Mohave Power Station

| Mohave Power Station | |

|---|---|

|

Mohave Generating Station | |

Location of Mohave Power Station | |

| Country | United States |

| Location | Laughlin, Nevada |

| Coordinates | 35°08′42″N 114°35′19″W / 35.14500°N 114.58861°WCoordinates: 35°08′42″N 114°35′19″W / 35.14500°N 114.58861°W |

| Status | Shut down[1] |

| Commission date | 1971[1] |

| Owner(s) | Southern California Edison |

| Thermal power station | |

| Primary fuel | Bituminous coal[1] |

| Type | Steam turbine[1] |

| Power generation | |

| Units operational | 2 x 818.1 MW (1,097,100 hp)[1] |

| Nameplate capacity | 1,636.2 MW (2,194,200 hp)[1] |

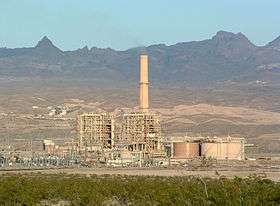

Mohave Power Station (known also as Mohave Generating Station, or MOGS) was a 1,580-megawatt (2,120,000 hp) coal-fired power plant located in Laughlin, Nevada. Southern California Edison is the majority owner of the plant and was its operator.[2] The plant is currently shut down and in the process of being dismantled.

The plant was composed of two units capable of generating 790 MW (1,060,000 hp) electrical each. Combustion Engineering supplied the boilers and GE supplied the turbines and generators. Bechtel performed engineering, procurement and construction.

The Mohave Generating Station was built on a 2,500-acre (1,000 ha) site in the Mojave Desert adjacent to the Colorado River in Laughlin, Clark County. It had supercritical boilers and cross-compound steam turbines. The plant was owned by a utility consortium of operator Southern California Edison Co (56%), LADWP (10%), Nevada Power (14%), and Salt River Project (20%).

Mohave was the only power plant in the United States that used coal delivered by coal-slurry pipeline. The 18 inches (460 mm) diameter Black Mesa Pipeline ran 275 miles (443 km) to the plant from the Peabody Energy Black Mesa Mine in Kayenta, AZ, and could deliver 660 short tons (600 t) per hour. The land where the mine is located is owned by the Navajo and Hopi tribes. Four 8-million-gallon storage tanks each held the equivalent of 20,000 short tons (18,000 t) of dry coal. The slurry transport water was recycled for cooling tower water makeup; this and all other waste water was reused, making Mohave a zero-discharge facility. A natural-gas line run to the facility from a gas main near Topock, Arizona supplied the required heat to start the plant, although the line was too small to run the plant exclusively on gas. The power was transmitted via two 500kV lines to substations in southern Nevada and southern California.

Commissioning

The plant's two identical units went into initial operation in 1971.[3]

Early Failures

The plant's turbine-generators suffered two early failures before 1975.

Both of these failures resulted in failures of the turbine-generators, and both failures occurred during unseasonally cold weather. The cold weather proved to be the essential clue. One of the joint owners (LADWP) was assigned to determine the cause of these failures, through use of computer simulations.

The power station and its connected 500 kV transmission systems (one to California, the other to Nevada) were subjected to extensive simulations, which ultimately led to identification of the root cause of the failures.

When initially installed, the then-new concept of "series compensation" (sets of series capacitors at the sending- and receiving-ends of the transmission lines) were installed, with the expectation that this "series compensation" would reduce or even eliminate the losses inherent in the very long distance 500 kV transmission lines.

What was not then known, but which was identified during the simulations, which were performed in the System Development Division of LADWP, was the series resistance of the ACSR transmission lines, when under near freezing conditions, combined with the "series compensation", which was designed to counter the series impedance of those ACSR lines, could under certain conditions of generation and load, and very low ambient temperatures, place an effective negative impedance on the generators, thereby causing a mechanical response by the turbine-generators which resulted in their destruction.

This behavior had not been anticipated, and as it had not been anticipated it could hardly have been simulated prior to the installation and commissioning of the power station. In general such simulations focus on steady-state system behavior, not subsystem transient behavior. But these two failures caused a renewed interest in "dynamic" simulation. Only "static" (that is, steady-state) simulation had been done previously.

General Electric, the manufacturer of the turbine-generators, refused to repair or replace subsequent damage—after all it had already replaced two failed turbine-generators due to reasons which were then unknown, and were subsequently proved not to be its fault, so new operational procedures were implemented to prevent subsequent failures.

These procedures were successful, and there were no more turbine-generator failures.

But, these new procedures would not address what later happened, due to other causes, including improper operation of the steam generator's "reheat" system, which is a usual, and necessary part of a "compound" turbine-generator system (a high-pressure 3600 rpm turbine section compounded with a lower-pressure 1800 rpm turbine section, both of which were supplied by the same steam generator, but using separate reheat "loops").

1985 pipe failure disaster

On June 9, 1985, a 30-inch (760 mm) hot reheat line, under 600 pounds per square inch of pressure, burst open. The reheat line cycles steam back through the boiler stack after it has expanded through the high pressure (HP) turbine and before it reached the low pressure (LP) turbine. A 1,000-degree steam cloud blew down a door leading to the control room of the station, fatally scalding six workers: Michael Bowman, John Dolan, Ernest Hernandez, Terry Leroy, Danny Norman and Howard Turner. Ten others were injured. The station was out of service for six months while all the steam piping was replaced.[4]

A report on the accident was completed in May, 1991, but was not released until Christmas Day because of Edison's objections that it would compromise civil suits.[5]

Although several factors contributed to the pipe's failure, the report said Edison's actions—or lack of actions—were "primary and critical factors in causing the accident":

- Edison knowingly operated the system at temperatures above design specification for long periods of time, and operators were unable to control the temperatures within the system as a result of a "design flaw."

- Even so, the pipe, part of a steam reheat system, was not routinely maintained or inspected, though the pipe shifted and distorted because of exposure to abnormal stresses, the report said.

- Edison's management made high production a priority over safety. In 1979, Edison disciplined a supervisor for ordering an unauthorized inspection of unrelated pipe welds. "The fear SCE management has instilled in its employees is counterproductive to safety and increases the chances that additional incidents as serious as this one may occur in the future," the report said.

The report found no evidence that the accident was caused by a specific action on the day of the pipe failure.

The report recommended sweeping changes to Edison's policies, including annual reports to the PUC on the utility's safety training, inspection and maintenance programs. In addition, the report argues that, because the accident was avoidable, the costs should be borne by Edison's shareholders, not its rate-paying customers.

Shutdown

The plant was shut down on December 31, 2005, with the possibility it might not reopen. With the shutdown of the plant, the mine providing the coal was closed. This closure had a major negative impact on the Hopi.[6]

The plant was shut to comply with a consent agreement reached to settle a 1998 CAA lawsuit brought by several environmental groups. The plant had been targeted as a major source of pollution in the Grand Canyon and other locations to the east. Furthermore, the Hopi and Navajo signed an agreement preventing the use of water from the local aquifer to make up slurry. Various plans were presented, including selling the plant and retrofitting it to burn natural gas, although the latter would have required construction of a second high pressure gas line from Topock, 30 miles (48 km) to the south. Another option would have been to install exhaust scrubbers, which would have cost $1 billion.

In May 2007, SCE discontinued efforts to restart or sell the plant.

Dismantling

On June 10, 2009, Southern California Edison announced that the Mohave Generating Station would be decommissioned and all generating equipment would be removed from the site.[7] Later, SCE announced that all administrative buildings on site would also be razed. The only structure remaining on the property will be the 500kV switchyard, which will continue to serve as a switching location for the bulk power system as well as provide electricity to a nearby Nevada Power substation supplying the Laughlin area.

Dismantling got underway in October 2009 and is expected to take 2 years and cost $30 million. About 300 staff lost their jobs when the plant was closed.

On March 11, 2011, the 500-foot (150 m) exhaust stack, a longtime landmark of the Laughlin/Bullhead City area, was felled by explosives.[8]

Owners

- Southern California Edison (56%)

- Salt River Project (20%)

- Nevada Power Company (14%)

- Los Angeles Department of Water and Power (10%)

References

- 1 2 3 4 5 6 "Existing Electric Generating Units in the United States, 2007" (Excel). Energy Information Administration, U.S. Department of Energy. 2007. Retrieved 2009-07-11.

- ↑ Woodall, Bernie (2005-11-10). "Mohave Power Plant Operation Future in Dark". Reuters News Service. Retrieved 2008-06-20.

- ↑ "Existing Electric Generating Units in the United States, 2008" (Excel). Energy Information Administration, U.S. Department of Energy. 2008. Retrieved 2008-07-14.

- ↑ Ceremony observes 25th anniversary of tragedy at Mohave Generating Station

- ↑ SoCal Edison Will Dispute Report on Plant Explosion http://articles.latimes.com/1992-01-18/business/fi-359_1_plant-explosion

- ↑ Miguel Bustillo (2005-12-30). "Edison to Shut Down Polluting Coal Plant" (PDF). Los Angeles Times. Retrieved 2010-09-17.

- ↑ Edwards, John G. (2009-06-11). "Laughlin coal-fired power plant going away". Las Vegas Review Journal. Retrieved 2009-06-11.

- ↑ Rogers, Keith (2011-03-11). "Landmark smokestack imploded in Laughlin". Las Vegas Review-Journal. Retrieved 2016-07-29.