Vinyl polymer

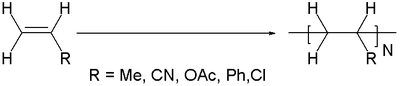

Vinyl polymers are a group of polymers derived from vinyl monomers. Their backbone is an extended alkane chain, made by polymerizing an alkene group (C=C) into a chain (..-C-C-C-C-..). In popular usage, "vinyl" refers only to polyvinyl chloride (PVC).

Overview

Vinyl polymers are the most common type of plastic:

- Polymerized simple alkenes: polyethylene from ethene, polypropylene from propene and polybutadiene from butadiene.

- Polystyrene is made from styrene or "vinyl benzene".

- Polyvinyl chloride (PVC) is made by polymerization of the monomer vinyl chloride (chloroethene) CH2=CHCl

- Polyvinyl acetate (PVAc) is made by polymerization of vinyl acetate. In a water suspension, this is used as a glue.

- Polyvinyl alcohol (PVA) is produced by hydrolysis of polyvinyl acetate. (Not by polymerization of the monomer vinyl alcohol or ethenol, which is an unfavored keto-enol tautomer of acetaldehyde.)

- Polyacrylonitrile is prepared from acrylonitrile

While polymerized forms of other 1,2-substituated vinyl monomers are thermodynamically favorable, they are not generally able to polymerize due to steric hindrance. A notable exception to this was found[1] with the monomer fumaronitrile, where polymerization occurs through an unconventional mechanism.

-

.

.

Vinyl polymers are produced catalytically; titanium-centered Ziegler-Natta catalyst is the main modern commercial catalyst.

A very thin film of monomer was prepared in a vacuum chamber on a tantalum substrate at -173°C and then photopolymerized. Due to the poor penetration depth of the radiation, thin polymer films with thickness several micrometres were obtained nevertheless with degree of polymerization in the 10,000 range. The polymerization is able to take place because the monomer molecules in the film are completely disorganized (isotropic) and therefore there is always a possibility for two monomers to react which they do not have in the crystalline phase.

See also

References

- ↑ Polymerization of "Unpolymerizable" Molecules through Topological Control Seth Washburn, Jochen Lauterbach, and Christopher M. Snively Macromolecules; 2006; 39(24) pp 8210 - 8212; (Communication to the Editor) doi: 10.1021/ma061724j