M1919 Browning machine gun

| Gun, Machine, Caliber .30, Browning, M1919A4 | |

|---|---|

| |

| Type | Medium machine gun |

| Place of origin | United States |

| Service history | |

| In service | 1919–present |

| Used by | See Users |

| Wars |

Banana Wars World War II Korean War First Indochina War Congo Crisis Vietnam War Rhodesian Bush War Cambodian Civil War other conflicts |

| Production history | |

| Designed | 1919 |

| Produced | 1919–45 |

| Number built | ~5 million |

| Variants | A1; A2; A3; A4; A5; A6; M37 and AN/M2 |

| Specifications | |

| Weight | 31 lb (14 kg) (M1919A4) |

| Length |

|

| Barrel length | 24 in (610 mm) |

|

| |

| Cartridge | |

| Caliber | Various |

| Action | Recoil-operated/short-recoil operation |

| Rate of fire | 400–600 round/min (1200–1500 for AN/M2 variant) |

| Muzzle velocity | 2,800 ft/s (850 m/s) |

| Effective firing range | 1,500 yd (1,400 m) (maximum effective range) |

| Feed system | 250-round belt |

The M1919 Browning is a .30 caliber medium machine gun widely used during the 20th century, especially during World War II, the Korean War, and the Vietnam War. An air-cooled development of the standard US machine gun of World War I, the John M. Browning-designed M1917, the M1919 saw service as a light infantry, coaxial, mounted, aircraft, and anti-aircraft machine gun by the U.S. and many other countries. Although it began to be superseded by newer designs, such as the M60, in the later half of the century, it remained in use in many North Atlantic Treaty Organization (NATO) countries and elsewhere for much longer.

The M1919 is very similar in design to the larger Browning-designed .50 caliber (12.7mm) M2 Machine Gun, especially in its "heavy-barrel" or HB version, still in NATO service. Many M1919s were rechambered for the new 7.62×51mm NATO round and served into the 1990s, as well as up to the present day in some countries. The United States Navy also converted many to 7.62mm NATO, and designated them Mk 21 Mod 0; they were commonly used on river craft in the 1960s and 1970s in Vietnam.

Operation

.jpg)

Loading

The M1919 originally fired the .30 cal M1906 (30-06) ball cartridge, and later the .30 caliber M2 ball cartridge, contained in a woven cloth belt, feeding from left to right. A metal M1 link was later adopted, forming a "disintegrating" belt.

Loading was accomplished by inserting the pull tab on the ammunition belt from the left side of the gun - either metal links or metal tab on cloth belts - until the belt-holding pawl at the entrance of the feed way grabbed the belt and held it in place. The cocking handle was then pulled back with the palm of the hand facing up, and then released. This advanced the first round of the belt in front of the bolt for the extractor/ejector on the bolt to grab the first cartridge. The cocking handle was pulled and released a second time. This removed the first cartridge from the belt, advanced the next round into position to be grabbed and moved the first round down into the chamber of the barrel ready for firing.

As the bolt went into battery, the extractor grabbed the next round on the belt that was advanced and was resting in the feedway waiting to be loaded. Every time the gun fired a single shot, the gun performed the sequence of extracting and ejecting the spent round as the bolt came rearward, loading the next round to be fired into the barrel, advancing the belt, grabbing the next round in preparation for loading, then chambering it as the bolt came forward again under tension from the spring. If the trigger was held down, the gun would continue to fire in full automatic, repeating the sequence over and over until stopped.

The gun's original design was as a water-cooled machine gun (see the M1917 Browning machine gun). When it was decided to try to lighten the gun and make it air-cooled, its design as a gun that fires from the closed bolt created a potentially dangerous situation. If the gun was very hot from prolonged firing, the cartridge ready to be fired could be resting in a red hot barrel, causing the propellant in the cartridge to heat up to the point that it would ignite on its own without warning. With each further shot heating the barrel even more as this happened, the gun would continue to fire and become uncontrollable until the ammunition ran out, since the trigger was not what was causing the gun to fire in this situation. This is known as a cook-off, and was the reason gunners were taught to cock the gun with the palm facing up, so that in the event of a cook-off, their thumb wouldn't be dislocated by the reciprocating charge handle. Gunners were trained to manage the barrel heat by firing in controlled bursts of three to five rounds, with a delay between bursts to delay its heating. Most other machine gun designs would be fired in the same way, even though most feature quick change barrels and fire from an open bolt, two features that make air-cooled machine guns capable of sustained fire, and features that the M1919 design lacked.

Firing

When the gun was ready to fire, a round would be in the chamber and the bolt and barrel group would be locked together, with the locking block at the rear of the bolt. When the rear of the trigger was pivoted upwards by the operator, the front of the trigger tipped downward, pulling the sear out of engagement with the spring-loaded firing pin, allowing it to move forward and strike the primer of the cartridge.

As the assembly of bolt, barrel and barrel extension recoiled to the rear of the gun upon firing, the locking block was drawn out of engagement by a cam in the bottom of the gun's receiver. The recoiling barrel extension struck the "accelerator" assembly, a half-moon shaped spring-loaded piece of metal pivoting from the receiver below the bolt and behind the barrel extension. The tips of the accelerator's two curving fingers engaged the bottom of the bolt and caused it to move rapidly to the rear. The extractor-ejector was a mechanism that pivoted over the front of the bolt, with a claw that gripped the base of the next round in the belt. A camming track in the left side of the receiver caused this to move down as the bolt moved back, lowering the next round down on top of the fired case, pushing it straight down out of the extraction grooves of the bolt face through the ejection port. A spring in the feed tray cover pushed the extractor-ejector down onto the next round, so if the feed tray cover was opened, the extractor-ejector would be pulled upwards if the belt needed to be removed.

The belt feed lever was connected to the belt feeding pawl at the front end, had a cam pin at the rear end which ran through a track in the top of the bolt, and a pin in the feed tray cover acted as the pivot between the two ends. The rearward movement of the bolt caused the rear end of the feed lever to pull to the right, causing the feeding pawl at the other end to move left over the belt. The pawl would pull the belt further to the right as the bolt came forward again, also sending the loose M1 link of the previous round to be taken out of the belt to fly out the right side of the receiver. A recoil buffer tube extended from the back of the receiver to make the cycle of the bolt smoother than previous designs, to absorb some of the recoil of the bolt, and formed a place for the pistol grip to be installed.

Except for the M1919A6, all other variants had to be mounted on a tripod or other type of mount to be used effectively. The tripod used by infantry allowed traverse and elevation. To aim the gun along its vertical axis, the adjustment screw needed to be operated. This allowed the gun to be pointed upwards or downwards, with free traverse to either side. The gun was aimed using iron sights, a small folding post at the front end of the receiver and a rear aperture sight on a sliding leaf with range graduations from 200 to 1,800 meters in 200 meter increments. When folded down, the aperture formed a notch that could be used to fire the gun immediately without flipping up the leaf. The rear sight also had windage adjustment with a dial on the right side.

Operational use

Infantry

As a company or battalion support weapon, the M1919 required at least a two-man machine gun team. But, in practice, four men were normally involved: the gunner (who fired the gun and when advancing carried the tripod and box of ammo), the assistant gunner (who helped feed the gun and carried the gun, and box of spare parts and tools), and two ammunition carriers.[1] The original idea was to allow the gun to be more easily packed for transport, and featured a light barrel and bipod when first introduced as the M1919A1. Unfortunately, it quickly became clear that the gun was too heavy to be easily moved, while at the same time too light for sustained fire. This led to the M1919A2, which included a heavier barrel and tripod, and could be continuously fired for longer durations.

The M1919A4 weighed about 31 pounds (14 kg), and was ordinarily mounted on a lightweight, low-slung tripod for infantry use. Fixed vehicle mounts were also employed. It saw wide use in World War II mounted on jeeps, armored personnel carriers, tanks, and amphibious vehicles. The M1919A4 played a key role in the firepower of the World War II US Army. Each infantry company normally had a weapons platoon in addition to its other organic units. The presence of M1919A4 weapons in the weapons platoon gave company commanders additional automatic fire support at the company level, whether in the assault or on defense.[2]

The A5 was an adaptation of the A4 with a forward mounting point to allow it to be mounted in tanks and armored cars. This, along with the M37 and the Browning M2 machine gun, was the most common secondary armament during World War II for the Allies.

Another version of the M1919A4, the M1919A6, was an attempt to make the weapon into a light machine gun by attaching a buttstock and lighter barrel—4 lb (1.8 kg) instead of 7 lb (3.2 kg). The A6 version was in fact heavier than the A4 without its tripod, at 32 lb (15 kg), though its bipod made for faster deployment and enabled the machine gun team to dispense with one man (the tripod bearer).[3] The A6 version saw increasing service in the latter days of World War II and was used extensively in Korea. The A6 variant had a folding bipod mounted on the front of the gun, a sheet-metal buttstock, carrying handle, and a tapered barrel. While the modifications were intended to make the weapon more useful as a squad light machine gun, it was a stopgap solution, as the M1919A6 was heavier than the old Lewis gun of World War I, let alone the contemporary light machine guns of other nations.

The M1919A6 was an attempt to combine the portability and low profile of the M1918 BAR with the sustained firing capability of the M1919A4. The M1919A4 was given a lighter barrel, buttstock, pistol grip, carrying handle, flash suppressor, and bipod to achieve the conversion. Even though it was reliable, it proved impractical for combat. While the 31 lb (14 kg) M1919A4 had a crew of two or more to carry the gun and the 14 lb (6.4 kg) tripod, one M1919A6 gunner was expected to carry and deploy the 32.5 lb (14.7 kg) gun by themself.[4]

During the Second World War, two additional variants of the M1919 were adopted by the US military. One version was the coaxial M37 variant, with the ability to feed from either the left or the right of the weapon. The M37 also featured an extended charging handle similar to those on the M1919A4E1 and A5. A trial variant fitted with special sighting equipment was designated M37F.

In the late 1950s, a M1919 designed for remote firing via a solenoid trigger was developed for use in the XM1/E1 armament subsystem was designated M37C. The US Navy later converted a number of M1919A4s to 7.62 mm NATO chambering and designated them Mk 21 Mod 0; some of these weapons were employed in Vietnam in riverine warfare patrols.

From the 1960s until the 1990s, the Israel Defense Forces (IDF) used ground tripod and vehicle-mounted M1919A4 guns converted to 7.62 mm NATO on many of their armored vehicles and M3 personnel carriers. Israel developed a modified link for these guns due to feeding problems with the original US M1 link design. The improved Israeli link worked with .30 caliber, 7.62mm NATO and 8×57mm cartridges.

Aircraft

With assistance from firearms engineers at Fabrique Nationale de Herstal,[5] Belgium, the Model 1919 was completely re-engineered into the .30 caliber M2 AN (Army-Navy) aircraft machine gun (see #AN/M2). The .30 in M2 AN Browning was widely adopted as both a fixed (offensive) and flexible (defensive) weapon on aircraft. Aircraft machine guns required light weight, firepower, and reliability, and achieving all three goals proved a difficult challenge, with the mandate for a closed bolt firing cycle to enable the gun to be safely and properly synchronized for fixed-mount, forward-aimed guns firing through a spinning propeller, a necessity on many single-engined fighter aircraft designs through to nearly the end of World War II. The receiver walls and operating components of the M2 were made thinner and lighter, and with air cooling provided by the speed of the aircraft, designers were able to reduce the barrel's weight and profile. As a result, the M2 weighed two-thirds that of the 1919A4, and the lightened mechanism gave it a rate of fire approaching 1,200 rpm (some variants could achieve 1,500 rpm),[5] a necessity for engaging fast-moving aircraft. The M2's feed mechanism had to lift its own loaded belt out of the ammunition box and feed it into the gun, equivalent to a weight of 11 lb (5 kg).[6] In Ordnance circles, the .30 M2 AN Browning had the reputation of being the most difficult-to-repair weapon in the entire US small arms inventory.[6]

The M2 also appeared in a twin-mount version which paired two M2 guns with opposing feed chutes in one unit for operation by a single gunner, with a combined rate of fire of 2,400 rpm. All of the various M2 models saw service in the early stages of World War II, but were phased out beginning in 1943, as hand-trained defensive machine guns became obsolete for air warfare (the .50 in/12.7 mm M2 Browning and 20 mm automatic cannon had replaced the .30 in as offensive air armament as well). The .30 in M2 aircraft gun was widely distributed to other US allies during and after World War II, and in British and Commonwealth service saw limited use as a vehicle-mounted anti-aircraft or anti-personnel machine gun.[7]

Other calibers

The same basic weapon was also chambered for the British .303 round, and was used as a basic fighter aircraft gun in fighters such as the Supermarine Spitfire until the widespread introduction of the larger caliber Hispano-Suiza HS.404 cannon, and throughout the war in bombers.

Similar versions for a variety of European calibers were delivered by the Belgian gun maker FN (Fabrique Nationale), notably German-standard 8×57mm Mauser which was widely used in Eastern Europe; and by Swedish gun maker Carl Gustaf SGF in 6.5×55mm and 8×63mm calibers.

Argentina used Colt-manufactured guns chambered for the standard Argentine 7.65x53mm cartridge.

US-manufactured M1919s were converted to the 7.62×54mmR cartridge by both the People's Republic of China and North Vietnam in order to use captured guns with their standard machine gun ammunition. The standard links and belts for the M1919 were retained. Similar conversions are available on the US commercial market for recreational shooters to take advantage of cheap surplus 7.62×54mmR ammunition.

On Soviet aircraft

The .303 variant equipped the Hawker Hurricanes delivered to Soviet Air Forces, during the Great Patriotic War. Soviet airmen compared them to Soviet ShKAS in terms of reliability: "But they often failed due to dust," recalled pilot Nikolai G. Golodnikov. "We tackled the problem gluing percale on all the machine-gun holes, and when you opened fire, bullets went right through. The machine guns became reliable then. They were of low efficiency when fired from distances of 150-300m."[8]

Production

The M1919 was manufactured during World War II by many different companies in the USA, including the Saginaw Steering Gear division of the General Motors Corporation, Buffalo Arms Corporation, and Rock Island Arsenal. In the UK, production was chiefly by BSA. Originally unit priced at $667 each, mass production lowered the price to $141.44.

Variants and derivatives

M1919 variants

In total there were six variants of the basic M1919 machine gun. The original M1919 featured a relatively heavy barrel, attempting to match the sustained fire capability of contemporary water-cooled machine guns. The M1919A1 featured a lighter barrel and a bipod. The M1919A2 was another lightweight development specifically for mounted cavalry units, utilizing a shorter barrel and a special tripod (though it could be fitted to either the M1917 or M2 tripods). This weapon was designed to allow greater mobility to cavalry units over the existing M1917 machine gun. The M1919A2 was used for a short period between World War I and World War II after the cavalry had converted from horses to wheeled and tracked vehicles. The M1919A3, an improved version of the M1919A2, was also developed.

M1919A4

However, by and large the most common variant of the series was the M1919A4. The M1919A4 was used in both fixed and flexible mounts, by infantry and on vehicles. It was also widely exported after World War II and continues to be used in small numbers around the world. Two variants were developed specifically for vehicular use, the M1919A5, with an extended charging handle, and the M1919A4E1, a sub-variant of the M1919A4 refitted with an extended charging handle.

M1919A6

The M1919A6 was an attempt to provide US forces with a more portable light machine gun, similar to the German MG 34 and MG 42 machine guns that they were facing. The M1919A6 had a metal buttstock assembly that clamped to the backplate of the gun, and a front barrel bearing that incorporated both a muzzle booster and a bipod similar to that used on the M1918 Browning Automatic Rifle (BAR). A lighter barrel than that of the M1919A4 was fitted. The M1919A6 was a heavy (32 pounds (15 kg)) and awkward weapon in comparison with the MG34 and MG42 and was eventually replaced in US service by the M60 machine gun in the 1960s.

T66 Machinegun

The M1919A6 was used by Springfield Armory in the late 1940s and early 1950s as a testbed for an interim general purpose machinegun. It was rechambered for the experimental T65 series cartridges, culminating in 1951 with the T66 Machinegun chambered for the T65E3 cartridge (one of the forerunners to the 7.62mm NATO cartridge). It had a new barrel with a flash-hider attachment, a shorter action, and modified M1 disintegrating belt links to feed the new cartridge. It was deemed still too heavy for field use and was not adopted.

AN/M2

A specific aircraft version of the .30 caliber Model 1919A4 was manufactured by Browning as the .30 AN/M2. It had a thinner barrel and receiver walls to keep down weight. It was used on US aircraft early in World War II but the lighter .30-caliber weapon was increasingly relegated to training duties as the war progressed. A derivative of this weapon was built by Colt as the civilian market MG40.

It was later replaced by the larger caliber .50 in (12.7 mm) M2 machine gun's "light barrel" version. The .50 M2 lacked the massive "cooling collar" of the heavy barrel M2HB version, which is still in service with the ground forces of the U.S. military in the 21st century.

The .30 caliber weapon is not to be confused with the Browning Machine Gun, Cal. .50, M2, Aircraft, and its full designation is Browning Machine Gun, Cal. .30, M2, Aircraft. The .30 in M2 Browning is sometimes referred to as AN/M2.

Browning .303 Mark II

The Browning was adopted by the Royal Air Force and manufactured by Vickers Armstrong and BSA to fire the .303 round and named Browning .303 Mk II in British Service. It was essentially the 1930 Pattern belt-fed Colt-Browning machine gun with a few minor modifications for British use, such as firing from an open bolt, hence prohibiting their use for gun synchronization through a spinning propeller. It was designed to fire hydraulically as a wing mounted machine gun but was also adopted as hand-fired mount for use in bombers and reconnaissance aircraft. It had a rate of fire of 1150 rounds per minute.[9][10]

T33

The AN/M2 was on occasion used as an infantry gun. Called the T33 it was fitted with a buttstock and bipod to allow for use without a tripod or other mount. The T33 consists of a butt stock from a M1919A6 and a rear sight and bipod from a BAR 1918. These conversions were based on field conversions carried out by soldiers in the Pacific Theater during World War II. A personally modified weapon of this type, using the butt stock from an M1 rifle, was used by Marine Corporal Tony Stein during the invasion of Iwo Jima. Stein would posthumously receive the Medal of Honor for his actions during the battle. It had a rate of fire in excess of 1,200 rpm and was nicknamed the "Stinger."[11] Barrel overheating and lack of control were the cause of its demise.

M37

In the late 1940s and early 1950s the US military was looking for an upgrade to the M1919 that could feed from either side for use as an improved coaxial machinegun. Saco-Lowell developed a model that had the driving spring attached to the back plate (eliminating the need for a mainspring and driving rod protruding out the back of the bolt), a solenoid trigger for remote firing, a feed cover that could open from either side, a bolt with dual tracks that could feed from either side, and a reversible belt feed pawl, ejector, and feed chute. The experimental T151 had a flat backplate (?), the T152 had spade grips and a "butterfly" trigger like the M2HB, and the T153 had a pistol grip and back-up trigger like the M1919A4 and an extended charging handle similar to those on the M1919A5. The T153 was adopted as the M37 and was produced by SACO-Lowell and Rock Island Arsenal from 1955 to 1957. It was in regular service from 1955 until it was replaced by the M37E1 in the late 1960s and the M73A1 in the early 1970s.

The M37 was used mostly on the M48 and M60 Patton medium tanks. The M37F was a trial variant fitted with special sighting equipment. The M37C was a variant without a sight bracket designed for use in aircraft armament (like the skid-mounted XM1/E1 helicopter armament subsystem).

The M37E1 was a M37 machine gun converted by Rock Island Arsenal and Springfield Armory to chamber the 7.62x51 mm NATO cartridge and feed the M13 disintegrating belt. They were designed for interim use until the M73 machine gun could be fielded.[12] The M37E1 was to be standardized as the M37A1 but development of the improved M73A1 precluded this.[13]

Mk 21 Mod 0

The increasing American involvement in Vietnam created a demand for small arms, especially the new M60 machinegun. The Navy had surplus machineguns left over from World War 2 and Korea, but they were chambered for the earlier .30-06 Springfield cartridge rather than the new standard 7.62mm NATO cartridge. The Mk 21 Mod 0 was a US Navy conversion of the .30 M1919A4 to fire the 7.62mm NATO cartridge. This was accomplished by replacing the barrel, bolt, and feed cover and adding a chamber bushing, a link-stripper, and a second belt-holding pawl to allow it to feed and fire the new cartridge.[14][15] Spacer blocks were added to the front and back of the feedway to guide the shorter round and block the use of the longer .30-06 Springfield ammunition.[14][16] A six-inch flash hider was also added to the barrel to reduce the muzzle flash from firing the shorter cartridge.[14]

The conversions were performed from 1966 through 1967. Modified M1919A4s had the designation "Machine Gun, 7.62mm / Mk 21 Mod 0" stamped on the receiver sideplate in 1/4-inch lettering. The replacement barrels had "7.62mm NATO-G" stamped on them in 1/8-inch letters to differentiate them from M1919A4 or M60 barrels;[17] the letter G indicated it used a grooved barrel bushing.[15]

The refurbished feed mechanism was left-hand feed only. It was different from the one in the M-60 GPMG in that the open end of the belt had to be on top so it could be stripped out.[14][18] To prepare the ammo, gunners had to take out both of the 100-round belts from an M19A1 ammo can, had to link them both together, and then loaded the resultant 200-round belt back into the M19A1 can upside-down so it would feed correctly.[14]

It used the standard 7.62mm NATO M13 link "strip-out" disintegrating link,[15] in which the bolt pushes the round out of the bottom of the two-part link and then forwards into the breech.[14] The old M1 link "pull-out" disintegrating links, which are pulled backwards out of the one-piece link by the extractor towards the bolt and then forwards into the breech, wouldn't feed through the new mechanism.[14] The M1 links, which were designed for the longer and thinner .30-06 Springfield, would also be too narrow to fit the shorter and thicker 7.62mm NATO round. The US Navy, because of their narrower inventory of 7.62mm NATO ammunition, used linked belts of either 7.62mm M80 Ball or a 4:1 ratio mix of 7.62mm M80 Ball and 7.62mm M62 Tracer.

International variants and derivatives

.jpg)

The M1919 pattern has been used in countries all over the world in a variety of forms and under a number of different designations.

- The Browning Mk 1 and Mk 2 were older-style Commonwealth designations for the .303 caliber Browning machine guns used on the vast majority of British aircraft of World War II.[19] The difference between the Mk 1 and Mk 2 versions is unknown, but the weapon visually is quite similar AN/M2 aircraft gun. The post-war designations for these weapons was L3, and they were used by the United Kingdom, Canada, and Australia to designate the fixed (A1) and flexible (A2) versions of the M1919A4 in .30-06 caliber. L3A3 and L3A4 denoted sear hold-open conversion of previous L3A1s and L3A2s. The A3 is the modified version of the A1, and the A4 is the modified version of the A2. The Canadians later adopted a separate designation for 7.62x51 mm rechambered M1919A4s for fixed (C1) and flexible (C1A1) applications. The C5 and C5A1 were product improvements of the previous C1 and C1A1 respectively.

- An M1919 derivative was manufactured in Belgium as the FN30.[20]

- The Rhodesian Air Force used twin Browning Mk 2 models, chambered in the British .303 cartridge, mounted on Alouette III G-Car helicopters[21] as well as modified variants fitted with FN MAG bipods, pistol grips and stocks for ground use.[22][23]

- The Browning was produced by FN-Herstal in Belgium as well, being used in, among others, the Fokker D.XXI fighter.

- FN-Browning mle 1938 was the French designation for the FN-built derivative converted to 7.5 mm MAS ammunition. Manufactured in the late 1930s.

- MG A4 is the Austrian designation for the M1919A4, not to be confused with MG4, a South African upgrade of the M1919 in current use with the South African National Defence Forces (SANDF). The MG4 was upgraded by Lyttleton Engineering Works, Pretoria.

- Mg M/52-1 and Mg M/52-11 were Danish designations for the M1919A4 and M1919A5 respectively.

- The Israel Defense Forces (IDF) used vehicle-mounted M1919A4 guns converted to 7.62 mm NATO on many of their armored vehicles.

- Ksp m/39 is the Swedish designation for M1919A4 license-built by Carl Gustafs Stads Gevärsfaktori chambered in 6.5×55mm and 8×63mm patron m/32, and from about 1975 rebarreled in 7.62×51mm NATO. Intended for use in tanks and armoured vehicles, it's available with both left- and right hand feeding, the former is used in CV 90.

- Ksp m/42 was the Swedish designation for license-built M1919A6 used for infantry support, normally chambered in 6.5×55mm but occasionally in 8×63mm patron m/32, and from about 1975, mostly fitted with barrels in 7.62×51mm NATO. The Ksp m/42B was a lighter version with bipod and shoulder stock (used in a similar way as the M1919A6), chambered in 6.5×55 mm and later in 7.62×51 mm. Even the ksp m/42B proved too heavy, and was replaced by the ksp m/58 (FN MAG). In the late 1980s, most remaining ksp m/42 was rebuilt into ksp m/39 to be installed into the CV 90s.

- The Poles developed a copy of the Browning M1919 chambered for 7.92 x 57mm Mauser, designated Ckm wz.32, similar to the earlier Ckm wz.30.

Commercial variants and derivatives

Colt MG40

Colt produced a derivative of the M2 aircraft machine gun, the Colt MG40. It shipped in a variety of calibers, including the basic .30-06 Springfield and popular 7mm Spanish Mauser, and was available in left- or right-hand feed.

The MG40-2 Light Aircraft Machine Gun could be used in flexible- (pintle-mounted), fixed- (wing-mounted), or synchronized- (through the propeller) models.[24] The Flexible mount machinegun came with grips and a "butterfly" trigger plate like the standard ground model. The Fixed model had a backplate. It used a cable connected to an operating slide connected to a stud on the bolt to fire it; tension in the cable causes the trigger to activate and slack in the cable causes it to stop.[25] The synchronized variant of the Fixed model had a trigger motor to coordinate fire with the rotation of the propeller.[26]

Civilian ownership

The Browning M1919 remains popular with civilian enthusiasts in the United States, though changes in 1986 to the National Firearms Act of 1934 (the US Federal law regulating private ownership of machine guns) prohibited the registration of new machine guns for sales to private citizens, thus freezing the number of "transferable" machine guns in private ownership. The inflation of prices that followed, and the availability of parts from surplussed and scrapped machine guns, led to the development of semi-automatic versions of the Browning M1919. Typically, these are built using a new right sideplate (the portion legally considered the "firearm" under US law), which has a raised "island" protruding into the interior of the receiver. This requires the use of a modified bolt, barrel extension and lock frame which have been designed to allow only semi-automatic firing. The "island" prevents the insertion of unmodified full-automatic parts. A number of small gun companies have produced these "semi-auto machine guns" for commercial sales. The fairly simple modifications necessary to convert M1919 parts to the semi-automatic version, and the relatively easy process of riveting used in the assembly of the Browning machine gun's receiver, have also made it a popular gun for hobbyists to build at home.

Similar "semi-auto machine guns" have been built using parts from other Browning pattern machine guns, to include the AN/M2 aircraft gun and FN30, and variations that never saw military use such as extremely short (8") barreled guns.

Current and former users

-

Argentina

Argentina -

Australia[27]

Australia[27] -

Burundi[28]

Burundi[28] -

Canada[28]

Canada[28] -

Chile[29]

Chile[29] -

Colombia[28]

Colombia[28] -

Costa Rica[28]

Costa Rica[28] -

Denmark[28]

Denmark[28] -

Dominican Republic[28]

Dominican Republic[28] -

El Salvador[28]

El Salvador[28] -

Finland

Finland -

France [30]

France [30] -

Gabon[28]

Gabon[28] -

Greece[28]

Greece[28] -

Guatemala[28]

Guatemala[28] -

Haiti[28]

Haiti[28] -

Indonesia

Indonesia -

Iran[28]

Iran[28] -

Ireland[31]

Ireland[31] -

Israel[28][32]

Israel[28][32] -

Italy[28]

Italy[28] -

South Korea[28]

South Korea[28] -

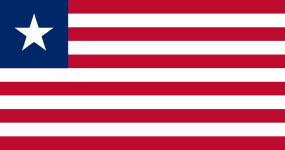

Liberia[28]

Liberia[28] -

Luxembourg

Luxembourg -

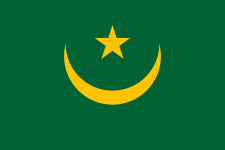

Mauritania[28]

Mauritania[28] -

Mexico[28]

Mexico[28] -

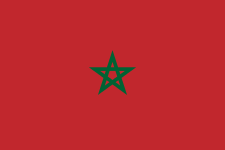

Morocco

Morocco -

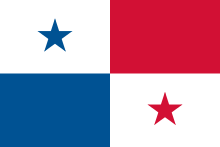

Panama[28]

Panama[28] -

Philippines[33]

Philippines[33] -

Portugal[34]

Portugal[34] -

Rhodesia[22][35]

Rhodesia[22][35] -

South Africa[28][36]

South Africa[28][36] -

Spain[28]

Spain[28] -

Republic of China[28]

Republic of China[28] -

Thailand[28]

Thailand[28] -

Tunisia[28]

Tunisia[28] -

United Kingdom[37]

United Kingdom[37] -

United States[38]

United States[38] -

Uruguay[28]

Uruguay[28] -

South Vietnam[28]

South Vietnam[28]

See also

- Dieudonné Saive

- List of U.S. Army weapons by supply catalog designation SNL A-6

- M1917 Browning machine gun

- M2 Browning machine gun

References

- ↑ Garrison, Gene, Unless Victory Comes, NAI Press (2004), ISBN 978-0-451-22224-4, ISBN 1-932033-30-0, p. 8

- ↑ Weeks, John, World War II Small Arms, New York:Galahad Books (1979), p.123

- ↑ Garrison, Gene, Unless Victory Comes, NAI Press (2004), ISBN 978-0-451-22224-4, ISBN 1-932033-30-0, p.38

- ↑ The Five Worst Light Machine Guns (LMGs) - Defensemedianetwork.com, 4 September 2013

- ↑ 5.0 5.1 Goldsmith, Dolf L., The Browning Machine Gun, Volume II: Rifle Caliber Brownings Abroad, Collector Grade Publications, 1st ed. (2006)

- ↑ 6.0 6.1 Dunlap, Roy F., Ordnance Went Up Front, Samworth Press (1948), pp. 4-5

- ↑ LRDG Weapons, Machine Guns, http://blindkat.hegewisch.net/lrdg/mgs.html

- ↑ Drabkinl 2007, p.126.

- ↑ "Browning 0.303in Mark II Machine Gun (R.A.F.)". Retrieved 27 November 2014.

- ↑ Dean Wingrin. "0.303 Inch Browning Machine gun". Retrieved 27 November 2014.

- ↑ http://www.navalorder.org/02-Feb-01%20MistHist.PDF

- ↑ "Springfield Armory Museum - Collection Record". Retrieved 27 November 2014.

- ↑ "Springfield Armory Museum - Collection Record". Retrieved 27 November 2014.

- ↑ 14.0 14.1 14.2 14.3 14.4 14.5 14.6 Ordnance Notes: Mk 21 Mod 0 7.62mm Machine Gun by Bob Stoner GMCM (SW) Ret.

- ↑ 15.0 15.1 15.2 Naval Ordnance Bulletin 3-67, Machine Gun Mk 21 Mod 0 - &.62mm NATO by Ronald Henry - Weapons Design Bureau, Naval Ammunition Depot Crane, pg.11 (1967).

- ↑ Naval Ordnance Bulletin 3-67, Machine Gun Mk 21 Mod 0 - &.62mm NATO by Ronald Henry - Weapons Design Bureau, Naval Ammunition Depot Crane, pg.8 (1967).

- ↑ Naval Ordnance Bulletin 3-67, Machine Gun Mk 21 Mod 0 - &.62mm NATO by Ronald Henry - Weapons Design Bureau, Naval Ammunition Depot Crane, pg.9 (1967).

- ↑ Naval Ordnance Bulletin 3-67, Machine Gun Mk 21 Mod 0 - &.62mm NATO by Ronald Henry - Weapons Design Bureau, Naval Ammunition Depot Crane, pp.10-11 (1967).

- ↑ http://1919a4.com/forums/picture.php?albumid=84&pictureid=1008

- ↑ http://www.defencetalk.com/pictures/data/4695/medium/FN30.jpg

- ↑ http://1.bp.blogspot.com/_KOo6bb1o3qY/Sy36bAeRdoI/AAAAAAAACNg/av8mHYdXyCk/s320/1114.jpg

- ↑ 22.0 22.1 http://www.britains-smallwars.com/RRGP/Agila/Subs19.jpg

- ↑ http://www.freewebs.com/dudleywall/Wpn%20modified%20303%20MG%20in%20tower.jpg

- ↑ Biggerhammer.net > Colt Light Aircraft Machine Gun MG-40

- ↑ Biggerhammer.net > Colt Light Aircraft Machine Gun MG-40

- ↑ Biggerhammer.net > Colt Light Aircraft Machine Gun MG-40

- ↑ http://www.dailytelegraph.com.au/news/army-sells-off-machine-guns/story-e6freuy9-1225941955479

- ↑ 28.0 28.1 28.2 28.3 28.4 28.5 28.6 28.7 28.8 28.9 28.10 28.11 28.12 28.13 28.14 28.15 28.16 28.17 28.18 28.19 28.20 28.21 28.22 28.23 28.24 28.25 Jones, Richard D.; Ness, Leland S., eds. (January 27, 2009). Jane's Infantry Weapons 2009/2010 (35th ed.). Coulsdon: Jane's Information Group. ISBN 978-0-7106-2869-5.

- ↑ Gander, Terry J.; Hogg, Ian V. Jane's Infantry Weapons 1995/1996. Jane's Information Group; 21 edition (May 1995). ISBN 978-0-7106-1241-0.

- ↑ Jordon, David (2005). The History of the French Foreign Legion: From 1831 to Present Day. The Lyons Press. p. 170. ISBN 1-59228-768-9.

- ↑ Karl Martin, Irish Army Vehicles, Transport & Armour Since 1922, Karl Martin 2002.

- ↑ Laffin, John (1982). The Israeli Army in the Middle East Wars 1948-73. Osprey Publishing. p. 15. ISBN 0-85045-450-6.

- ↑ http://stukaph.files.wordpress.com/2008/08/navsoghumveeblog1_lowres.jpg

- ↑ Portuguese Army Afghanistan

- ↑ http://www.rhodesianforces.org/graphics_air/G-Car303Browning.jpg

- ↑ "home". Retrieved 27 November 2014.

- ↑ Hogg, Ian (1989). Jane's Infantry Weapons 1989-90, 15th Edition. Jane's Information Group. p. 341. ISBN 0-7106-0889-6.

- ↑ "Machine Gun, Cal. .30, M1919A4/M1919A6". Retrieved 27 November 2014.

Further reading

- Frank Iannamico, Hard Rain: History of the Browning Machine Guns

- Dolf L. Goldsmith, The Browning Machine Gun, Vol I & II

- Drabkin, Artem. The Red Air Force at War: Barbarossa & the retreat to Moscow – Recollections of Fighter Pilots on the Eastern Front. Barnsley (South Yorkshire), Pen & Sword Military, 2007. ISBN 1-84415-563-3

External links

| Wikimedia Commons has media related to Browning M1919. |

- (1986) C-71-126-000 Parts Identification Lists - Machine Gun, 7.62mm, C5A1

- Beltfedshooters.com For Beltfed Enthusiasts

- The Light Machine Gun

- M1919A4 Enthusiasts and semi-auto rebuilders

- Gothia Association for Weapon History on the Ksp m/42

- How machine guns work

- History of the Browning Machine Gun at browningmgs.com

- TM 9-2012, a manual covering the M-37 Browning Machine Gun

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||