PDCA

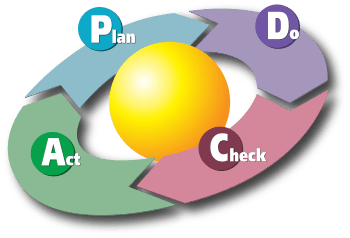

PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continuous improvement of processes and products. It is also known as the Deming circle/cycle/wheel, Shewhart cycle, control circle/cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition." This emphasis on observation and current condition has currency with Lean manufacturing/Toyota Production System literature.[1]

Meaning

- PLAN

- Establish the objectives and processes necessary to deliver results in accordance with the expected output (the target or goals). By establishing output expectations, the completeness and accuracy of the spec is also a part of the targeted improvement. When possible start on a small scale to test possible effects.

- DO

- Implement the plan, execute the process, make the product. Collect data for charting and analysis in the following "CHECK" and "ACT" steps.

- CHECK

- Study the actual results (measured and collected in "DO" above) and compare against the expected results (targets or goals from the "PLAN") to ascertain any differences. Look for deviation in implementation from the plan and also look for the appropriateness and completeness of the plan to enable the execution, i.e., "Do". Charting data can make this much easier to see trends over several PDCA cycles and in order to convert the collected data into information. Information is what you need for the next step "ACT".

- ACT

- If the CHECK shows that the PLAN that was implemented in DO is an improvement to the prior standard (baseline), then that becomes the new standard (baseline) for how the organization should ACT going forward (new standards are enACTed). If the CHECK shows that the PLAN that was implemented in DO is not an improvement, then the existing standard (baseline) will remain in place. In either case, if the CHECK showed something different than expected (whether better or worse), then there is some more learning to be done... and that will suggest potential future PDCA cycles. Note that some who teach PDCA assert that the ACT involves making adjustments or corrective actions... but generally it would be counter to PDCA thinking to propose and decide upon alternative changes without using a proper PLAN phase, or to make them the new standard (baseline) without going through DO and CHECK steps.

Note: Some modern trainers now also refer to the "A" as "Adjust". This helps trainees to understand that the 4th step is more about adjusting/correcting the difference between the current state and the planned state instead of thinking that the "A" is all about action and implementation (which actually happens in the second ("D") stage). However, it also loses the essential point of enACTing new standards (new baselines), which is the essence of continuous improvement. For those who prefer "Adjust" be aware that the thing being adjusted are the standards. Those adjusted, or enACTed, standards will now inform and guide the next "Planning" phase. Sometimes "Adjust" may lead some to believe that it is the "Plan" itself that is being adjusted. The new plan may well look a bit different, but it is now because it was formulated while resting on a new set of standards. This is subtle, but important. The reason for the dispute may be this. In a manufacturing environment quantification that lends itself easily to the statistics dear to Deming's heart are more straight forward compared to many jobs in, say, the IT business or sales, where there may not be an exact, quantifiable standard as much as fluffier models, concepts or principles.

About

PDCA was made popular by Dr W. Edwards Deming, who is considered by many to be the father of modern quality control; however, he always referred to it as the "Shewhart cycle". Later in Deming's career, he modified PDCA to "Plan, Do, Study, Act" (PDSA) because he felt that "check" emphasized inspection over analysis.

The concept of PDCA is based on the scientific method, as developed from the work of Francis Bacon (Novum Organum, 1620). The scientific method can be written as "hypothesis"–"experiment"–"evaluation" or plan, do and check. Shewhart described manufacture under "control"—under statistical control—as a three-step process of specification, production, and inspection.[3] He also specifically related this to the scientific method of hypothesis, experiment, and evaluation. Shewhart says that the statistician "must help to change the demand [for goods] by showing [...] how to close up the tolerance range and to improve the quality of goods."[4] Clearly, Shewhart intended the analyst to take action based on the conclusions of the evaluation. According to Deming, during his lectures in Japan in the early 1950s, the Japanese participants shortened the steps to the now traditional plan, do, check, act.[5] Deming preferred plan, do, study, act because "study" has connotations in English closer to Shewhart's intent than "check".[6]

A fundamental principle of the scientific method and PDCA is iteration—once a hypothesis is confirmed (or negated), executing the cycle again will extend the knowledge further. Repeating the PDCA cycle can bring us closer to the goal, usually a perfect operation and output.[6]

Another fundamental function of PDCA is the "hygienic" separation of each phase, for if not properly separated measurements of effects due to various simultaneous actions (causes) risk becoming confounded.[7]

PDCA (and other forms of scientific problem solving) is also known as a system for developing critical thinking. At Toyota this is also known as "Building people before building cars."[8] Toyota and other Lean companies propose that an engaged, problem-solving workforce using PDCA is better able to innovate and stay ahead of the competition through rigorous problem solving and the subsequent innovations. This also creates a culture of problem solvers using PDCA and creating a culture of critical thinkers.

In Six Sigma programs, the PDCA cycle is called "define, measure, analyze, improve, control" (DMAIC). The iterative nature of the cycle must be explicitly added to the DMAIC procedure.

Deming continually emphasized iterating towards an improved system, hence PDCA should be repeatedly implemented in spirals of increasing knowledge of the system that converge on the ultimate goal, each cycle closer than the previous. One can envision an open coil spring, with each loop being one cycle of the scientific method - PDCA, and each complete cycle indicating an increase in our knowledge of the system under study. This approach is based on the belief that our knowledge and skills are limited, but improving. Especially at the start of a project, key information may not be known; the PDCA—scientific method—provides feedback to justify our guesses (hypotheses) and increase our knowledge. Rather than enter "analysis paralysis" to get it perfect the first time, it is better to be approximately right than exactly wrong. With the improved knowledge, we may choose to refine or alter the goal (ideal state). Certainly, the PDCA approach can bring us closer to whatever goal we choose.[9]

Rate of change, that is, rate of improvement, is a key competitive factor in today's world. PDCA allows for major "jumps" in performance ("breakthroughs" often desired in a Western approach), as well as Kaizen (frequent small improvements). In the United States a PDCA approach is usually associated with a sizable project involving numerous people's time, and thus managers want to see large "breakthrough" improvements to justify the effort expended. However, the scientific method and PDCA apply to all sorts of projects and improvement activities.[10]

See also

- Business process improvement

- COBIT

- Decision cycle

- DMAIC

- Lean manufacturing

- Learning cycle

- Lesson study

- OODA loop

- Performance management

- Quality management

- Quality storyboard

- Robert S. Kaplan (closed loop management system)

- Six sigma

- Theory of constraints

- Total security management

References

- ↑ Rother, Mike (2010). "6". Toyota Kata. New York: MGraw-Hill. ISBN 978-0-07-163523-3.

- ↑ "Taking the First Step with PDCA". 2 February 2009. Retrieved 17 March 2011.

- ↑ Shewhart (1939), p. 45

- ↑ Shewhart (1939), p. 48

- ↑ Deming, p. 88

- ↑ 6.0 6.1 Moen, Ronald; Norman, Clifford. "Evolution of the PDCA Cycle" (PDF). Retrieved 1 October 2011.

- ↑ Berengueres, Jose (2007). The toyota production system re-contextualized. Tokyo. p. 74. ISBN 1847534775.

- ↑ Liker, Jeffrey (2004). "1". The Toyota Way. McGraw-Hill. ISBN 0-07-139231-9.

- ↑ Rother, Mike (2009), Toyota Kata, McGraw-Hill, p. 160

- ↑ Rother, Mike (2009), Toyota Kata, McGraw-Hill, p. 76

Further reading

- Shewhart, Walter Andrew (1980). Economic Control of Quality of Manufactured Product/50th Anniversary Commemorative Issue. American Society for Quality. ISBN 0-87389-076-0.

- The Improvement Guide: A Practical Approach to Enhancing Organizational Performance, 2nd Edition by Gerald J. Langley, Ronald Moen, Kevin M. Nolan, Thomas W. Nolan, Clifford L. Norman, Lloyd P. Provost Published by Jossey-Bass ISBN 978-0-470-19241-2

- Shewhart, Walter Andrew (1939). Statistical Method from the Viewpoint of Quality Control. New York: Dover. ISBN 0-486-65232-7.

- Deming, W. Edwards (1986). Out of the Crisis. MIT Center for Advanced Engineering Study. ISBN 0-911379-01-0.

External links

| Wikimedia Commons has media related to PDCA. |