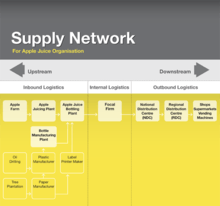

Supply chain network

Due to the rapid advancement of technology such as pervasive or ubiquitous wireless and internet networks, connective product marking technologies like RFID and emerging standards for the use of these defining specific locations using Global Location Number(s), the basic supply chain is rapidly evolving into what is known as a Supply Chain Network.

Origins of the concept

All organizations have or can purchase the components to build a supply chain network, it is the collection of physical locations, transportation vehicles and supporting systems through which the products and services your firm markets are managed and ultimately delivered.

Physical locations included in a Supply Chain Network can be manufacturing plants, storage warehouses, carrier crossdocks, major distribution centres, ports, intermodal terminals whether owned by your company, your suppliers, your transport carrier, a third-party logistics provider, a retail store or your end customer.

Transportation modes that operate within a Supply Chain Network can include the many different types of trucks, trains for boxcar or intermodal unit movement, container ships or cargo planes.

The many systems which can be utilized to manage and improve a Supply Chain Network include Order Management Systems, Warehouse Management System, Transportation Management Systems, Strategic Logistics Modeling, Inventory Management Systems, Replenishment Systems, Supply Chain Visibility, Optimization Tools and more.

Emerging technologies and standards such as the RFID and the GS1 Global Standards are now making it possible to automate these Supply Chain Networks in a real time manner making them more efficient than the simple supply chain of the past.

See also

Document automation in supply chain management & logistics

External links

References

Slack, N, Chambers S. Harland, C., Harrison, A. and Johnston, R. (1997) Operations Management, 2nd edn, Harlow: Ft/Prentice Hall