Janney coupler

The Janney Coupler is a semi-automatic railway coupler. The earliest commercially successful version of the knuckle coupler, it was patented by Eli H. Janney in 1873 (U.S. Patent 138,405).[1]

In the United Kingdom, where it is fitted to some rolling stock, mostly for passenger trains, it is also known as a Buckeye Coupler, possibly originating from the coupler's manufacture as early as 1890 by the Buckeye Steel Castings firm in Columbus, Ohio.

The AAR/APTA Type E, Type F, and Type H tightlock couplers are all compatible knuckle couplers, but are employed on specific rail car types (general freight, tank cars, rotary hoppers, passenger, etc.).

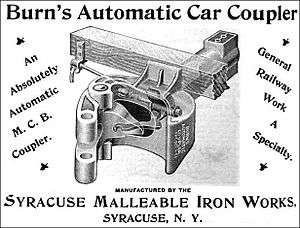

Early knuckle couplers using a variety of proprietary head designs, but all using the most up to date MCB contour when cast, were the MCB, Janney (later version), Tower, Sharon, Climax, Gould, Burns, Miller, and as many as 100 others.

Prior to the formation of the AAR (Association of American Railroads) these were known as MCB Couplers (Master Car Builders Association).[2] After 1910 the MCB reconstituted itself into the AAR.

In 1913 the American Steel Foundries (ASF) had developed the new Type "D" coupler that was accepted as the standard coupler for the United States, and no new equipment could be built using any other coupler. This standard design ended the market for couplers with a proprietary head design, which were common in the MCB days, to all but those exported from the US to other countries not governed by the AAR standards.

The Alliance coupler, named after the ASF-owned foundry in Alliance, Ohio, was developed as a lighter build than the AAR Type "D" coupler, and was marketed by the Amsted Corporation, the parent corporation of ASF, as the "Standard Coupler for the World". It was and is still the most used knuckle coupler in the world. The modern Alliance coupler still uses the modern AAR-10 and/or -10A contour, as well as others, but cannot be used in the US on an "interchanging" railway.

Brand names of the now standard AAR Type "E", "F" and "Tightlock" couplers are ASF, Buckeye (now known as Columbus Castings), and McConway & Torley.[3][4]

The Interlocking contour of knuckle couplers was the first aspect to be standardized. In the MCB years, prior to about 1910, and as early as the first Janney in 1873, there were many proprietary "head" designs, and many MCB standard contours, which were constantly evolving and changing (as the approved standard contour for new couplers) every few years. In about 1910 the producers were all using the then standardized MCB-10 contour, soon to become the AAR-10. In the 1930s the AAR Type "D" was improved and became the Type "E"; the contour, however, stayed the same. A few years later the 10 contour was modified into a then optional standard called the 10A contour.

The most modern contour, for a plain Type "E" knuckle coupler, is still the AAR-10 and -10A, which are indistinguishable from the 1910 era MCB-10 contour. The same MCB-10 contour has been an approved standard for interchange service for over 100 years, with only the slightest dimensional changes.

The Type "H" "Tightlock" couplers, which are used on passenger-carrying rolling stock, also use slight revisions to the old 10A contour.

Purpose

The purpose of couplers is to join rail cars or locomotives to each other so they all are securely linked together. Major Eli Janney, a Confederate veteran of the Civil War, invented the semi-automatic knuckle coupler in 1868. It automatically locks the couplers on cars or locomotives together without a rail worker having to get between the cars, and replaced the "link and pin" coupler, which was a major cause of injuries to railroad workers. The locking pin that ensures Janney couplers remain fastened together is withdrawn manually by a worker using the "cut lever", which is operated from either side of the railroad car and does not require the person to go between the cars. The only time the worker has to go between cars is after they have been securely coupled, to hook up the air lines for the pneumatic brakes, and the head-end power cables in the case of passenger cars.

Janney couplers are usually attached to draw gear, but sometimes, in the case of locomotives, the Type "E" is bolted directly on the headstock.

Janney/MCB/ARA/AAR/APTA Coupler

The Janney coupler is used in Canada, the United States, Mexico, Japan, Australia, South Africa, Saudi Arabia, Cuba, Chile, Brazil, China and elsewhere.

Among its features:

- Maximum tonnage as high as 32,000 metric tons (35,000 short tons; 31,000 long tons) such as on the Fortescue Railway.

- Minimum ultimate tensile strength:

- Several Janney coupler types exist to accommodate various cars, but all are required to have certain common dimensions allowing for compatibility.[7]

- Lighter weight railways, notably narrow gauge lines with no need for interchange, sometimes use smaller (three-quarter- or half-size) versions of the Janney MCB coupler.[8] Such as Victorian narrow gauge lines.

- Janney couplers are always right-handed, i.e., their shape resembles the human right hand with fingers curled, as viewed from above.

- Required coupler heights, in North America[6]

- Empty cars: 33.5 inches (850 mm) ± 1-inch (25 mm)

- Loaded cars: 32.5 inches (830 mm) in ± 1-inch (25 mm)

- Janney couplers are uncoupled by lifting the pin with a lever at the corner of the car. This pin is locked when the coupler is under tension, so the usual uncoupling steps are to compress the coupling with a locomotive, lift and hold up the pin, then pull the cars apart. Side operated variants are called the "Sharon" or "Buckeye" coupler.[9]

- Most Janney couplers are now bottom operated.[10]

- Trains fitted with Janney couplers can accommodate heavier loads than any other type of coupler. Thus, the heaviest coal trains in New Zealand use Janney couplings, even though the remainder of the fleet has the Norwegian "meat chopper" kind. Also, long-distance freight trains in North America are commonly more than 1-mile (1.6 km) long, whereas this is not seen in Europe, where most freight trains still use English buffers and chain couplers.

Gooseneck coupler

With gooseneck couplers or offset shank couplers, the horizontal centerline of the coupler head is above the horizontal centerline of the coupler shank, or shaft, and the draw gear. This arrangement is designed for use with low-floor freight cars, to lift the coupler head high enough to match the couplers on other rolling stock.[11] The large bogie boxvans for car parts, used on the Victorian Railways, were fitted with gooseneck couplers for that reason.

History

Janney was a dry goods clerk and former Confederate Army officer from Alexandria, Virginia, who used his lunch hours to whittle from wood an alternative to the link and pin coupler. The term Buckeye comes from the nickname of the US state of Ohio, the "Buckeye state" and the Ohio Brass Company[12] which originally marketed the coupling.[9][13]

In 1893, satisfied that an automatic coupler could meet the demands of commercial railroad operations and, at the same time, be manipulated safely, the United States Congress passed the Safety Appliance Act. Its success in promoting switchyard safety was stunning. Between 1877 and 1887, approximately 38% of all railworker accidents involved coupling. That percentage fell as the railroads began to replace link and pin couplers with automatic couplers. By 1902, only two years after the SAA's effective date, coupling accidents constituted only 4% of all employee accidents. Coupler-related accidents dropped from nearly 11,000 in 1892 to just over 2,000 in 1902, even though the number of railroad employees steadily increased during that decade.

When the Janney coupling was chosen to be the American standard, there were 8,000 patented alternatives to choose from. The only significant disadvantage of using the AAR (Janney) design is that sometimes the drawheads need to be manually aligned.

During the transition period from link-and-pin couplers, knuckle couplers on many locomotives had a horizontal gap and a vertical hole in the knuckle itself to accommodate, respectively, a link and a pin, to enable it to couple to vehicles which were still equipped with the older link-and-pin couplers.

Changes since 1873

The Janney coupler has withstood the test of time since its invention, with only minor changes:[8]

- The current AAR contour dates back to the 1888 Master Car Builders Association (MCBA) design, which, in turn is based on the 1879 Janney patent.[2]

- Buckeye coupler, a side-operated version of the MCBA coupler[9]

- Type D coupler, adopted in 1916 by the MCBA (predecessor of ARA), had individual parts interchangeable, simplifying maintenance. Earlier designs had compatible profiles, but component parts differed between manufacturers, creating maintenance problems when cars were interchanged with other railroads.

- Type E coupler, adopted in 1930 by the ARA (predecessor of AAR), also had individual parts interchangeable, though not with Type D due to improvements. Still the most widely use design today.[14] Tank cars carrying hazardous materials are equipped with Type E double shelf couplers[15][16]

- Type F coupler, a vertically interlocking variation to prevent accidents, derailments and wrecks from disconnecting the coupler. Type F also includes versions with rotating shafts for hopper car rotary dumpers, such as on the Pilbara railways and Transnet Freight Rail's Sishen-Sandanha Iron Ore and Ermelo-Richards Bay Coal Terminal lines.

- Type H coupler, a "tight-lock" variation to reduce slack action and improve safety for passenger cars. Now under the supervision of the APTA (American Public Transportation Association).

- Improvements in metallurgy and casting techniques to increase maximum trailing load.

- Narrow-gauge railways such as the Victorian Puffing Billy Railway use a three-quarter-[8] or one-half-scale version of the Janney/MCB coupler.

Bazeley Coupler

Bazeley Coupler 1905-1918 M.C.B. D Type established as the Universal M.C.B. Standard, Adopted 1915

Arthur James Bazeley (1872-1937), Railway Couplings Inventor/Design Engineer; was born in Bristol, England in 1872, and worked for the Great Western Railway until the age of 34 when he immigrated to Cleveland, Ohio in 1906, where he worked as a mechanical engineer for National Malleable Castings, Co., inventing and designing improvements in the function, strength, and durability of the (MCB/ARA/AAR/APTA) Janney, Knuckle, Alliance couplers and other coupling devices/draw gear for the evolving heavier demands by U.S.A. Railways, as well as, National Malleable Castings' international customers in the U.K., England, India, and many other countries building and expanding their railway systems. A.J. Bazeley, USA was directly responsible for over 90 registered U.S. patents for railway automatic coupler improvements through design, under the coupler type names which included the "Buckeye Coupler", the "Sharon Coupler" PAT APP Nov. 10, 1910, 1911,1913, 1914, the "Simplex Coupler" PAT APP May 3, 1903, the " Climax Coupler", the "Latrobe Coupler", the "Tower Coupler", the "Major Coupler", the "Gould Coupler", the "Pitt Coupler", the "R.E. Janney Coupler", the "Kelso Coupler" and others.

A.J. Bazeley related railway inventions, U.S. Patents and Railway Coupler Mechanical Drawings and Illustrations filed and assigned to National Malleable Castings Company can be referenced by a patent search under "Bazeley, Railway Couplings" or "Arthur James Bazeley, Railway Couplings Patents" which have been drawn/filed and provided by Roger Bazeley-USA, M.S.T.M, M.S.I.D., C.H.S.R.M. Mineta Transportation Institute, Transportation Industrial Designer. A.J. Bazeley Railway Coupling, Construction/Design Improvements and Draft Rigging related patents include: US 1193222, US 124622, US 1932719, US 1518299, US 1932503, US 2235194, US 1932440 and others.

National Malleable Castings, Co. in 1891 absorbed the Chicago Malleable Iron Co. which was founded in 1873 by Alfred A. Pope and John C. Coonley, who operated similar companies in Ohio and Indiana. By the late 1880s, the company employed nearly 1,000 men at its 26th and Western Chicago works, which manufactured various railroad couplers and steel products for the railroad industries. In 1891, Chicago Malleable became part of the new National Malleable Castings Co., the Cleveland-based company, where Arthur J. Bazeley-USA was employed as a Senior Design Engineer, had additional manufacturing plants across the Midwest. National Malleable purchased the Latrobe Steel & Coupler Co.'s plant in Melrose Park, Illinois in 1909. In 1923, when it had begun to supply the automobile industry, the company changed its name to National Malleable & Steel Castings Co. Its stock was listed on the New York Stock Exchange beginning in 1936 [17]

The National Malleable Castings Bazeley Coupler 1905-1918 M.C.B. D Type as Universal M.C.B. Standard Adopted 1915

At a joint M.C.B. Coupler Committee meeting on July 15, 1913 out of numerous studied competing railway coupler manufacturers and designs two couplers were selected for the new proposed universal U.S./Canadian coupler design standard, adopted, June 15, 1916 by the M.C.B. The two couplers accepted were the Malleable Castings Company Bazeley Coupler, and the American Steel Foundries No.3 modified Alliance Coupler, out of nine couplers submitted to the committee as embodying the joint specification of design, The TYPE D coupler design based on The National Malleable Castings Bazeley Coupler patented designs and improvements was selected as the standard M.C.B Association’s standard from 1918., after M.C.B. performance tested it along with the Type C designs.

The Type “D” Experimental Standard M.C.B. Coupler was unanimously recommended by the Master Car Builders. Association and it’s Coupler Committee for adoption as the National/International (United States/Canadian) standard for coupler design and manufacturing specification uniformity by the M.C.B. Master Car Builders’ Association on June 15, 1916 after its 1915 Convention. This resulted in the sharing of U.S. Patent improvements and agreed to by The National Malleable Castings Company, Henry Pope President; The Buckeye Steel Castings Company, The Gould Coupler Company, American Steel Foundries and The Monarch Steel Castings Company, and to be the active standard M.C.B. D Type forward from January 1, 1918. Buckeye Steel Castings Company was founded in 1881 as the Murray-Hayden Foundry before changing to The Buckeye Automatic Car Coupler Company and in 2002 after filing bankruptcy was reformed as Columbus Castings.

Railway couplers were manufactured in accordance with the Standard Specifications of the American Railway Association (A.R.A.) covering the purchase and acceptance of couplers, knuckles, locks and other working parts as shown in their "Mechanical Division Manual of Standards and Recommended Practice". Specifications as of March 1939 required that the fabrication casting material be of open hearth or electric furnace grade "B" steel with specific metallurgic requirements to insure proper tensile strength and reliability of the coupler and its moving parts. In order to govern uniform standards for the interchangeability and the proper relation between fitting parts, the A.R.A. Committee on Couplers and draft gears designed and distributed templates, gauges, and master guides to assure the proper interchangeability and fitting of parts to maintain the proper operation of various multi-source manufactured railway couplers.[18]

Gallery

Modern Janney/AAR Type E couplers, note that these are bottom operated

Modern Janney/AAR Type E couplers, note that these are bottom operated AAR Type "E" coupler serving as a tow hitch on a mobile crane. Pulling up on the link at the rear releases the knuckle allowing uncoupling.

AAR Type "E" coupler serving as a tow hitch on a mobile crane. Pulling up on the link at the rear releases the knuckle allowing uncoupling. British-style dual buffer-and-chain/Janney coupler with knuckle swung out of the way (drophead).

British-style dual buffer-and-chain/Janney coupler with knuckle swung out of the way (drophead). A British Railways Mark 1 coach fitted with a British-style dual buffer-and-chain/janney coupler with knuckle swung out of the way (drophead).

A British Railways Mark 1 coach fitted with a British-style dual buffer-and-chain/janney coupler with knuckle swung out of the way (drophead). Standard AAR Type E couplers in a freight train. The upper coupler is bottom-operated, while the near coupler (on the locomotive) is top-operated by the chain.

Standard AAR Type E couplers in a freight train. The upper coupler is bottom-operated, while the near coupler (on the locomotive) is top-operated by the chain.

.jpg) Janney couplers were required by the 1893 Safety Appliance Act. An older, top operated, type is shown to the right.

Janney couplers were required by the 1893 Safety Appliance Act. An older, top operated, type is shown to the right. A tightlock coupling on a British Rail Class 321. Note the large rectangular multi-connector below the coupling, which automatically connects head-end-power and control lines.

A tightlock coupling on a British Rail Class 321. Note the large rectangular multi-connector below the coupling, which automatically connects head-end-power and control lines.- Transition era AAR knuckle coupler. The gap in the knuckle accommodates the link of a link and pin coupler and the vertical hole in the knuckle accommodates the pin.

See also

- 6 Fully Automatic Couplings

- Buckeye Steel Castings

- Draft gear

- Dual coupling

- Gangway connection

- Length over coupler pulling faces

- Railway coupling

- Railway coupling by country

- SA3 coupler

- Slack action

- South Station (Boston), includes a sculpture built of railroad car couplers

References

- ↑ Eli Janney — The Janney Coupler

- 1 2 MCB

- ↑ McConway & Torley

- ↑ McConway & Torley

- 1 2 AAR Manual of Standards and Recommended Practices, Section S, Part I:Casting Details, Issue 06/2007

- 1 2 AAR 2011 Field Manual

- ↑ AAR Manual of Standards and Recommended Practices, Section S, Part III:Coupler and Yoke Details, Issue 06/2007

- 1 2 3 NATIONAL MODEL RAILROAD ASSOCIATION DATA SHEET

- 1 2 3 Buckeye coupler (scroll down) Archived September 26, 2006, at the Wayback Machine.

- ↑ Bottom operated

- ↑ Offset or gooseneck couplers

- ↑ Ohio Brass Company

- ↑ Ohio Brass company

- ↑ http://cprr.org/Museum/Ephemera/Link-Pin_Couplers.html

- ↑ Type E and Type F couplers

- ↑ Safety and research

- ↑ Wilson, Mark R. "Electronic Encyclopedia of Chicago". www.encyclopedia.chicagohistory.org. Retrieved 30 June 2014.

- ↑ The A.R.A. STANDARD Type "E" COUPLER March 1931, page 9