Steam shovel

A steam shovel is a large steam-powered excavating machine designed for lifting and moving material such as rock and soil. It is the earliest type of power shovel or excavator. They played a major role in public works in the 19th and early 20th century, being key to the construction of railroads and the Panama Canal. The development of simpler, cheaper diesel-powered shovels caused steam shovels to fall out of favour in the 1930s.

History

Origins and development

The steam shovel was invented by William Otis, who received a patent for his design in 1839.

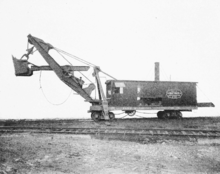

The first machines were known as 'partial-swing', since the boom could not rotate through 360 degrees. They were built on a railway chassis, on which the boiler and movement engines were mounted. The shovel arm and driving engines were mounted at one end of the chassis, which accounts for the limited swing. Bogies with flanged wheels were fitted, and power was taken to the wheels by a chain drive to the axles. Temporary rail tracks were laid by workers where the shovel was expected to work, and repositioned as required.

Steam shovels became more popular in the latter half of the nineteenth century. Originally configured with chain hoists, the advent of steel cable in the 1870s allowed for easier rigging to the winches.

Later machines were supplied with caterpillar tracks, obviating the need for rails.

The full-swing, 360° revolving shovel was developed in England in 1884, and became the preferred format for these machines.

Growth and uses

Expanding railway networks (in the US and the UK) fostered a demand for steam shovels. The extensive mileage of railways, and corresponding volume of material to be moved, forced the technological leap. As a result, steam shovels became commonplace.

American manufacturers included the Marion Steam Shovel Company, which was founded in 1884, Erie, P and H, and Bucyrus-Erie Shovel Companies.

The booming cities in North America used shovels to dig foundations and basements for the early skyscrapers.

Perhaps the most famous application of steam shovels is the digging of the Panama Canal across the Isthmus of Panama. One hundred and two shovels worked in that decade-long dig. Of these, seventy-seven were built by Bucyrus;[1] the remainder were Marion shovels. These machines 'moved mountains' in their labours. The shovel crews would race to see who could move the most dirt.[2]

Steam shovels assisted mining operations: the iron mines of Minnesota, the copper mines of Chile and Montana, placer mines of the Klondike – all had earth-moving equipment. But it was with the burgeoning open-pit mines – first in Bingham Canyon, Utah – that shovels came into their own. The shovels systematically removed hillsides. As a result, steam shovels were used around the world from Australia to Russia to coal mines in China. Shovels were also used for construction, road and quarry work.

Steam shovels came into their own in the 1920s with the publicly funded road building programs around North America. Thousands of miles of State Highways were built in this time period, together with new factories, such as Henry Ford's River Rouge Plant, and many docks, ports, buildings, and grain elevators.

Successors

During the 1930s steam shovels lost out to the simpler, cheaper diesel-powered excavating shovels that were the forerunners of those still in use today. Open-pit mines were electrified at this time. Only after the Second World War, with the advent of robust high-pressure hydraulic hoses, did the more versatile hydraulic backhoe shovels take pre-eminence over the cable-hoisting winch shovels.

Many steam shovels remained at work on the railways of developing nations until diesel engines supplanted them. Most have since been scrapped.

Large, multi-ton mining shovels still use the cable-lift shovel arrangement. In the 1950s and 1960s Marion Shovel built massive stripping shovels for coal operations in the Eastern US. Shovels of note were the Marion 360, the Marion 5900, and the largest shovel ever built, Marion 6360 The Captain – with a 180-cubic-yard (140 m3) bucket – while Bucyrus constructed one of the most famous monsters: the Big Brutus, the largest still in existence. The GEM of Egypt (GEM standing for "Giant Excavating Machine" and Egypt referring to the Egypt Valley in Belmont County, eastern Ohio where it was first put to use), which operated from 1967 to 1988, was of comparable size; it has since been dismantled.[3] Although these big machines are still called steam shovels, they are more correctly known as power shovels since they use electricity to wind their winches.

Operation

A steam shovel consists of:

- a bucket, usually with a toothed edge, to dig into the earth

- a "dipper" or "dipper stick" connecting the bucket to the boom

- a "boom" mounted on the rotating platform, supporting the dipper and its control wires

- a boiler

- a water tank and coal bunker

- steam engines and winches

- operator's controls

- a rotating platform on a truck, on which everything is mounted

- wheels (or sometimes caterpillar tracks or railroad wheels)

- a house (on the platform) to contain and protect 'the works'

The shovel has several individual operations: it can raise or luff the boom, rotate the house, or extend the dipper stick with the boom or crowd engine, and raise or lower the dipper stick.

When digging at a rock face, the operator simultaneously raises and extends the dipper stick to fill the bucket with material. When the bucket is full, the shovel is rotated to load a railway car or motor truck. The locking pin on the bucket flap is released and the load drops away. The operator lowers the dipper stick, the bucket mouth self-closes, the pin relocks automatically and the process repeats.

Steam shovels usually had a three-man crew: engineer, fireman and ground man. There was much jockeying to do to move shovels: rails and timber blocks to move; cables and block purchases to attach; chains and slings to rig; and so on. On soft ground, shovels used timber mats to help steady and level the ground. The early models were not self-propelled, rather they would use the boom to manoeuvre themselves.

Steam shovel manufacturers

North American manufacturers:

- Ball Engine Co.

- Bucyrus

- Erie

- Marion Steam Shovel Dredge Company

- Moore Speedcrane (later Manitowoc Cranes)

- Northwest Shovels

- Vulcan Iron Works

European manufacturers:

- Demag (Germany)

- Fiorentini (Italy)

- Lubecker

- Menck

- Newton & Chambers (UK)

- Orenstein and Koppel GmbH (Germany)

- Ruston & Hornsby (UK)

Power shovel/dragline manufacturers

|

|

|

Preservation

Most steam shovels have been scrapped, although a few reside in industrial museums and private collections.

The Le Roy Marion

The world's largest steam shovel surviving intact is a Marion machine, dating from either 1906 or 1911, located in the small American town of Le Roy, New York. It was listed on the National Register of Historic Places in 2008.[4]

Ruston Proctor Steam Navvy No 306

Dating from 1909, this machine – Ruston's called it a 'crane navvy'[5] – is the oldest surviving steam navvy in the world.[6] It was originally used at a chalk pit at Arlesey, in Bedfordshire, England. After the pit was closed, the steam navvy was simply abandoned and 'lost' as the pit became flooded with water. By the mid-1970s, the area had become a local beauty spot, known as The Blue Lagoon (from chemicals from the quarry colouring the water), and after long periods of drought, the top of the rusty navvy could be seen protruding from the water. Ruston & Hornsby expert Ray Hooley heard of its existence, and organised the difficult task of rescuing it from the water-filled pit.[7] Hooley arranged for its complete restoration to working order by apprentices at the Ruston-Bucyrus works. Subsequently it passed into the care of the Museum of Lincolnshire Life.[8] The museum was unable to make full use of the machine, and, not being stored under cover, its condition deteriorated. In 2011, Ray Hooley donated the machine to the Vintage Excavator Trust at Threlkeld Quarry and Mining Museum in Cumbria. It was moved to the quarry in 2011,[6] and (as of 2013) full restoration is once again under way.[9]

1923 Bucyrus Model 50-B

Twenty-five Bucyrus Model 50-B steam shovels were sent to the Panama Canal to build bridges, roads, and drains and remove the huge quantities of soil and rock cut from the canal bed. All the shovels but one were scrapped at Panama. The survivor was shipped back to California and then brought to Denver. In the early 1950s it was transported to Rollinsville by Roy and Russell Durand, who operated it at the Lump Gulch Placer, six miles south of Nederland, Colorado, until 1978. This steam shovel is one of two (the other at the Western Minnesota Steam Thresher's Reunion in Rollag, MN) remaining operational Bucyrus Model 50-Bs,[10] and is preserved at the Nederland Mining Museum. Roots of Motive Power in Willits, CA has also acquired a 50-B and operates it for the public once a year at their Steam Festival in early September.

Northwest Model

Two steam shovels sit abandoned in Zamora, California, north of Sacramento beside Highway 5. The one in better condition is shown in the picture.

In fiction

- The children's classic book Mike Mulligan and His Steam Shovel features a steam shovel as a main character.

- A power shovel, also known as a "Snort", features towards the climax of the children's book Are You My Mother? by P. D. Eastman. The little bird is returned to its nest by the power shovel but this is not necessarily a steam shovel.

- In the Thomas & Friends TV series, a steam shovel named Ned appears as a minor character. A rail mounted steam shovel named Marion also appears in Thomas & Friends, beginning with the movie Tale of the Brave.

- In the Australian children's TV series Mr. Squiggle, Bill the Steam Shovel provides comic relief and produces steam from his "nose" when he laughs.

See also

- Steam crane

- Crane (railroad)

- Dredge

Notes

- ↑ "Syncrude Newsletter Article." Bucyrus International. March 16, 2006. Retrieved 23 June 2010

- ↑ Baker, Ray Stannard. "Goethals: the Man and How He Works." The American Magazine. 1913. Retrieved 23 June 2010

- ↑ http://stripmine.org/gem_01.htm

- ↑ "National Register Information System". National Register of Historic Places. National Park Service. 2009-03-13.

- ↑ http://www.oldengine.org/members/ruston/Arlesey2.htm – Photo of works plate

- ↑ 6.0 6.1 http://www.oldglory.co.uk/news/steam-navvy-on-the-move

- ↑ "Ruston Proctor Steam Navvy No 306 Recovery". (includes photos of navvy at work). Retrieved 2008-01-03.

- ↑ "The Museum of Lincoln Life (steam engines)". (includes photo of Ruston Proctor no 306). Retrieved 2008-01-03.

- ↑ http://www.threlkeldquarryandminingmuseum.co.uk/vintage-excavator-trust/

- ↑ "Nederland Area Historical Society". (Photos of Model 50-B and history of the steam shovel). Retrieved 2011-08-22.

References

- Marsh Jr., Robert (1920). Steam Shovel Mining. New York: McGraw-Hill.

- Construction Service Co. (1911). Handbook of Steam Shovel Work. The Bucyrus Company.

- Hermann, E.A. (1894). Steam Shovels and Shovel Work. New York: Engineering News Publishing Corp.

External links

| Wikimedia Commons has media related to Steam shovels. |

- Photo of the Le Roy Marion shovel at work

- The Long Journey of a Steam Shovel – the story of a preserved Ruston-Bucyrus steam shovel in Spain

- Digging with steam power on YouTube – Video of a working steam shovel and a clamshell-fitted steam crane

- Bucyrus Official Website

- Steam shovel photo register, including many working shovels.

- Copper Range Steam Shovel X-2

| ||||||||||||||||||||||||||||||||||