Bolt-on neck

Bolt-on neck is a method of guitar (or similar stringed instrument) construction that involves joining a guitar neck and body using screws or bolts, as opposed to glue as with set-in neck joints.

Methods

The "bolt-on" method is used frequently on solid body electric guitars and on acoustic flattop guitars. In the typical electric guitar bolt-on neck joint, the body and neck cross in horizontal plane, the neck is inserted in a pre-routed "pocket" in the body, and they are joined using 3 or 4 (rarely 6) screws.

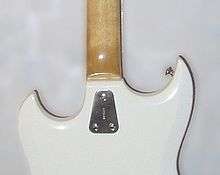

As screw heads damage the wood and could put extra stress on it, typically a rectangular metal plate or a pair of metal plates are used to secure the joint and re-distribute the screw pressure evenly. Such a plate is usually criticized for making playing on top frets uncomfortable, so, manufacturers sometimes employ some kind of more intricate method to hide a metal plate, smooth the angles and make access to top frets easier. However, a visible metal plate is usually considered as a part of "vintage" style and they are a popular place to emboss manufacturer's logos, stamp out serial numbers and put other artwork.

Many electric guitars with bolt-on necks, Fender in particular, writes the production date on the end of the neck, where it is hidden when the neck is attached to the body. The neck must be removed to see the date. The neck date is often cross referenced with the serial number to accurately date the guitar.[1]

The typical acoustic guitar bolt-on neck as popularized by Taylor Guitars includes threaded inserts in the heel of the neck. Bolts inserted through the neck block of the body from inside the instrument attach the neck to the body.[2]

"Real" bolted joints as opposed to wood screw

The term is usually a misnomer, introduced mostly by Fender whose guitars traditionally had what is called bolt-on necks. Real bolted joints (i.e., using bolt coupled with a nut) exist—particularly in acoustic guitars—but are less common in electric guitars.[3] However, at least one aftermarket manufacturer[4] offers a replacement for Fender neckplates and screws that uses captive inserts—embedded in the guitar body by means of an external self-tapping thread — and M4 machine screws. The maker claims this permits a higher fastening torque than ordinary wood screws, and hence a better coupling between neck and body.

"Bolt-in" as opposed to "bolt-on"

Some sources[5][6] differentiate bolt-on and bolt-in neck construction.

The difference is that a bolt-on neck involves constructing a protruding flange that fits inside a routed pocket in the guitar body. Then the neck is secured inside this pocket using screws that run perpendicular (at right angles) to the surface of the guitar. In contrast, a bolt-in neck doesn't need to have such a flange inside the guitar body, and screws or bolts run parallel to the surface of guitar, entering the back of the heel.[7]

Usually (but not always), in bolt-in variant, a neck pickup is mounted directly on the extended neck wood underneath it, not on the guitar body. This has been referred to as "direct coupling", because the pickup is mounted on the neck and not the body, in other words, directly coupled to the neck, and is considered superior by some in terms of tone.[8]

Bolt-in neck is used in electric guitars on a regular basis, but on acoustic guitars it is somewhat rare, and harder to produce. However it is considered superior by some in terms of sound and playability.[9] However, given a relative uncommonness of bolt-in necks in electric guitars, most luthiers call both neck joints "bolt-on".

Advantages

Luthiers and guitar players cite both advantages and disadvantages of bolt-on neck construction. Note that most of these views are highly subjective and relative. It is not easy to measure most of the claims objectively or even compare objective factors, as guitars differ considerably. Typically cited advantages of bolt-on neck include:

- Easier and cheaper to mass produce and to repair if damaged.[10] Necks that allow Fender "standard" 4-screw joint are frequently interchangeable provided they are intended for the same style of guitar (e.g. Stratocaster or Telecaster):[11] for example, one can order custom neck (with personal profile or radius) and change one by just removing one neck and attaching the other. A Stratocaster neck can also be fitted to a Telecaster body, although the reverse is untrue unless some minor modifications are made. Less traditional versions exist, such as 3-screw plate (with easier micro-tilt adjustment) or even 6-screw plate bolt-on joint, but they may differ widely in the shapes, sizes and position of screws. Which one is better is debatable,[12] but budget guitar manufacturers often choose 3-screw joints for its minimal cost, notwithstanding the quality.

- Easy to control: sometimes bolt-on neck includes some sort of adjustment screw that can control neck-to-body angle,[10] such as the Fender Deluxe American Stratocaster's "Micro-Tilt" adjustment.

- More attack and "snap", slightly brighter tone,[3] but this advantage is frequently debated.[10]

- More resonance and sustain

Disadvantages

Typically cited disadvantages of bolt-on neck include:

- For solid body electric guitars, harder access to top frets, especially if screw plate is used and visible. Slick heel with hidden plate (such as depicted one) makes playing the top frets more comfortable and special neck joint techniques, such as the Ibanez AANJ (All Access Neck Joint), Music Man Silhouette and Stephen's Extended Cutaway mitigate this problem.

- Sloppy construction or assembly of a bolt-on guitar exacerbates any of its inherent disadvantages.[10]

Manufacturers

Notable manufacturers of guitars with bolt-on necks include:

- Fender

- Squier

- Music Man

- Ibanez

- Kiesel Guitars / Carvin Guitars

- ESP Guitars

- Epiphone

- Hagström

- Taylor Guitars (a patented bolt-in construction process with three bolts

- Seagull, an acoustic guitar brand manufactured by Canadian company Godin Guitars

- Jackson—a subsidiary of Fender

- Charvel—a subsidiary of Fender

- Walden Guitars, one of the first Asian acoustic guitar brands to incorporate a bolt-on heel and glued-down fingerboard extension.

- Cort Guitars

References

- ↑ Fender Serial Number Guide article at the Guitar Repair Bench Luthier Website

- ↑ Bolt-on Neck Joint for Acoustic Instruments article at Liutaio Mottola Lutherie Information Website

- 1 2 Burrluck, Dave (1998). "Types of neck". The player's guide to guitar maintenance: a practical manual to get the most from your electric guitar. London, England: Balafon Books. p. 25. ISBN 978-0-87930-549-9.

- ↑ Heavy-Duty Fixing Plates Archived March 22, 2008, at the Wayback Machine.

- ↑ Bolt-in neck Archived February 28, 2007, at the Wayback Machine. at Sweetwater.com music technology glossary

- ↑ Neck construction Archived December 7, 2006, at the Wayback Machine. article at Ed Roman Guitars

- ↑ William Cumpiano's hardware-based neck joint, featuring drawings that illustrate basics of bolt-in method.

- ↑ Direct Coupling Archived December 7, 2006, at the Wayback Machine. article at Ed Roman Guitars

- ↑ Neck Mounting Myths article at Ed Roman Guitars

- 1 2 3 4 Lipman, Barry (2002). "What are the pros and cons of bolt-on necks". Guitar questions: the novice's guide to guitar repairs. New York, NY: Cherry Lane Music Co. p. 19. ISBN 978-1-57560-452-7.

- ↑ What we love about Fenders at Guitar DNA

- ↑ Lipman, Barry (2002). "Is a three-bolt neck joint as strong as a four-bolt". Guitar questions: the novice's guide to guitar repairs. New York, NY: Cherry Lane Music Co. p. 20. ISBN 978-1-57560-452-7.