Tesla turbine

The Tesla turbine is a bladeless centripetal flow turbine patented by Nikola Tesla in 1913. It is referred to as a bladeless turbine. The Tesla turbine is also known as the boundary layer turbine, cohesion-type turbine, and Prandtl layer turbine (after Ludwig Prandtl) because it uses the boundary layer effect and not a fluid impinging upon the blades as in a conventional turbine. Bioengineering researchers have referred to it as a multiple disk centrifugal pump.[1][2] One of Tesla’s desires for implementation of this turbine was for geothermal power, which was described in Our Future Motive Power.[3]

Description

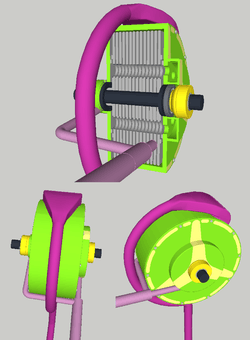

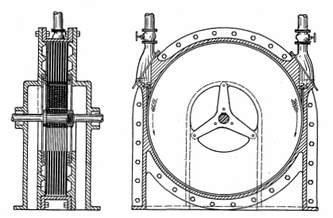

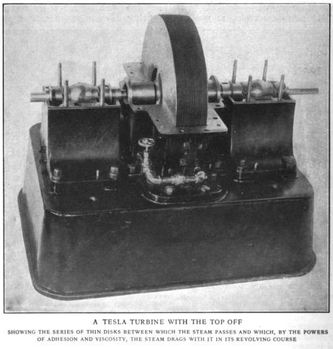

A Tesla turbine consists of a set of smooth disks, with nozzles applying a moving gas to the edge of the disk. The gases drag on the disk by means of viscosity and the adhesion of the surface layer of the gas. As the gas slows and adds energy to the disks, it spirals into the center exhaust. Since the rotor has no projections, it is very sturdy.

Tesla wrote, "This turbine is an efficient self-starting prime mover which may be operated as a steam or mixed fluid turbine at will, without changes in construction and is on this account very convenient. Minor departures from the turbine, as may be dictated by the circumstances in each case, will obviously suggest themselves but if it is carried out on these general lines it will be found highly profitable to the owners of the steam plant while permitting the use of their old installation. However, the best economic results in the development of power from steam by the Tesla turbine will be obtained in plants especially adapted for the purpose."[4]

This turbine can also be successfully applied to condensing plants operating with high vacuum. In such a case, owing to the very great expansion ratio, the exhaust mixture will be at a relatively low temperature and suitable for admission to the condenser. Better fuel has to be used and special pumping facilities provided but the economic results attained will fully justify the increased outlay.

All the plates and washers are fitted on and keyed to a sleeve threaded at the ends and equipped with nuts and collars for drawing the thick end-plates together or, if desired, the collars may be simply forced onto it and the ends upset. The sleeve has a hole fitting snugly on the shaft, to which it is fastened as usual.

This construction permits free expansion and contraction of each plate individually under the varying influence of heat and centrifugal force and possesses a number of other advantages which are of considerable practical importance. A larger active plate area and consequently more power is obtained for a given width, improving efficiency. Warping is virtually eliminated and smaller side clearances may be used, which results in diminished leakage and friction losses. The rotor is better adapted for dynamic balancing and through rubbing friction resists disturbing influences thereby ensuring quieter running. For this reason and also because the discs are not rigidly joined it is protected against damage which might otherwise be caused by vibration or excessive speed.

The Tesla turbine has the trait of being in an installation normally working with a mixture of steam and products of combustion and in which the exhaust heat is used to provide steam which is supplied to the turbine, providing a valve governing the supply of the steam so that the pressures and temperatures can be adjusted to the optimum working conditions.

As diagrammed, a Tesla turbine installation is:

- Able to start with steam alone

- A disc type adapted to work with fluids at high temperature.

An efficient Tesla turbine requires close spacing of the disks. For example, a steam-powered type must maintain 0.4 millimeter (.016 inch) inter-disk spacing. The disks must be extremely smooth to minimize surface and shear losses. Disks must also be very thin to prevent drag and turbulence at disk edges. Unfortunately, preventing disks from warping and distorting was a major challenge in Tesla's time. It is thought that this inability to prevent the disks distorting contributed to the commercial failure of the turbines, because metallurgical technology at the time was not able to produce disks of sufficient quality and rigidity.

Pump

If a similar set of disks and a housing with an involute shape (versus circular for the turbine) are used, the device can be used as a pump. In this configuration a motor is attached to the shaft. The fluid enters near the center, is given energy by the disks, then exits at the periphery. The Tesla turbine does not use friction in the conventional sense; precisely, it avoids it, and uses adhesion (the Coandă effect) and viscosity instead. It utilizes the boundary layer effect on the disc blades.

Smooth rotor disks were originally proposed, but these gave poor starting torque. Tesla subsequently discovered that smooth rotor disks with small washers bridging the disks in ~12–24 places around the perimeter of a 10″ disk and a second ring of 6–12 washers at a sub-diameter made for a significant improvement in starting torque, without compromising efficiency.

Applications

Tesla's patents state that the device was intended for the use of fluids as motive agents, as distinguished from the application of the same for the propulsion or compression of fluids (though the device can be used for those purposes as well). As of 2006, the Tesla turbine has not seen widespread commercial use since its invention. The Tesla pump, however, has been commercially available since 1982[5] and is used to pump fluids that are abrasive, viscous, shear sensitive, contain solids, or are otherwise difficult to handle with other pumps. Tesla himself did not procure a large contract for production. The main drawback in his time, as mentioned, was the poor knowledge of materials characteristics and behaviors at high temperatures. The best metallurgy of the day could not prevent the turbine disks from moving and warping unacceptably during operation.

In 2003 Scott O’Hearen took a patent on the Radial turbine blade system. This invention utilizes a combination of the concepts of a smooth runner surface for working fluid frictional contact and that of blades projecting axially from plural transverse runner faces. Author, Harikishan Gupta E., & Author, Shyam P. Kodali (2013). Design and Operation of Tesla Turbo machine - A state of the art review. International Journal of Advanced Transport Phenomena, 2(1), 2-3.

Today, many amateur experiments in the field have been conducted using Tesla turbines which use compressed air, steam as its power source (the steam being generated with heat from fuel combustion, from a vehicle's turbocharger or from solar radiation). The issue of the warping of the discs has been partially solved using new materials such as carbon fiber. For example, both PNGinc and International Turbine And Power, LLC[6] use carbon fiber discs in their Tesla turbine designs.

One proposed current application for the device is a waste pump, in factories and mills where normal vane-type turbine pumps typically get blocked.

Applications of the Tesla turbine as a multiple-disk centrifugal blood pump have yielded promising results.[7]

Biomedical engineering research on such applications has been continued into the 21st century.[8]

In 2010, U.S. Patent 7,695,242 was issued to Howard Fuller for a wind turbine based on the Tesla design.[9]

Efficiency and calculations

In Tesla's time, the efficiency of conventional turbines was low because the aerodynamic theory needed for effective blade design did not exist and the low quality of materials available to construct those blades put severe limitations on operating speeds and temperatures. The efficiency of a conventional turbine is related to the pressure difference between the intake and the exhaust. Tesla turbine's ability to run on higher temperature gasses than bladed turbines of the time could lend to its greater efficiency.

Tesla's design sidestepped the key drawbacks of the bladed turbine. It does suffer from other problems such as shear losses and flow restrictions. Some of Tesla turbine's advantages lie in relatively low flow rate applications or when small applications are called for. The disks need to be as thin as possible at the edges in order not to introduce turbulence as the fluid leaves the disks. This translates to needing to increase the number of disks as the flow rate increases. Maximum efficiency comes in this system when the inter-disk spacing approximates the thickness of the boundary layer, and since boundary layer thickness is dependent on viscosity and pressure, the claim that a single design can be used efficiently for a variety of fuels and fluids is incorrect. A Tesla turbine differs from a conventional turbine only in the mechanism used for transferring energy to the shaft. Various analyses demonstrate the flow rate between the disks must be kept relatively low to maintain efficiency. Reportedly, the efficiency of the Tesla turbine drops with increased load. Under light load, the spiral taken by the fluid moving from the intake to the exhaust is a tight spiral, undergoing many rotations. Under load, the number of rotations drops and the spiral becomes progressively shorter. This will increase the shear losses and also reduce the efficiency because the gas is in contact with the discs for less distance.

Efficiency is a function of power output. A moderate load makes for high efficiency. Too heavy a load increases the slip in the turbine and lowers the efficiency; with too light a load, little power is delivered to the output, which also decreases efficiency (to zero at idle). This behaviour is not exclusive to Tesla turbines.

The turbine efficiency of the gas Tesla turbine is estimated to be above 60, reaching a maximum of 95 percent. Keep in mind that turbine efficiency is different from the cycle efficiency of the engine using the turbine. Axial turbines which operate today in steam plants or jet engines have efficiencies of about 60–70% (Siemens Turbines Data). This is different from the cycle efficiencies of the plant or engine which are between approximately 25% and 42%, and are limited by any irreversibilities to be below the Carnot cycle efficiency. Tesla claimed that a steam version of his device would achieve around 95 percent efficiency.[10][11] Actual tests of a Tesla Steam Turbine at the Westinghouse works showed a steam rate of 38 pounds per horsepower-hour, corresponding to a turbine efficiency in the range of 20%, while contemporary steam turbines could often achieve turbine efficiencies of well over 50%. The methods and apparatus for the propulsion of fluids and thermodynamic transformation of energy were disclosed in various patents. The thermodynamic efficiency is a measure of how well it performs compared to an isentropic case. It is the ratio of the ideal to the actual work input/output. This can be taken to be the ratio of the ideal change in enthalpy to the real enthalpy for the same change in pressure.

In the 1950s, Warren Rice attempted to re-create Tesla's experiments, but he did not perform these early tests on a pump built strictly in line with the Tesla's patented design (it, among other things, was not a Tesla multiple staged turbine nor did it possess Tesla's nozzle).[12] Rice's experimental single stage system's working fluid was air. Rice's test turbines, as published in early reports, produced an overall measured efficiency of 36–41% for a single stage.[12] Higher percentages would be expected if designed as originally proposed by Tesla.

In his final work with the Tesla turbine and published just prior to his retirement, Rice conducted a bulk-parameter analysis of model laminar flow in multiple disk turbines. A very high claim for rotor efficiency (as opposed to overall device efficiency) for this design was published in 1991 titled "Tesla Turbomachinery".[13] This paper states:

With proper use of the analytical results, the rotor efficiency using laminar flow can be very high, even above 95%. However, in order to attain high rotor efficiency, the flowrate number must be made small which means high rotor efficiency is achieved at the expense of using a large number of disks and hence a physically larger rotor. For each value of flow rate number there is an optimum value of Reynolds number for maximum efficiency. With common fluids, the required disk spacing is dismally small causing [rotors using] laminar flow to tend to be large and heavy for a prescribed throughflow rate.Extensive investigations have been made of Tesla-type liquid pumps using laminar-flow rotors. It was found that overall pump efficiency was low even when rotor efficiency was high because of the losses occurring at the rotor entrance and exit earlier mentioned.[14]:4

Modern multiple stage bladed turbines typically reach 60–70% efficiency, while large steam turbines often show turbine efficiency of over 90% in practice. Volute rotor matched Tesla-type machines of reasonable size with common fluids (steam, gas, and water) would also be expected to show efficiencies in the vicinity of 60–70% and possibly higher.[14]

See also

- List of Tesla patents

- Radial turbine

- Tesla coil

External links

References

- ↑ Miller, G. E.; Sidhu, A; Fink, R.; Etter, B. D. (1993). "July). Evaluation of a multiple disk centrifugal pump as an artificial ventricle". Artificial Organs 17 (7): 590–592. doi:10.1111/j.1525-1594.1993.tb00599.x. PMID 8338431.

- ↑ Miller, G. E.; Fink, R. (1999). "June). Analysis of optimal design configurations for a multiple disk centrifugal blood pump". Artificial Organs 23 (6): 559–565. doi:10.1046/j.1525-1594.1999.06403.x. PMID 10392285.

- ↑ Nikola Tesla, "Our Future Motive Power".

- ↑ Nicola Tesla in British Patent 179,043 on RexResearch - a website dedicated to old inventions and inventors.

- ↑ Discflo Disc Pump Technology

- ↑ ITC using carbon fiber discs in their Tesla turbines

- ↑ Miller, G. E.; Etter, B. D.; Dorsi, J. M. (1990). "February). A multiple disk centrifugal pump as a blood flow device". IEEE Trans. Biomed Eng 37 (2): 157–163. doi:10.1109/10.46255. PMID 2312140.

- ↑ Manning, K. B.; Miller, G. E. (2002). "Flow through an outlet cannula of a rotary ventricular assist device". Artificial Organs 26 (8): 714–723. doi:10.1046/j.1525-1594.2002.06931_4.x. PMID 12139500.

- ↑ "New Wind Turbine Patent Issued" (Press release). Solar Aero Research. 3 May 2010. Retrieved 11 May 2010.

- ↑ Stearns, E. F., "The Tesla Turbine". Popular Mechanics, December 1911. (Lindsay Publications)

- ↑ Andrew Lee Aquila, Prahallad Lakshmi Iyengar, and Patrick Hyun Paik, "The Multi-disciplinary Fields of Tesla; bladeless turbine". nuc.berkeley.edu.

- ↑ 12.0 12.1 "Debunking the Debunker, Don Lancaster Again Puts His Foot In", Tesla Engine Builders Association.

- ↑ "Interesting facts about Tesla" Q&A: I've heard stories about the Tesla turbine that cite a figure of 95% efficiency. Do you have any information regarding this claim? And, why haven't these devices been utilized in the mainstream?. 21st Century Books.

- ↑ 14.0 14.1 Rice, Warren, "Tesla Turbomachinery". Conference Proceedings of the IV International Tesla Symposium, September 22–25, 1991. Serbian Academy of Sciences and Arts, Belgrade, Yugoslavia. (PDF)

Books and publications

- Tesla, Nikola, "Dr. Tesla Talks Of Gas Turbines". Motor World. September 18, 1911.

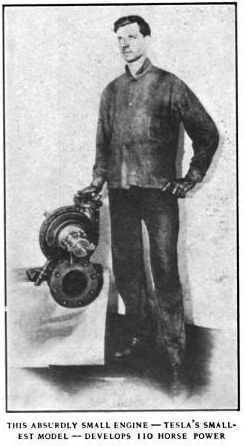

- Stockbridge, Frank Parker (March 1912). "The Tesla Turbine: A Machine As Big As A Derby Hat That Generates 110 Horsepower". The World's Work: A History of Our Time. XXIII: 543–548. Retrieved 2009-07-10.

Patents

Tesla

- US1061206 Turbine - New and useful Improvements in Rotary Engines and Turbines

- US1329559 Valvular Conduit - Includes the Tesla gas turbine

- GB186082 Improvements in the Construction of Steam and Gas Turbines - Form of rotor

- GB186083 Economic Transformation of the Energy of Steam by Turbines - Tesla turbine system

Other

- U.S. Patent 6,726,442, Disc turbine inlet to assist self-starting, Letourneau (February 11, 2002)

- U.S. Patent 6,682,077, Labyrinth seal for disc turbine, Letourneau (February 13, 2002)

- U.S. Patent 6,692,232, Rotor assembly for disc turbine, Letourneau (March 15, 2002)

- U.S. Patent 6,973,792, Method of and apparatus for a multi-stage boundary layer engine and process cell, Hicks (December 13, 2005)

Photos

- "Tesla turbine". PBS.

Boundary layers

- Boundary Layer Effect from National Advisory Committee for Aeronautics, a division of NASA

External links

| Wikimedia Commons has media related to Tesla turbines. |

Kits

- Tesla Engine Builders Association, from Jeff Hayes in Milwaukee, WI

- Phoenix Turbine Builders Club, from Ken Rieli in Munising, MI

- Metal Experimental Modular Turbine and Hybrid Tesla Turbine, Glenn Turner in Gloucester, England

- Tesla Turbine reconfigurable evaluation kit, from Paolo Rossi in Milan, Italy

- Tesla Turbine Kit, from Paul Flynn Dublin, Ireland

Video

- 80,000 RPM Tesla Turbine YouTube user YTEngineer

- Tesla Turbo-generator LIVE! Ken Rieli tests his design.

- small model of Tesla's bladeless turbine YouTube user PlasmaStar9

- 9" stainless steel and polycarbonate turbine operating on 80 psi air and then hooked up to a power meter

- Plaster turbine printed in one piece including bearings

- Build your own Tesla Turbine A series of 6 construction videos on YouTube.

Tesla turbine sites

- Tesla Turbine List.

- Phoenix Turbine Builders Club.

- Tesla Engine Builder's Association (TEBA).

- Vanderbilt Tesla Turbine.

- Plastic Turbine, Metal Turbine and Hybrid Tesla Turbine from Gyroscope.com.

- Tesla turbine, from Uncle Taz Library.

- Tesla Turbine Kit, Turbo-Generator, from OBI Laser Products.

- Tesla Turbine - Features the work of Ken Rieli and others (FreeEnergyNews.com).

- Building a Tesla turbine using hard disk platters. (story) and the instruction page (resulting how-to).

- Rice, Warren, ""Tesla Turbomachinery." Proc. IV International Nikola Tesla Symposium, Sept. 23-25, 1991.

- Redmond, Stephen, "Building a Disk Turbine."

- Germano, Frank D., "Tesla's Bladeless Boundary Disk Turbine and Pump." International Turbine and Power.

- Swithenbank, Alan, "The Tesla Boundary Layer Turbine". September 3, 2005.

- Peterson, Gary, Nikola Tesla's Disk Turbine Tomorrow's Gas Engine". Feed Line No. 7, 21st Century Books.

- Exhale fans - Tesla turbine used as a smooth flow residential fan.