Microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by a microscope above 25× magnification.[1] The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behavior or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure’s influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure. These defects can take many forms but the primary ones are the pores. Even if those pores play a very important role in the definition of the characteristics of a material, so does its composition. In fact, for many materials, different phases can exist at the same time. These phases have different properties and if managed correctly, can prevent the fracture of the material.

Methods

The concept of microstructure is observable in macrostructural features in commonplace objects. Galvanized steel, such as the casing of a lamp post or road divider, exhibits a non-uniformly colored patchwork of interlocking polygons of different shades of grey or silver. Each polygon is a single crystal of zinc adhering to the surface of the steel beneath. Zinc and lead are two common metals which form large crystals (grains) visible to the naked eye. The atoms in each grain are organized into one of seven 3d stacking arrangements or crystal lattices (cubic, tetrahedral, hexagonal, monoclinic, triclinic, rhombohedral and orthorhombic). The direction of alignment of the matrices differ between adjacent crystals, leading to variance in the reflectivity of each presented face of the interlocked grains on the galvanized surface. The average grain size can be controlled by processing conditions and composition, and most alloys consist of much smaller grains not visible to the naked eye. This is to increase the strength of the material (see Hall-Petch Strengthening).

Microstructure Characterizations

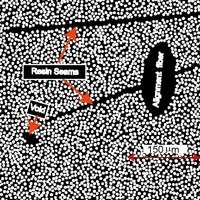

To quantify microstructural features, both morphological and material property must be characterized. Image processing is a robust technique for determination of morphological features such as volume fraction,[2] inclusion morphology,[3] void and crystal orientations. To acquire micrographs, optical as well as electron microscopy are commonly used. To determine material property, Nanoindentation is a robust technique for determination of properties in micron and submicron level for which conventional testing are not feasible. Conventional mechanical testing such as tensile testing or dynamic mechanical analysis (DMA) can only return macroscopic properties without any indication of microstructural properties. However, nanoindentation can be used for determination of local microstructural properties of homogeneous as well as heterogeneous materials.[4]

Microscopy

Optical

When a polished flat sample reveals traces of its microstructure, it is normal to capture the image using macrophotography. More sophisticated microstructure examination involves higher powered instruments: optical microscopy, electron microscopy, X-ray diffraction and so on, some involving preparation of the material sample (cutting, microtomy, polishing, etching, vapor-deposition etc.). The methods are known collectively as metallography as applied to metals and alloys, and can be used in modified form for any other material, such as ceramics, glasses, composites, and polymers.

Two kinds of optical microscope are generally used to examine flat, polished and etched specimens: a reflection microscope and an inverted microscope. Recording the image is achieved using a digital camera working through the eyepiece.

X-Ray microtomographic

Nondestructive testing of microstructure for biological materials is a challenge and computer microtomography is the current solution. In fact, CMT can be used for the evaluation of microstructure of many other materials also. CMT can be very expensive though, and for research purposes, it is a necessity to generate a three-dimensional microstructure from two-dimensional cross-sectional images of the material. This is an area of active research and pursued by many scientists.

3D compositional microstructure

Microscopic distribution of material compositions in a material sample can be obtained using a data constrained modelling technique together with quantitative X-Ray computed tomography. A software implementation of the technique is available.[5]

Electron microscopy

For high-resolution information on metallurgical microstructures, electron microscopic methods can be employed. This can allow for direct observation of atomic-scale features such as very fine precipitation reactions, dislocations or grain-boundary interfaces. Such methods may be critical in determining parameters such as solid state diffusivities.

Atomic force microscopy

Atomic force microscopy is a powerful technique used to study the surface properties of materials. It relies on the interactions that can be observed between the surface of a material and the very fine tip (ideally one atom in diameter) of the AFM. This tip is mounted on a cantilever that will move in certain directions according to the surface’s charge, topography or composition. The information received can provide inside knowledge on the topography of the material, the dimensions of certain particles, the interactions between the different molecules, the mechanical properties of the sample (a bending test can be realized using AFM), as well as other properties such as the electrical and magnetic properties.[6] The resolution of this technique is one of the best you can achieve using microscopy techniques. In fact, unlike other electron microscopy techniques such as SEM, STM and so forth, AFM provides a resolution in the range of Angstrom. This technique is therefore perfect for studying nanomaterials and is sometimes referred to as a single atom resolved technique. Another big advantage of this technique is the minimal sample preparation it requires.[7] The data collection process it relies on is also quite simple. The movements of the cantilever are recorded using a photo detector and a laser that is deflected by the cantilever. These movements induce a change in the voltage of the photodetector which then transforms this signal into an “image”.[8]

Microstructure Generation

Computer-simulated microstructures are generated to replicate the microstructural features of actual microstructures. Such microstructures are referred to as synthetic microstructures. Synthetic microstrucures are used to investigate what microstructural feature is important for a given property. To ensure statistical equivalence between generated and actual microstructures, microstructures are modified after generation to match the statistics of an actual microstructure. Such procedure enables generation of theoretically infinite number of computer simulated microstructures that are statistically the same (have the same statistics) but stochastically different (have different configurations) [9]

Influence of pores and composition

A pore in a microstructure, unless desired, is bad news for the properties. In fact, in nearly all of the materials, a pore will be the starting point for the rupture of the material. It is the initiation point for the cracks. Furthermore, a pore is usually quite hard to get rid of. Those techniques described later involve a high temperature process. However, even those processes can sometimes make the pore even bigger. Pores with large coordination number (surrounded by many particles) tend to grow during the thermal process. This is caused by the thermal energy being converted to a driving force for the growth of the particles which will induce the growth of the pore as the high coordination number prohibits the growth towards the pore. For many materials, it can be seen from their phase diagram that multiple phases can exist at the same time. Those different phases might exhibit different crystal structure, thus exhibiting different mechanical properties.[11] Furthermore, these different phases also exhibit a different microstructure (grain size, orientation).[12] This can also improve some mechanical properties as crack deflection can occur, thus pushing the ultimate breakdown further as it creates a more tortuous crack path in the coarser microstructure.[13]

Improvement techniques

In some cases, simply changing the way the material is processed can influence the microstructure. An example is the titanium alloy TiAl6V4.[14] Its microstructure and mechanical properties are enhanced using SLM (selective laser melting) which is a 3D printing technique using powder and melting the particles together using high powered laser.[15] Other conventional techniques for improving the microstructure are thermal processes.[16] Those processes rely in the principle that an increase in temperature will induce the reduction or annihilation of pores.[17] Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability.[18] The HIP process exposes the desired material to an isostatic gas pressure as well as high temperature in a sealed vessel (high pressure). The gas used during this process is mostly Argon. The gas needs to be chemically inert so that no reaction occurs between it and the sample. The pressure is achieved by simply applying heat to the hermetically sealed vessel. However, some systems also associate gas pumping to the process to achieve the required pressure level. The pressure applied on the materials is equal and comes from all directions (hence the term “isostatic”).[19] When castings are treated with HIP, the simultaneous application of heat and pressure eliminates internal voids and microporosity through a combination of plastic deformation, creep, and diffusion bonding; this process improves fatigue resistance of the component.[20]

See also

References

- ↑ Adapted from ASM Metals Handbook, Ninth Edition, v. 9, "Metallography and Microstructures", American Society for Metals, Metals Park, OH, 1985, p. 12.

- ↑ https://www.researchgate.net/publication/279771139_Uncorrelated_volume_element_for_stochastic_modeling_of_microstructures_based_on_local_fiber_volume_fraction_variation

- ↑ https://www.researchgate.net/publication/305803249_Characterization_synthetic_generation_and_statistical_equivalence_of_composite_microstructures

- ↑ https://www.researchgate.net/publication/292208855_Length-scale_dependence_of_variability_in_epoxy_modulus_extracted_from_composite_prepreg

- ↑ Sam Yang, Andrew Tulloh, Clement Chu, Fiona Chen, John Taylor, DCM - A Software Platform for Advanced 3D Materials Modelling, Characterisation and Visualization. CSIRO Data Access Portal. PID: https://data.csiro.au/dap/landingpage?pid=csiro:9448

- ↑ Meyer, E., Atomic force microscopy. Progress in surface science 1992, 41 (1), 3-49.

- ↑ Binnig, G.; Quate, C. F.; Gerber, C., Atomic force microscope. Physical review letters 1986, 56 (9), 930.

- ↑ Rugar, D.; Hansma, P., Atomic force microscopy. Physics today 1990, 43 (10), 23-30.

- ↑ https://www.researchgate.net/publication/305803249_Characterization_synthetic_generation_and_statistical_equivalence_of_composite_microstructures

- ↑ https://www.researchgate.net/publication/305803249_Characterization_synthetic_generation_and_statistical_equivalence_of_composite_microstructures

- ↑ Oberwinkler, B., Modeling the fatigue crack growth behavior of Ti-6Al-4V by considering grain size and stress ratio. Materials Science and Engineering: A 2011, 528 (18), 5983-5992.

- ↑ Sieniawski, J.; Ziaja, W.; Kubiak, K.; Motyka, M., Microstructure and mechanical properties of high strength two-phase titanium alloys. Titanium Alloys-Advances in Properties Control 2013, 69-80.

- ↑ Nalla, R.; Boyce, B.; Campbell, J.; Peters, J.; Ritchie, R., Influence of microstructure on high-cycle fatigue of Ti-6Al-4V: bimodal vs. lamellar structures. Metallurgical and Materials Transactions A 2002, 33 (13), 899-918.

- ↑ Henriques, V. A. R.; Campos, P. P. d.; Cairo, C. A. A.; Bressiani, J. C., Production of titanium alloys for advanced aerospace systems by powder metallurgy. Materials Research 2005, 8 (4), 443-446.

- ↑ Kruth, J.-P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M., Binding mechanisms in selective laser sintering and selective laser melting. Rapid prototyping journal 2005, 11 (1), 26-36.

- ↑ Murr, L.; Quinones, S.; Gaytan, S.; Lopez, M.; Rodela, A.; Martinez, E.; Hernandez, D.; Martinez, E.; Medina, F.; Wicker, R., Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. Journal of the mechanical behavior of biomedical materials 2009, 2 (1), 20-32.

- ↑ Kasperovich, G.; Hausmann, J., Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. Journal of Materials Processing Technology 2015, 220, 202-214.

- ↑ Lin, C. Y.; Wirtz, T.; LaMarca, F.; Hollister, S. J., Structural and mechanical evaluations of a topology optimized titanium interbody fusion cage fabricated by selective laser melting process. Journal of Biomedical Materials Research Part A 2007, 83 (2), 272-279.

- ↑ Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.; Maier, H., On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. International Journal of Fatigue 2013, 48, 300-307.

- ↑ Larker, H. T.; Larker, R., Hot isostatic pressing. Materials Science and Technology 1991.