Diphenyl ether

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name

1,1'-Oxydibenzene | |

| Other names

Oxydibenzene Diphenyl ether Diphenyl oxide 1,1'-Oxybisbenzene Phenoxybenzene | |

| Identifiers | |

| 3D model (JSmol) |

|

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.002.711 |

| UNII | |

| |

| |

| Properties | |

| C12H10O | |

| Molar mass | 170.21 g·mol−1 |

| Appearance | Colorless solid or liquid |

| Odor | geranium-like |

| Density | 1.08 g/cm3 (20°C)[1] |

| Melting point | 25 to 26 °C (77 to 79 °F; 298 to 299 K) |

| Boiling point | 121 °C (250 °F; 394 K) at 1.34 kPa (10.05 mm Hg), 258 °C at 100 kPa (1 bar) |

| Insoluble | |

| Vapor pressure | 0.02 mmHg (25°C)[1] |

| -108.1·10−6 cm3/mol | |

| Hazards | |

| Safety data sheet | Aldrich MSDS |

| NFPA 704 | |

| Flash point | 115 °C (239 °F; 388 K) |

| Explosive limits | 0.7%-6.0%[1] |

| Lethal dose or concentration (LD, LC): | |

| LD50 (median dose) |

3370 mg/kg (rat, oral) 4000 mg/kg (rat, oral) 4000 mg/kg (guinea pig, oral)[2] |

| US health exposure limits (NIOSH): | |

| PEL (Permissible) |

TWA 1 ppm (7 mg/m3)[1] |

| REL (Recommended) |

TWA 1 ppm (7 mg/m3)[1] |

| IDLH (Immediate danger) |

100 ppm[1] |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| | |

| Infobox references | |

Diphenyl ether is the organic compound with the formula O(C6H5)2. The molecule is subject to reactions typical of other phenyl rings, including hydroxylation, nitration, halogenation, sulfonation, and Friedel–Crafts alkylation or acylation.[3] This simple diaryl ether enjoys a variety of niche applications.

Synthesis

Diphenyl ether and many of its properties were first reported as early as 1901.[4] It is synthesized by a modification of the Williamson ether synthesis, here the reaction of phenol and bromobenzene in the presence of base and a catalytic amount of copper:

- PhONa + PhBr → PhOPh + NaBr

Involving similar reactions, diphenyl ether is a significant side product in the high-pressure hydrolysis of chlorobenzene in the production of phenol.[5]

Uses

The main application of diphenyl ether is as a eutectic mixture with biphenyl, used as a heat transfer medium. Such a mixture is well-suited for heat transfer applications because of the relatively large temperature range of its liquid state. A eutectic mixture [commercially, Dowtherm A] is 73.5% diphenyl ether (diphenyl oxide) and 26.5% diphenyl (biphenyl).[6][7]

Diphenyl ether is a starting material in the production of phenoxathiin via the Ferrario reaction.[8] Phenoxathiin is used in polyamide and polyimide production.[9]

Because of its odor reminiscent of scented geranium, as well as its stability and low price, diphenyl ether is used widely in soap perfumes.[10] Diphenyl ether is also used as a processing aid in the production of polyesters.

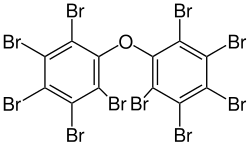

Several polybrominated diphenyl ethers (PBDEs) are useful flame retardants. Of penta-, octa-, and decaBDE, the three most common PBDEs, only decaBDE is still in widespread use since its ban in the European Union in 2003.[11] DecaBDE, also known as decabromodiphenyl oxide,[12] is a high-volume industrial chemical with over 450,000 kilograms produced annually in the United States. Decabromodiphenyl oxide is sold under the trade name Saytex 102 as a flame retardant in the manufacture of paints and reinforced plastics.

References

- 1 2 3 4 5 6 "NIOSH Pocket Guide to Chemical Hazards #0496". National Institute for Occupational Safety and Health (NIOSH).

- ↑ "Phenyl ether". Immediately Dangerous to Life and Health. National Institute for Occupational Safety and Health (NIOSH).

- ↑ Fiege, H.; Voges, H.-M.; Hamamoto, T; Umemura, S.; Iwata, T.; Miki, H.; Fujita, Y.; Buysch, H.-J.; Garbe, D.; Paulus, W. (2000). "Phenol Derivatives". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. ISBN 3-527-30673-0. doi:10.1002/14356007.a19_313.

- ↑ Cook, A. N. (1901). "Derivatives of Phenylether". Journal of the American Chemical Society. 23 (11): 806–813. doi:10.1021/ja02037a005.

- ↑ Fahlbusch, K.-G.; Hammerschmidt, F.-J.; Panten, J.; Pickenhagen, W.; Schatkowski, D.; Bauer, K.; Garbe, D.; Surburg, H. (2003). "Flavor and Fragrances". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. ISBN 3-527-30673-0. doi:10.1002/14356007.a11_141.

- ↑ Patent Appeal No. 7555 United States Court of Customs and Patent Appeals 7 April 1966 http://openjurist.org/358/f2d/750/application-of-edward-s-blake-and-william-c-hammann

- ↑ http://www.sigmaaldrich.com/catalog/product/aldrich/44570

- ↑ Suter, C. M.; Maxwell, C. E. (1943). "Phenoxthin". Org. Synth.; Coll. Vol., 2, p. 485

- ↑ Mitsuru Ueoda; Tatsuo Aizawa; Yoshio Imai (1977). "Preparation and properties of polyamides and polyimides containing phenoxathiin units". Journal of Polymer Science: Polymer Chemistry Edition. 15 (11): 2739–2747. doi:10.1002/pol.1977.170151119.

- ↑ Ungnade, H. E.; Orwoll, E. F. (1955). "2-Methoxy Diphenyl Ether". Org. Synth.; Coll. Vol., 3, p. 566

- ↑ DIRECTIVE 2003/11/EC of the European Parliament and of the Council

- ↑ Sutker, B. J. (2005). "Flame Retardants". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. ISBN 3-527-30673-0. doi:10.1002/14356007.a11_123.