Hartley Colliery disaster

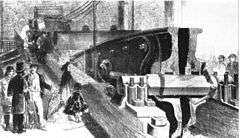

Drawing of the fractured cast iron beam, from the Illustrated London News, 1864 | |

| Date | January 16, 1862 |

|---|---|

| Time | 10:30 |

| Location | New Hartley, Northumberland, England |

| Coordinates | 55°5′15″N 1°31′42″W / 55.08750°N 1.52833°WCoordinates: 55°5′15″N 1°31′42″W / 55.08750°N 1.52833°W |

| Also known as | Hester Pit |

| Type | Coal mine disaster |

| Cause | Fracture of pumping engine beam |

| Deaths | 204 |

| Property damage | Pit closed |

| Burial | St Alban's Church, Earsdon |

| OS grid reference | NZ 30205 77108 |

| Led to a requirement for all mines to have at least two shafts | |

The Hartley Colliery disaster (also known as the Hartley Pit disaster or Hester Pit disaster) was a coal mining accident in Northumberland, England that occurred on Thursday 16 January 1862 and resulted in the deaths of 204 men. The beam of the pit's pumping engine broke and fell down the shaft, trapping the men below. The disaster prompted a change in UK law that henceforth required all collieries to have at least two independent means of escape.[1]

The colliery

Hartley old pit

Hartley old pit was established in the coastal village of Hartley (now part of Seaton Sluice), Northumberland during the 13th century; the earliest extant records date from 1291.[2] The colliery suffered increasingly from flooding as the seams were worked out under the sea and in 1760 the first atmospheric engine was installed, followed by later, more powerful, engines. The flooding became so severe that the old pit was abandoned in 1844.[2]

Hester pit

The coal was sufficiently valuable that the following year a new shaft (A on the diagram alongside) was sunk about a mile inland. The low main seam (F) was reached on 29 May 1846.[2] The colliery was called the New Hartley Colliery and the shaft the Hester Pit.[lower-alpha 1] Around the pit a new village grew up that was called New Hartley. Women and young children were not employed in the pit and according to E. Raper (Social and Working Conditions in the village of New Hartley 1845–1900) this gave a higher standard of life for the miners: "the miner in New Hartley would return home after a hard day's work to a warm, clean, comfortable home and usually a substantial hot meal".[1]

In common with many collieries of the period and locality only a single 12 feet (3.7 m) shaft was dug.[3] Coal, men, and materials traveled up and down the shaft, which also accommodated the pumps. In addition, the shaft provided vitally important fresh air ventilation and extraction of the firedamp.[4]

In collieries with two or more pits (for instance see the description of Felling), one pit was the downcast pit down which fresh air travelled, the other the upcast pit up which spent air escaped. Within the colliery the air was forced to traverse the whole of the workings by the use of walls of coal left in place, stoppings[lower-alpha 2] and traps.[lower-alpha 3] At this date the normal means of creating the updraft needed was by using a furnace in the upcast pit.[5]

With a single shaft colliery this simple arrangement could not be followed, and so a timber brattice[lower-alpha 4] (B) was built from the top of the shaft to the bottom. Men and materials passed up and down on the downcast side,[lower-alpha 5] the pumps worked in the upcast. At Hartley a furnace was kept burning in the yard seam (E) with the rising hot gasses passing up the furnace drift[lower-alpha 6] (I) to join and draw foul air up the upcast side of the shaft.[5]

The pit was known as a wet pit, the lower main would flood with seawater percolating through the roof of the seam from the North Sea above it. A substantial pump was therefore employed to keep the pit workable. As was common practice at that date the pump was a beam engine working the pumps directly. The pumps were in three stages. The lowest stage lifted water from a sump connected to an adit[lower-alpha 7] below the low main seam up to the yard seam. There a second stage lifted the water up to a sump in the high main.[2] These first two stages were driven by the main beam. The third stage was driven by a subsidiary beam above the pump staple (C).[lower-alpha 8][3] The pump was a nominal 300 horsepower making it the largest pumping engine in the North of England.[2] According to Gardiner & Smith 2001 it could raise 1,500 imperial gallons (6,800 l; 1,800 US gal) per minute, whilst The Illustrated London News 1862, p. 107 claimed 180 tons of water per stroke making five to six strokes per minute.

At the time of the disaster the high main had been worked out and was closed off. The yard seam likewise was not being worked, but remained in communication with the low main by means of a staple within which was a wire ladder.[3]

The attached drawing is a simplified and corrected version of one that appeared in the Illustrated London News of 1862. C is the pump staple in which pump rods worked by a subsidiary beam operated. D is the worked out and abandoned high main seam. G is the location of the blockage above the yard seam and covering the end of the furnace drift. The vertical passage near H is the staple containing a wire ladder connecting the yard and low main seams.[4]

The disaster

On 16 January 1862 the fore shift went on duty at 02:30. At 10:30 the same morning the back shift were taking over from the fore shift, so most men of both shifts were at the coal face. As the first eight men were ascending, the beam of the pumping engine snapped and fell down the shaft. Although much of the brattice was destroyed, the first part seems to have deflected the beam away from the cage. Other debris did fall on the cage snapping two of the four support chains. Four of the eight men fell, the others managed to cling on. The beam came to rest jammed in the shaft and other falling debris created a blockage 30 yards (27 m) deep between the yard seam and the high main.[2]

Rescue attempts

One of the deputies, Matthew Chapman, had been on his way home when he heard the crash. Retracing his steps he had himself lowered on a rope and started to clear away some of the debris with an axe. Realising that the man was exhausted, having just come off shift, the manager Joseph Humble (the great-great-great grandfather of TV presenter Kate Humble) sent him home to rest whilst the main rescue effort was organised. As well as being the first man down and thereby entering into the unknown, Chapman had the good fortune to be one of the two longest lived survivors. On the fiftieth anniversary of the disaster he was interviewed by Mr T Mason and his testimony forms the basis of Mason & Atkinson (1911).

The initial rescue attempt was carried out under the direction of Humble, Carr (owner and viewer), G B Hunter (Cowpen & North Seaton), Hugh Taylor (Backworth) and Matthias Dunn (HM Inspector of Mines). By midnight rescuers had reached the damaged cage and George Sharp Snr was brought up in a rope sling. However, he jammed against some overhanging timbers, came out of the sling and fell to his death. The rescuers (including the by then rested Chapman) then descended the pump staple and lowered a rope sling from the high main. William Shape and Ralph Robinson were brought up from the cage in this manner. Thomas Watson, a local preacher, had earlier descended from the cage to the men who had fallen. He remained with them to pray and comfort them until they died. Watson likewise ascended in a sling and was therefore the last man out alive.[5]

With the pumps stopped, all knew that the low main would quickly flood. Those on the surface therefore assumed correctly that the men below would make their way via the staple up to the yard seam. There was even a suggestion that the quickest way to clear the blockage was to drop the other half of the beam down the shaft, an idea that was not supported by the more experienced miners.[5] Throughout the night men continued to work from ropes.[5]

The following morning (Friday) Mr William Coulson, a master sinker,[lower-alpha 9] was passing and volunteered his service. Coulson would have been familiar with the shaft, having supervised its sinking in 1845–46.[2] He was put in charge, the previous committee yielding to his greater experience. Proper working parties were organised, sinkers from surrounding pits being preferred. Men worked, suspended by a rope from above, two at a time for a shift of an hour.[5] During this period the rescuers could at times distinctly hear the trapped men attempting to break upwards.[4]

On the Friday the rescuers were within 5 fathoms (30 ft; 9.1 m) when the upper part of the shaft caved in and the rescuers had to be withdrawn.[5] On Saturday a further fall occurred when the rescuers were within 4 fathoms of the trapped men, hundreds of tons of rock left a cavity 30 feet (9.1 m) across. The cavity was shored up but further falls continued to hinder the work.[5] Tuesday brought another problem. As the men worked through the blockage they were overcome by fumes of carbon monoxide from the upcast furnace and from measures it had ignited. Men could only work in 20-minute shifts.[5]

To restart some ventilation a cloth brattice was rigged from the surface down to the work area. On the Wednesday the furnace drift was reached but George Emerson, who attempted to enter it, was forced back by the gas. He did report seeing an axe, saw and sawn timber which indicated that the trapped miners had attempted to escape along that route. Later in the day William Adams of Cowpen and Robert Wilson of Backworth managed to enter the yard seam and found the men dead.[5] Humble and Hall penetrated further and found the dead miners, but on their return to the bank were severely affected by the gas. The corn bins to feed the horses had been emptied to provide emergency food for the trapped miners, some miners were found with corn in their pockets. Although other men went down after Humble and Hall, no survivors were found and all returned seriously affected by the gas.[4] All work ceased with the extinguishing of the last hope and the rescue moved into the recovery phase.[2]

Recovery

Before recovery could begin the shaft had to be timbered and the brattice completed. During rescue attempts safety concerns had been minimised, but now the welfare of the recovery workers took priority. By the Saturday the works were complete and the sinkers and shaftmen withdrawn. First down were Humble and Hall (a manager from a nearby collier) followed by Chapman and Brown then other men.[4]

Evidence was visible that the trapped miners had attempted to dig their way out but ultimately had accepted their fate. Carbon monoxide poisoning leads to headaches and nausea followed by dizziness and fatigue.[6] Contemporary accounts relate that a man sat with his stepson on his knee, others that fathers lay with their arms around their sons at their sides.[5]

The first men down all suffered in varying degrees from poisoning, but were brought to the surface before permanent injury occurred. Enough clearance of rubble was performed to allow the recovery of the bodies. The original plan had been to coffin them below ground, but owing to the good state of preservation of the bodies they were brought to the pit head to be shrouded and coffined.[7] The medical staff were worried about contagion if the bodies were allowed to go back to their homes, but compassion over-ruled science. As each body was coffined it was either sent home or, if unidentified, chalked "unknown" and sent to a storehouse for later identification.[7] At one o'clock on the Sunday carts arrived at the cottages and most of the coffins were carried in procession to Earsdon Church. The graveyard was not large enough for such a sudden influx and more land was given by the Duke of Northumberland.[8]

The loss of life was extreme, even by Victorian era coal mining standards, and remains one of the worst mining accidents in England.[9]

Causes

The cause of the fracture in the beam was attributed to overload from the pump rod system to which one end of the beam was attached. However, on the Sunday before the disaster pumping was stopped and the beam raised off its bearing to enable new bearing brasses to be put in. This was a common procedure for engines of this class, after four years of work the originals had worn. As the beam was being replaced it fell from its supporting jacks and "fell with great force into its bearings".[5]

The beam had a breaking strain of 175 tons and had been made nearby by Messrs Losh, Wilson and Bell of Walker.[5] The beam weighed 43 tons.[10] It was of substantial construction, 8 feet (2.4 m) across in the centre with metal 5 inches (130 mm) thick at its thinnest part.[4] In the engraving (shown on the right) note the figure to the left of the beam for an appreciation of its size.

It was already well known at the time, however, that cast iron was susceptible to sudden brittle failure, often from internal defects such as blowholes, notwithstanding that the beam was reputed to be made of "the best material".[4] Several such blowholes are visible in the fracture surfaces shown in the detailed engraving. The fall from the jacks may also have started or increased internal cracks. Cast iron, like other metals, is susceptible to metal fatigue where repeated loading is involved. Generally construction metals gradually lose their strength when subjected to repetitive strain. The amount of such loss depends on the load and the number of its applications. Thus, in engineering, the fatigue limit is calculated to prove a specific construction will survive its intended lifespan without failure caused by fatigue. Such proof basically calculates the loss of strength inflicted by a high number of repetitive applications of the maximum expected load and shows it is well below the limits. This is generally safe but any strain well above the expected load invalidates such calculations. This likely happened when the beam fell off its jacks.

Aftermath

As the rescuers struggled in vain to rescue the men trapped underground, Queen Victoria sent messages of condolence. On 22 January she enquired by telegram about the hope of rescue.[8] Initially Mr Carr, the viewer, replied that hope was by then faint, but not extinguished. Shortly thereafter he had to send a second telegram announcing all hope was lost. The Queen sent a telegram of condolence the following day, following it up by a letter. The letter was read by clergy to the widows which was "a great comfort and a consolation to them".[8] The Queen had lost her husband, Prince Albert, only a month previously and so her sympathy was understood to be genuine and deep. In her personal journal she recorded: "The accounts of the colliery accident are terrible, — such awful misery".[11] The heroism of the volunteers who attempted to rescue the victims was marked by a special medal, the Hartley Disaster Medal.[2] There is a memorial obelisk, commemorating those who died, in the churchyard at St Alban's church in Earsdon.[10]

Hester pit was never reopened. In 1874 a new colliery consisting of the Hastings and Melton pits was sunk nearby. Eventually the pit did drain and break into the low main workings of the old Hester pit during 1900. From 1929 onwards a series of takeovers and modernisations occurred until eventually in 1947 the new National Coal Board took over. Gradual decline followed with the whole colliery being abandoned in 1959 leaving a further 70 years (at peak production) worth of coal below ground.[2]

Legislation

The inquest verdict was delivered on 6 February 1862. The jury added the following rider to their verdict:

The Jury cannot close this painful inquiry without expressing their strong opinion of the imperative necessity that all working collieries should have at least a second shaft or outlet, to afford the workmen the means of escape should any obstruction take place.[1]

On 7 August 1862, just 6 months after the inquest and less than 7 months from the disaster, an Act of Parliament was passed which required all new mines to have two shafts and all existing mines to sink a second shaft before the end of 1864.[1][12]

January 2016

References

Footnotes

- ↑ A pit is a single shaft. A colliery (or mine) may be accessed by several pits, though not in this case.

- ↑ A stopping is a partition made of wood, stone, or brick to block up a hole in a wall. Stoppings force the air to follow the desired route and not to take short cuts

- ↑ A trap is a movable door in a stopping. The trap is opened for the passage of men and coal, but normally kept closed to force the air to follow the desired path

- ↑ A brattice is a partition (usually of timber) which seals off air flow

- ↑ As with the term downcast pit, this implies that air is moving down this side

- ↑ A drift is a tunnel leading to coal workings which is more horizontal than a shaft

- ↑ A tunnel cut below a working tunnel for the purpose of collecting water, a drain

- ↑ A staple is a very small shaft

- ↑ A sinker was responsible for the initial sinking of colliery shafts, including shoring up and lining the shaft.

Citations

- 1 2 3 4 BBC 2004.

- 1 2 3 4 5 6 7 8 9 10 Gardiner & Smith 2001.

- 1 2 3 The Illustrated London News 1862, p. 107.

- 1 2 3 4 5 6 7 The Illustrated London News 1862, p. 81.

- 1 2 3 4 5 6 7 8 9 10 11 12 13 Mason & Atkinson 1911.

- ↑ Wikipedia article

- 1 2 The Illustrated London News 1862, p. 105.

- 1 2 3 The Illustrated London News 1862, p. 106.

- ↑ See mining disaster

- 1 2 Wanless 1993.

- ↑ Queen Victoria 1862, p. 18.

- ↑ NEIMME 2016.

Bibliography

- BBC (February 2004), "Work: The Hartley Mining Disaster", Legacies – Tyne, BBC, retrieved 3 October 2013

- Duckham, Frederick; Duckham, Helen (1973), Great pit disasters: Great Britain, 1700 to the present day, Newton Abbot: David and Charles, ISBN 0-7153-5717-4

- Fordyce, T (1867), Local Records of Historical Register of Remarkable Events, Durham Mining Museum, retrieved 3 October 2013

- Gardiner, Jeff; Smith, Mark (2001), The Hartley Colliery Disaster Medal, National Mining Memorabilia Association

- Lewis, Peter (2007), Disaster on the Dee: Robert Stephenson's Nemesis of 1847: The Collapse of the Dee Bridge, 1847, Tempus Publishing, ISBN 0-7524-4266-X

- McCutcheon, John Elliott (1963), The Hartley Colliery Disaster, Seaham, England: E McCutcheon, OCLC 4858395

- Mason, T.; Atkinson, Peter (1911), "The Hartley Pit Disaster", The Science and Art of Mining, Durham Mining Museum, retrieved 3 October 2013

- The Illustrated London News (1862), The Hartley Pit Disaster, The Illustrated London News

- "The Hartley Catastrophe", The Mechanics' Magazine, London, p. 43, 24 January 1862a, retrieved 25 September 2011 – contemporary news report and analysis

- "The Hartley Catastrophe", The Mechanics' Magazine, London, p. 59, 31 January 1862b, retrieved 25 September 2011 – subsequent, more detailed analysis with diagram

- "The causes of the Hartley catastrophe", The Mechanics' Magazine, London, p. 83, 31 January 1862b, retrieved 25 September 2011 – report of the coroner's inquest

- NEIMME (January 2016), Government and Mining: Legislation, Inspection, Enquiries, a resource list (PDF), North of England Institute of Mining and Mechanical Engineers, retrieved 17 June 2017

- Queen Victoria, Journal, 51 (14th December 1861-31st December 1862), retrieved 21 April 2016

- Wanless, Colin (January 1993), "The Hartley Pit Disaster Northumberland 1862" (PDF), Tree Magazine