m-Xylene

| |||

| Names | |||

|---|---|---|---|

| Other names

m-Xylol 1,3-Dimethylbenzene | |||

| Identifiers | |||

| 108-38-3 | |||

| ChEBI | CHEBI:28488 | ||

| ChEMBL | ChEMBL286727 | ||

| ChemSpider | 7641 | ||

| |||

| Jmol-3D images | Image Image | ||

| KEGG | C07208 | ||

| PubChem | 7929 | ||

| RTECS number | ZE2275000 | ||

| |||

| UNII | O9XS864HTE | ||

| Properties | |||

| C8H10 | |||

| Molar mass | 106.16 g/mol | ||

| Appearance | Colorless liquid | ||

| Density | 0.86 g/mL | ||

| Melting point | −48 °C (−54 °F; 225 K) | ||

| Boiling point | 139 °C (282 °F; 412 K) | ||

| insoluble | |||

| Solubility in ethanol | very soluble | ||

| Solubility in diethyl ether | very soluble | ||

| Refractive index (nD) |

1.49722 | ||

| Viscosity | 0.8059 cP at 0 °C 0.6200 cP at 20 °C | ||

| Dipole moment | 0.33-0.37 D[1] | ||

| Hazards | |||

| MSDS | External MSDS | ||

| Main hazards | Harmful or fatal if swallowed. Vapor harmful. Flammable liquid and vapor. | ||

| R-phrases | R10 R20 R21 R38 | ||

| S-phrases | S25 | ||

| NFPA 704 | |||

| Flash point | 25 °C | ||

| Explosive limits | 1.1%-7.0%[2] | ||

| US health exposure limits (NIOSH): | |||

| PEL (Permissible) |

TWA 100 ppm (435 mg/m3)[2] | ||

| Related compounds | |||

| Related aromatic hydrocarbons |

benzene toluene o-xylene p-xylene | ||

| Supplementary data page | |||

| Refractive index (n), Dielectric constant (εr), etc. | |||

| Thermodynamic data |

Phase behaviour solid–liquid–gas | ||

| UV, IR, NMR, MS | |||

| Except where noted otherwise, data is given for materials in their standard state (at 25 °C (77 °F), 100 kPa) | |||

| | |||

| Infobox references | |||

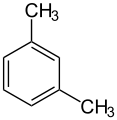

m-Xylene (or meta-xylene) is an aromatic hydrocarbon, based on benzene with two methyl substituents. It is an isomer of o-xylene and p-xylene. The m stands for meta, meaning the two methyl substituents are at locants 1 and 3 on the aromatic ring. m-Xylene is commonly produced in BTX processes, and separated as needed from the other aromatic hydrocarbons.

The major chemical use of meta-xylene is in the manufacture of isophthalic acid, which is used as a copolymerizing monomer to alter the properties of polyethylene terephthalate (PET), making PET more suitable for the manufacture of soft drinks bottles. To convert m-xylene on an industrial scale to isophthalic acid, the two methyl groups are both catalytically oxidized to carboxyl groups. It is also used as a raw material in the manufacture of 2,4- and 2,6-xylidine as well as a range of smaller-volume chemicals.[3]

References

- ↑ DeanHandb, Lange´s Handbook of chemistry, 15th edition,1999.

- ↑ 2.0 2.1 "NIOSH Pocket Guide to Chemical Hazards #0669". National Institute for Occupational Safety and Health (NIOSH).

- ↑ Ashford's Dictionary of Industrial Chemicals, third edition, page 9692.