Suzuki GT550

The Suzuki GT550 is a two-stroke, air-cooled, three cylinder 1970s-era motorcycle in Suzuki's "Grand Touring" GT series. Even though total production of the 550 exceeded 60,000 examples spread over a six model year production run, this total was exceeded by both of its three cylinder GT series brothers. Suzuki produced over 80,000 units of the GT750 and over 100, 000 units of the GT380. All three models were originally offered for sale with the beginning of the 1972 model year with the 550 christened "Indy" for the North American market.[1] Production of the 550 was delayed because it was not available to dealers in the U.S. until after April, 1972. In Suzuki's numbering scheme, automobile race tracks identify each of its 3 cylinder GT bikes for the North America market: 380 for Sebring, 550 for Indy, 750 for Le Mans.

Due to poor styling,high weight,poor ground clearance, a relatively low top speed and economical pricing the GT550 was more of a commuting and touring bike than a racer, despite its racetrack-derived name.[1]

Restoration

Both the 380 and the 750 are more popular for restoration. Each of these models still commands a large following of enthusiasts when compared to the 550. One drawback to the desirability of the 550, is its lack of a racing heritage. This is due to the 550's unique engine displacement (actually 543cc) which prevented it from competing in the 500cc class. Equally, the 550 could not compete in the 750 class because it would not have been competitive against the 750s of the day. Most collectors/restorers are drawn to bikes with a claim to racing fame. Consequently, there are relatively few nice original or restored examples of the 550 around today, some 30+ years after the last 550 rolled off the assembly line in Hamamatsu.

Unique features

Ram air system

A unique feature of the 550 (and the 380 ) was its Ram-air cooling system for the one piece cylinder head. Two-stroke engines lose power quite rapidly after the engine reaches its critical temperature, so Suzuki decided to try out an idea that had been used with some success on its 500cc two stroke twin cylinder racer, the T500.[2]

This system consisted of a two piece aluminum shroud bolted to the cylinder head to duct ambient air over the cylinder head finning. The centre part of the head had an increased fin area and a larger shroud entry area in an effort to keep the centre cylinder running at the same temperature as the naturally more exposed outboard cylinders.[3] In practice, it has been found that the centre cylinder actually runs somewhat cooler at speed than the outboard cylinders, so the system does work as intended.

Visible emissions control

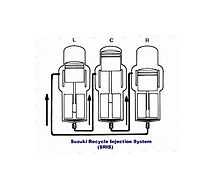

Another unique feature for its time was the Suzuki Recycle Injection System (SRIS). This was the first attempt by anyone to reduce visible emissions from a two stroke motorcycle. It consisted of a small check valve in the bottom of each crank chamber. The logic behind this arrangement was that two strokes have a tendency to collect unburnt oil and gas in the bottom of the crank chamber at idle. Upon acceleration, after a period of idling, the unburned oil and gas gets sucked up the transfer ports and contributes to an overrich mixture for the first 5 to 10 seconds resulting in a smokescreen from the exhaust. The SRIS plumbing routed the unburned gas and oil to the next cylinder in the firing order thus allowing it to mix more thoroughly with the incoming charge of that cylinder and lowering the production of visible smoke. Overall fuel and oil consumption was unchanged but visible smoke was greatly reduced on sudden acceleration from rest.[4] See the attached illustration for more details.

Exhaust system

The exhaust itself was unusual for the time in that the centre exhaust header was split in two and exited into two mufflers much smaller than the single mufflers supplied for the two outboard cylinders. This gave a bike a balanced look with two mufflers per side. The header pipes were all joined via balance tubes, known as Exhaust Coupler Tube System (ECTS), to increase low end torque.

This feature was continued through to the end of production for the North American market but was dropped from the M model onwards in some other markets.

Automatic oil/gas mixing

Suzuki had pioneered its version of automatic lubrication in 1966 to eliminate premixing of oil and gas as had been the norm for all two strokes up until then. This system was launched to eliminate mixtures with far too much oil due to the operator's unnecessary effort to preclude engine seizures. The 550 had the latest version of this multipoint oil injection called Crankcase Cylinder Injection (CCI).

Undersquare engine

The 550 was considered by some to be well suited as a touring motorcycle with its long wheelbase and unstressed torquey engine. The engine will pull quite easily from ~3,500 RPM. The smaller bore/longer stroke dimensions allow quick burning of the air fuel mixture, allowing the use of regular grade gasoline. This type of undersquare engine configuration has long since been discarded for use in street bikes by most Japanese motorcycle engine designers due to its inherent limitations on power increases and the recent advances in combustion chamber design allowing the use of large bore cylinders and high compression without detonation issues.

Specifications

- Engine type : Air-cooled 3-cylinder two-stroke with equal 120-deg. crank throws; rubber mountings for vibration reduction.

- Max. power : 48.5 HP @ 6500 RPM (SAE net, rated at the crankshaft) (36.1 kW); later models outside North America 53 HP

- Torque : 42.8 ft/lb @ 5000 RPM (58 Nm); later models outside North America 38.7ft/lb @ 6000RPM

- Induction system : Piston port w/3 Mikuni VM type round slide carburators

- Bore & stroke : 61 mm x 62 mm

- Displacement : 543cc (nominal)

- Compr. ratio : 6.7:1 (corrected)

- Ignition : Battery/coil with contact breakers

- Electrical system: 12 volt DC with 11 A-hr battery

- Charging system: 3 phase excited field type alternator w/max output of-

- Nippon Denso = 28A @ 6000 RPM

- Kokusan = 15.5 A @ 6000 RPM

- Transmission : 5 speed in unit, constant mesh, foot shift

- Final drive type : Heavy duty endless 530 chain

- Frame : All welded mild steel tubing; all tubes of circular x-section

- Dry weight : 441 lb. (200 kg)[5] Earlier models were rated at 418 lb (187 kg)[6]

- Overall length : 86.4" (2195 mm)

- Overall width : 32.1" (815 mm)

- Overall height : 45.7" (1160 mm)

- Wheelbase : 57.7" (1465 mm) nominal

- Ground clearance: 5.7" (145 mm)

- Fuel capacity : 3.3 Imperial gal. (15.0 litres) including reserve

- Fuel consumption: 44mpg[1]

- Brakes, front : 4LS twin panel drum (1972 MY only)

- Single caliper hydraulic disc (subsequent MY)

- Brakes, rear : 1LS single panel drum

- Tire, front : 3.25 x 19

- Tire, rear : 4.00 x 18

Changes Year By Year

Model Change Info

Sales Figures[7]

1972 Model (Suzuki MY designation “J”)

The GT550 introductory model was Suzuki’s counter to Kawasaki’s 500cc three cylinder street bike designated H1. The H1 produced more power and was faster. The 550 had a broader power band with less peak power . With its broader supply of torque lower in the rev range, the 550 would pull away from a stop quite easily from ~3000 RPM. With its longer wheelbase, the 550 was stable in corners and at speed. Suzuki’s conservative design philosophy aimed to create a “gentleman’s tourer” rather than a “dragstrip burner”.

The initial model featured two striking paint schemes in the customer’s choice of Redondo Blue or Aztec Gold with contrasting striping on the tank and matching paint on the side covers.

Mechanical features included a massive four leading shoe double panel drum front brake shared with the GT750. The conventional telescopic front forks featured rubber gaiters covering the fork stanchions giving a dated appearance. Both fenders were chromed steel. Chrome and polished aluminum were used on the rest of the bike. The gas cap was, unusually for the times, lockable and this feature was carried on through to the end of production. The rear turn signal lenses were red . Engine cooling was by the Ram Air system. First year sales were 11,000+ units.

1973 Model (Suzuki MY designation “K”)

Two new paint and stripe schemes in Grace Lime Metallic and Hermosa Blue were featured for the annual model changeover.

A significant upgrade appeared in the form of a single hydraulically operated front disc brake. Otherwise the bike was the same as the previous model.

Both the wheel and the other fork leg are capable of accepting another disc and caliper and a switch to a twin-disc front brake (like the GT750) was not an uncommon modification some owners made (although the larger master cylinder from the 750 was required). The single disc arrangement continued throughout the rest of the GT550's production.

For some reason Suzuki also chose to have the brake light operated only by the rear brake (in the UK market). A switch was available as a spare part to fit onto the front brake master cylinder casting which would also operate the brake light. The necessary wiring was already included on the main wiring harness in the headlamp shell. Thus, the brake light would operate no matter which brake was used.

While the new disc brake was acceptable in dry riding conditions, in the rain, the disc brake was dangerous with an almost total lack of initial stopping power. Suzuki thoughtfully affixed a sticker to one of the fork sliders warning the rider of this fact. Fortunately the rear drum brake was very good.

This marginal braking setup was to plague the 550 (and all the disc braked motorcycles of the period) until the widespread adoption of the sintered brake pad in the mid 1970s. It took this advance in materials to finally make the use of stainless steel discs a less risky proposition on all bikes.

This MY sales were 14,000+.

1974 Model (Suzuki MY designation “L”)

This MY saw significant changes, both mechanical and appearance-wise, to keep the 550 abreast of the competition. Two different paint and stripe schemes were offered with a striking “swoosh” decal on the gas tank. Choice of colours were Hawaii Green or Marble Scarlet. Some markets received a third choice of Stardust Silver Metallic .

Gone was the rubber-gaitered front end, replaced by a cleaned up “Ceriani-style” set of forks. A touted benefit was better engine cooling but, with Ram Air, this was a non-issue for the most part. The three separate carburetors were gone, replaced by three “unitized” rack mounted items with a push-pull cable arrangement. Benefits were less costly carb balancing jobs and more accurate fuel metering. The handlebar mounted cable operated “choke” was gone, replaced by a lever mounted directly on the rack of carbs. The cylinder head and the Ram Air shroud were redesigned to cater for this new carb setup. The Ram Air shroud was now smoother and more modern looking without the cast-in ribs of the previous two models.

Along with the new carburetor arrangement there came a new airbox and filter assembly. It featured bright chrome end caps for an attractive appearance upgrade and easier servicing of the filters. The frame side covers were all new as well to blend in with the lines of the airbox end caps.

The chain guard was now chromed steel instead of black enamel. The shape of the guard was updated. The red turn signal lenses had disappeared, never to return on any of the GT series thereafter.

The instrument cluster still contained the speedometer and tachometer but a new item had been added. In another “first” for the motorcycle industry, Suzuki now supplied a digital gear indicator in the instrument cluster. There was a single digit LED number display in the centre of the instrument panel showing gear numbers 1 through 5 in a bright red colour. The neutral light indicator, however, was retained as a separate item.

This MY sales were 10,000+

1975 Model (Suzuki MY designation “M”)

Once again, two new paint schemes were featured to keep up appearances. Colour choices were, Candy Orange, Gloss Black (Green and Red in UK). Some markets received Candy Turquoise in lieu of Gloss Black. A more restrained striping scheme compared to the previous MY was in evidence.

The front forks were upgraded once again. However, the changes were mostly invisible to the average customer because the bulk of the changes were to the internal parts of the forks.

The Exhaust Coupler Tube System (ECTS) link between the exhaust pipes disappeared in some markets outside of North America. The North America marketing area kept the exhaust coupler tubes through to the end of production. Power is now up slightly (53 bhp instead of 48.5 bhp claimed) for some markets outside North America.

This MY sales were 14,000+.

1976 Model (Suzuki MY designation “A”)

Very few changes from M model. Front mudguard stay was removed. Rear shock stiffened up and a very slight change to pin striping. Gear indicator changed to led segments rather than the previous dot matrix. Electric starter modification included.

Again, two new paint and striping schemes were introduced. Colour choices were, Forest Green or Targa Red. No Forest Green in UK only Black and Red.

Continued with chrome bores. This was touted as a more durable arrangement with less repair costs when major servicing was required. Typical replacement costs were for new rings only rather than pistons, rings and reboring of the cylinder(s). The composite lining was supposed to last for the predicted life of the engine barring, of course, the effects of poor maintenance and/or abuse. The main benefit is equal expansion of the Cylinder and piston due to similar materials resulting in the safe use of tighter clearances without the risk of cold seizure. Other benefits involved lower ring/cylinder wall friction for better efficiency along with better piston ring sealing capabilities. The GT550 was the only motorcycle in Suzuki's lineup, with the exception of the RE5 and a few RG500 racing machines, to receive this forward thinking feature. Many years would pass before Suzuki again used this type of rather expensive construction on a conventional road-going motorcycle.

The North American market machines carried on with chrome rings in iron linered cylinders.

Otherwise the 550 remained pretty much the same as per the previous MY machine. This MY sales were 9,000+.

1977 Model (Suzuki MY designation “B”)

The final 550 model had two new paint and stripe schemes but the side covers were now only available in a semi-gloss black colour, regardless of the tank colour. The headlamp holders were also finished in black. Tank colours were Spark Silver or Uranos Blue.

The faces of the speedometer and tachometer were changed from a blue background to brown to match the appearance of the instruments on the GS models. There was also a change in the plastic used as the 'glass' because it no longer developed serious opacity and cracks after long exposure to sunlight. The instruments did not get the then-unique 'rose coloured' back-lighting that the GS models had.

Trim items such as turn signals and taillight assembly were changed over to the same items as used on the new GS series four stroke bikes.

The front brake caliper was changed to a pivoting unit made by Asco rather than the fixed Tokico caliper that had been supplied from the introduction of the disc brake system.

The GT and GS series were sold side by side during this one year overlap. This was the last MY for GT550 production. This MY sales were ~6,000+ making this the rarest of all the 550 models.

GT550 Engineering Changes And Modifications

- From engine no. 23036 onwards: a new screw-in style of SRIS check valve was fitted to replace the original press fitted style.[8]

- From engine no. 24552 onwards: a new spring type washer was fitted to retain the primary drive gear. Retrofitting earlier engines was recommended.[9]

- From engine no. 25054 onwards: a new hardened steel key was fitted to the primary drive gear. Retrofitting earlier engines was recommended.[9]

- From frame no. 32292 onwards: a revised front brake caliper piston, seals and brake pad set were fitted to alleviate brake disc squeaking.[10]

- From engine no. 27536 onwards: for Nippon Denso alternators only a new rotor with revised winding style was fitted. This was to prevent premature failure of the field windings and consequent loss of charging current.[11]

- From engine no. 32854 onwards: a new metal particle strainer was fitted to the SRIS check valves to replace the previous plastic items which had been found to melt in service.[12]

- From frame no. 36783 onwards: a new style of spark plug cap and insulator to prevent unwanted high tension current flashover to ground on the Ram Air shroud.[13]

- From frame no. 39304 onwards: a modified fuel petcock was fitted to prevent fuel starvation at high speed.[14]

- From frame no. 60143 onwards: a revised Ram Air shroud with new style spark plug caps was fitted to again try to finally cure unwanted high tension current flashover to the shroud under certain conditions.[15]

- From frame no. 60904 onward: a new style rear brake panel with wider brake shoes, a revised cam and arm are all fitted to improve rear braking performance.[16]

- From engine no. 63692 onwards: a completely revised Borg-Warner style starter clutch and associated parts were fitted to improve the durability of the starter clutch. Field experience had shown that the old style 3 roller starter clutch was not durable enough. This modification can be retrofitted to earlier bikes as necessary.[17]

- From frame no. 64337 onwards: a new style petcock lever seal was fitted to prevent fuel seepage from around the lever.[18]

- From engine no. 66724 onwards: a new style gear indicator switch was fitted. The crankcases were also revised to accept this new style switch along with additional parts to cater for the new switch.[19]

See also

References

- ↑ 1.0 1.1 1.2 Siegal, Margie (November–December 2011). "1975 Suzuki GT550 Indy". Motorcycle Classics. Retrieved 23 April 2013.

- ↑ Cycle World, Vol. 11, No. 6, pg. 57

- ↑ GT550 Owner's Manual Suzuki Part #99011-34611

- ↑ Suzuki GT750 Service Manual Part #SR-3100 dtd. 07/72

- ↑ GT550 Owner's Manual Suzuki Part #99011-34611

- ↑ GT550 Service Manual, 2nd ed.

- ↑ U.S. Suzuki Service Publication #3 dtd. 03/25/94

- ↑ Radco Sales/Suzuki Canada Service Bulletin #115 dtd. 01/16/73

- ↑ 9.0 9.1 Radco Sales/Suzuki Canada Service Bulletin #93 dtd. 06/25/72

- ↑ Radco Sales/Suzuki Canada Service Bulletin #112 dtd. 01/16/73

- ↑ Radco Sales/Suzuki Canada Service Bulletin #137 dtd. 06/11/73

- ↑ Radco Sales/Suzuki Canada Service Bulletin #116 dtd. 01/16/73

- ↑ US Suzuki Service Bulletin GT20 dtd. 05/01/75

- ↑ US Suzuki Service Bulletin GT21 dtd. 05/01/75

- ↑ Suzuki Canada Service Bulletin 75-29 dtd. 08/22/75

- ↑ US Suzuki Service Bulletin GT33 dtd. 01/30/76

- ↑ US Suzuki Service Bulletin GT26 dtd. 08/15/76

- ↑ US Suzuki Service Bulletin GT37 dtd. 03/11/77

- ↑ US Suzuki Service Bulletin GT38 dtd. 04/29/77