Rolls-Royce Trent

| Trent | |

|---|---|

| |

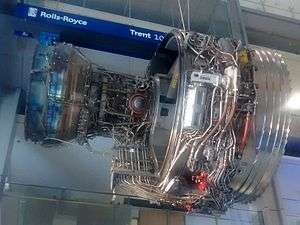

| A Trent turbofan engine installed on a test bench at the Rolls-Royce Test Facility in Derby, UK. | |

| Type | Turbofan |

| National origin | United Kingdom |

| Manufacturer | Rolls-Royce |

| First run | August 1990 |

| Major applications | Airbus A330 Airbus A340 Airbus A350 Airbus A380 Boeing 777 Boeing 787 |

| Developed from | Rolls-Royce RB211 |

| Variants | Rolls-Royce Trent 500 Rolls-Royce Trent 700 Rolls-Royce Trent 800 Rolls-Royce Trent 900 Rolls-Royce Trent 1000 Rolls-Royce Trent XWB Rolls-Royce Trent 7000 |

| Developed into | Rolls-Royce MT30 |

Rolls-Royce Trent is a British family of three spool, high bypass turbofan aircraft engines manufactured by Rolls-Royce plc. All are developments of the RB211 with thrust ratings of 53,000 to 97,000 pounds-force (240 to 430 kN). Versions of the Trent are in service on the Airbus A330, A340, A350, A380, Boeing 777, and 787. The Trent has also been adapted for marine and industrial applications.

First run in August 1990 as the model Trent 700, the Trent has achieved significant commercial success, having been selected as the launch engine for both of the 787 variants (Trent 1000) note 1, the A380 (Trent 900) and the A350 (Trent XWB). Its overall share of the markets in which it competes is around 40%.[1] Sales of the Trent family of engines have made Rolls-Royce the second biggest supplier of large civil turbofans after General Electric,[2] relegating rival Pratt & Whitney to third position.

In keeping with Rolls-Royce's (sometimes neglected) tradition of naming its jet engines after rivers,[3] this engine is named after the River Trent in the Midlands of England. Singapore Airlines is currently the largest operator of Trents, with five variants in service or on order.note 3

Design and development

Origin

When Rolls-Royce was privatised in April 1987, its share of the large civil turbofan market was only 8%.[4] Despite increasing sales success with the RB211, General Electric and Pratt & Whitney still dominated the market. At that time, the aircraft manufacturers were proposing new planes that would require unprecedented levels of thrust. Furthermore, the Boeing 777 and Airbus A330 were to be twin-engined, and their airline customers were demanding that they be capable of operating in the Extended-range Twin-engine Operations (ETOPS) environment at the time of their initial introduction into service.

Rolls-Royce decided that to succeed in the large engine market of the future, it would have to offer engines for every large civil airliner. In view of the enormous development costs required to bring a new engine to market, the only way to do this would be to have a family of engines based on a common core. The three-shaft design of the RB211 was an ideal basis for the new family as it provided flexibility, allowing the high-pressure (HP), intermediate-pressure (IP) and low-pressure (LP) systems to be individually scaled. Rolls decided to launch a new family of engines, which was formally announced at the 1988 Farnborough Airshow. Reviving a name last used 30 years earlier, the new engine was named the Trent. The name had been used for two previous Rolls-Royce engines: the first Trent was the world's first turboprop engine; the second Trent was the 1960s RB203 bypass turbofan, designed to replace the Spey. Rated at 9,980 lbf (44.4 kN) it was the first three-spool engine, forerunner of the RB211 series, but never entered service.

Rolls-Royce has obtained significant sums of "launch investment" from the British government for the Trent programmes, including £200 million approved in 1997 for Trent 8104, 500 and 600 and £250 million for Trent 600 and 900 in 2001. No aid was sought for Trent 1000. Launch investment is repaid to the government by a royalty on each engine sold.[5]

The basis for the Trent was the RB.211-524L, work on which began in 1987.[6]

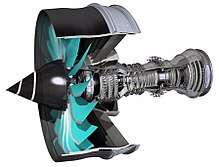

Design

Like its RB211 predecessor, the Trent uses a three-spool design rather than the more common two-spool configuration. Although more complex, the engine is shorter and more rigid, and suffers less performance degradation in service than an equivalent twin-spool. The advantage three spools gives is that the front-most fan (driven by the third, rearmost turbine) can be tuned to rotate at its optimal (fairly low) speed; the two compressors are driven by the two other turbines via their spools. The three spools are concentric.

All the engines in the Trent family share a similar layout, but their three-spool configuration allows each engine module to be individually scaled to meet a wide range of performance and thrust requirements. For example, the large 116-inch (290 cm) diameter fan of the Trent 900 keeps the mean jet velocity at take-off at a relatively low level to help meet the stringent noise levels required by the Airbus A380's customers.[7] Similarly, core size changes enable the (High Pressure) turbine rotor inlet temperature to be kept as low as possible, thereby minimising maintenance costs. The overall pressure ratio of the Trent 800 is higher than the 700's despite sharing the same HP system and Intermediate Pressure turbine; this was achieved by increasing the capacity of the IP compressor and the Low Pressure turbine.

Trent engines use hollow titanium fan blades with an internal Warren-girder structure to achieve strength, stiffness and robustness at low weight. For the Trent 800, the 110-inch diameter[8] fan can rotate at 3300 rpm with a tip speed of about 483 m/s, well above the speed of sound. The single-crystal nickel alloy turbine blades are also hollow, and air is pushed through laser-drilled holes in them to cool them because the gas temperature is higher than the melting point of the blades. Each blade removes up to 560 kW from the gas stream.[9]

The completely redesigned core turbomachinery delivers better performance, noise and pollution levels than the RB211. So significant are the improvements that Rolls-Royce fitted the Trent 700's improved HP system to the RB211-524G and -524H,[10] creating -524G-T and -524H-T respectively.

When the RB211 programme started, it was intended that none of the compression system would require variable stators, unlike the American competition. Unfortunately, it was found that, because of the shallow working line on the Intermediate Pressure Compressor (IPC), at least one row of variable stators was required on the IPC, to improve its surge margin at throttled conditions. This feature has been retained throughout the RB211 and Trent series. Although the original intent was not met, Rolls-Royce eliminated the need for many rows of variable stators, with all their inherent complexity, thereby saving weight, cost and improving reliability.

On 17 January 2008, a British Airways Boeing 777-236ER, operating as BA038 from Beijing to London, crash-landed at Heathrow after both Trent 800 engines lost power during the aircraft's final approach. The subsequent investigation found that ice released from the fuel system had accumulated on the fuel-oil heat exchanger, leading to a restriction of fuel flow to the engines.[11] This resulted in Airworthiness Directives mandating the replacement of the heat exchanger.[12] This order was extended to the 500 and 700 series engines after a similar loss of power was observed on one engine of an Airbus A330[12] in one incident, and both engines in another.[13] The modification involves replacing a face plate with many small protruding tubes with one that is flat.[14]

Variants

Trent 600 – First proposal

The initial variant, the Trent 600, was to power the McDonnell Douglas MD-11 with British Caledonian as the engine's launch customer. However, British Airways cancelled the MD-11 order when it acquired British Caledonian in 1987. With the collapse in 1991 of Air Europe in the aftermath of the 1990-91 Gulf War, the only other Trent-powered MD-11 customer was lost. As the MD-11 was itself suffering poor sales due to its failure to meet its performance targets, the Trent 600 was downgraded to a demonstrator programme, engine development being switched to the Trent 700 for the Airbus A330.[15]

Trent 700

In April 1989, Cathay Pacific became the first customer to specify an Airbus aircraft powered by Rolls-Royce engines when it ordered ten Airbus A330s powered by the Trent 700. The following month Trans World Airlines followed suit with an order for twenty A330s.

The Trent 700 first ran in August 1990, and certification was achieved in January 1994. 90-minutes ETOPS approval was achieved in March 1995, and this was extended to 120 minutes in December 1995 and 180 minutes in May 1996.[16]

The first Trent 700-powered A330 flew in August 1994, and entered service with Cathay Pacific in March 1995.[17]

Trent 800

At the same time, Boeing was investigating an enlarged development of its 767 model dubbed the 767X, for which Rolls-Royce proposed the Trent 760. By 1990 Boeing abandoned its planned 767X and instead decided to launch a new, larger aircraft family designated 777 with a thrust requirement of 80,000 lbf (360 kN) or more. The Trent 700's 2.47 m (97 in) diameter fan would not be big enough to meet this requirement, so Rolls proposed a new version with a 2.80 m (110 in) fan diameter, designated Trent 800.

Testing of the Trent 800 began in September 1993, and certification was achieved in January 1995.[16] The first Boeing 777 with Trent 800 engines flew in May 1995, and entered service with Cathay Pacific in April 1996.

Initially Rolls-Royce had difficulty selling the engine; British Airways, traditionally a Rolls-Royce customer, submitted a large order for the competing General Electric GE90 engine. The breakthrough came when it won orders from Singapore Airlines, previously a staunch Pratt & Whitney customer, for its 34 Boeing 777s. The Trent 800 has a 41% share of the engine market on the 777 variants for which it is available.[18]

Trent 8104/8115

In 1998 Boeing proposed new longer range variants of the 777. Taking advantage of the Trent 800's growth capability, Rolls-Royce designed and built an improved engine designated Trent 8104, which was later scaled upwards to the even larger 8115. This development was the first engine to break through 100,000 lbf (440 kN) thrust and subsequently the first to reach 110,000 lbf (490 kN). However, GE Aviation former president James McNerney (now Boeing ex-CEO) successfully offered the aircraft manufacturer up to $500 million in money to develop the 777 in exchange for exclusivity in powering the family. Boeing agreed in July 1999 to such a deal with the GE90-110B and GE90-115B to be the sole engines on the long-range 777s.[19] This resulted in the 8104 becoming just a demonstrator programme, despite setting further industry firsts for thrust levels achieved and the first to demonstrate the use of a fully swept wide chord fan.

It would have come in two thrust ratings, 104,000 lbf (460 kN) and 114,000 lbf (510 kN), and has been tested up to 117,000 lbf (520 kN). As Boeing's thrust requirements increased, Rolls-Royce began developing the 115,000 lbf (510 kN) 8115 which was to be an enlarged version of the 8104, with a 3.05 m (120 in) fan and a core scaled up 2.5 percent from the 8104. It featured swept-back fan blades and a host of new technologies such as contra-rotating spools. The 8115 was never built, as Boeing signed a contract with General Electric to be the sole supplier of engines for the 777X aircraft, owing to GEs willingness to risk-share on the airframe part of the project, and sales of the aircraft to GECAS.

Trent 500

.jpg)

In 1995, Airbus began considering an engine for two new long-range derivatives of its four-engine A340 aircraft, designated A340-500/-600. In April 1996, Airbus signed an agreement with General Electric to develop a suitable engine, but decided not to proceed when GE demanded an exclusivity deal on the A340. After a contest with Pratt & Whitney, Airbus announced on 15 June 1997 at the Paris Air Show that it had selected the Trent 500 to power the A340-500 and -600.[20] Two years later, in May 1999, the Trent 500 first ran and certification was achieved in December 2000. It entered service on the A340-600 with Virgin Atlantic Airways in July 2002 and on the ultra-long range A340-500 with Emirates in December 2003.

After production of the Airbus A340 ended in 2011, a total of 131 A340-500/-600 have been delivered with 524 Trent 500 engines altogether; Lufthansa is the largest operator, with 24 delivered A340-600.[21]

Trent 900

In the early 1990s, Airbus had begun development of a larger successor to the Boeing 747, an aircraft designated A3XX, which was later to be formally launched as the Airbus A380. By 1996, its definition had progressed to the extent that Rolls-Royce was able to announce that it would develop the Trent 900 to power the A380. In October 2000, the Trent 900 became the A380's launch engine when Singapore Airlines specified the engine for its order for 10 A380s; this was quickly followed by Qantas in February 2001.

The Trent 900 first ran on May 17, 2004 on Airbus' A340-300 testbed, replacing the port inner CFM56-5 engine, and its final certification was granted by the European Aviation Safety Agency (EASA) on 29 October 2004 and the Federal Aviation Administration (FAA) on 4 December 2006.[22][23] Rolls-Royce announced in October 2007 that production of the Trent 900 had been restarted after a twelve-month suspension caused by delays to the A380.[24]

On 27 September 2007, British Airways announced the selection of the Trent 900 to power 12 A380 aircraft,[25] helping to take the engine's share of the A380 engine market to 52% at the end of February 2009.

On 4 November 2010, a Trent 900 experienced an uncontained failure on Qantas Flight 32 over Singapore. After investigation, Rolls-Royce announced the problem was specific to the Trent 900,[26] and in particular unrelated to failure of a Trent 1000 under test.[27] However, others have noted that although the specific part may be only found in the 900, in both cases the intermediate pressure turbine and lubrication system are suspect.[28]

Trent 600 – Second proposal

In July 2000, Rolls-Royce signed an agreement with Boeing to offer the Trent 600 engine on developments of 767 and 747 aircraft.[29] The 767 variant was to be a new longer-range version of the Boeing 767-400ER to be powered by the Trent 600 and Engine Alliance GP7172, although in the end this aircraft was never launched. When Boeing finally launched the 747-8 in 2005 it announced that the General Electric GEnx would be the only engine that would be available for the 747-8.

Trent 1000

On 6 April 2004 Boeing announced that it had selected two engine partners for its new 787, Rolls-Royce and General Electric. Initially, Boeing considered the idea of sole sourcing the powerplant for the 787, with GE being the most likely candidate. However, potential customers demanded choices and Boeing relented. Both engine types will have a standard interface with the aircraft, allowing any 787 to be fitted with either a GE or Rolls-Royce engine at any time as long as the pylon is also modified.Note 2

In June 2004, the first public engine selection was made by Air New Zealand, who chose the Trent 1000 for its two firm orders. In the largest 787 order, that of Japan's All Nippon Airways, Rolls-Royce was selected as the engine supplier on October 13, 2004. The deal is valued at $1 billion (£560 million) and covers 30 787-3s and 20 787-8s. The Trent 1000 will be the launch engine on all three current 787 models, the -8 with ANA, the -9 with Air New Zealand and the -10 with Singapore Airlines.[30] On 7 July 2007, Rolls Royce secured its largest ever order from an aircraft leasing company when ILFC placed an order worth $1.3 billion at list prices for Trent 1000s to power 40 of the 787s which it has on order,[31] and on 27 September 2007 British Airways announced the selection of the Trent 1000 to power 24 Boeing 787 aircraft. Trent 1000's share of the 787 engine market was 40% at the end of August 2008.

The first run of the Trent 1000 was on 14 February 2006,[32] with first flight on Rolls-Royce's own flying testbed (a modified Boeing 747-200) successfully performed on June 18, 2007 from TSTC Waco Airport in Waco, TX.[33] The engine received joint certification from the FAA and EASA on 7 August 2007[34] (written 7/8/7 outside the US). Entry into service was delayed to September 2011 following a series of delays to the Boeing 787 programme.[35] The Trent 1000, along with the General Electric GEnx, is distinguished from other turbofans with the use of noise-reducing chevrons on the engine nacelle when in use.

Trent 1500

A Trent 500 replacement engine, known unofficially as the Trent 1500, was proposed for the Airbus A340-500/600 to help them compete with the Boeing 777-200LR/300ER.[36] However, the announcement of the A350 XWB, which covers the A340 market, will most likely prevent the Trent 1500 from ever becoming a reality.

The Trent 1500 would retain the 2.47-metre (8 ft 1 in) fan diameter of the current Trent 500 engine, as well as the nacelle, but incorporates the smaller, more advanced, Trent 1000/XWB gas generator and LP turbine, suitably modified.

Trent XWB

The Trent XWB is a series of turbofan engines, developed from the RB211 and used exclusively for the Airbus A350 XWB.[37] It has a take-off thrust range of 75,000–97,000 lbf (330–430 kN) and a fan diameter of 118 in (3.0 m).[38]

Trent 7000

Officially announced on 14 July 2014 at the Farnborough Airshow the Trent 7000 is to be the exclusive engine for the Airbus A330neo. The Trent 7000 will use previous experience from the Trent 700 as used on the A330, architecture from the Trent 1000-TEN, which is the latest version of the Trent 1000, and technology from the Trent XWB. The engines will offer a thrust range of 68,000–72,000 lbf (300–320 kN) and have an electronic bleed air system (EBAS). Compared to the A330 engines the Trent 7000 will improve specific fuel consumption by twelve per cent (net ten per cent), double the bypass ratio to 10:1, increase maximum compression ratio to 50:1 and halve emitted noise energy enabling the A330neo to meet the stricter London airport (QC) noise regulations of QC1/0.25 for departure and arrivals respectively.[39][40] The Trent 7000 performed its first engine test run on 27 November 2015.[41] The fan diameter is 112 inches and it has 20 fan blades.[42]

Non-aircraft variants

MT30

The MT30 is a derivative of the Trent 800, (with a Trent 500 gearbox fitted), producing 36 MW for maritime applications. The current version is a turboshaft engine, producing 36 MW, using the Trent 800 core to drive a power turbine which takes power to an electrical generator or to mechanical drives such as waterjets or propellers. It will power the Royal Navy's Queen Elizabeth class aircraft carriers.

Industrial Trent 60 Gas Turbine

This derivative is designed for power generation and mechanical drive, much like the Marine Trent. It delivers up to 66 MW of electricity at 42% efficiency.[43] It comes in two key versions DLE and WLE. The WLE is water injected, allowing it to produce 58 MW in ISA conditions instead of 52 MW. It shares components with the Trent 700 and 800.[43] The heat from the exhaust, some 416–433 °C,[43] can be used to heat water and drive steam turbines, improving efficiency of the package. Besides Rolls-Royce, a leading packager of the Trent 60 is UK-based Centrax LTD,[44] a privately owned engineering firm based in Newton Abbot, UK.

Future developments

On 26 February 2014, Rolls-Royce detailed its Trent future developments. The Advance is the first design could be ready from the end of the 2010s and aim to offer at least 20% better fuel burn than the first generation of Trents. Next is the UltraFan, which could be ready for service from 2025, a geared turbofan with a variable pitch fan system, promising at least 25% improvement in fuel burn.[45] The Advance bypass ratio should exceed 11:1 and its overall pressure ratio 60:1, while the geared/variable pitch UltraFan aims for a 15:1 bypass ratio and 70:1 overall pressure ratio.[46]

Advance

In previous Trents, the HP spool was similar and the engine grew by expanding the intermediate pressure spool work. The Advance reverses this trend and the load is shifted towards the high pressure spool, with a greater pressure ratio, up to 10 stages compressor compared to 6 on the Trent XWB and a two-stage turbine against the current single-stage, while the IP compressor will shrink from the 8 stages of today’s XWB to 4 and the IP turbine will be single instead of two stages.[47]

The Advance3 ground-based demonstrator includes lean burn, run before on a Trent architecture only; ceramic matrix composite (CMC) for turbine high-temperature capability in the first stage seal segments and cast-bond first stage vanes; hybrid ball bearings with ceramic rollers running on metallic races, required to manage high load environments inside smaller cores.[48] The core will be combined with a Trent XWB-84 fan and a Trent 1000 LP turbine for mid-2017 ground testing.[49]

The Advance3 demonstrator will be sent from the Bristol production facility to the Derby test stand in July 2017 to be evaluated till early 2018. Opened in 2016, R-R’s $30 million CMC facility in California produced its first parts, seals, for the start of their deployment before being used in the static components of the second-stage HP turbine. The twin fuel-distribution system in the lean-burn combustor adds complexity by doubling the pipework and with a sophisticated control and switching system but should improve fuel consumption and lower NOx emissions, while a standalone engine will test the advanced lean and efficient combustion system (ALECSys) on ground before an other will be flight tested. Hybrid ceramic bearings are newly configured to deal with loading changes and will cope with higher temperatures.[50]

More variable vanes in one IP and four HP compressor stages will be optimised for constant changes through the flight envelope. An air pipe is produced by additive manufacturing and prototype components come from new suppliers. The Advance3 will survey bearing load, water ingestion, noise sources and their mitigation, heat and combustor rumble while blade-tip, internal clearances and adaptive control operation are radiographed in-motion to verify the thermo-mechanical modelling. The Boeing New Midsize Airplane needs falls in its thrust range. Advanced cooled metallic components and ceramic matrix composite parts will be tested in a late 2018 demonstrator based on a Trent XWB-97 within the high temperature turbine technology (HT3) initiative.[50]

UltraFan

The Ultrafan will keep the Advance core but won't be a true 3-shaft design but more a “two-and-a-half” configuration with the fan geared. As the fan will vary pitch to be optimised for each flight phase, it won't need a thrust reverser. Rolls will use carbon composite fan blades instead of its usual hollow titanium blades, and along new material adoption will save 750 lb (340 kg) per engine.[47]

The variable pitch fan will facilitate low pressure ratio fan operability.[51] Rolls-Royce will work with Industria de Turbo Propulsores to test IP turbine technologies that will go into the UltraFan.[52] In Dahlewitz near Berlin, Rolls-Royce has built a power rig simulating loading conditions in flight, sized for 15–80 MW (20,000–107,000 hp) gear systems; and recruits 200 engineers. The ratio of the initial test gear will approach 4:1 and thrust could be up to 100,000 lbf (440 kN).[53] The specially constructed test rig is an €84 million ($94 million) investment.[50]

In partnership with Liebherr, the 100,000 hp UltraFan gearbox was first run in October 2016.[54][55] After the initial set of low-speed fan rig tests and the casting of second-generation titanium aluminide IP turbine blades, the initial UltraFan demonstrator concept design should be frozen in 2017.[49] Tests simulated aircraft pitch and roll on an attitude rig in September 2016. The gearbox went through high-power tests in May 2017.[56][57] The UltraFan will be 3 m (118 in) in diameter and its fan blades with titanium leading edges are evaluated under the advanced low-pressure system programme.

Applications

- Airbus A330

- Airbus A340 (-500 and -600 series only)

- Airbus A350 (exclusive engine)

- Airbus A380

- Boeing 777 (-200, -200ER and -300 series only)

- Boeing 787 Dreamliner

Specifications

| Variant | Thrust | Weight | Bypass | Pressure | Config | Fan | Cruise TSFC | First run | Application |

|---|---|---|---|---|---|---|---|---|---|

| Trent 700[59] | 300–316 kN 67,500–71,100 lbf |

6,160 kg 13,580 lb |

5.0:1[60] | 36:1[60] | 8 IPC, 6 HPC 1 HPT, 1 IPT, 4 LPT |

97.4 in (247 cm) 26 blades |

0.562 lb/lbf/h 15.9 g/kN/s |

1990 | Airbus A330 |

| Trent 800[61] | 334–415 kN 75,000–93,400 lbf |

6,078 kg 13,400 lb |

6.4:1 | 33.9-40.7:1 | 8 IPC, 6 HPC 1 HPT, 1 IPT, 5 LPT |

110 in (280 cm) | 0.560 lb/lbf/h 15.9 g/kN/s |

1993 | Boeing 777-200/200ER/300 |

| Trent 500[62] | 240–250 kN 53,000–56,000 lbf |

4,990 kg 11,000 lb |

7.6:1 | 36.3:1 | 8 IPC, 6 HPC 1 HPT, 1 IPT, 5 LPT |

97.4 in (247 cm) | 0.542 lb/lbf/h 15.4 g/kN/s |

1999 | Airbus A340-500/600 |

| Trent 600 | 280 kN 63,000 lbf |

4,840 kg 10,660 lb |

41:1 | 8 IPC, 6 HPC 1 HPT, 1 IPT, 5 LPT |

97.4 in (247 cm) | 0.542 lb/lbf/h 15.4 g/kN/s |

dropped | 747-400 developments | |

| Trent 900[23] | 334.29–374.09 kN 75,152–84,098 lbf |

6,246 kg 13,770 lb |

8.7–8.5:1 | 37–39:1 | 8 IPC, 6 HPC 1 HPT, 1 IPT, 5 LPT |

116 in (290 cm) | 0.522 lb/lbf/h 14.8 g/kN/s |

2004 | Airbus A380 |

| Trent 1000[63] | 285–331 kN 64,100–74,400 lbf |

5,936–6,120 kg 13,087–13,492 lb |

10:1 | 50:1 | 8 IPC, 6 HPC 1 HPT, 1 IPT, 6 LPT |

112 in (280 cm) | 0.5062 lb/lbf/h 14.34 g/kN/s |

2006 | Boeing 787 |

| Trent XWB[64] | 370–430 kN 84,000–97,000 lbf |

7,277 kg 16,043 lb |

9.6:1 | 50:1 | 8 IPC, 6 HPC 1 HPT, 2 IPT, 6 LPT |

118 in (300 cm) 22 blades |

0.478 lb/lbf/h 13.5 g/kN/s[lower-alpha 1] |

2010 | Airbus A350 XWB |

| Trent 7000[65] | 300–320 kN 68,000–72,000 lbf |

7,747 kg 17,080 lb [lower-alpha 2] |

10:1 | 50:1 | 8 IPC, 6 HPC 1 HPT, 1 IPT, 6 LPT |

112 in (280 cm) 20 blades |

0.506 lb/lbf/h 14.3 g/kN/s[lower-alpha 3] |

2018 | Airbus A330neo |

See also

- Related development

- Rolls-Royce RB211

- Rolls-Royce Trent 500

- Rolls-Royce Trent 700

- Rolls-Royce Trent 800

- Rolls-Royce Trent 900

- Rolls-Royce Trent 1000

- Rolls-Royce MT30

- Related lists

Footnotes

Notes

- 1.^ All Nippon Airways, the sole customer of the 787-3, has cancelled its order, leaving the -8 and -9 the only two variants under development.

- 2.^ Engine interchangeability makes the 787 a more flexible asset to airlines, allowing them to change from one manufacturer's engine to the other's in light of any future engine developments which conform more closely to their operating profile. The cost of such a change would require a significant operating cost difference between the two engine types to make it economical. A difference that does not exist with the engines today.

- 3.^ Singapore Airlines has 58 Trent 800 powered 777s and 5 Trent 500 powered A340-500s; it also has a further 19 Trent 700 powered A330-300s, 19 Trent 900 powered A380-800s and 20 Trent XWB powered A350 XWB-900s on order. Should it select the Trent 1000 for its order of 20 787-9s, it will become the first airline to operate 6 different versions of the Trent.

References

- ↑ "Biggest Market share for new generation of widebodied aircraft". Archived from the original on 2007-07-18. Retrieved 2007-07-22.

- ↑ "GE holds the key to power - Airliner delivery analysis 2007". Flight International. February 21, 2007. Retrieved 2007-02-23.

- ↑ See Gunston, Bill (1989). World Encyclopedia of Aero Engines. Cambridge, United Kingdom: Patrick Stephens Limited. ISBN 978-1-85260-163-8.

- ↑ Pugh, Peter (2002). The Magic of a Name, Part Three. Icon Books. ISBN 1-84046-405-4.

- ↑ "Repayable launch investment (RLI)". House of Commons. Retrieved 2010-11-22.

- ↑ "World Encyclopedia of Aero Engines—5th edition" by Bill Gunston, Sutton Publishing, 2006, p.201

- ↑ Donoghue, J.A. (November 1, 2004). "The fan is the thing". Air Transport World. Retrieved 2007-02-03.

- ↑ EASA Type Certificate for Trent 800

- ↑ Spittle, Peter. "Gas turbine technology" Rolls-Royce plc, 2003. Retrieved: 21 July 2012.

- ↑ "Rolls-Royce standardises on hybrid RB211 after entry success". Flight International. 6 May 1998. Retrieved 2007-01-20.

- ↑ "Rolls-Royce to modify Trent as tests replicate BA 777 icing". Flight International. March 12, 2009. Retrieved 2009-03-15.

- 1 2 "Airworthiness Directives; Rolls-Royce plc RB211-Trent 500, 700, and 800 Series Turbofan Engines" (PDF). Archived from the original (PDF) on 2015-10-19.

- ↑ David Kaminsky-Morrow (12 March 2010). "EASA suspects dual-engine icing in A330 incident". FlightGlobal.

- ↑ David Kaminsky-Morrow (9 Feb 2010). "Rolls-Royce: Trent modification will 'eliminate' fuel-ice risk". FlightGlobal.

- ↑ "Trent 600". Jane’s Information Group. Retrieved 2010-11-22.

- 1 2 "Aero-Engines—Rolls-Royce Trent". Jane's. February 13, 2001. Archived from the original on 2007-11-10. Retrieved 2007-07-26.

- ↑ "B-HLA Dragonair Airbus A330-300—cn 071". planespotters.net. Retrieved 28 March 2015.

- ↑ "Rolls-Royce Trent 800". Retrieved 2009-02-15.

- ↑ BW Online | August 9, 1999 | How GE Locked Up That Boeing Order

- ↑ "AIRBUS SHOOTS FOR 25". Aviationweek. 21 July 1997. Retrieved 2015-03-28.

- ↑ "Airbus Orders & deliveries" (Excel). Airbus. Retrieved 12 July 2014.

- ↑ European Aviation Safety Agency (2005-08-11). "RB211 Trent 900 Series Engines Type-Certificate Data Sheet" (PDF). Archived from the original (PDF) on 2006-10-13. Retrieved 2007-01-26.

- 1 2 Federal Aviation Administration FAA (2007-06-06). "Type Certificate Data Sheet" (PDF). Retrieved 2007-11-03.

- ↑ "Rolls-Royce settles into a launch groove for A380". Flight International. October 15, 2007. Retrieved 2007-10-17.

- ↑ "Rolls-Royce hit by Airbus delays". BBC News. October 6, 2006. Retrieved 2007-02-15.

- ↑ "Rolls-Royce: A380 Engine Failure Specific to Trent 900".

- ↑ "Oil Fire Suspected In Trent 1000 Failure".

- ↑ "Qantas A380 Investigation Go Beyond Engines".

- ↑ "Rolls-Royce signs Trent 600 agreement with Boeing". Retrieved 2015-03-28.

- ↑ "787 special: Starting block". Flight International. September 26, 2006. Retrieved 2007-02-18.

- ↑ "ILFC selects Rolls-Royce Trent 1000 for 40 Boeing 787s". Archived from the original on 2007-09-27. Retrieved 2007-07-14.

- ↑ "Trent 1000 completes testbed run". Flight International. 22 February 2006. Retrieved 2007-02-18.

- ↑ "Rolls-Royce flies Boeing 787’s Trent 1000 engine on 747 testbed". Flight International. June 19, 2007. Retrieved 2007-06-19.

- ↑ "European and US regulators certify Trent 1000 for Boeing 787". Flight International. 7 August 2007. Retrieved 2007-08-07.

- ↑ "Boeing 787 Dreamliner on track to fly in June". Reuters. 27 May 2009. Retrieved 2009-05-29.

- ↑ "Enhanced A340 to take on 777". Flight International. November 29, 2005. Retrieved 2017-01-24.

- ↑ "Trent XWB". Rolls-Royce. Retrieved 2013-05-09.

- ↑ "Airbus revises A350 Trent XWB thrust values following weight increases". Flight International. 13 May 2009.

- ↑ "Airbus selects Rolls-Royce Trent 7000 as exclusive engine for the A330neo". www.rolls-royce.com/. Rolls Royce. 14 July 2014.

- ↑ Guy Norris (14 July 2014). "Rolls-Royce Details Trent 7000 Plans For A330neo". aviationweek.com. Aviation Week.

- ↑ "Rolls-Royce celebrates first run of Trent 7000 engine". 27 November 2015.

- ↑ "Trent 7000 infographic". www.rolls-royce.com. Rolls-Royce.

- 1 2 3 "Gas Turbine Industrial Trent 60". Retrieved 2015-03-28.

- ↑ "Generator Set Trent 60 WLE (66 MW)". Centrax Gas Turbines. Retrieved 2015-03-28.

- ↑ "Rolls-Royce shares next generation engine designs" (Press release). rolls-royce.com. 26 February 2014.

- ↑ "Rolls-Royce Reveals Next-Gen Engine Plan". Aviation Week. 26 February 2014.

- 1 2 "Rolls-Royce Details Advance And UltraFan Test Plan". Aviation Week & Space Technology. 25 August 2014.

- ↑ "Advance3 - Moving The State Of The Art Forward". Aviation Week. Feb 23, 2016.

- 1 2 Guy Norris (Apr 3, 2017). "Rolls-Royce Might Pitch UltraFan For Boeing New Midsize Airplane". Aviation Week & Space Technology.

- 1 2 3 Dominic Perry (16 June 2017). "Rolls-Royce moves forward with Advance3 demonstrator". Flight Global.

- ↑ Mark Thomas (21 October 2014). "Next Generation Engines" (PDF). Rolls Royce.

- ↑ "Rolls-Royce joins with ITP for UltraFan™ research programme" (Press release). Rolls-Royce. 15 July 2015.

- ↑ Guy Norris (May 27, 2015). "Rolls Freezes Design Of First UltraFan Test Gear". Aviation Week & Space Technology.

- ↑ "Rolls-Royce runs world’s most powerful aerospace gearbox for the first time" (Press release). Rolls-Royce. 24 October 2016.

- ↑ Gregory Polek (October 24, 2016). "Rolls-Royce Performs First Run of UltraFan Gearbox". Aviation International News.

- ↑ "UltraFan gearbox starts high-power testing". Flight Global. 25 May 2017.

- ↑ Victoria Moores (May 25, 2017). "Rolls-Royce begins UltraFan gearbox high-power testing". Aviation Week Network.

- ↑ "Gas Turbine Engines" (PDF). Aviation Week. January 28, 2008. pp. 137–138.

- ↑ "Type-Certificate Data Sheet RB211 Trent 700 series engines" (PDF). EASA. 14 October 2014.

- 1 2 "Trent 700 poster". Rolls-Royce.

- ↑ "Trent 800 Type-Certificate Data Sheet" (PDF). EASA.

- ↑ "Trent 500 Type-Certificate Data Sheet" (PDF). EASA.

- ↑ "Type certificate data sheet" (PDF). EASA. 11 July 2016.

- ↑ "Type Certificate Data Sheet E.111" (PDF). EASA. 20 April 2016.

- ↑ "Trent 7000 infographic" (PDF). Rolls-Royce Holdings. Nov 2016.

External links

| Wikimedia Commons has media related to Rolls-Royce Trent. |

_(cropped).jpg)