Primus Green Energy

| |

| Private company | |

| Industry | Alternative fuels, Gas-to-liquids |

| Founded | 2007 |

| Headquarters | Hillsborough, NJ, USA |

Key people |

Robert J. Johnsen (CEO) |

Number of employees | ~50 |

| Website | www.primusge.com |

Primus Green Energy is a U.S.-based alternative fuel company that has developed a gas to liquids (GTL) process to produce drop-in gasoline, jet fuel, diesel fuel and organic solvents from a variety of feedstocks, including natural gas, biomass, municipal solid waste and others. Primus has a fully operational, 100,000 gallon-per-year demonstration plant at its Hillsborough facility that converts natural gas directly into 90+-octane gasoline.[1]

History

In 2007, Primus Green Energy began development of its proprietary syngas to gasoline plus (STG+) technology, a gas-to-liquids process that converts natural gas, other gaseous hydrocarbons or gasified biomass into drop-in fuels such as gasoline, diesel or jet fuel.[2] That same year, Primus received an initial investment from IC Green Energy, the renewable energy arm of Israel Corp., Israel’s largest holding company.

Primus completed its pilot plant in 2010, which consists of two units: a hydrocarbon gasifier/reformer to produce syngas and a STG+ unit to convert that syngas directly into drop-in fuels. In 2011, Primus produced its first liter of biomass-derived gasoline at its pilot plant using premium wood pellets as a feedstock, and a third-party laboratory verified that the gasoline met or exceeded all ASTM standards for conventional gasoline.[3]

In 2012, Primus broke ground on a full-scale single-loop demonstration plant in Hillsborough, N.J., holding a dedication ceremony to commemorate the event. Several notable New Jersey politicians, including former Gov. James Florio, U.S. Rep. Leonard Lance, Board of Public Utilities Commissioner Joseph Fiordaliso and New Jersey Department of Environmental Protection Assistant Commissioner Robert Marshall, spoke at the dedication ceremony. The ceremony also marked the first time that 93-octane gasoline produced via Primus’ STG+ process was used to fuel the test drive of a car.[4]

Primus commissioned its full-scale demonstration plant in October 2013. The plant, which produces 100,000 gallons of 90+-octane gasoline from natural gas per year, is a scaled down version of the company’s first commercial plant. Primus held another ceremony to commemorate the event, with the speaking lineup being headlined by N.J. Lt. Gov. Kim Guadagno, N.J. Sen. Christopher Bateman and Israel Corporation President and CEO Nir Gilad.[5]

Technology

Primus’ core technology, STG+, is a proprietary thermochemical process to convert natural gas, gasified biomass, municipal solid waste or other gaseous hydrocarbons into drop-in fuels such as gasoline, diesel fuel, jet fuel and organic solvents. The fuels produced through the STG+ process are drop-in substitutes, which means that they require no modifications to engines, fuel delivery infrastructure or consumer behavior. The STG+ process consists of three basic steps: syngas generation, scrubbing and the STG+ process.[6]

For the first step, STG+ utilizes syngas produced via other technologies as a feedstock. This syngas can be produced through several commercially available technologies and from a wide variety of feedstocks, including natural gas, biomass and municipal solid waste. Natural gas and other methane-rich gases, including those produced from municipal waste, are converted into syngas through methane reforming technologies such as steam methane reforming and auto-thermal reforming. Biomass gasification technologies utilize fixed bed or fluidized bed reactors.[7]

After the syngas has been produced, it is scrubbed to remove impurities, such as sulfur and carbon dioxide. This step utilizes an industrial-grade scrubber that is commonly used throughout the manufacturing industry.[8]

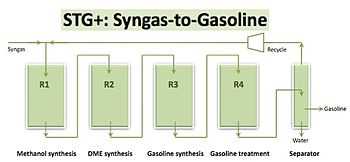

The final step is the STG+ process, which uses four separate reactors. In the first reactor, syngas is converted into methanol. The second reactor converts the methanol into dimethyl ether. The third reactor produces heavy gasoline, which has an undesirable durene content. The fourth reactor cleans the heavy gasoline by converting durenes into other compounds, with a finished transportation fuel being produced at the end. The end product depends partly on the catalysts used in the four-reactor system. Primus uses standard catalysts similar to those used in other gas-to-liquids technologies, specifically in methanol to gasoline processes.[9]

Based on data from Primus’ pilot and demonstration plants, the STG+ process converts approximately one MMBtu of natural gas into more than five gallons of 90+-octane gasoline, which is one of the highest process efficiencies in the industry.

In Q4 2014, Primus’ demonstration plant achieved 720 hours of continuous operation. The company also released results of an independent engineer’s report prepared by E3 Consulting LLC, which concluded that Primus’ technology exceeded expectations during plant operation.

Primus has also received independent verification of gasoline quality, process efficiency and system economics from Bureau Veritas, an independent, multinational inspection, sampling and testing company. Primus’ gasoline was found to meet or exceed all ASTM specifications, the gold standard used to measure gasoline quality.[10]

At commercial scale, these process efficiencies would lead to lower capital and operating expenditures in comparison with those of standard gas to liquids facilities. Additionally, in comparison with traditional gas to liquids technologies, which include Fischer-Tropsch and methanol to gasoline, Primus’ STG+ process can produce a greater variety of end products. Preliminary studies suggest that the STG+ process is more energetically efficient and the highest yielding methanol to gasoline process.[11][12][13]

In early 2014, the U.S. Patent and Trademark Office (USPTO) allowed patents covering Primus’ single-loop STG+ technology, confirming the novelty of the process.[14] Primus has also secured additional patents from the USPTO regarding its STG+ technology.[15] [16] [17] [18]

Commercialization

Primus recently commissioned its first full-scale demonstration plant in Hillsborough, N.J., which produces more than 100,000 gallons of drop-in gasoline annually from natural gas.[19]

Primus is now working toward a commercial-scale facility that will produce fuels directly from natural gas or from syngas provided by a third party. The commercial plant is producing an approximately 27.8 million gallons of fuel annualized rate per year. The company has announced that it expects to break ground on its first commercial plant in the second half of 2014.[20]

Partnerships

Primus has several research and technology partnerships in place. Through its participation as an industry collaborator to the Northeast Woody/Warm-season Biomass Consortium (NEWBio), Primus Green Energy has partnered with the U.S. Department of Agriculture. NEWBio was awarded a $10 million grant by the USDA to research the development of sustainable biomass ecosystems for the biofuel industry.[21] Primus’ technology suppliers and consultants include Honeywell, a global technology and instrumentation provider.

In July 2014, Primus announced the signing of a Memorandum of Understanding with Lexington Group International to deploy small-scale STG+ units to convert flare gas directly into drop-in transportation fuels at oilfields on-site.

IC Green Energy is the primary investor in Primus Green Energy, investing over $63 million since 2007.[22]

See also

- Alternative fuel

- Biomass

- Biofuel

- Biomass to liquid

- Natural gas

- Gas to liquids

- Syngas to gasoline plus

References

- ↑ http://www.primusge.com/?press-release=primus-green-energy-demonstration-plant-operating-results-confirm-compelling-performance-and-economics-according-to-independent-engineers-report

- ↑ http://www.forbes.com/sites/christopherhelman/2013/06/05/should-natural-gas-powered-cars-run-on-cng-lng-or-gasoline/

- ↑ http://money.cnn.com/video/technology/2012/07/05/bsg-biogas-primus-wood.cnnmoney/

- ↑ http://domesticfuel.com/2012/06/27/car-drives-on-primus-new-biomass-natural-gas-fuel/

- ↑ http://www.primusge.com/?press-release=primus-green-energy-commissions-its-up-to-100000-gallon-per-year-alternative-fuel-plant

- ↑ Methanol to Gasoline (MTG) Production of Clean Gasoline from Coal ExxonMobil, December 2009. Retrieved: 30 April 2013.

- ↑ http://www.primusge.com/wp-content/uploads/2013/03/White-paper-STG+-FINAL_smaller.pdf

- ↑ http://www.primusge.com/wp-content/uploads/2013/03/White-paper-GTL-Comparison_FINAL.pdf

- ↑ http://www.wpi.edu/Pubs/E-project/Available/E-project-022813-170709/unrestricted/Primus_Green_Energy_IQP.pdf

- ↑ http://www.primusge.com/?press-release=primus-green-energy-demonstration-plant-operating-results-confirm-compelling-performance-and-economics-according-to-independent-engineers-report

- ↑ Comparison of STG+ With Other GTL Technologies Primus Green Energy, April 2013. Retrieved: 29 April 2013.

- ↑ D. Peterson and S. Haase (July 2009). Market Assessment of Biomass Gasification and Combustion Technology for Small- and Medium-Scale Applications (Report). National Renewable Energy Laboratory. p. 9. Retrieved 30 April 2013.

- ↑ Richard C. Baliban, Josephine A. Elia, and Christodoulos A. Floudas "Novel Natural Gas to Liquids Processes: Process Synthesis and Global Optimization Strategies" in American Institute of Chemical Engineers Journal, 2013, AIChE. doi:10.1002/aic.13996

- ↑ http://www.primusge.com/?press-release=primus-green-energy-patent-application-for-gas-to-liquids-technology-allowed-by-uspto

- ↑ Single loop multistage fuel production US8686206 — US Patents — 1-Apr-2014 — PRIMUS GREEN ENERGY INC Synthetic fuels are produced from synthesis gas in a four-stage reactor system with a single recycle loop providing the requisite thermal capacity to moderate the high heat release of the reactions and to provide the reactants and reaction environments for the efficient operation of the process. The first stage...

- ↑ Fuel composition US8722951 — US Patents — 13-May-2014 — PRIMUS GREEN ENERGY INC This invention relates to fuel compositions for use in combustion engines, such as for motor vehicle and aircraft usage. The fuel composition contains at least 99.5% of aromatic hydrocarbons and paraffinic hydrocarbons. The composition also preferably contains no lead, no multi-ring compound only single ring compounds...

- ↑ Novel fuel composition US20140018587 — US Applications — 16-Jan-2014 — PRIMUS GREEN ENERGY INC This invention relates to fuel compositions for use in combustion engines, such as for motor vehicle and aircraft usage. The fuel composition contains at least 99.5% of aromatic hydrocarbons and paraffinic hydrocarbons. The composition also preferably contains no lead, no multi-ring compound only single ring compounds...

- ↑ Fuel composition US8569554 — US Patents — 29-Oct-2013 — PRIMUS GREEN ENERGY INC This invention relates to fuel compositions for use in combustion engines, such as for motor vehicle and aircraft usage. The fuel composition contains at least 99.5% of aromatic hydrocarbons and paraffinic hydrocarbons. The composition also preferably contains no lead, no multi-ring compound only single ring compounds...

- ↑ http://www.primusge.com/?press-release=primus-green-energy-commissions-its-up-to-100000-gallon-per-year-alternative-fuel-plant

- ↑ Primus Green Energy's Johnsen discusses competition in alternative fuels market E&E TV, 17 April 2013. Retrieved: 30 April 2013.

- ↑ http://www.newbio.psu.edu/partners.asp

- ↑ http://www.israelcorp.com/Holdings/Energy/ICGreenEnergy.aspx