Percussion cap

The percussion cap, introduced circa 1820, was the crucial invention that enabled muzzleloading firearms to fire reliably in any weather.[1] This gave rise to the caplock or percussionlock system.

Before this development, firearms used flintlock ignition systems that produced flint-on-steel sparks to ignite a pan of priming powder and thereby fire the gun's main powder charge (the flintlock mechanism replaced older ignition systems such as the matchlock and wheellock). Flintlocks were prone to misfire in wet weather, and many flintlock firearms were later converted to the more reliable percussion system.

The percussion cap is a small cylinder of copper or brass with one closed end. Inside the closed end is a small amount of a shock-sensitive explosive material such as fulminate of mercury. The percussion cap is placed over a hollow metal "nipple" at the rear end of the gun barrel. Pulling the trigger releases a hammer that strikes the percussion cap and ignites the explosive primer. The flame travels through the hollow nipple to ignite the main powder charge. Percussion caps were, and still are, made in small sizes for pistols and larger sizes for rifles and muskets.[1]

While the metal percussion cap was the most popular and widely used type of primer, their small size made them difficult to handle under the stress of combat or while riding a horse. Accordingly, several manufacturers developed alternative, "auto-priming" systems. The "Maynard tape primer", for example, used a roll of paper "caps" much like today's toy cap gun. The Maynard tape primer was fitted to some firearms used in the mid-nineteenth century and a few saw brief use in the American Civil War. Other disc or pellet-type primers held a supply of tiny fulminate detonator discs in a small magazine. Cocking the hammer automatically advanced a disc into position. However, these automatic feed systems were difficult to make with the manufacturing systems in the early and mid-nineteenth century and generated more problems than they solved. They were quickly shelved in favor of a single percussion cap that, while awkward to handle in some conditions, could be carried in sufficient quantities to make up for occasionally dropping one while a jammed tape primer system reduced the rifle to an awkward club.[1]

The first practical solution for the problem of handling percussion caps in battle was the Prussian 1841 (Dreyse needle gun), which used a long needle to penetrate a paper cartridge filled with black powder and strike the percussion cap that was fastened to the base of the bullet. While it had a number of problems, it was widely used by the Prussians and other German states in the mid-nineteenth century and was a major factor in the 1866 Austro-Prussian War.

In the 1850s, the percussion cap was first integrated into a metallic cartridge, which contained the bullet, powder charge and primer. By the late 1860s, breech-loading metallic cartridges had made the percussion cap system obsolete. Today, reproduction percussion firearms are popular for recreational shooters and percussion caps are still available (though some modern muzzleloaders use shotshell primers instead of caps). Most percussion caps now use non-corrosive compounds such as lead styphnate.[1]

History

The percussion cap replaced the flint, the steel "frizzen", and the powder pan of the flint-lock mechanism. It was only generally applied to the British military musket (the Brown Bess) in 1842, a quarter of a century after the invention of percussion powder and after an elaborate government test at Woolwich in 1834. The first percussion firearm produced for the US military was the percussion carbine version (c.1833) of the M1819 Hall rifle.

The discovery of fulminates was made by Edward Charles Howard (1774–1816) in 1800.[2][3] The invention that made the percussion cap possible using the recently discovered fulminates was patented by the Rev. Alexander John Forsyth of Belhelvie, Aberdeenshire, Scotland in 1807.[1]

This early system coined "Percussion Lock" operated in a near identical fashion to flintlock firearms and utilized fulminating primer made of fulminate of mercury, chlorate of potash, sulphur, and charcoal, which was ignited by concussion.[4][5] It was an invention born of necessity: Rev. Forsyth had noticed that sitting birds would startle when smoke puffed from the powder pan of his flintlock shotgun, giving them sufficient warning to escape the shot. His invention of a fulminate-primed firing mechanism deprived the birds of their early warning system, both by avoiding the initial puff of smoke from the flintlock powder pan, as well as shortening the interval between the trigger pull and the shot leaving the muzzle.

Fulminate-primed guns were also less likely to misfire than flintlock guns. However, it was not until after Forsyth's patents expired that the conventional percussion cap system was developed. The percussion cap helped lead to the self-contained cartridge, where the bullet is held in by the casing, the casing is filled with gunpowder, and a primer is at the end.

Joshua Shaw, an English-born American, is sometimes credited with the development of the first metallic percussion cap in 1814, but his claim remains clouded with controversy as he did not patent the idea until 1822. Furthermore, according to Lewis Winant, the US government's decision to award Shaw $25,000 as compensation for his invention was actually a mistake. Congress believed Shaw's patent was the earliest and awarded him a large sum of money based on this belief. However, a claim for the percussion cap was filed in 1819 and granted in 1820 as an addition to an 1818 patent by Francois Prelat, two years before Shaw's patent. This doesn't necessarily make Prelat the inventor however, as he made a habit of copying English patents and inventions at the time and the mode of operation he describes is flawed.[6] According to historian Sidney James Gooding, the most likely inventor of the percussion cap is Joseph Egg, around 1817.[7] Shaw's percussion caps used a mixture of fulminate of mercury, chlorate of potash, and ground glass contained in a small metallic cup. Other possible claimants include Joseph Manton and Col. Peter Hawker.

This invention was gradually improved, and came to be used, first in a steel cap, and then in a copper cap, by various gunmakers and private individuals before coming into general military use nearly thirty years later.

The alteration of the military flintlock to the percussion musket was easily accomplished by replacing the powder pan and steel "frizzen" with a nipple, and by replacing the cock or hammer that held the flint by a smaller hammer formed with a hollow made to fit around the nipple when released by the trigger. On the nipple was placed the copper cap containing the detonating composition, now made of three parts of chlorate of potash, two of fulminate of mercury and one of powdered glass. The hollow in the hammer contained the fragments of the cap if it fragmented, reducing the risk of injury to the firer's eyes.

The detonating cap, thus invented and adopted, brought about the invention of the modern cartridge case, and rendered possible the general adoption of the breech-loading principle for all varieties of rifles, shotguns and pistols.

Caps are used in cartridges, grenades, rocket-propelled grenades, and rescue flares. Percussion caps are also used in land mine fuzes, boobytrap firing devices and anti-handling devices.

Firing devices and fuze mechanisms

As a rule, most purpose-made military booby-trap firing devices contain some form of spring-loaded firing pin designed to strike a percussion cap connected to a detonator at one end. The detonator is inserted into an explosive charge—e.g., C4 or a block of TNT. Triggering the booby-trap (e.g., by pulling on a trip-wire) releases the cocked firing pin that flips forward to strike the percussion cap, firing both it and the attached detonator. The resulting shock-wave from the detonator sets off the main explosive charge.

Alternative design of USSR booby trap firing device – pull fuze: normally connected to tripwire. Percussion cap is clearly labelled

Alternative design of USSR booby trap firing device – pull fuze: normally connected to tripwire. Percussion cap is clearly labelled USSR boobytrap firing device – pressure fuze: victim steps on loose floorboard with fuze concealed underneath

USSR boobytrap firing device – pressure fuze: victim steps on loose floorboard with fuze concealed underneath

Cross-sectional view of a Japanese Type 99 grenade showing percussion primer

Cross-sectional view of a Japanese Type 99 grenade showing percussion primer Cross-sectional view of the fuze fitted to a German S-mine. Percussion cap is clearly labelled

Cross-sectional view of the fuze fitted to a German S-mine. Percussion cap is clearly labelled Percussion cap nipples, the ignition flame travels though the hole.

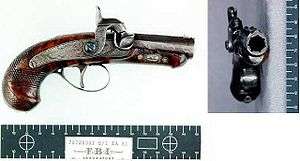

Percussion cap nipples, the ignition flame travels though the hole. Percussion caps

Percussion caps

See also

References

- 1 2 3 4 5 Fadala, Sam (17 November 2006). The Complete Blackpowder Handbook. Iola, Wisconsin: Gun Digest Books. pp. 159–161. ISBN 0-89689-390-1.

- ↑ Howard, Edward (1800) "On a New Fulminating Mercury," Philosophical Transactions of the Royal Society of London 90 (1): 204–238.

- ↑ Edward Charles Howard at National Portrait Gallery

- ↑ Percussion lock

- ↑ Samuel Parkes, The chemical catechism : with notes, illustrations, and experiments, New York : Collins and Co., 1818, page 494 (page 494 online, see “LVI. A New Kind of Gunpowder.”)

- ↑ "Early Percussion Firearms". Spring Books. 2015-10-25.

- ↑ "Canadian Journal Of Arms Collecting, Vol. 36, No. 3". Arms Collecting Publications, Inc. 2017-05-13.

- Winant, L. (1956). Early percussion firearms. Bonanza Books