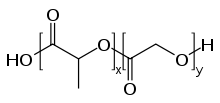

PLGA

PLGA or poly(lactic-co-glycolic acid) is a copolymer which is used in a host of Food and Drug Administration (FDA) approved therapeutic devices, owing to its biodegradability and biocompatibility. PLGA is synthesized by means of ring-opening co-polymerization of two different monomers, the cyclic dimers (1,4-dioxane-2,5-diones) of glycolic acid and lactic acid. Polymers can be synthesized as either random or block copolymers thereby imparting additional polymer properties. Common catalysts used in the preparation of this polymer include tin(II) 2-ethylhexanoate, tin(II) alkoxides, or aluminum isopropoxide. During polymerization, successive monomeric units (of glycolic or lactic acid) are linked together in PLGA by ester linkages, thus yielding a linear, aliphatic polyester as a product.[1]

Depending on the ratio of lactide to glycolide used for the polymerization, different forms of PLGA can be obtained: these are usually identified in regard to the molar ratio of the monomers used (e.g. PLGA 75:25 identifies a copolymer whose composition is 75% lactic acid and 25% glycolic acid). The crystallinity of PLGAs will vary from fully amorphous to fully crystalline depending on block structure and molar ratio. PLGAs typically show a glass transition temperature in the range of 40-60 °C. PLGA can be dissolved by a wide range of solvents, depending on composition. Higher lactide polymers can be dissolved using chlorinated solvents whereas higher glycolide materials will require the use of fluorinated solvents such as HFIP.

PLGA degrades by hydrolysis of its ester linkages in the presence of water. It has been shown that the time required for degradation of PLGA is related to the monomers' ratio used in production: the higher the content of glycolide units, the lower the time required for degradation as compared to predominantly lactide materials. An exception to this rule is the copolymer with 50:50 monomers' ratio which exhibits the faster degradation (about two months). In addition, polymers that are end-capped with esters (as opposed to the free carboxylic acid) demonstrate longer degradation half-lives.{Samadi N, Abbadessa A, Di Stefano A, van Nostrum CF, Vermonden T, Rahimian S, Teunissen EA, van Steenbergen MJ, Amidi M, and Hennink WE. The effect of lauryl capping group on protein release and degradation of poly(D,L-lactic-co-glycolic acid) particles. Journal of Controlled Release 172, 436-443, 2013.}

PLGA has been successful as a biodegradable polymer because it undergoes hydrolysis in the body to produce the original monomers, lactic acid and glycolic acid. These two monomers under normal physiological conditions, are by-products of various metabolic pathways in the body. Since the body effectively deals with the two monomers, there is minimal systemic toxicity associated with using PLGA for drug delivery or biomaterial applications. Also, the possibility to tailor the polymer degradation time by altering the ratio of the monomers used during synthesis has made PLGA a common choice in the production of a variety of biomedical devices, such as, grafts, sutures, implants, prosthetic devices, surgical sealant films, micro and nanoparticles. Specific examples of use include:

- successful in the delivery of amoxicillin for the treatment listeriosis (treatment of Listeria monocytogenes infection).

- a commercially available drug delivery device using PLGA is Lupron Depot for the treatment of advanced prostate cancer.

- prophylactic delivery of the antibiotic vancomycin into the central nervous system when applied to the surface of the brain after brain surgery[2]

References

- ↑ Astete, C. E. and Sabliov, C. M. (2006). "Synthesis and characterization of PLGA nanoparticles". Journal of Biomaterials Science - Polymer Edition 17 (3): 247–289. doi:10.1163/156856206775997322. PMID 16689015.

- ↑ "Dissolvable Plastic Nanofibers could Treat Brain Infections". Scientific Computing (Advantage Business Media). August 28, 2013. Retrieved September 3, 2013.

See also

Other biodegradable polymers:

- polycaprolactone

- polyglycolide

- polylactic acid

- poly-3-hydroxybutyrate

External links

- Information on Polyglactin 910 / PGLA Sutures

- Farazuddin, Mohammad*; Chauhan, Arun*; Khan, Raza M.M.†; Owais, Mohammad* (2010-08-05). "Amoxicillin bearing microparticles: potential in treatment of Listeria monocytogenes infection in Swiss albino mice". Bioscience Reports (* Interdisciplinary Biotechnology Unit, Aligarh Muslim University, Aligarh-202002, India; and, † Department of Chemistry, Aligarh Muslim University, Aligarh-202002, India.: Biochemical Society) 31 (4): 265–72. doi:10.1042/BSR20100027. PMID 20687896. Retrieved 2013-03-03.