price decline over the last decade.[6]

Appearance

The crystalline structure of silicon forms a diamond cubic.

The crystalline structure of silicon forms a diamond cubic.

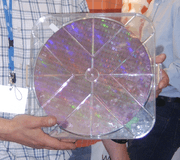

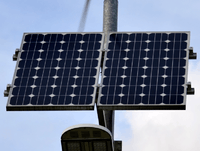

Solar panel made of octagonal monocrystalline silicon cells

Solar panel made of octagonal monocrystalline silicon cells Comparison of solar cells: multi-Si (left) and mono-Si (right)

Comparison of solar cells: multi-Si (left) and mono-Si (right)

See also

References

- ↑ W.Heywang, K.H.Zaininger, Silicon: the semiconductor material, in Silicon: evolution and future of a technology, P.Siffert, E.F.Krimmel eds., Springer Verlag, 2004.

- ↑ Peter Clarke, Intel enters billion-transistor processor era, EE Times, 14 October 2005

- ↑ Photovoltaics Report, Fraunhofer ISE, July 28, 2014, pages 18,19

- ↑ S.R.Wenham, M.A.Green, M.E.Watt., R.Corkish, Applied Photovoltaics, Earthscan, 2007, Chapt. 2

- ↑ Solar cell efficiency tables (version49), November 28, 2016 and errata thereof

- ↑ Photovoltaics Report, Fraunhofer ISE, July 28, 2014, pages 23 and 29