StressCheck

|

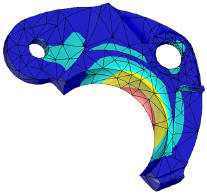

Linear Static Analysis Example | |

| Developer(s) | ESRD, Inc. |

|---|---|

| Stable release | V10.1 / June 2014 |

| Operating system | Windows XP, Windows Vista, Windows 7, Windows 8 |

| Type | Computer Aided Engineering (CAE) software |

| Website | www.esrd.com |

StressCheck is a finite element analysis software product developed and supported by ESRD, Inc. of St. Louis, Missouri. It is one of the first commercially available FEA products to utilize the p-version of the finite element method. As of v10.1, it is a fully 64-bit product and is supported on Windows 7 and Windows 8 64-bit OS.

History

Development of StressCheck software began shortly after the founding in 1989 of ESRD, Inc. by Dr. Barna Szabó, Dr. Ivo Babuška, and Mr. Kent Myers. The principals have been performing research and development related to p-version finite element analysis for more than 20 years. Close ties to the Washington University Center for Computational Mechanics facilitates incorporation of the latest research results into StressCheck.

Capabilities

StressCheck is a complete 3D finite element analysis tool with an integrated pre- and post-processor, a suite of analysis modules supporting advanced solutions in elasticity and heat transfer, and utility modules that offer functionality to import CAD models and perform 2D and 3D automatic meshing.[1] Below is an abbreviated summary of current analysis modules and general capabilities.

Pre-Processing

- Fully parametric modeling capability, including parameter- or formula-controlled:

- Geometric dimensioning

- Meshing parameters

- Material properties

- Boundary conditions (loads and constraints)

- Tractions can be directly applied to the model to meet the requirements of elasticity

- Intrinsic capability to represent sinusoidal bearing loads

- Support for residual stress (RS) inputs (bulk residual stress or machining induced residual stress)

- Support for a wide variety of constraint conditions

- Solution settings

- Extraction settings

- Geometric (blended) mapping capability for higher-order approximation of geometry[2]

- This is critical for detailed stress analysis and composite modeling

- Automatic meshing capability in 2D and 3D

- Advanced boundary layer meshing and crack insertion for fracture mechanics problems

- Handmeshing capability in 2D and 3D for improved discretization

- H-discretization capability to automatically refine hand mesh

- Global-local capability, i.e. importing structural nodal loads from a global model into a local StressCheck detail model

- TLAP (Total Load At a Point) bearing and traction capability converts discrete point loads/moments into statically equivalent, smooth stress distributions

- Advanced laminated composite modeling capability

- Support for high aspect ratio elements (200:1 and larger) for representation of individual plies

- Automatic lamination capability for discretization of a simple mesh to a ply-by-ply or homogenized representation

- Ability to use geometry for laminate directions

- Standardization via Handbook Solutions and Toolkit FEA

- Each installation of StressCheck contains a library of pre-built Handbook models to encompass a variety of commonly solved engineering problems.

- Users may generate organization-specific Handbook solutions for standardization purposes.

Finite Element Solver Features

- Linear Elasticity, including multi-body contact analysis of metallic and composite structures

- Nonlinear Elasticity, including material (i.e. plasticity) and geometric nonlinearities

- Modal/Buckling analysis, including pre-stress buckling

- Steady-State Conduction Heat Transfer, including radiation and convection boundary conditions

- 64-bit Windows batch solver capability for solutions with extraordinary degrees of freedom (DOF)

Post-Processing

- Inherent verification capability for identifying and controlling discretization errors

- Parameter and formula based post-processing

- Fracture mechanics extractions, including stress intensity factors and J integral computation of separated energy release rates (i.e. J1, J2, and J3) with or without residual stress effects

- Ply by Ply extraction capability for laminated composite materials

Interfacing with External Tools

- COM API, allowing the ability to create or load models, solve them, and extract solution data using external programs such as AFGROW, Microsoft Excel, MATLAB and Visual Basic .NET

- Allows for the development of custom applications

- Optimization programs can interface with parametric modeling capability

- Automation scripts can be written to update and solve multiple models

Technology

StressCheck uses the p-version of the finite element method. The utilization of the p-version in finite element analysis was pioneered by Dr. Barna Szabó during his tenure at Washington University in St. Louis. The p-version finite element method spans a space of high order polynomials by nodeless basis functions, chosen approximately orthogonal for numerical stability. Since not all interior basis functions need to be present, the p-version finite element method can create a space that that contains all polynomials up to a given degree with many fewer degrees of freedom.[2]

In practice, the name p-version means that accuracy is increased by increasing the order of the approximating polynomials (thus, p) rather than decreasing the mesh size, h. Thus, to check for solution convergence by increasing the number of degrees of freedom in a given model, the shape function polynomial level is increased rather than remeshing with more elements, which is the standard FEA tool method. In StressCheck the maximum p-level is set to eight (8).

Application

StressCheck is used in a variety of industries, notably aerospace, and for a range of applications such as aircraft damage tolerance assessment and analysis of composite materials for which high order elements are particularly useful.[3]

References

- ↑ "What is StressCheck?"

- ↑ 2.0 2.1 Barna Szabó and Ivo Babuška, Finite element analysis, John Wiley & Sons, Inc., New York, 1991. ISBN 0-471-50273-1

- ↑ "Market Trends: Composites Affordability Initiative, Part II," Composites World, May 2007 .

- 4. Barna Szabó and Ivo Babuška, Introduction to Finite Element Analysis: Formulation, Verification and Validation, John Wiley & Sons, Inc., United Kingdom, 2011. ISBN 978-0-470-97728-6. http://www.wiley.com//legacy/wileychi/szabo/

See also

| ||||||||||