Radiant barrier

Radiant barriers (also known as reflective insulation) are a type of thermal (heat) insulations that inhibits heat transfer by thermal radiation. Thermal energy may also be transferred via conduction or convection, however, and radiant barriers do not necessarily protect against heat transfer via conduction (without airspace facing the heat source) or convection (perforated).

There are many definitions of thermal/heat insulation and it is commonly misinterpreted as “Bulk/Mass/Batt Insulation”, which is actually used to resist conduction heat transfer with certain R-values.

Heat/thermal insulation is a barrier material which resists/blocks/reflects heat energy (either one or more of conduction, convection or radiation) to prevent its transfer through the boundary between two systems which are at different temperatures. Heat transfer always occurs from a region of higher temperature to one of lower temperature.

Radiant barrier (or reflective) insulation is heat/thermal insulation which reflects radiation heat (radiant heat), preventing transfer from one side to another due to a reflective (or low emittance) surface.

As such materials reflect radiant heat with negligible “R-values” they should also be classified as thermal/heat insulation.

Reflectivity and emissivity

All materials give off, or emit, energy by thermal radiation as a result of their temperature. The amount of energy radiated depends on the surface temperature and a property called emissivity (also called "emittance"). Emissivity is expressed as a number between zero (0) and one (1) at a given wavelength. The higher the emissivity, the greater the emitted radiation at that wavelength. A related material property is reflectivity (also called "reflectance"). This is a measure of how much energy is reflected by a material at a given wavelength. Reflectivity is also expressed as a number between 0 and 1 (or a percentage between 0 and 100). At a given wavelength and angle of incidence the emissivity and reflectivity values sum to 1 by Kirchhoff's law.

Radiant barrier materials must have low emissivity (usually 0.1 or less) at the wavelengths at which they are expected to function. For typical building materials, the wavelengths are in the mid- and long-infrared spectrum, in the range of 3-15 micrometres.

Radiant barriers may or may not exhibit high visual reflectivity. While reflectivity and emissivity must sum to 1 at a given wavelength, reflectivity at one set of wavelengths (visible) and emissivity at a different set of wavelengths (thermal) do not necessarily sum to 1. Therefore, it is possible to create visibly dark colored surfaces with low thermal emissivity.

To perform properly, radiant barriers need to face open space (e.g., air or vacuum) through which there would otherwise be radiation.

History

In 1860, the French scientist Jean Claude Eugene Peclet[1] experimented with the insulating effect of high and low emissive metals facing air spaces.[2] Peclet experimented with a wide variety of metals ranging from tin to cast iron, and came to the conclusion that neither the color nor the visual reflectance were significant determining factors in the materials’ performance. Peclet calculated the reduction in BTUs for high and low emissive surfaces facing into various air spaces, discovering the benefits of a radiant barrier in reducing the transfer of heat.

In 1925, two German businessmen Schmidt and Dykerhoff filed for patents on reflective surfaces for use as building insulation because recent improvements in technology allowed low emissivity aluminum foil to be commercially viable. This became the launching pad for radiant barrier and reflective insulation around the world, and within the next 15 years, millions of square feet of radiant barrier were installed in the US alone.[1] Within 30 years, radiant barrier was making a name for itself, and was included in projects at MIT, Princeton, and Frank Sinatra’s residence in Palm Springs, California. [3]

Applications

Space exploration

For the Apollo program, NASA helped develop a thin aluminum metalized film that reflected 95% of the radiant heat.[4] A metalized film was used to protect spacecraft, equipment, and astronauts from thermal radiation or to retain heat in the extreme temperature fluctuations of space.[4] The aluminum was vacuum-coated to a thin film and applied to the base of the Apollo landing vehicles. It was also used in numerous other NASA projects like the James Webb Space Telescope and Skylab. In the vacuum of space where temperatures can range from 250°F above to 400°F below zero,[5] heat transfer is only by radiation, so a radiant barrier is much more effective than it is on earth, where 5% to 45% of the heat transfer can still occur via convection and conduction, even when an effective radiant barrier is deployed. Radiant barrier[5] is a Space Foundation Certified Space Technology(TM). Radiant barrier was inducted into the Space Technology Hall of Fame in 1996.

Textiles

Since the 1970s,[4] sheets of metalized polyester called space blankets have been commercially available as a means to prevent hypothermia and other cold weather injuries. Because of their durability and light weight, these blankets are popular for survival and first aid applications. Swarms of people can be seen draped in reflective metalized film after a marathon, especially where the temperatures are particularly cold, like during the annual ING New York City marathon which takes place in the fall.

Window treatments

Windows glass can be coated to achieve low emissivity or “low-e”. Some windows use laminate polyester film where at least one layer has been metalized using a process called sputtering. Sputtering occurs when a metal, most often aluminum, is vaporized and the polyester film is passed through it. This process can be adjusted to control the amount of metal that ultimately coats the surface of the film.

These metalized films are applied to one or more surfaces of the glass to resist the transfer of radiant heat, yet the films are so thin that they allow visible light to pass through. Since the thin coatings are fragile and can be damaged when exposed to air and moisture, manufacturers typically use multiple pane windows. While films are typically applied to the glass during manufacturing, some films may be available for homeowners to apply themselves. Homeowner-applied window films are typically expected to last 10–15 years.[6]

Construction

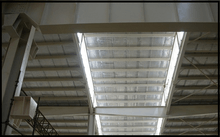

Roofs and attics

When radiant solar energy strikes a roof, heating the shingles, felt paper and roof sheathing by conduction, it causes the underside of the sheathing and the roof framing to radiate heat downward through the attic toward the attic floor. When a radiant barrier is placed between the roofing material and the insulation on the attic floor, much of the heat radiated from the hot roof is reflected back toward the roof and the low emissivity of the underside of the radiant barrier means that very little radiant heat is emitted downwards. This makes the top surface of the insulation cooler than it would have been without a radiant barrier and thus reduces the amount of heat that moves through the insulation into the rooms below.

This is different from the cool roof strategy which reflects solar energy before it heats the roof, but both are means of reducing radiant heat. According to a study by Florida Solar Energy Center,[7] a white tile or white metal cool roof can outperform traditional black shingle roof with a radiant barrier in the attic, but the black shingle roof with radiant barrier outperformed the red tile cool roof.

For installing a radiant barrier under a metal or tile roof, the radiant barrier may be applied directly over the roof sheathing. Then furring strips (1x4s) are applied over the radiant barrier before the metal or tile roof is applied. The furring strips ensure that the radiant barrier faces into a sufficient air space. If an air space is not present or is too small, heat may be able to conduct through the radiant barrier. Since the metal in the radiant barrier is highly conductive, the heat transfer would be by conduction and the heat would not be blocked. According to the US Department of Energy, “Reflective insulation and radiant barrier products must have an air space adjacent to the reflective material to be effective.”[8]

The most common application for a radiant barrier is as a facing for attics. For a traditional shingle roof, radiant barriers may be applied over the rafters or trusses and under the roof decking. This application method has the radiant barrier sheets draped over the trusses of rafters, creating a small air space above with the radiant barrier facing into the entire interior attic space below.[9]

Another method of applying radiant barrier to the roof in new construction is to use a radiant barrier that is pre-laminated to OSB panels or roof sheathing. Manufacturers of this installation method often tout the savings in labor costs in using a product that serves as roof decking and radiant barrier in one.

To apply radiant barrier in an existing attic, a radiant barrier may be stapled to the underside of the roof rafters. This method offers the same benefits as the draped method in that dual air spaces are provided. However, it is essential that the vents be allowed to remain open to prevent moisture from being trapped in the attic. In general, it is preferred to have the radiant barrier applied to the underside of the roof with an air space facing down to prevent the accumulation of dust, preventing the radiant barrier from conducting.[10]

The final method of installing a radiant barrier in an attic is to lay it over the top of the insulation on the attic floor. While this method can be more effective in the winter[11] there are a few potential concerns with this application, which the US Department of Energy[10] and the Reflective Insulation Manufacturers Association International[9] feel the need to address. First, a breathable radiant barrier should always be used here. This is usually achieved by small perforations in the radiant barrier foil. The vapor transmission rate of the radiant barrier should be at least 5 perms, as measured with ASTM E96, and the moisture in the insulation should be checked before installation. Second, the product should meet the required flame spread, which includes ASTM E84 with the ASTM E2599 method. Lastly, this method allows for dust to accumulate over the top surface of the radiant barrier, potentially reducing the efficiency over time.

Energy savings

According to a 2010 study by the Building Envelope Research Program of the Oak Ridge National Laboratory,[12] homes with air-conditioning duct work in the attic in the hottest climate zones, such as in the US Deep South, could benefit the most from radiant barrier interventions, with annual utility bill savings up to $150, whereas homes in milder climates, e.g., Baltimore, could see savings about half those of their southern neighbors. On the other hand, if there are no ducts or air handlers in the attic, the annual savings could be even much less, from about $12 in Miami to $5 in Baltimore. Nevertheless, a radiant barrier may still help to improve comfort and to reduce the peak air-conditioning load.

Shingle temperature

One common misconception regarding radiant barrier is that the heat reflecting off the radiant barrier back to the roof has the potential to increase the roof temperature and possibly damage the shingles. Performance testing by Florida Solar Energy Center[7] demonstrated that the increase in temperature at the hottest part of the day was no more than about 5 degrees F. In fact, this study showed that radiant barrier had the potential to decrease the roof temperature once the sun went down because it prevented heat loss through the roof. RIMA International wrote a technical paper on the subject which included statements collected from large roofing manufacturers, and none said that radiant barrier would in any way affect the warranty of the shingles.[13]

Attic dust accumulation

When laying a radiant barrier over the insulation on the attic floor, it is possible for dust to accumulate on the top side. Many factors like dust particle size, dust composition and the amount of ventilation in the attic affect how dust accumulates and thus the ultimate performance of radiant barrier in the attic. A study by the Tennessee Valley Authority[11] mechanically applied a small amount of dust over a radiant barrier and found no significant effect when testing for performance. However, TVA referenced a previous study which stated that it was possible for the radiant barrier to collect so much dust that its reflectivity could be decreased by nearly half. It is not true that a double-sided radiant barrier on the attic floor is immune to the dust concern. The TVA study[11] also tested a double-sided radiant barrier with black plastic draped on top to simulate heavy dust accumulation, as well as a single-sided radiant barrier with heavy kraft paper on the top. The test indicated that the radiant barrier was not performing, and the small air spaces created between the peaks of the insulation were not sufficient to block radiant heat.

Walls

Radiant barrier may be used as a vented skin around the exterior of a wall.[9] Furring strips are applied to the sheathing to create a vented air space between the radiant barrier and the siding, and vents are used at the top and bottom to allow convective heat to rise naturally to the attic. If brick is being used on the exterior, then a vented air space may already be present, and furring strips are not necessary. Wrapping a house with radiant barrier can result in a 10% to 20% reduction in the tonnage air conditioning system requirement, and save both energy and construction costs.

Floors

Radiant barriers are also quite effective in floor systems above unheated basements and crawl spaces. The radiant barrier may be either stapled below the floor joists, creating a single reflective air space, or between the joists, followed by some type of sheathing. Radiant barrier works extremely well in this application for two reasons.[9] First, a radiant barrier that is not perforated for breathability acts as an excellent vapor barrier. This means that ground moisture will not be able to pass through the radiant barrier and enter the living space. Secondly, the floor is the only part of the building where the heat flow is always down, unlike a roof where the heat would descend during the summer and rise in the winter.[14] When the heat flow is down, 93% of the heat is radiant heat, which is exactly what the radiant barrier is designed to block.

See also

- Aluminized cloth

- Bivouac sack

- Cool Roof

- Emissivity

- Fire proximity suit

- Insulation

- Interior radiation control coating

- Low emissivity

- Reflectivity

- R-value

- Space blanket

- Aluminize

References

- ↑ 1.0 1.1 , Wilkes, MIT, 1939.

- ↑ , Practical Laws and Data on the Condensation of Steam in Covered and Bare Pipes, Paulding, page 2.

- ↑ , Infra Insulation Projects.

- ↑ 4.0 4.1 4.2 , NASA Spinoff Technology 2006.

- ↑ 5.0 5.1 , NASA Spinoff 2004.

- ↑ , US Dept of Energy: Low-E Windows.

- ↑ 7.0 7.1 , FSEC Radiant Barrier Study.

- ↑ , Challenging the Code Status.

- ↑ 9.0 9.1 9.2 9.3 , RIMA International Handbook.

- ↑ 10.0 10.1 , US Dept of Energy: Energy Savers.

- ↑ 11.0 11.1 11.2 , Tennessee Valley Authority Test.

- ↑ , ORNL Radiant Barrier Fact Sheet, 2010.

- ↑ RIMA International: Shingle Study Bulletin.

- ↑ , RIMA International Crawlspace Study Bulletin.

External links

- How a radiant barrier saves energy

- Radiant Barriers: A Question and Answer Primer

- This entry incorporates public domain text originally from the Oak Ridge National Laboratory and the U.S. Department of Energy.

- Radiant Barrier Fact Sheet Department of Energy

- Reflective Insulation Manufacturers Association International