Critical resolved shear stress

Critical resolved shear stress (CRSS) is the component of shear stress, resolved in the direction of slip, necessary to initiate slip in a grain. Resolved shear stress (RSS) is the shear component of an applied tensile or compressive stress resolved along a slip plane that is other than perpendicular or parallel to the stress axis. The RSS is related to the applied stress by a geometrical factor, m, typically the Schmid factor [1]:

where σapp is the magnitude of the applied tensile stress, Φ is the angle between the normal of the slip plane and the direction of the applied force, and λ is the angle between the slip direction and the direction of the applied force. The Schmid Factor is most applicable to FCC single crystal metals,[3] but for polycrystal metals the Taylor factor has been shown to be more accurate.[4] The CRSS is the value of resolved shear stress at which yielding of the grain occurs, marking the onset of plastic deformation. CRSS, therefore, is a material property and is not dependent on the applied load or grain orientation. The CRSS is related to the observed yield strength of the material by the maximum value of the Schmid factor:

CRSS is a constant for crystal families. Hexagonal close packed crystals, for example, have three main families - basal, prismatic, and pyramidal - with different values for the critical resolved shear stress.

Slip Systems and Resolved Shear Stress

In crystalline metals, slip occurs in specific directions on crystallographic planes, and each combination of slip direction and slip plane will have its own Schmid factor. As an example, for a face-centered cubic (FCC) system the primary slip planes and directions belong to the {111} and <110> families. The Schmid Factor for the plane in the direction for an applied tensile load in the direction can be calculated as:

In a single crystal sample, the macroscopic yield stress will be determined by the Schmid factor of the single grain. Thus, in general, different yield strengths will be observed for applied stresses along different crystallographic directions. In polycrystalline specimens, the yield strength of each grain is different depending on its maximum Schmid factor, which indicates the operational slip system(s).[5] The macroscopically observed yield stress will be related to the material's CRSS by an average Schmid factor, which is roughly 1/3.06 for FCC and 1/2.75 for body-centered cubic (BCC) structures.[6]

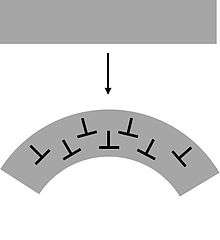

The onset of plasticity in polycrystals is influenced by the number of available slip systems to accommodate incompatibilities at the grain boundaries. In the case of two adjacent, randomly oriented grains, one grain will have a larger Schmid factor and thus a smaller yield stress. Under load, this "weaker" grain will yield prior to the "stronger" grain, and as it deforms a stress concentration will build up in the stronger grain near the boundary between them. This stress concentration will activate dislocation motion in the available glide planes. These dislocations are geometrically necessary to ensure that the strain in each grain is equivalent at the grain boundary, so that the compatibility criteria are satisfied. Taylor showed [4] that a minimum of five active slip systems are required to accommodate an arbitrary deformation. In crystal structures with fewer than 5 active slip systems, such as hexagonal close-packed (HCP) metals, the specimen will exhibit brittle failure instead of plastic deformation.

| Crystal Structure | Primary Slip System | Number of Independent Systems |

|---|---|---|

| Face-centered cubic (FCC) | {111}<1-10> | 5 |

| Body-centered cubic (BCC) | {110}<-111> | 5 |

| Hexagonal close-packed (HCP) | {0001}<11-20> | 2 |

Effects of Temperature and Solid Solution Strengthening

At lower temperatures, more energy (i.e. - larger applied stress) is required to activate some slip systems. This is particularly evident in BCC materials, in which not all 5 independent slip systems are thermally activated at temperatures below the ductile-to-brittle transition temperature, or DBTT, so BCC specimens therefore become brittle. In general, the CRSS increases as the homologous temperature decreases because it becomes energetically more costly to activate the slip systems, although this effect is much less pronounced in FCC.

Solid solution strengthening also increases the CRSS compared to a pure single component material because the solute atoms distort the lattice, preventing the dislocation motion necessary for plasticity. With dislocation motion inhibited, it becomes harder to activate the necessary 5 independent slip systems, so the material becomes stronger and more brittle.

References

- ↑ Schmid E., Boas W., Plasticity of Crystals with Special Reference to Metals, F.A. Hughes & Co. Ltd., 1935.

- ↑ Gottstein G., Physical Foundations of Materials Science, Springer, 2004, page 227.

- ↑ Hosford W.F., Mechanical Behavior of Materials, 2nd ed., Cambridge University Press, 2010, page 113.

- 1 2 Taylor, Sir Geoffrey Ingram. Plastic strain in metals. 1938.

- ↑ Meyers and Chawla. (1999) Mechanical Behaviors of Materials. Prentice Hall, Inc. Page 301.

- 1 2 H., Courtney, Thomas (2013). Mechanical Behavior of Materials. McGraw Hill Education (India). p. 160. ISBN 1259027511. OCLC 929663641.