CANDU reactor

The CANDU, for CANada Deuterium Uranium, is a Canadian-developed, pressurized heavy water reactor used to generate electric power. The acronym refers to its deuterium oxide (heavy water) moderator and its use of (originally, natural) uranium fuel. CANDU reactors were first developed in the late 1950s and 1960s by a partnership between Atomic Energy of Canada Limited (AECL), the Hydro-Electric Power Commission of Ontario, Canadian General Electric, and other companies.

There have been two major types of CANDU reactors, the original design of around 500 MWe that was intended to be used in multi-reactor installations in large plants, and the rationalized CANDU6 in the 600 MWe class that is designed to be used in single stand-alone units or in small multi-unit plants. CANDU6 units were built in Quebec and New Brunswick, as well as Pakistan, Argentina, South Korea, Romania, and China. A single example of a non-CANDU6 design was sold to India. The multi-unit design was used only in Ontario, Canada, and grew in size and power as more units were installed in the province, reaching ~880 MWe in the units installed at the Darlington Nuclear Generating Station. An effort to rationalize the larger units in a fashion similar to CANDU6 led to the CANDU9 effort, but did not achieve any sales.

By the early 2000s, sales prospects for the original CANDU designs were dwindling due to the introduction of newer designs from other companies. AECL responded by cancelling CANDU9 and moving to the Advanced CANDU reactor (ACR) design. ACR failed to find any buyers; its last potential sale was to Darlington, but this expansion was cancelled in 2009. In October 2011, the Canadian Federal Government licensed the CANDU design to Candu Energy (a wholly owned subsidiary of SNC-Lavalin), which also acquired the former reactor development and marketing division of AECL at that time. Candu Energy offers support services for existing sites, and are completing formerly stalled installations in Romania and Argentina through a partnership with China National Nuclear Corporation. Further design and new sales efforts have ended.

Design

Basic design and operation

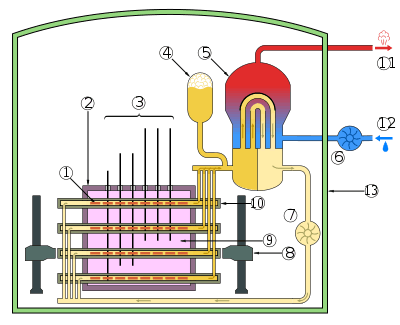

- Fuel bundle

- Calandria (reactor core)

- Adjuster rods

- Heavy water pressure reservoir

- Steam generator

- Light water pump

- Heavy water pump

- Fueling machines

- Heavy water moderator

- Pressure tube

- Steam going to steam turbine

- Cold water returning from turbine

- Containment building made of reinforced concrete

Fission reactions in the reactor core heat pressurized heavy water in a primary cooling loop. A heat exchanger, also known as a steam generator, transfers the heat to a light-water secondary cooling loop, which powers a steam turbine with an electric generator attached to it (for a typical Rankine thermodynamic cycle). The exhaust steam from the turbines is then condensed and returned as feedwater to the steam generator, often using cooling water from a nearby source, such as a lake, river, or ocean. Newer CANDU plants, such as the Darlington Nuclear Generating Station near Toronto, Ontario, use a diffuser to spread the warm outlet water over a larger volume and limit the effects on the environment. A cooling tower can be used, but it reduces efficiency and increases costs considerably. Some of the unique features of the CANDU design are listed below:

- Use of natural uranium: Since CANDU uses heavy water as both moderator and coolant, it has the advantage of maintaining a very high neutron economy. This means that the subsequent neutrons resulting from fission are used more effectively and there are fewer losses (compared to light water moderated reactors). This allows the use of natural uranium as fuel and saves the cost of enrichment.

- Pressure-tube design: pressurized water reactors (PWR) and boiling water reactors (BWR) are mostly pressure-vessel type reactors. CANDU instead uses pressure tubes. Each pressure tube is inside the calandria tubes and there are normally 380–480 such tubes assembled in a reactor. This design enables the use of online refuelling and many other unique features of CANDU.

- Refuelling the reactor while it is in operation: Unlike PWRs and BWRs, CANDU reactors do not undergo batch refuelling. Instead two robotic machines hook up to the reactor faces and open the end caps of a pressure tube. One machine simply pushes in the new fuel, whereby the depleted fuel is pushed out and collected at the other end.

In a light water reactor (LWR), the entire reactor core is a single large pressure vessel containing the light water, which acts as moderator and coolant, and the fuel arranged in a series of long bundles running the length of the core. At the time of CANDU's design, Canada lacked the heavy industry to cast and machine the pressure vessels.[1] In CANDU the pressure (and the fuel bundles) is contained in much smaller (10 cm diameter), easier-to-fabricate tubes. Each bundle is a cylinder assembled from alloy tubes containing ceramic pellets of fuel. In older designs the assembly had 28 or 37 half-meter-long fuel tubes with 12 such assemblies lying end to end in a pressure tube. The newer CANFLEX bundle has 43 tubes, with two pellet sizes (so the power rating can be increased without melting the hottest pellets). It is about 10 centimetres (3.9 in) in diameter, 0.5 metres (20 in) long and weighs about 20 kilograms (44 lb) and replaces the 37-tube bundle. To allow the neutrons to flow freely between the bundles, the tubes and bundles are made of neutron-transparent zircaloy (zirconium + 2.5% wt niobium).

The zircaloy tubes are surrounded by a much larger low-pressure tank known as a calandria, which contains the majority of the moderator. To keep the hot coolant from boiling the moderator, a calandria tube surrounds each pressure tube, with insulating carbon dioxide gas in between. Slowing down neutrons releases energy, so a cooling system dissipates the heat. The moderator is actually a large heat sink that acts as an additional safety feature. The use of individual high pressure fuel channels passing through the CANDU's low-pressure moderator calandria makes it easier to refuel: a pressure-vessel reactor must be shut down, the pressure dropped, the lid removed, and a sizeable fraction of the fuel, e.g. one-third, replaced all at once. In CANDU, individual channels can be refuelled without taking the reactor offline, improving the capacity factor. One fueling machine inserts new fuel into one end of the channel while the other receives discharged fuel from the opposite end. One significant operational advantage of online refuelling is that a failed or leaking fuel bundle can be removed from the core once it has been located, thus reducing the radiation fields in the primary systems.

Purpose of using heavy water

Natural uranium is a mix of isotopes—mainly uranium-238, with 0.72% fissile uranium-235 by weight. A reactor aims for a steady rate of fission over time (criticality), where the neutrons released by fission cause an equal number of fissions in other fissile atoms. These neutrons are fairly energetic and don't readily react with (get "captured" by) the surrounding fissile material—they must have their energy "moderated" (i.e., be slowed down ) as much as possible, ideally to the same energy as the atoms themselves ("thermal neutrons") or lower. During moderation it helps to separate the neutrons and uranium, since 238U has a large affinity for intermediate-energy neutrons ("resonance" absorption), but is only easily fissioned by the few energetic neutrons above ≈1.5–2 MeV. Since most of the fuel is usually 238U, most reactor designs are based on thin fuel rods separated by moderator, allowing the neutrons to travel in the moderator before entering the fuel again. More neutrons are released than is needed to maintain the chain reaction; when uranium-238 absorbs just the excess, plutonium is created which helps to make up for the depletion of uranium-235. Eventually the build-up of fission products that are even more neutron-absorbing than 238U slows the reaction and calls for refuelling.

Light water makes an excellent moderator—the light hydrogen atoms are very close in mass to a neutron and can absorb a lot of energy in a single collision (like a collision of two billiard balls). However, light hydrogen is also fairly effective at absorbing neutrons, and there will be too few left over to react with the small amount of 235U in natural uranium, preventing criticality. In order to allow criticality, the fuel must be "enriched", increasing the amount of 235U to an acceptable level. In light water reactors, the fuel is typically enriched to between 2% and 5% 235U (the leftover fraction with less 235U is called depleted uranium). Enrichment facilities are expensive to build and operate. They are also a proliferation concern as they can be used to enrich the 235U much further, up to weapons-grade material (90% or more 235U). However, this can be remedied if the fuel is supplied and reprocessed by an internationally approved supplier.

The main advantage of heavy water moderator over light water is reduced absorption of the neutrons that sustain the chain reaction, allowing a lower concentration of active atoms (to the point of using unenriched natural uranium fuel). Deuterium ("heavy hydrogen") already has the extra neutron that light hydrogen would absorb, reducing the tendency to capture neutrons. However, deuterium is twice the mass of a single neutron (vs light hydrogen which is about the same mass); the mismatch means more collisions are needed to moderate the neutrons, requiring a larger thickness of moderator between the fuel rods. This increases the size of the reactor core and the leakage of neutrons. It is also the practical reason for the calandria design, otherwise a very large pressure vessel would be needed.[1] The low 235U density in natural uranium also implies that less of the fuel will be consumed before the fission rate drops too low to sustain criticality, because the ratio of 235U to fission products+238U is lower. However, in CANDU most of the moderator is at lower temperatures than in other designs, reducing the spread of speeds and the overall speed of the moderator particles. This means most of the neutrons will end up at a lower energy and be more likely to cause fission, so CANDU not only "burns" natural uranium, but it does so more effectively as well. Overall, CANDU reactors use 30–40% less mined uranium than light-water reactors per unit of electricity produced. This is a major advantage to the heavy water design; it not only requires less fuel, but as the fuel does not have to be enriched, it is much less expensive as well.

A further unique feature of heavy-water moderation is the greater stability of the chain reaction. This is due to the relatively low binding energy of the deuterium nucleus (2.2 MeV), leading to some energetic neutrons and especially gamma rays breaking the deuterium nuclei apart to produce extra neutrons. Both gammas produced directly by fission and by the decay of fission fragments have enough energy, and the half-lives of the fission fragments range from seconds to hours or even years. The slow response of these gamma-generated neutrons delays the response of the reactor and gives the operators extra time in case of an emergency. Since gamma rays travel for meters through water, an increased rate of chain reaction in one part of the reactor will produce a response from the rest of the reactor, allowing various negative feedbacks to stabilize the reaction.

On the other hand, the fission neutrons are thoroughly slowed down before they reach another fuel rod, meaning that it takes neutrons a longer time to get from one part of the reactor to the other. Thus if the chain reaction accelerates in one section of the reactor, the change will propagate itself only slowly to the rest of the core, giving time to respond in an emergency. The independence of the neutrons' energies from the nuclear fuel used is what allows for such fuel flexibility in a CANDU reactor, since every fuel bundle will experience the same environment and affect its neighbors in the same way, whether the fissile material is uranium-235, uranium-233 or plutonium.

Canada developed the heavy water moderated design in the post-World War II era to explore nuclear energy while lacking access to enrichment facilities. War-era enrichment systems were extremely expensive to build and operate, whereas the heavy water solution allowed the use of natural uranium in the experimental ZEEP reactor. A much less expensive enrichment system was developed, but the United States classified work on the cheaper gas centrifuge process. The CANDU was therefore designed to use natural uranium.

Safety features

The CANDU includes a number of active and passive safety features in its design. Some of these are a side-effect of the physical layout of the system.

CANDU designs have a positive void coefficient as well as a small power coefficient, normally considered bad in reactor design. This implies that steam generated in the coolant will increase the reaction rate, which in turn would generate more steam. This is one of the many reasons for the cooler mass of moderator in the calandria, as even a serious steam incident in the core would not have a major impact on the overall moderation cycle. Only if the moderator itself starts to boil would there be any significant effect, and the large thermal mass ensures this will occur slowly. The deliberately "sluggish" response of the fission process in CANDU allows controllers more time to diagnose and deal with problems.[2]

The fuel channels can only maintain criticality if they are mechanically sound. If the temperature of the fuel bundles increases to the point where they are mechanically unstable, their horizontal layout means they will bend under gravity, shifting the layout of the bundles and reducing the efficiency of the reactions. Because the original fuel arrangement is optimum for a chain reaction and the natural uranium fuel has little excess reactivity, any significant deformation will stop the inter-fuel pellet fission reaction. This will not stop heat production from fission product decay, which would continue to supply a considerable heat output. If this process further weakens the fuel bundles, they will eventually bend far enough to touch the calandria tube, allowing heat to be efficiently transferred into the moderator tank. The moderator vessel has a considerable thermal capability on its own, and is normally kept relatively cool.[2]

Heat generated by fission products would initially be at about 7% of full reactor power, which requires significant cooling. The CANDU designs have several emergency cooling systems, as well as having limited self-pumping capability through thermal means (the steam generator is well above the reactor). Even in the event of a catastrophic accident and core meltdown, it is important to remember that the fuel is not critical in light water.[2] This means that cooling the core with water from nearby sources will not add to the reactivity of the fuel mass.

Normally the rate of fission is controlled by light-water compartments called liquid zone controllers, which absorb excess neutrons, and by adjuster rods which can be raised or lowered in the core to control the neutron flux. These are used for normal operation, allowing the controllers to adjust reactivity across the fuel mass as different portions would normally burn at different rates depending on their position. The adjuster rods can also be used to slow or stop criticality. Because these rods are inserted into the low-pressure calandria, not the high-pressure fuel tubes, they would not be "ejected" by steam, a design issue for many pressurized-water reactors.

There are two independent, fast-acting safety shutdown systems as well. Shutoff rods are held above the reactor by electromagnets, and drop under gravity into the core to quickly end criticality. This system works even in the event of a complete power failure, as the electromagnets only hold the rods out of the reactor when power is available. A secondary system injects a high-pressure gadolinium nitrate neutron absorber solution into the calandria.[3]

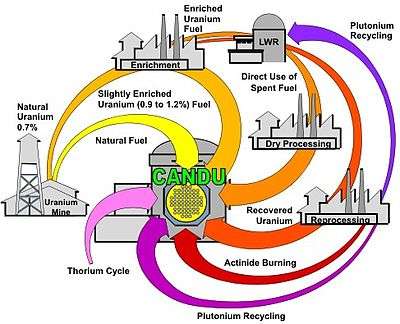

Fuel cycles

A heavy water design can sustain a chain reaction with a lower concentration of fissile atoms than light water reactors, allowing it to use some alternative fuels; for example, "recovered uranium" (RU) from used LWR fuel. CANDU was designed for natural uranium with only 0.7% U-235, so RU with 0.9% U-235 is a rich fuel. This extracts a further 30–40% energy from the uranium. The DUPIC (Direct Use of spent PWR fuel In CANDU) process under development can recycle it even without reprocessing. The fuel is sintered in air (oxidized), then in hydrogen (reduced) to break it into a powder, which is then formed into CANDU fuel pellets. CANDU can also breed fuel from the more abundant thorium. This is being investigated by India to take advantage of its natural thorium reserves.[4]

Even better than LWRs, CANDU can utilize a mix of uranium and plutonium oxides (MOX fuel), the plutonium either from dismantled nuclear weapons or reprocessed reactor fuel. The mix of isotopes in reprocessed plutonium is not attractive for weapons, but can be used as fuel (instead of being simply nuclear waste), while burning weapons-grade plutonium eliminates a proliferation hazard. If the aim is explicitly to burn plutonium or other actinides from spent fuel, then special inert-matrix fuels are proposed to do this more efficiently than MOX. Since they contain no uranium, these fuels do not breed any extra plutonium.

Economics

The neutron economy of heavy water moderation and precise control of on-line refueling allow CANDU to use a great range of fuels other than enriched uranium, e.g., natural uranium, reprocessed uranium, thorium, plutonium, and used LWR fuel. Given the expense of enrichment, this can make fuel much cheaper. There is however an initial investment into the tonnes of 99.75% pure[5] heavy water to fill the core and heat transfer system. In the case of the Darlington plant costs released as part of a freedom of information act request put the overnight cost of the plant (four reactors totalling 3,512 MWe net capacity) at $5.117 billion CAD (about $4.2 billion USD at early 1990s exchange rates). Total capital costs including interest were $14.319 billion CAD (about $11.9 billion USD) with the heavy water accounting for $1.528 billion, or 11%, of this.[6]

Since heavy water is less efficient at slowing neutrons, CANDU needs a larger moderator to fuel ratio and a larger core for the same power output. Although a calandria-based core is cheaper to build, its size increases the cost for standard features like the containment building. Generally nuclear plant construction and operations are ≈65% of overall lifetime cost; for CANDU costs are dominated by construction even more. Fueling CANDU is cheaper than other reactors, costing only ≈10% of the total, so the overall price per kWh electricity is comparable. The next-generation Advanced CANDU Reactor (ACR) mitigates these disadvantages by having light water coolant and using a more compact core with less moderator.

When first introduced, CANDUs offered much better capacity factor (ratio of power generated to what would be generated by running at full power, 100% of the time) than LWRs of a similar generation. The light-water designs spent, on average, about half the time being refueled or maintained. However, since the 1980s dramatic improvements in LWR outage management have narrowed the gap, with several units achieving capacity factors ~90% and higher, with an overall fleet performance of 92% in 2010.[7] The latest-generation CANDU 6 reactors have an 88–90% CF, but overall performance is dominated by the older Canadian units with CFs on the order of 80%.[8] Refurbished units have demonstrated poor performance to date, on the order of 65%.[9]

Some CANDU plants suffered from cost overruns during construction, often from external factors such as government action.[10] For instance, a number of imposed construction delays led to roughly a doubling of the cost of the Darlington Nuclear Generating Station near Toronto, Ontario. Technical problems and redesigns added about another billion to the resulting $14.4 billion price.[11] In contrast, in 2002 two CANDU 6 reactors at Qinshan in China were completed on-schedule and on-budget, an achievement attributed to tight control over scope and schedule.[12]

Nuclear nonproliferation

In terms of safeguards against nuclear weapons proliferation, CANDUs meet a similar level of international certification as other reactors. There is a common misconception that the plutonium for India's first nuclear detonation, Operation Smiling Buddha in 1974, was produced in a CIRUS design. In fact, it was produced in the safeguarded indigenously built PHWR reactor. In addition to its two PHWR reactors, India has some safeguarded pressurised heavy water reactors (PHWRs) based on the CANDU design, and two safeguarded light-water reactors supplied by the US. Plutonium has been extracted from the spent fuel from all of these reactors;[13] however India mainly relies on an Indian designed and built military reactor called Dhruva. The design is believed to be derived from the CIRUS reactor, with the Dhruva being scaled-up for more efficient plutonium production. It is this reactor which is thought to have produced the plutonium for India's more recent (1998) Operation Shakti nuclear tests.[14]

Although heavy water is relatively immune to neutron capture, a small amount of the deuterium turns into tritium in this way. Tritium+deuterium mix undergoes nuclear fusion more easily than any other substance. Tritium can be used in both the "fusion boost" of a boosted fission weapon and the main fusion process of an H-bomb. However, in an H-bomb, it is usually created in situ by neutron irradiation of lithium-6.

Tritium is extracted from some CANDU plants in Canada, mainly to improve safety in case of heavy-water leakage. The gas is stockpiled and used in a variety of commercial products, notably "powerless" lighting systems and medical devices. In 1985 what was then Ontario Hydro sparked controversy in Ontario due to its plans to sell tritium to the U.S. The plan, by law, involved sales to non-military applications only, but some speculated that the exports could have freed American tritium for the U.S. nuclear weapons program. Future demands appear to outstrip production, in particular the demands of future generations of experimental fusion reactors like ITER. Currently between 1.5 and 2.1 kg of tritium are recovered yearly at the Darlington separation facility, of which a minor fraction is sold.[15]

The 1998 Operation Shakti test series in India included one bomb of about 45 kt yield that India has publicly claimed was a hydrogen bomb. An offhand comment in the BARC publication Heavy Water — Properties, Production and Analysis appears to suggest that the tritium was extracted from the heavy water in the CANDU and PHWR reactors in commercial operation. Janes Intelligence Review quotes the Chairman of the Indian Atomic Energy Commission as admitting to the tritium extraction plant, but refusing to comment on its use.[16] However India is also capable of creating tritium more efficiently by irradiation of lithium-6 in reactors.

Tritium emissions

Tritium is a radioactive form of hydrogen (H-3), with a half-life of 12.3 years. It is produced in small amounts in nature (about 4 kg/year globally), by cosmic ray interactions in the upper atmosphere. Tritium is considered a weak radionuclide because of its low-energy radioactive emissions (beta particle energy up to 18.6 keV).[17] The beta particles travel 6 mm in air and only penetrate skin up to 6 micrometers. The biological half-life of inhaled, ingested, or absorbed tritium is 10–12 days.[18]

Tritium is generated in the fuel of all reactors; however, CANDU reactors generate tritium also in their coolant and moderator, due to neutron capture in heavy hydrogen. Some of this tritium escapes into containment and is generally recovered; however a small percentage (about 1%) escapes containment and is considered a routine radioactive emission (also higher than from an LWR of comparable size). Responsible operation of a CANDU plant therefore includes monitoring tritium in the surrounding environment (and publishing the results).

In some CANDU reactors the tritium is periodically extracted. Typical emissions from CANDU plants in Canada are less than 1% of the national regulatory limit, which is based on International Commission on Radiological Protection (ICRP) guidelines[19] (for example, the maximum permitted drinking water concentration for tritium in Canada,[20] 7,000 Bq/L, corresponds to 1/10 of the ICRP's dose limit for members of the public). Tritium emissions from other CANDU plants are similarly low.[17][21]

In general there is significant public controversy about radioactive emissions from nuclear power plants, and for CANDU plants one of the main concerns is tritium. In 2007 Greenpeace published a critique of tritium emissions from Canadian nuclear power plants[17] by Ian Fairlie.[22] This report was criticized[23] by Richard Osborne.[24]

History

Evolving designs

The CANDU development effort has gone through four major stages over time. The first systems were experimental and prototype machines of limited power. These were replaced by a second generation of machines of 500 to 600 MWe (the CANDU6), a series of larger machines of 900 MWe, and finally developing into the CANDU9 and current ACR-1000 effort.[25][26]

Early efforts

The first heavy water moderated design in Canada was the ZEEP, which started operation just after the end of World War II. ZEEP was joined by several other experimental machines, including the NRX in 1947 and NRU in 1957. These efforts led to the first CANDU-type reactor, the Nuclear Power Demonstration (NPD), in Rolphton, Ontario. It was intended as a proof-of-concept and rated for only 22 MWe, a very low power for a commercial power reactor. NPD produced the first nuclear-generated electricity in Canada, and ran successfully from 1962 to 1987.[27][28]

The second CANDU was the Douglas Point reactor, a more powerful version rated at roughly 200 MWe and located near Kincardine, Ontario. It went into service in 1968, and ran until 1984. Uniquely among CANDU stations, Douglas Point had an oil-filled window with a view of the east reactor face, even when the reactor was operating. Douglas Point was originally planned to be a two-unit station, but the second unit was cancelled because of the success of the larger 515 MWe units at Pickering.[29][30]

Gentilly-1, in Bécancour, Quebec near Trois-Rivières, Quebec, was also an experimental version of CANDU, using a boiling light-water coolant and vertical pressure tubes, but was not considered successful and closed after seven years of fitful operation.[31] Gentilly-2, a CANDU-6 reactor, has been operating since 1983. Following statements from the in-coming Parti Québécois government in September 2012 that Gentilly would close, the operator, Hydro-Québec, has decided to cancel a previously announced refurbishment of the plant and announced its shutdown at the end of 2012, citing economic reasons for the decision. The company will then undertake a 50-year decommissioning process estimated to cost $1.8 billion.[32]

In parallel with the classic CANDU design, experimental variants were being developed. WR-1, located at the AECL's Whiteshell Laboratories in Pinawa, Manitoba, used vertical pressure tubes and organic oil as the primary coolant. The oil used has a higher boiling point than water, allowing the reactor to operate at higher temperatures and lower pressures than a conventional reactor. WR-1 operated successfully for many years, and promised a significantly higher efficiency than water-cooled versions.[33][34]

600 MWe designs

The successes at NPD and Douglas Point led to the decision to construct the first multi-unit station in Pickering, Ontario. Pickering A, consisting of Units 1 to 4, went into service in 1971. Pickering B with units 5 to 8 came online in 1983, giving a full-station capacity of 4,120 MWe. The station is very close to the city of Toronto, in order to reduce transmission costs.

A series of improvements to the basic Pickering design led to the CANDU 6 design, which first went into operation in the early 1980s. CANDU 6 was essentially a version of the Pickering power plant that was re-designed to be able to be built in single-reactor units. CANDU 6 was used in several installations outside Ontario, including the Gentilly-2 in Quebec, and Point Lepreau Nuclear Generating Station in New Brunswick. CANDU 6 forms the majority of foreign CANDU systems, including the designs exported to Argentina, Romania, China and South Korea. Only India operates a CANDU system that is not based on the CANDU 6 design.

900 MWe designs

The economics of nuclear power plants generally scale well with size. However, this improvement at larger sizes is offset by the sudden appearance of large quantities of power on the grid, which leads to a lowering of electricity prices through supply and demand effects. Predictions in the late 1960s suggested that growth in electricity demand would overwhelm these downward pricing pressures, leading most designers to introduce plants in the 1000 MWe range.

Pickering A was quickly followed by such an upscaling effort for the Bruce Nuclear Generating Station, constructed in stages between 1970 and 1987. It is the largest nuclear facility in North America, and second largest in the world (after Kashiwazaki-Kariwa in Japan), with eight reactors at around 800 MWe each, in total 6,232 MW (net) and 7,276 MW (gross). Another, smaller, upscaling led to the Darlington Nuclear Generating Station design, similar to the Bruce plant, but delivering about 880 MWe per reactor.

As was the case for the development of the Pickering design into the CANDU 6, the Bruce design was also developed into the similar CANDU 9.[35] Like the CANDU 6, the CANDU 9 is essentially a re-packaging of the Bruce design so it can be built as a single-reactor unit. However, no CANDU 9 reactors have been built.

Generation III+ designs

Through the 1980s and 90s the nuclear power market suffered a major crash, with few new plants being constructed in North America or Europe. Design work continued throughout, however, and a number of new design concepts were introduced that dramatically improved safety, capital costs, economics and overall performance. These Generation III+ and Generation IV machines became a topic of considerable interest in the early 2000s as it appeared a nuclear renaissance was underway and large numbers of new reactors would be built over the next decade.[36]

AECL had been working on a design known as the ACR-700, using elements of the latest versions of the CANDU 6 and CANDU 9, with a design power of 700 MWe.[26] During the nuclear renaissance, the upscaling seen in the earlier years re-expressed itself, and the ACR-700 was developed into the 1200 MWe ACR-1000. ACR-1000 is the next-generation (officially, "Generation III+") CANDU technology which makes some significant modifications to the existing CANDU design.[37]

The main change, and the most radical among the CANDU generations, is the use of pressurized light water as the coolant. This significantly reduces the cost of implementing the primary cooling loop, which no longer has to be filled with expensive heavy water. The ACR-1000 uses about 1/3rd the heavy water needed in earlier generation designs. It also eliminates tritium production in the coolant loop, the major source of tritium leaks in operational CANDU designs. The redesign also allows for a slightly negative void reactivity, a major design goal of all Gen III+ machines.[37]

However, the design also requires the use of slightly enriched uranium, enriched by about 1 or 2%. The main reason for this is to increase the burn-up ratio, allowing bundles to remain in the reactor longer, so that only a third as much spent fuel is produced. This also has effects on operational costs and timetables, as the refuelling frequency is reduced. As is the case with earlier CANDU designs, the ACR-1000 also offers online refuelling.[37]

Outside of the reactor, the ACR-1000 has a number of design changes that are expected to dramatically lower capital and operational costs. Primary among these changes is the design lifetime of 60 years, which dramatically lowers the price of the electricity generated over the lifetime of the plant. The design also has an expected capacity factor of 90%. Higher pressure steam generators and turbines improve efficiency downstream of the reactor.[37]

Many of the operational design changes were also applied to the existing CANDU 6 to produce the Enhanced CANDU 6. Also known as CANDU 6e or EC 6, this was an evolutionary upgrade of the CANDU 6 design with a gross output of 740 MWe per unit. The reactors are designed with a lifetime of over fifty years, with a mid-life program to replace some of the key components e.g. the fuel channels. The projected average annual capacity factor is more than ninety percent. Improvements to construction techniques (including modular, open-top assembly) decrease construction costs. The CANDU 6e is designed to operate at power settings as low as 50%, allowing them to adjust to load demand much better than the previous designs.[38]

Sales efforts

In Ontario

By most measures, the CANDU is "the Ontario reactor". The system was developed almost entirely in Ontario, and only two experimental designs were built in other provinces. Of the 29 commercial CANDU reactors built, 22 are in Ontario. Of these 22, a number of reactors have been removed from service. Two new CANDU reactors have been proposed for Darlington with Canadian government help with financing,[39] but these plans ended in 2009 due to high costs.[40]

In Canada

AECL has heavily marketed CANDU within Canada, but has found a limited reception. To date, only two non-experimental reactors have been built in other provinces, one each in Quebec and New Brunswick, other provinces have concentrated on hydro and coal-fired plants. Several Canadian provinces have developed large amounts of hydro power. Alberta and Saskatchewan do not have extensive hydro resources, and use mainly fossil fuels to generate electric power.

Interest has been expressed in Western Canada, where CANDU reactors are being considered as heat and electricity sources for the energy-intensive oil sands extraction process, which currently uses natural gas. Energy Alberta Corporation announced 27 August 2007 that they had applied for a licence to build a new nuclear plant at Lac Cardinal (30 km west of the town of Peace River, Alberta), with two ACR-1000 reactors going online in 2017 producing 2.2 gigawatts (electric).[41] However, a 2007 parliamentary review suggested placing the development efforts on hold.[42]

The company was later purchased by Bruce Power,[43] who proposed expanding the plant to four units of a total 4.4 gigawatts.[44] However, these plans were upset and Bruce later withdrew its application for the Lac Cardinal, proposing instead a new site about 60 km away.[45] The plans are currently moribund after a wide consultation with the public demonstrated that while about 1⁄5 of the population were open to reactors, 1⁄4 were opposed.[46][47]

Foreign sales

During the 1970s, the international nuclear sales market was extremely competitive, with many national nuclear companies being supported by their governments' foreign embassies. In addition, the pace of construction in the United States had meant that cost overruns and delayed completion was generally over, and subsequent reactors would be cheaper. Canada, a relatively new player on the international market, had numerous disadvantages in these efforts. However, the CANDU was deliberately designed to reduce the need for very large machined parts, making it suitable for construction by countries without a major industrial base. Sales efforts have had their most success in countries that could not locally build designs from other firms.

In the late 1970s, AECL noted that each reactor sale would employ 3,600 Canadians and result in $300 million in balance-of-payments income.[48] However, these sales efforts were aimed primarily at countries being run by dictatorships or similar, a fact that led to serious concerns in parliament.[49] These efforts also led to a scandal when it was discovered millions of dollars had been given to foreign sales agents, with little or no record of who they were, or what they did to earn the money.[50] This led to a Royal Canadian Mounted Police investigation after questions were raised about sales efforts in Argentina, and new regulations on full disclosure of fees for future sales.[51]

CANDU's first success was the sale of early CANDU designs to India. In 1963, an agreement was signed for export of a 200 MWe power reactor based on the Douglas Point reactor. The success of the deal led to the 1966 sale of a second reactor of the same design. The first reactor, then known as RAPP-1 for "Rajasthan Atomic Power Project", began operation in 1972. However, a serious problem with cracking of the reactor's end shield led to the reactor being shut down for long periods, and the reactor was finally downrated to 100 MW.[52] Construction of the RAPP-2 reactor was still underway when India detonated its first atomic bomb in 1974, leading to Canada ending nuclear dealings with the country. Part of the sales agreement was a technology transfer process. When Canada withdrew from development, India continued construction of CANDU-like plants across the country.[53] By 2010, CANDU-based reactors were operational at the following sites: Kaiga (3), Kakrapar (2), Madras (2), Narora (2), Rajasthan (6), and Tarapur (2).

In Pakistan, the Karachi Nuclear Power Plant with a gross capacity of 137 MWe was built between 1966 and 1971.

In 1972, AECL submitted a design based on the Pickering plant to Argentina's Comision Nacional de Energia Atomica process, in partnership with the Italian company Italimpianti. High inflation during construction led to massive losses, and efforts to re-negotiate the deal were interrupted by the March 1976 coup led by General Videla. The Embalse Nuclear Power Station began commercial operation in January 1984.[54] There have been ongoing negotiations to open more CANDU 6 reactors in the country, including a 2007 deal between Canada, China and Argentina, but to date no firm plans have been announced.[55]

A licensing agreement with Romania was signed in 1977, selling the CANDU 6 design for $5 million per reactor for the first four reactors, and then $2 million each for the next twelve. In addition, Canadian companies would supply a varying amount of equipment for the reactors, about $100 million of the first reactor's $800 million price tag, and then falling over time. In 1980, Nicolae Ceaușescu asked for a modification to provide goods instead of cash, in exchange the amount of Canadian content was increased and a second reactor would be built with Canadian help. Economic troubles in the country worsened throughout the construction phase. The first reactor of the Cernavodă Nuclear Power Plant only came online in April 1996, a decade after its December 1985 predicted startup.[56] Further loans were arranged for completion of the second reactor, which went online in November 2007.[57]

In January 1975, a deal was announced for a single CANDU 6 reactor to be built in South Korea, now known as the Wolsong-1 Power Reactor. Construction started in 1977 and commercial operation began in April 1983. In December 1990 a further deal was announced for three additional units at the same site, which began operation in the period 1997–1999.[58] However, South Korea also negotiated development and technology transfer deals with Westinghouse for their advanced System-80 reactor design, and all future development is based on locally built versions of this reactor.[59]

In June 1998, construction started on a CANDU 6 reactor in Qinshan China Qinshan Nuclear Power Plant, as Phase III (units 4 and 5) of the planned 11 unit facility. Commercial operation began in December 2002 and July 2003, respectively. These are the first heavy water reactors in China. Qinshan is the first CANDU-6 project to use open-top reactor building construction, and the first project where commercial operation began earlier than the projected date.

Future sales

CANDU Energy is continuing marketing efforts in China.[60] In addition, China and Argentina have agreed a contract to build a 700 MWe Candu-6 derived reactor. Construction is planned to start in 2018 at Atucha.[61][62]

Economic performance

The cost of electricity from any power plant can be calculated by roughly the same selection of factors: capital costs for construction or the payments on loans made to secure that capital, the cost of fuel on a per-watt-hour basis, and fixed and variable maintenance fees. In the case of nuclear power, one normally includes two additional costs, the cost of permanent waste disposal, and the cost of decommissioning the plant when its useful lifetime is over. Generally, the capital costs dominate the price of nuclear power, as the amount of power produced is so large that it overwhelms the cost of fuel and maintenance.[63] The World Nuclear Association calculates that the cost of fuel, including all processing, accounts for less than one cent(USD) per kWh.[64]

Information on economic performance on CANDU is somewhat lopsided; the majority of reactors are in Ontario, which is also the "most public" among the major CANDU operators, so their performance dominates the available information. Based on Ontario's record, the economic performance of the CANDU system is quite poor. Although much attention has been focussed on the problems with the Darlington plant, every CANDU design in Ontario went over budget by at least 25%, and average over 150% higher than estimated.[65] Darlington was the worst, at 350% over budget, but this project was stopped in-progress thereby incurring additional interest charges during a period of high interest rates, which is a special situation that was not expected to repeat itself.

In the 1980s, the pressure tubes in the Pickering A reactors were replaced ahead of design life due to unexpected deterioration caused by hydrogen embrittlement. Extensive inspection and maintenance has avoided this problem in later reactors.

All the Pickering A and Bruce A reactors were shut down in 1999 in order to focus on restoring operational performance in the later generations at Pickering, Bruce, and Darlington. Before restarting the Pickering A reactors, OPG undertook a limited refurbishment program. The original cost and time estimates based on inadequate project scope development were greatly below the actual time and cost and it was determined that Pickering units 2 and 3 would not be restarted for commercial reasons. Despite this refurbishment, the reactors have not performed well since the restart.

These overruns were repeated at Bruce, with Units 3 and 4 running 90% over budget.[65] Similar overruns were experienced at Point Lepreau,[66] and Gentilly-2 plant was shut down on December 28, 2012.[67]

Based on the projected capital costs, and the low cost of fuel and in-service maintenance, in 1994 power from CANDU was predicted to be well under 5 cents/kWh.[68] In 1998, Ontario Hydro calculated that the cost of generation from CANDU was 7.7 cents/kWh, whereas hydropower was only 1.1 cents, and their coal-fired plants were 4.3 cents. As Ontario Hydro received a regulated price averaging 6.3 cents/kWh for power in this period, the revenues from the other forms of generation were being used to fund the operating losses of the nuclear plants. The debt left over from the nuclear construction could not be included in the rate base until the reactors were declared in service, thereby exacerbating the total capital cost of construction with unpaid interest, at that time around $15 billion, and another $3.5 billion in debts throughout the system[69] was held by a separate entity and repaid through a standing charge on electricity bills.

In 1999, Ontario Hydro was broken up and its generation facilities re-formed into Ontario Power Generation (OPG). In order to make the successor companies more attractive for private investors, $19.4 billion in "stranded debt" was placed in the control of the Ontario Electricity Financial Corporation. This debt is slowly paid down through a variety of sources, including a 0.7-cent/kWh tariff on all power, all income taxes paid by all operating companies, and all dividends paid by the OPG and Hydro One. Even with these sources of income, the amount of debt has grown on several occasions, and in 2010 stood at almost $15 billion. This is in spite of total payments on the order of $19 billion, ostensibly enough to have paid off the debt entirely if interest repayment requirements are ignored.[69]

Darlington is currently in the process of considering a major re-build of several units, as it too is reaching its design mid-life time. The budget is currently estimated to be between $8.5 and $14 billion, and produce power at 6 to 8 cents/kWh. However, this prediction is based on three assumptions that appear to have never been met in operation: that the rebuild will be completed on-budget, that the system will operate at an average capacity utilization of 82%, and that the Ontario taxpayer will pay 100% of any cost overruns.[70] Although Darlington Units 1, 3 and 4 have operated with an average lifetime annual capacity factor of 85% and Unit 2 with a capacity factor of 78%,[71] refurbished units at Pickering and Bruce have lifetime capacity factors between 59 and 69%.[70] However, this includes periods of several years while the units were shut down for the retubing and refurbishing. In 2009, Bruce A Units 3 and 4 had capacity factors of 80.5% and 76.7%, respectively, in a year when they had a major Vacuum Building outage.[72]

Active CANDU reactors

Today there are 29 CANDU reactors in use around the world, and 13 "CANDU-derivatives" in India, developed from the CANDU design. After India detonated a nuclear bomb in 1974, Canada stopped nuclear dealings with India. The breakdown is:

- Canada: 19 and 5 decommissioned.

- South Korea: 4.

- China: 2.

- India: 2, 13 active CANDU-derivatives, and 3 CANDU-derivatives under construction.

- Argentina: 1, and 1 planned.

- Romania: 2, and 2 dormant part-constructed.

- Pakistan: 1.

See also

- ZEEP reactor

- Nuclear power in Canada

- List of nuclear reactors

- Embalse plant – Argentina

- Wolseong Plant – South Korea

- Cernavodă Plant – Romania

- Advanced CANDU Reactor

- CANDU Owners Group

References

- 1 2 B. Rouben, "Basic CANDU Design", University Network for Excellence in Nuclear Engineering, 2005

- 1 2 3 "Canadian Nuclear FAQ, Section D". The Canadian Nuclear FAQ by Dr. Jeremy Whitlock. Retrieved 2005-03-05.

- ↑ "Canadian Nuclear FAQ, Section A". The Canadian Nuclear FAQ by Dr. Jeremy Whitlock. Retrieved 2005-03-05.

- ↑ "Canada and China work on Thorium Candu Fuel and India May Start Mining 1 million tons of Thorium", Next Big Future, Aug. 2, 2012

- ↑ "Canadian Nuclear FAQ". The Canadian Nuclear FAQ by Dr. Jeremy Whitlock. Retrieved 5 March 2005. A. CANDU Nuclear Power Technology A.3 What is "heavy water"? "'reactor-grade' heavy water, nominally 99.75 wt% deuterium content."

- ↑ "Final and Total Capital Costs of the Darlington Nuclear Generating Station", Ontario Power Generation, 27 April 2004

- ↑ "U.S. Nuclear Industry Capacity Factors (1971–2010)", Nuclear Energy Institute, 2010

- ↑ CANDU Lifetime Performance to 30 September 2009, Canadian Nuclear Society

- ↑ Jack Gibbons, "Darlington Re-Build Consumer Protection Plan", Ontario Clear Air Alliance, 23 September 2010, pg. 3

- ↑ "Ontario Votes 2003 - Features - Who's got the power?". CBC.

- ↑ "Can CANDU estimates be trusted?" by J.A.L. Robertson (2004)

- ↑ Library/20031701.pdf Qinshan CANDU Project Construction Experiences

- ↑ Milhollin, Gary (July 1987). "Stopping the Indian Bomb". The American Journal of International Law. American Society of International Law. 81 (3): 593. JSTOR 2202014. doi:10.2307/2202014.

- ↑ Albright, David (September 1992). "India's Silent Bomb". Bulletin of the Atomic Scientist. 48 (7): 27–31.

- ↑ Scott Willms, "Tritium Supply Considerations", Los Alamos National Laboratory, 14 January 2003

- ↑ Canadian Coalition for Nuclear Responsibility (1996-03-27). "Tritium from Power Plants gives India an H-bomb capability".

- 1 2 3 Dr. Ian Fairlie, , Greenpeace, June 2007

- ↑ http://www.ehso.emory.edu/content-forms/3anuclidedatasafetysheets.pdf

- ↑ "Ontario Power Generation: Safety". Opg.com. Retrieved 2008-12-01.

- ↑ "Canadian Drinking Water Guidelines". Hc-sc.gc.ca. Retrieved 2008-12-01.

- ↑ "Overview of the tritium-in-air monitoring system of Cernadova NPP U1", ROMANIA – MODERNIZATION AND IMPROVEMENT PROJECT, 10–13 September 2001

- ↑ "Dr. Ian Fairlie", CERRIE

- ↑ Dr. Richard Osborne, "Review of the Greenpeace report: 'Tritium Hazard Report: Pollution and Radiation Risk from Canadian Nuclear Facilities'", Canadian Nuclear Association, 13 August 2007

- ↑ "Biography: Dr. Richard V. Osborne", Canadian Nuclear Association

- ↑ V.G. Snell, "CANDU Safety, #1 - CANDU Nuclear Power Plant Design", AECL, 24 May 2001

- 1 2 "CANDU Evolution", AECL

- ↑ Jeremy Whitlock, "NPD Historical Plaque", Canadian Nuclear Society, 22 February 2002

- ↑ "First Candu reactor powers Canadian homes", CBC News, 4 June 1962

- ↑ Canadian Nuclear Society. "The Douglas Point Story". Archived from the original on 17 May 2008.

- ↑ Canadian Nuclear Society. "Douglas Point Nuclear Power Station". Archived from the original on 19 March 2008.

- ↑ Gordon Edwards, "Nuclear Power in Quebec", Canadian Coalition for Nuclear Responsibility, 1995

- ↑ CBC News (3 October 2012). "Quebec nuclear reactor shutdown will cost $1.8 billion". Canadian Broadcasting Corporation. Retrieved 4 October 2012.

- ↑ "Fact Sheet: WR-1 Reactor", Canadian Nuclear Society

- ↑ "Whiteshell Reactor no. 1", Canadian Nuclear Society

- ↑ "CANDU 9 Evolution and Future Heavy Water Reactors", AECL, 15–20 August 1999

- ↑ "The Nuclear Renaissance", World Nuclear Association

- 1 2 3 4 "ACR-1000 Technical Summary", AECL

- ↑ "Enhanced CANDU 6", AECL

- ↑ Ljunggren, David (7 August 2008). "Canada nuclear firms seek Ottawa financing". Reuters. Retrieved 2008-08-10.

- ↑ Hamilton, Tyler (14 July 2009). "$26B cost killed nuclear bid". Toronto Star.

- ↑ "Company begins process to build Alberta's 1st nuclear plant", CBC News, 28 August 2007

- ↑ "Canada wary of nuclear power for oil sands", Reuters, 28 May 2007

- ↑ "Bruce Power Signs Letter of Intent With Energy Alberta Corporation" Archived 27 August 2011 at the Wayback Machine., Marketwire, 29 November 2007

- ↑ "Bruce Power to prepare Alberta site", World Nuclear News, 14 March 2008

- ↑ "Bruce thinks again on Alberta site", World Nuclear News, 9 January 2009

- ↑ "Province releases results of nuclear consultation". 14 December 2009.

- ↑ Johnson, Doug (13 April 2016). "Though there is potential for nuclear power in Alberta, there’s more than just public opinion holding it back". Edmonton Examiner.

- ↑ "The push to sell Candus abroad", CBC, 7 December 1978

- ↑ "Selling Candus to 'the wrong people, at the wrong time'", CBC, 1976

- ↑ "Mysterious millions spent on Candu sales commissions", CBC, 14 October 1976

- ↑ "$4 million bribe given on Candu Argentina says", Toronto Star, 13 June 1985

- ↑ "Datafile: India", Nuclear Engineering International, February 1995, p. 22

- ↑ David Martin, "Exporting Disaster: CANDUs for India", Canadian Coalition for Nuclear Responsibility, November 1996

- ↑ David Martin, "Exporting Disaster: The Cordoba CANDU", Canadian Coalition for Nuclear Responsibility, November 1996

- ↑ "Canada, Argentina and China to cooperate on Candu projects", World Nuclear News, 5 September 2007

- ↑ David Martin, "Exporting Disaster: Romania", Canadian Coalition for Nuclear Responsibility, November 1996

- ↑ "Cernavoda", AECL

- ↑ David Martin, "Exporting Disaster: South Korea", Canadian Coalition for Nuclear Responsibility, November 1996

- ↑ "South Korea's nuclear power independence", World Nuclear News, 28 May 2008

- ↑ url=http://www.newswire.ca/en/story/1441373/candu-energy-inc-welcomes-positive-review-of-afcr-technology-in-china

- ↑ "Argentina-China talks on new nuclear plants". World Nuclear News. 8 May 2015. Retrieved 19 May 2017.

- ↑ "Argentina and China sign contract for two reactors". World Nuclear News. 18 May 2017. Retrieved 19 May 2017.

- ↑ "Cost of Nuclear Power", nuclearinfo.net

- ↑ "The Economics of Nuclear Power". World Nuclear Association.

- 1 2 Jack Gibbons, "Darlington Re-Build Consumer Protection Plan", Ontario Clear Air Alliance, 23 September 2010, Appendix A, pg. 7–8

- ↑ "Point Lepreau overruns to cost $1.6B", CBC News, 20 October 2009

- ↑ CBC News, "Quebec's Gentilly-2 nuclear plant shuts down after 29 years", CBC, December 28, 2012

- ↑ "How do the economic benefits of nuclear power compare to other sources in Canada?", CANDU FAQ, Section C.1

- 1 2 "Ontario’s Stranded Nuclear Debt: A Cautionary Tale", Ontario Clean Air Alliance, 1 March 2011

- 1 2 Jack Gibbons, "Darlington Re-Build Consumer Protection Plan", Ontario Clear Air Alliance, 23 September 2010, pg. 5

- ↑ "CANDU Lifetime Performance", Canadian Nuclear Society

- ↑ Bruce Power Focus - 2009 Year in Review, 2010