Self-assembly

Self-assembly is a process in which a disordered system of pre-existing components forms an organized structure or pattern as a consequence of specific, local interactions among the components themselves, without external direction. When the constitutive components are molecules, the process is termed molecular self-assembly.

Self-assembly can be classified as either static or dynamic. In static self-assembly, the ordered state forms as a system approaches equilibrium, reducing its free energy. However in dynamic self-assembly, patterns of pre-existing components organized by specific local interactions are not commonly described as "self-assembled" by scientists in the associated disciplines. These structures are better described as "self-organized".

Self-assembly in chemistry and materials science

Self-assembly (SA) in the classic sense can be defined as the spontaneous and reversible organization of molecular units into ordered structures by non-covalent interactions. The first property of a self-assembled system that this definition suggests is the spontaneity of the self-assembly process: the interactions responsible for the formation of the self-assembled system act on a strictly local level—in other words, the nanostructure builds itself.

Distinctive features

At this point, one may argue that any chemical reaction driving atoms and molecules to assemble into larger structures, such as precipitation, could fall into the category of SA. However, there are at least three distinctive features that make SA a distinct concept.

Order

First, the self-assembled structure must have a higher order than the isolated components, be it a shape or a particular task that the self-assembled entity may perform. This is generally not true in chemical reactions, where an ordered state may proceed towards a disordered state depending on thermodynamic parameters.

Interactions

The second important aspect of SA is the key role of slack interactions (e.g. Van der Waals, capillary,  , hydrogen bonds) with respect to more "traditional" covalent, ionic, or metallic bonds. Although typically less energetic by a factor of 10, these weak interactions play an important role in materials synthesis. It can be instructive to note how slack interactions hold a prominent place in materials, especially in biological systems, although they are often considered marginal with respect to "strong" (i.e. covalent, etc.) interactions. For instance, they determine the physical properties of liquids, the solubility of solids, and the organization of molecules in biological membranes.

, hydrogen bonds) with respect to more "traditional" covalent, ionic, or metallic bonds. Although typically less energetic by a factor of 10, these weak interactions play an important role in materials synthesis. It can be instructive to note how slack interactions hold a prominent place in materials, especially in biological systems, although they are often considered marginal with respect to "strong" (i.e. covalent, etc.) interactions. For instance, they determine the physical properties of liquids, the solubility of solids, and the organization of molecules in biological membranes.

Building blocks

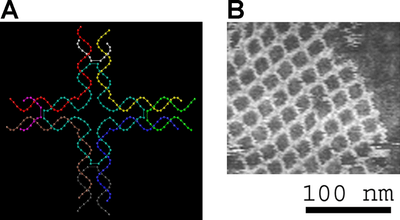

The third distinctive feature of SA is that the building blocks are not only atoms and molecules, but span a wide range of nano- and mesoscopic structures, with different chemical compositions, shapes and functionalities.[3] Recent examples of novel building blocks include polyhedra and patchy particles. These nanoscale building blocks (NBBs) can in turn be synthesised through conventional chemical routes or by other SA strategies such as Directional Entropic Forces.

Examples

Important examples of SA in materials science include the formation of molecular crystals, colloids, lipid bilayers, phase-separated polymers, and self-assembled monolayers.[4][5] The folding of polypeptide chains into proteins and the folding of nucleic acids into their functional forms are examples of self-assembled biological structures. Recently, the three-dimensional macroporous structure was prepared via self-assembly of diphenylalanine derivative under cryoconditions, the obtained material can find the application in the field of regenerative medicine or drug delivery system.[6] P. Chen et al. demonstrated a microscale self-assembly method using the air-liquid interface established by Faraday wave as a template. This self-assembly method can be used for generation of diverse sets of symmetrical and periodic patterns from microscale materials such as hydrogels, cells, and cell spheroids.[7]

Properties

SA extends the scope of chemistry aiming at synthesising products with order and functionality properties, extending chemical bonds to weak interactions and encompassing the self-assembly of NBBs on all length scales.[8] In covalent synthesis and polymerisation, the scientist links atoms together in any desired conformation, which does not necessarily have to be the energetically most favoured position; self-assembling molecules, on the other hand, adopt a structure at the thermodynamic minimum, finding the best combination of interactions between subunits but not forming covalent bonds between them. In self-assembling structures, the scientist must predict this minimum, not merely place the atoms in the location desired.

Another characteristic common to nearly all self-assembled systems is their thermodynamic stability. For SA to take place without intervention of external forces, the process must lead to a lower Gibbs free energy, thus self-assembled structures are thermodynamically more stable than the single, unassembled components. A direct consequence is the general tendency of self-assembled structures to be relatively free of defects. An example is the formation of two-dimensional superlattices composed of an orderly arrangement of micrometre-sized polymethylmethacrylate (PMMA) spheres, starting from a solution containing the microspheres, in which the solvent is allowed to evaporate slowly in suitable conditions. In this case, the driving force is capillary interaction, which originates from the deformation of the surface of a liquid caused by the presence of floating or submerged particles.[9]

These two properties—weak interactions and thermodynamic stability—can be recalled to rationalise another property often found in self-assembled systems: the sensitivity to perturbations exerted by the external environment. These are small fluctuations that alter thermodynamic variables that might lead to marked changes in the structure and even compromise it, either during or after SA. The weak nature of interactions is responsible for the flexibility of the architecture and allows for rearrangements of the structure in the direction determined by thermodynamics. If fluctuations bring the thermodynamic variables back to the starting condition, the structure is likely to go back to its initial configuration. This leads us to identify one more property of SA, which is generally not observed in materials synthesised by other techniques: reversibility.

SA is a process which is easily influenced by external parameters: if this can make synthesis more problematic due to the many free parameters that require control, on the other hand it has the exciting advantage that a large variety of shapes and functions on many length scales can be obtained.[10]

Generally speaking, the fundamental condition needed for NBBs to self-assemble into an ordered structure is the simultaneous presence of long-range repulsive and short-range attractive forces.[11]

By choosing precursors with suitable physicochemical properties, it is possible to exert a fine control on the formation processes that produce complex structures. Clearly, the most important tool when it comes to designing a synthesis strategy for a material, is the knowledge of the chemistry of the building units. For example, it was demonstrated that it was possible to use diblock copolymers with different block reactivities in order to selectively embed maghemite nanoparticles and generate periodic materials with potential use as waveguides.[12]

In 2008, Advances in Colloid and Interface Science published a study in which it was concluded that every self-assembly process in reality presents a co-assembly, which makes the former term a misnomer of a kind.[13] The thesis is built on the concept of mutual ordering of the self-assembling system and its environment.

Self-assembly at the macroscopic scale

Self-assembly processes can be observed in systems of macroscopic building blocks. These building blocks can be externally propelled[14] or self-propelled.[15] Since the 1950s, scientists have built self-assembly systems exhibiting centimeter-sized components ranging from passive mechanical parts to mobile robots.[16] For systems at this scale, the component design can be precisely controlled. For some systems, the components' interaction preferences are programmable. The self-assembly processes can be easily monitored and analyzed by the components themselves or by external observers.

In April 2014, Skylar Tibbits of the Massachusetts Institute of Technology, demonstrated a combination of 3D printed plastic with a "smart material" that self-assembles in water.[17] Tibbits refers to this as "4D printing".[18]

Consistent concepts of self-organization and self-assembly

Self-organization and self-assembly are regularly used interchangeably. As complex system science becomes more popular though, there is a higher need to clearly distinguish the differences between the two mechanisms to understand their significance in physical and biological systems. Both processes explain how collective order is developed from "dynamic small-scale interactions" according to an article in a November/December 2008 issue of the journal Complexity. Self-organization is a nonequilibrium process where self-assembly is a spontaneous process that leads toward equilibrium. Self-assembly requires components to remain essentially unchanged throughout the process. Besides the thermodynamic difference between the two, there is also a difference in formation. The first difference is what "encodes the global order of the whole" in self-assembly whereas in self-organization these initial encodings are not necessary. Another slight contrast refers to the minimum number of units needed to make an order. Self-organization appears to have a minimum number of units whereas self-assembly does not. These terms are becoming more necessary as more is learned about natural selection. Eventually, these patterns may form one theory regarding the pattern formation in nature.[19]

See also

- Crystal engineering

- Autopoiesis

- Langmuir–Blodgett film

- Nanotechnology

- Pick-and-place machine

- Self-assembly of nanoparticles

References

- ↑ 1.0 1.1 Wetterskog, Erik; Agthe, Michael; Mayence, Arnaud; Grins, Jekabs; Wang, Dong; Rana, Subhasis; Ahniyaz, Anwar; Salazar-Alvarez, German; Bergström, Lennart (2014). "Precise control over shape and size of iron oxide nanocrystals suitable for assembly into ordered particle arrays". Science and Technology of Advanced Materials 15 (5): 055010. doi:10.1088/1468-6996/15/5/055010.

- ↑ Strong, M. (2004). "Protein Nanomachines". PLoS Biol. 2 (3): e73–e74. doi:10.1371/journal.pbio.0020073. PMC 368168. PMID 15024422.

- ↑ "Structural Diversity and the Role of Particle Shape and Dense Fluid Behavior in Assemblies of Hard Polyhedra". Archived from the original on 2012-02-10. Retrieved 23 June 2012.

- ↑ Whitesides, G.M.; Boncheva, M. (2002). "Beyond molecules: Self-assembly of mesoscopic and macroscopic components". PNAS 99 (8): 4769–74. doi:10.1073/pnas.082065899. PMC 122665. PMID 11959929.

- ↑ Whitesides, George M.; Kriebel, Jennah K.; Love, J. Christopher (2005). "Molecular engineering of surfaces using self-assembled monolayers". Science Progress 88 (Pt 1): 17–48. doi:10.3184/003685005783238462. PMID 16372593.

- ↑ Berillo, Dmitriy; Mattiasson, Bo; Galaev, Igor Yu.; Kirsebom, Harald (2012). "Formation of macroporous self-assembled hydrogels through cryogelation of Fmoc–Phe–Phe". Journal of Colloid and Interface Science 368 (1): 226–230. doi:10.1016/j.jcis.2011.11.006. PMID 22129632.

- ↑ Chen, Pu; Luo, Zhengyuan; Güven, Sinan; Tasoglu, Savas; Ganesan, Adarsh Venkataraman; Weng, Andrew; Demirci, Utkan (2014). "Microscale Assembly Directed by Liquid-Based Template". Advanced Materials 26 (34): 5936–5941. doi:10.1002/adma.201402079. PMID 24956442.

- ↑ Ozin, Geoffrey A.; Arsenault, André C. (2005). Nanochemistry: a chemical approach to nanomaterials. Cambridge: Royal Society of Chemistry. ISBN 0-85404-664-X.

- ↑ Denkov, N.; Velev, O.; Kralchevski, P.; Ivanov, I.; Yoshimura, H.; Nagayama, K. (1992). "Mechanism of formation of two-dimensional crystals from latex particles on substrates". Langmuir 8 (12): 3183. doi:10.1021/la00048a054.

- ↑ Lehn, Jm (Mar 2002). "Toward self-organization and complex matter". Science 295 (5564): 2400–3. doi:10.1126/science.1071063. PMID 11923524.

- ↑ Forster, Paul M.; Cheetham, Anthony K. (2002). "Open-Framework Nickel Succinate, [Ni7(C4H4O4)6(OH)2(H2O)2]⋅2H2O: A New Hybrid Material with Three-Dimensional Ni−O−Ni Connectivity". Angewandte Chemie International Edition 41 (3): 457. doi:10.1002/1521-3773(20020201)41:3<457::AID-ANIE457>3.0.CO;2-W.

- ↑ Gazit, Oz; Khalfin, Rafail; Cohen, Yachin; Tannenbaum, Rina (2009). "Self-Assembled Diblock Copolymer “Nanoreactors” as “Catalysts” for Metal Nanoparticle Synthesis". The Journal of Physical Chemistry C 113 (2): 576–583. doi:10.1021/jp807668h.

- ↑ Uskoković, Vuk (2008). "Isn't self-assembly a misnomer? Multi-disciplinary arguments in favor of co-assembly". Advances in Colloid and Interface Science 141 (1-2): 37–47. doi:10.1016/j.cis.2008.02.004. PMID 18406396.

- ↑ Hosokawa K.; Shimoyama, I.; Miura, H. (1994). "Dynamics of self-assembling systems: Analogy with chemical kinetics". Artificial Life 1 (4): 413–427. doi:10.1162/artl.1994.1.413.

- ↑ Groß R.; Dorigo, M.; Mondada, Francesco; Dorigo, Marco (2006). "Autonomous self-assembly in swarm-bots". IEEE Transactions on Robotics 22 (6): 1115–1130. doi:10.1109/TRO.2006.882919.

- ↑ Groß R.; Dorigo, M. (2008). "Self-assembly at the macroscopic scale". Proceedings of the IEEE 96 (9): 1490–1508. doi:10.1109/JPROC.2008.927352.

- ↑ D’Monte, Leslie (7 May 2014) Indian market sees promise in 3D printers. livemint.com

- ↑ The emergence of "4D printing". ted.com (2013)

- ↑ Halley, J. D.; Winkler, D.A. (2008). "Consistent Concepts of Self-organization and Self-assembly". Complexity 14 (2): 10. doi:10.1002/cplx.20235.

External links and further reading

- Book chapter "Challenges and breakthroughs in recent research on self-assembly", Sci. Technol. Adv. Mater. 9 (2007) 014109 (96 pages) (free download)

- Kuniaki Nagayama, Freeview Video 'Self-Assembly: Nature's Way To Do It, A Royal Institution Lecture by the Vega Science Trust.

- Paper Molecular Self-Assembly

- Paper Beyond molecules: Self-assembly of mesoscopic and macroscopic components

- Whitesides, G. M.; Grzybowski, B. (2002). Science 295: 2418–2421. doi:10.1126/science.1070821. Missing or empty

|title=(help) - Damasceno, Pablo F.; Engel, Michael; Glotzer, Sharon (2012). Science 337: 453–457. doi:10.1126/science.1220869. Missing or empty

|title=(help) - Rothemund, PWK; Papadakis, N; Winfree, E (2004). "Algorithmic Self-Assembly of DNA Sierpinski Triangles". PLoS Biol 2: 12.

- Wiki: C2 Self Assembly from a computer programming perspective.

- Pelesko, J.A., (2007) Self Assembly: The Science of Things That Put Themselves Together, Chapman & Hall/CRC Press.

- A brief page on self-assembly at the University of Delaware Self Assembly

- Mohammadzadegan R, Sheikhi MH (2007) DNA Nano-Gears Molecular Simulation 33(13); 1071-1081.

- Structure and Dynamics of Organic Nanostructures

- Metal organic coordination networks of oligopyridines and Cu on graphite