Thermosonic bonding

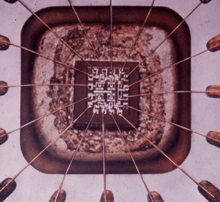

Thermosonic bonding is the most widely used wire bonding method to electrically connect silicon integrated circuits. Alexander Coucoulas introduced it in 1966.[1][2][3] Owing to the reliability of a thermosonic bond, it is extensively used to connect the all important central processing unit (CPU) which are encapsulated integrated circuits that serve as the mainstay and "brains" of the computer.

Thermosonic bonding is a akin to friction welding since it creates a scrubbing action at the contact points between the pre-heated deforming lead-wire and the metallized pads of the silicon integrated circuit. In addition, it produces a temporary ultrasonic or acoustic softening in the lead-wire which facilitates its deformation to form the desirable contact area at relatively low temperatures and forces. As a result of the frictional action and acoustic softening induced in the lead wire during the bonding cycle, thermosonic bonding can be used to reliably bond high melting point metals lead wires, (such as gold, and lower cost aluminum and copper) with relatively low bonding parameters. This ensures that the fragile and costly silicon integrated circuit “chip” used to form Central Processing Units (CPU) for computers are not exposed to damaging high temperatures or mechanical stresses during the bonding process.

History

Earlier wire bonding methods were thermocompression bonding,[4] which used heat and pressure and ultrasonic bonding,[5] which used vibratory energy and pressure. Thermosonic bonding improved upon the reliability of the earlier processes by preheating the lead wire and metallized chip prior to introducing the ultrasonic cycle. It resulted in eliminating the incidences of cracking in the fragile and costly silicon chip. The improvement occurred because pre-heating the lead-wire softened it which facilitated its deformation in forming the required contact area during the ultrasonic bonding cycle. Under these conditions, the onset of recrystallization (metallurgy) or hot working of the deforming wire tends to occur while it is forming the required contact area. Owing to hot working during the bonding cycle, the final deformed-bonded wire would be in a relatively soft and stable state. If the wire was ultrasonically deformed at room temperature, it would tend to strain hardened (cold working) and therefore tend to transmit damaging mechanical stresses to the silicon chip. Thermosonic bonding, initially referred to as hot work ultrasonic bonding, was found to work on bonding aluminum and copper wires to tantalum and palladium thin films on aluminum oxide and glass substrates which simulated the metallized chip.[2][3]

Applications

At present, the majority of connections to the silicon integrated circuit chip are made using thermosonic bonding[1] because it employs lower bonding temperatures, forces and dwell times than thermocompression bonding, as well as lower vibratory energy levels and forces than ultrasonic bonding to form the required bond area. Therefore the use of thermosonic bonding eliminates damaging the relatively fragile silicon integrated circuit chip during the bonding cycle. The proven reliability of thermosonic bonding has made it the process of choice, since such potential failure modes could be costly whether they occur during the manufacturing stage or detected later, during an operational field-failure of a chip which had been connected inside a computer or myriad other microelectronic devices.

Thermosonic bonding is also used in the flip chip process which is an alternate method of electrically connecting silicon integrated circuits.

Josephson effect and superconducting interference (DC SQUID) devices use the thermosonic bonding process as well. In this case, other bonding methods would degrade or even destroy YBaCuO7 microstructures, such as microbridges, Josephson junctions and superconducting interference devices[6] (DC SQUID).

When electrically connecting light-emitting diodes with thermosonic bonding techniques, an improved performance of the device has been shown.[7]

See also

- Flip chip

- Semiconductor device fabrication

- Transistor

- SQUID

- Light-emitting diodes

- LED lamps

References

- ↑ 1.0 1.1 Harman, G., Wire Bonding In Microelectronics, McGraw-Hill, Ch. 2, p. 36

- ↑ 2.0 2.1 Coucoulas, A. (1966) “Ultrasonic Welding of Aluminum Leads to Tantalum Thin Films”, Trans. Metallurgical Society Of AIME, pp. 587–589.

- ↑ 3.0 3.1 Coucoulas, Alexander (1970) Hot Work Ultrasonic (Thermosonic) Bonding, Proceedings 1970 20th Electronic Components Conference, pp. 549–556.

- ↑ Anderson, O. L.; Christensen, H.; Andreatch, P. (1957). "Technique for Connecting Electrical Leads to Semiconductors". Journal of Applied Physics 28: 923. doi:10.1063/1.1722893.

- ↑ Carlin, B. (1960) Ultrasonics. McGraw-Hill Book Co.

- ↑ Burmeister, L.; Reimer, D.; Schilling, M. (1994). "Thermosonic bond contacts with gold wire to YBa2Cu3O7 microstructures". Superconductor Science and Technology 7 (8): 569. doi:10.1088/0953-2048/7/8/006.

- ↑ Seck-Hoe Wong et al. (2006) "Packaging Of Power LEDs Using Thermosonic Bonding Of Au-Au Interconnects", Surface Mount Technology Association International Conference.