Methylococcus capsulatus

| Methylococcus capsulatus | |

|---|---|

| |

| Scientific classification | |

| Kingdom: | Bacteria |

| Phylum: | Proteobacteria |

| Class: | Gammaproteobacteria |

| Order: | Methylococcales |

| Family: | Methylococcaceae |

| Genus: | Methylococcus |

| Species: | M. capsulatus |

| Binomial name | |

| Methylococcus capsulatus Foster and Davis 1966 (Approved Lists 1980) | |

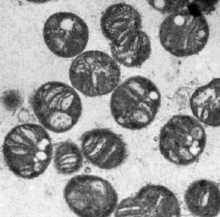

Methylococcus capsulatus is an obligately methanotrophic gram-negative, non-motile coccoid bacterium. M. capsulatus cells are encapsulated and tend to have a diplococcoid arrangement. In addition to methane, M. capsulatus is able to oxidize some organic hydrogen containing compounds such as methanol. M. capsulatus has also been demonstrated to be thermotolerant- that is, it can grow well up to 50 °C, though its optimum growth temperature is 37 °C. In addition, M. capsulatus can live in conditions in which there is little molecular oxygen available.

Methylococcus capsulatus is a Type I methanotroph, meaning that it is a member of the Gammaproteobacteria and that it utilizes the ribulose monophosphate pathway (RuMP) for formaldehyde assimilation. Methane is first oxidized to methanol, which then gets converted into formaldehyde. Formaldehyde can then be 1) further oxidized to formate and carbon dioxide for energy production or 2) assimilated into biomass.

The genome sequence of M. capsulatus (Bath) is available.[1]

Various strains of M. capsulatus have been isolated and studied, particularly M. capsulatus (Bath), M. capsulatus (Texas) and M. capsulatus (Aberdeen).

In 1999, Norferm a subsidiary of the Norwegian oil company Statoil, opened a 10,000 tons per year plant to produce animal feed from natural gas from M. capsulatus[2] in Tjeldbergodden, Norway.[3] The plant was shut down in 2006 because of low animal feed prices, the product had not yet been approved by the EU[4] and high natural gas prices.[5]

In 2016 Calysta, an American biotech company, opened a plant in Teeside, UK, to produce up to 100 tons of fish feed a year from natural gas using M. capsulatus.[4] The company also announced plans to build a similar plant in Memphis, Tennessee, USA[6] with an eventual capacity of 200,000 ton a year with the agricultural business company Cargill.[4][7] Another company, Unibio, also opened a plant to produce animal feed from natural gas in 2016 with a capacity of 80 tons per year using M. capsulatus[8] in Kalundborg, Denmark.[9]

References

- ↑ Ward, Naomi; Larsen, ØIvind; Sakwa, James; Bruseth, Live; Khouri, Hoda; Durkin, A. Scott; Dimitrov, George; Jiang, Lingxia; et al. (2004). "Genomic Insights into Methanotrophy: the Complete Genome Sequence of Methylococcus capsulatus (Bath)". PLoS Biology. 2 (10): e303. PMC 517821

. PMID 15383840. doi:10.1371/journal.pbio.0020303.

. PMID 15383840. doi:10.1371/journal.pbio.0020303. - ↑ "Natures Value Chain.. Biiomass Production" (PDF). Norferm.

- ↑ "Bioprotein begins". Statoil. 1999-02-17. Retrieved 2016-12-12.

- 1 2 3 Le Page, Michael (2016-11-19). "Food made from natural gas will soon feed farm animals – and us". New Scientist. Retrieved 2016-12-11.

- ↑ Fletcher, Rob (2015-07-10). "Making a meal out of methane". Fish Farming Expert. Norsk Fiskeoppdrett AS. Retrieved 2016-12-12.

- ↑ Lane, Jim (2016-12-04). "Going to Graceland: Cargill, Calysta select Tennessee for methane-to-feed project". Biofuels Digest. Retrieved 2016-12-13.

- ↑ "New venture selects Cargill’s Tennessee site to produce Calysta FeedKind® Protein". Calysta. 2016-11-29. Retrieved 2016-12-11.

- ↑ Nandy, Subir Kumar (2016-08-08). "Towards a green future: bacterial biomass used for feed". Euro Biomass 2016 Conference, Birmingham, UK. OMICS International. Retrieved 2016-12-12.

- ↑ "Unibio Completes Commercial Plant in Denmark and Enters Commercial Phase". BusinessWire. 2016-10-31. Retrieved 2016-12-12.