Cladding (metalworking)

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure.

The United States Mint uses cladding to manufacture coins from different metals. This allows a cheaper metal to be used as a filler.

Roll bonding

In roll bonding, two or more layers of different metals are thoroughly cleaned and passed through a pair of rollers under sufficient pressure to bond the layers. The pressure is high enough to deform the metals and reduce the combined thickness of the clad material. Heat may be applied, especially when metals are not ductile enough. As an example of application, bonding of the sheets can be controlled by painting a pattern on one sheet; only the bare metal surfaces bond, and the un-bonded portion can be inflated if the sheet is heated and the coating vaporizes. This is used to make heat exchangers for refrigeration equipment. [1]

Explosive welding

In explosive welding, the pressure to bond the two layers is provided by detonation of a sheet of chemical explosive. No heat-affected zone is produced in the bond between metals. The explosion propagates across the sheet, which tends to expel impurities and oxides from between the sheets. Pieces up to 4 x 16 metres can be manufactured. The process is useful for cladding metal sheets with a corrosion-resistant layer. [1]

Laser cladding

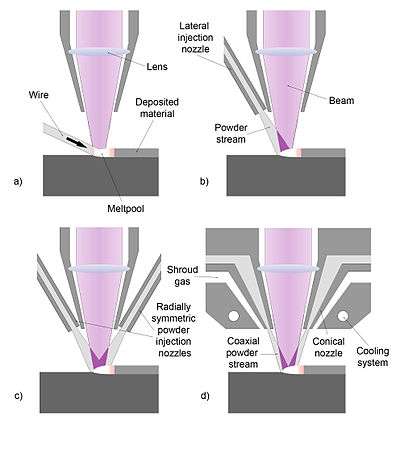

Laser cladding[2][3] is a method of depositing material by which a powdered or wire feedstock material is melted and consolidated by use of a laser in order to coat part of a substrate or fabricate a near-net shape part (additive manufacturing technology) .

It is often used to improve mechanical properties or increase corrosion resistance, repair worn out parts,[4][5] and fabricate metal matrix composites.[6]

Process

The powder used in laser cladding is normally of a metallic nature, and is injected into the system by either coaxial or lateral nozzles. The interaction of the metallic powder stream and the laser causes melting to occur, and is known as the melt pool. This is deposited onto a substrate; moving the substrate allows the melt pool to solidify and thus produces a track of solid metal. This is the most common technique, however some processes involve moving the laser/nozzle assembly over a stationary substrate to produce solidified tracks. The motion of the substrate is guided by a CAD system which interpolates solid objects into a set of tracks, thus producing the desired part at the end of the trajectory.

A great deal of research is now being concentrated on developing automatic laser cladding machines. Many of the process parameters must be manually set, such as laser power, laser focal point, substrate velocity, powder injection rate, etc., and thus require the attention of a specialized technician to ensure proper results. However, many groups are focusing their attention on developing sensors to measure the process online. Such sensors monitor the clad's geometry (height and width of deposited track), metallurgical properties (such as the rate of solidification, and hence the final microstructure), and temperature information of both the immediate melt pool and its surrounding areas. With such sensors, control strategies are being designed such that constant observation from a technician is no longer required to produce a final product. Further research has been directed to forward processing where system parameters are developed around specific metallurgical properties for user defined applications (such as microstructure, internal stresses, dilution zone gradients, and clad contact angle).

Advantages

- Best technique for coating any shape => increase life-time of wearing parts.

- Particular dispositions for repairing parts (ideal if the mould of the part no longer exist or too long time needed for a new fabrication).

- Most suited technique for graded material application.

- Well adapted for near-net-shape manufacturing.

- Low dilution between track and substrate (unlike other welding processes and strong metallurgical bond.

- Low deformation of the substrate and small heat affected zone (HAZ).

- High cooling rate => fine microstructure.

- A lot of material flexibility (metal, ceramic, even polymer).

- Built part is free of crack and porosity.

- Compact technology.

See also

References

- 1 2 Bralla, James G. Handbook of Manufacturing Processes Industrial Press 2007 ISBN 978-0-8311-3179-1 pages 310-312

- ↑ Vilar, R. (1999). "Laser cladding". Journal of Laser Applications. 11 (2): 64–79. doi:10.2351/1.521888.

- ↑ Toyserkani, Ehsan; Stephen Corbin; Amir Khajepour (2004). Laser Cladding. Boca Raton, FL: CRC Press.

- ↑ Capello, E.; Colombo, D.; Previtali, B. (2005). "Repairing of sintered tools using laser cladding by wire". Journal of Materials Processing Technology. 164-165: 990. doi:10.1016/j.jmatprotec.2005.02.075.

- ↑ Brandt, M.; Sun, S.; Alam, N.; Bendeich, P.; Bishop, A. (2009). "Laser cladding repair of turbine blades in power plants: From research to commercialisation". International Heat Treatment & Surface Engineering. 3 (3): 105. doi:10.1179/174951409X12542264513843.

- ↑ Yakovlev, A.; Bertrand, P.; Smurov, I. (2004). "Laser cladding of wear resistant metal matrix composite coatings". Thin Solid Films. 453-454: 133. Bibcode:2004TSF...453..133Y. doi:10.1016/j.tsf.2003.11.085.

External links

- http://apollomachine.com/services/apollo-clad/

- https://web.archive.org/web/20150720051133/http://www.beam-machines.fr/uk/innovation/techology.html

- https://web.archive.org/web/20101207085306/http://www.ccl.fraunhofer.org/download/cladding_titanium.pdf (Link does not function)

- http://www.lasercladding.com/index.html

- http://www.designforlasermanufacture.com/

- https://web.archive.org/web/20110926224642/http://www.alspi.com/lasercladding.htm

- http://www.laserweldingsolutions.com/

- https://web.archive.org/web/20100311075620/http://www.fwgartner.com/fwgts_prodserv_qa_laser.htm

- http://www.laserline-inc.com/diode-laser-cladding-coating-laser-repair-welding.php

- http://www.optoiq.com/index/lasers-for-manufacturing/laser-surface-treatment/laser-cladding.html

- http://www.swansonindustries.com/lasercladding.php

- http://www.precoinc.com/capabilities/clad.html

- http://www.neotechservices.com/lens.html

- https://archive.is/20130116124148/http://www.additive3d.com/lens.htm

- http://www.darron-sbo.com/

- http://www.vectorautomationinc.com/systems/robotic-laser-cladding/

- http://www.ceramicfacades.com//

- http://www.cladmetal.com/