Lithium–air battery

| Specific energy | 11,140 (theoretical) W·h/kg |

|---|---|

| Energy density | ??? |

| Specific power | ??? |

| Nominal cell voltage | 2.91 V |

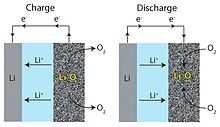

The lithium-air battery, Li-air for short, is a metal-air battery chemistry that uses oxidation of lithium at the anode and reduction of oxygen at the cathode to induce a current flow.[1] It is an all-solid-state battery.

Originally proposed in the 1970s as a possible power source for battery electric vehicles, Li-air batteries recaptured scientific interest in the late 2000s due to advances in materials technology and an increasing demand for renewable energy sources.

The major appeal of the Li-air battery is the extremely high specific energy, a measure of the amount of energy a battery can store for a given weight. A lithium-air battery has an energy density (per kilogram) comparable to gasoline. Li-air batteries gain this advantage in specific energy since they use oxygen from the air instead of storing an oxidizer internally.

The technology requires significant advances in multiple fields before a viable commercial implementation can be developed.[2] Four approaches are active: aprotic,[3][4] aqueous,[5] solid state,[6] and mixed aqueous/aprotic.[7]

Metal-air batteries, specifically zinc-air, have received attention due to the potential for high energy densities. The theoretical specific energy densities for metal-air batteries are higher than for ion-based approaches, due to the use of atmospheric oxygen as the cathode, eliminating a traditional cathode structure. Recently, lithium-air batteries have been proposed as the next step in lithium battery architecture, due to the high energy density of lithium with respect to air (3840 mA·h/g).[8]

A major driver in lithium-air battery development is the automotive sector. The energy density of gasoline is approximately 13 kW·h/kg, which corresponds to 1.7 kW·h/kg of energy provided to the wheels after losses. The theoretical energy density of the lithium-air battery is 12 kW·h/kg (43.2 MJ/kg) excluding the oxygen mass. It has been theorized that the same 1.7 kW·h/kg could reach the wheels using Li-air after losses from over-potentials, other cell components and battery pack ancillaries, given the much higher efficiency of electric motors.[9]

Lithium-air batteries have the potential of 5–15 times the specific energy of current lithium-ion batteries.[10]

History

Lithium batteries have received attention since the 1970s. The first commercial lithium cells emerged during the 1990s. Lithium batteries offer high performance due to their intrinsic high specific energy densities.[11]

In the mid-1990s, K.M. Abraham and co-workers demonstrated the first non-aqueous Li–air battery with the use of a Li negative electrode (anode), a porous carbon positive electrode (cathode), and a gel polymer electrolyte membrane that served as both the separator and ion-transporting medium.[12][13] Oxygen from the atmosphere enters the pores of the carbon cathode to serve as the cathode active material. Under discharge this oxygen was reduced and the products stored in the pores of the carbon electrode. The Li ion conducting gel polymer electrolytes were based on polyacrylonitrile (PAN)[14] and polyvinylidene fluoride (PVdF).[15]

Operation

Although the electrochemical details vary by battery design (and related electrolyte type), in general, lithium is oxidized at the anode forming lithium ions and electrons. The electrons follow the external circuit to do electric work and the lithium ions migrate across the electrolyte to reduce oxygen at the cathode. When an externally applied potential is greater than the standard potential for the discharge reaction, lithium metal plates onto the anode and O

2 is generated at the cathode.[16]

Anode

Lithium metal is the current choice of anode material for Li-air batteries. At the anode, electrochemical potential forces the lithium metal to give off electrons as per the oxidation. The half reaction is:[17]

- Li ↔ Li+ + e−

Lithium has high specific capacity (3840 mAh/g) compared with other metal-air battery materials (820 mAh/g for Zinc, 2965 mAh/g for aluminium).[11] Several issues affect such cells. Upon charging/discharging in aprotic cells, layers of lithium salts precipitate onto the anode, eventually covering it and creating a barrier between the lithium and electrolyte. This barrier initially prevents corrosion, but eventually inhibits the reaction kinetics between the anode and the electrolyte.[18] This chemical change of the solid-electrolyte interface (SEI) results in varying chemical composition across the surface, causing the current to vary from point to point. The uneven current distribution furthers branch-like dendrite growth and typically leads to a short between the anode and cathode.[19] Also, in aqueous cells, problems at the SEI stem from the high reactivity of lithium metal with water.[20]

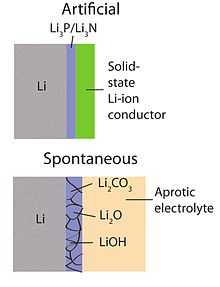

Several approaches have been taken to overcome problems at the SEI:

- Formation of a Li-ion conductive artificial protective layer using di- and triblock copolymer electrolytes.[21] According to Seeo, Inc.,[21] electrolytes made from di- and triblock copolymer (e.g. polystyrene with the high Li-ion conductivity of a soft polymer segment, such as a poly(ethylene oxide PEO/ Li-salt mixture) ) combine the mechanical stability of a hard polymer segment with the high ionic conductivity of the soft polymer/lithium salt mixture. The hardness inhibits dendrite shorts via mechanical blocking.

- Use of a Li-ion conducting glass or glass-ceramic material.[6][22][23] Li-ion conducting ceramic materials are (generally) readily reduced by lithium metal, and therefore a thin film of a stable lithium conducting material, such as Li

3P or Li

3N, could be inserted between the ceramic and metal. This ceramic based SEI inhibits the formation of dendrites and protects the lithium metal from atmospheric contamination.

Cathode and electrolyte

At the cathode, reduction occurs by the recombination of lithium ions with oxygen. Mesoporous carbon has been used as a cathode material with metal catalysts.[24] Metal catalysts incorporated into the carbon electrode enhance oxygen reduction kinetics and increase the cathode's specific capacity.[10] Manganese, cobalt, ruthenium, platinum, silver, or a mixture of cobalt and manganese are under consideration as metal catalysts. Under some circumstances manganese-catalyzed cathodes performed best, with a specific capacity of 3137 mA·H/g carbon and cobalt-catalyzed cathodes performed second best, with a specific capacity of 2414 mA·H/g carbon.[12] Based on the first pore-scale modeling of lithium-air batteries, the microstructure of the cathode significantly affects battery capacity in both non-pore-blocking and pore-blocking regimes.[25]

Li-air cell performance is limited by the efficiency of reaction at the cathode because most of the cell voltage drop occurs there.[11] Multiple battery chemistries, delineated by electrolyte, display varying electrochemical reactions at the cathode. The discussion below is focused on aprotic and aqueous electrolytes as the exact electrochemistry taking place in solid-state electrolytes is not well understood.

In a cell with an aprotic electrolyte lithium oxides are produced through reduction at the cathode:

- Li+ + e− +O

2 + * → LiO

2*- Li+ + e− +LiO

2* →Li

2O

2* - where "*" denotes a surface site on Li

2O

2 where growth proceeds, which is essentially a neutral Li vacancy in the Li

2O

2 surface.

- Li+ + e− +LiO

Lithium oxides are insoluble in aprotic electrolytes, which leads to cathode clogging.[26]

In a cell with an aqueous electrolyte the reduction at the cathode can also produce lithium hydroxide:

- Acidic electrolyte

- 2Li + 1⁄2O

2 + 2H+ → 2Li++ H

2O - A conjugate base is involved in the reaction. The theoretical maximal Li-air cell specific energy and Li-air cell energy density is 1400 W·h/kg and 1680 W·h/l, respectively.[9]

- Alkaline aqueous electrolyte

- 2Li + 1⁄2O

2 + H

2O → 2LiOH - Water molecules are involved in the redox reactions at the air cathode. The theoretical maximal Li-air cell specific energy and Li-air cell energy density is 1300 W·h/kg and 1520 W·h/l, respectively.[9]

The development of new cathode materials must account for the accommodation of substantial amounts of LiO

2,Li

2O

2 and/or LiOH without causing a blockage of the cathode pores and find suitable catalysts to make the electrochemical reactions energetically practical.

- As an example, dual pore system materials are the most promising in terms of energy capacity.[27]

- The first pore system serves as an oxidation product store.

- The second pore system serves as oxygen transport.

Design

Cathode

A MnO

2 nanowire array cathode augmented by a genetically-modified version of the M13 virus offers two to three times the energy density of current lithium-ion batteries. The virus increased the size of the nanowire array, which is about 80 nm across. The resulting wires had a rough, spiked surface. Spikes create more surface area to host reaction sites. The viral process creates a cross-linked 3D structure, rather than isolated wires, stabilizing the electrode. The viral process is water-based and takes place at room temperature.[28][29]

Electrolyte

Efforts in Li-air batteries have focused on four different chemical designs. All the designs have distinct advantages and significant technical challenges.

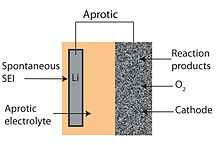

Aprotic

Most effort has focused on aprotic materials, which consist of a lithium metal anode, a liquid organic electrolyte and a porous carbon cathode. Electrolytes can be made of any organic capable of solvating lithium salts (LiPF

6, LiAsF

6, LiN(SO

2CF

3)

2, and LiSO

3CF

3), but have typically consisted of carbonates, ethers and esters.[16] The carbon cathode is usually made of a high surface area carbon material with a nanosized metal oxide catalyst (commonly MnO

2 or Mn

3O

4). A major advantage is the spontaneous formation of a barrier between anode and electrolyte (much like the barrier formed between electrolyte and carbon-lithium anodes in conventional Li-ion batteries) that protects the lithium metal from further reaction with the electrolyte. Although rechargeable,[9] the Li

2O

2 produced at the cathode is generally insoluble in the organic electrolyte, leading to buildup along the cathode/electrolyte interface. This makes cathodes in aprotic batteries prone to clogging and volume expansion that progressively reduces conductivity and degrades battery performance.[5][20][30] Another issue is that organic electrolytes are flammable and can rupture and ignite.[6]

In 2012, researchers announced that a dimethyl sulfoxide electrolyte and gold nanoparticles cathode achieved 100 charge cycles with 5% capacity loss.[31]

Aqueous

An aqueous Li-air battery consists of a lithium metal anode, an aqueous electrolyte and a porous carbon cathode. The aqueous electrolyte combines lithium salts dissolved in water. It avoids the issue of cathode clogging because the reaction products are water soluble.[5] The aqueous design has a higher practical discharge potential than its aprotic counterpart. However, lithium metal reacts violently with water and thus the aqueous design requires a solid electrolyte interface between the lithium and electrolyte. Commonly, a lithium-conducting ceramic or glass is used, but conductivities are generally low (on the order of 10−3 S/cm at ambient temperatures).[20]

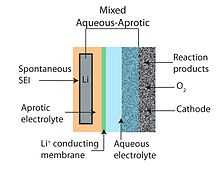

Mixed aqueous/aprotic

The aqueous/aprotic or mixed Li-air battery design attempts to unite advantages of the aprotic and aqueous battery designs. The common feature of hybrid designs is a two-part (one part aqueous and one part aprotic) electrolyte connected by a lithium-conducting membrane. The lithium metal anode abuts the aprotic side while the porous cathode is in contact with the aqueous side. A lithium-conducting ceramic is typically employed as the membrane joining the two electrolytes.[5][9]

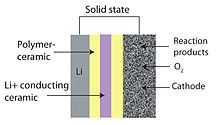

Solid state

The solid-state battery design is attractive from a safety standpoint, eliminating the possibility of rupture and ignition.[6] Current solid-state Li-air batteries use a lithium anode, a ceramic, glass, or glass-ceramic electrolyte, and a porous carbon cathode. The anode and cathode are typically separated from the electrolyte by polymer-ceramic composites that enhance charge transfer at the anode and electrochemically couple the cathode to the electrolyte. The polymer-ceramic composites reduce overall impedance. The main drawback of the solid-state battery design is the low conductivity of most glass-ceramic electrolytes. The ionic conductivity of current lithium fast ion conductors is still lower than liquid electrolyte alternatives.[8]

Challenges

As of 2013 many challenges confronted designers of Li-air batteries, limiting them to the laboratory.

Cathode

Most of the current limitations in Li-air battery development are at the cathode, which is also the source of its potential advantages. Incomplete discharge due to blockage of the porous carbon cathode with discharge product such as lithium peroxide (in aprotic designs) is the most serious.

The effect of pore size and pore size distribution remains poorly understood.[11]

Catalysts have shown promise in creating preferential nucleation of Li

2O

2 over Li

2O, which is irreversible with respect to lithium.[32]

Atmospheric oxygen must be present at the cathode, but contaminants such as water vapor can damage it.[3]

Anode

The main challenge in anode development is preventing the anode from reacting with the electrolyte. Alternatives include new electrolyte materials or redesigning the interface between electrolyte and anode.

Dendritic lithium deposits can decrease energy capacity or trigger a short circuit.

Electrochemical

In current cell designs, the charge overpotential is much higher than the discharge overpotential. Significant charge overpotential indicates the presence of secondary reactions.[33] As a result, electrical efficiency is only around 65%.[11]

Catalysts such as MnO

2, Co, Pt and Au can potentially reduce the overpotentials, but the effect is poorly understood.[32] Several catalysts improve cathode performance, notably MnO

2. The mechanism of improvement is unknown, but may alter the structure of the oxide deposits.[34][35]

Significant drops in cell capacity with increasing discharge rates are another issue. The decrease in cell capacity is attributed to kinetic charge transfer limitations.[11] Since the anodic reaction occurs very quickly, the charge transfer limitations are thought to occur at the cathode.

Stability

Long term battery operation requires chemical stability of all cell components. Current cell designs show poor resistance to oxidation by reaction products and intermediates. Many aqueous electrolytes are volatile and can evaporate over time.[11]

Applications

Automotive

The primary application for Li-air battery development is automotive power supplies. The high specific energy and volumetric energy densities required for next-generation applications are the prime motivation for this design. Secondarily, Li-air batteries are attractive for any application where weight is a primary concern, such as in mobile devices.[36]

Grid backup

In 2014 researchers announced a hybrid solar cell/battery. Up to 20% of the energy produced by conventional solar cells is lost as it travels to and charges a battery. The hybrid stores nearly 100% of the energy produced. The first version of the hybrid used a potassium-air battery. It offered higher energy density than conventional Li-ion batteries and was cheap to produce, avoided toxic byproducts and was almost 100% energy-efficient. The latest device essentially substituted lithium for potassium.[37]

The solar cell used a mesh made from microscopic rods of titanium dioxide to allow the required oxygen to pass through. Captured sunlight produces electrons that decompose lithium peroxide into lithium ions, thereby charging the battery. During discharge, oxygen from air replenishes the lithium peroxide.[37]

See also

- Lithium-ion battery

- Lithium iron phosphate battery

- Lithium-ion polymer battery

- Lithium-ion flow battery

- Lithium-sulfur battery

- Metal-air battery

- Nanowire battery

- Nanopore battery

- Power-to-weight ratio

- Zinc–air battery

References

- ↑ Badwal, Sukhvinder P. S.; Giddey, Sarbjit S.; Munnings, Christopher; Bhatt, Anand I.; Hollenkamp, Anthony F. (24 September 2014). "Emerging electrochemical energy conversion and storage technologies". Frontiers in Chemistry 2. doi:10.3389/fchem.2014.00079.

- ↑ Christensen, J.; Albertus, P.; Sanchez-Carrera, R. S.; Lohmann, T.; Kozinsky, B.; Liedtke, R.; Ahmed, J.; Kojic, A. (2012). "A Critical Review of Li∕Air Batteries". Journal of the Electrochemical Society 159 (2): R1. doi:10.1149/2.086202jes.

- ↑ 3.0 3.1 Ogasawara, T.; Débart, A. L.; Holzapfel, M.; Novák, P.; Bruce, P. G. (2006). "Rechargeable Li2O2Electrode for Lithium Batteries". Journal of the American Chemical Society 128 (4): 1390–1393. doi:10.1021/ja056811q. PMID 16433559.

- ↑ Debart A, Bao,J et al (2008). "α-MnO

2 Nanowires: A Catalyst for theO

2 Electrode in Rechargeable Lithium Batteries",Angew.Chem.,47(24):p.4521-4524. - ↑ 5.0 5.1 5.2 5.3 He, P.; Wang, Y.; Zhou, H. (2010). "A Li-air fuel cell with recycle aqueous electrolyte for improved stability". Electrochemistry Communications 12 (12): 1686. doi:10.1016/j.elecom.2010.09.025.

- ↑ 6.0 6.1 6.2 6.3 Kumar, B.; Kumar, J.; Leese, R.; Fellner, J. P.; Rodrigues, S. J.; Abraham, K. M. (2010). "A Solid-State, Rechargeable, Long Cycle Life Lithium–Air Battery". Journal of the Electrochemical Society 157: A50. doi:10.1149/1.3256129.

- ↑ Wang, Yonggang (2010). "A lithium-air battery with a potential to continuously reduce O2 from air for delivering energy". Journal of Power Sources 195 (1): 358–361. doi:10.1016/j.jpowsour.2009.06.109.

- ↑ 8.0 8.1 Kumar, B.; Kumar, J. (2010). "Cathodes for Solid-State Lithium–Oxygen Cells: Roles of Nasicon Glass-Ceramics". Journal of the Electrochemical Society 157 (5): A611. doi:10.1149/1.3356988.

- ↑ 9.0 9.1 9.2 9.3 9.4 Girishkumar, G.; McCloskey, B.; Luntz, A. C.; Swanson, S.; Wilcke, W. (2010). "Lithium−Air Battery: Promise and Challenges". The Journal of Physical Chemistry Letters 1 (14): 2193. doi:10.1021/jz1005384.

- ↑ 10.0 10.1 Ed. Jurgen O. Besenhard, Handbook of Battery Materials,New Your, Wiley-VCH, 1999, ISBN 3-527-29469-4.

- ↑ 11.0 11.1 11.2 11.3 11.4 11.5 11.6 Kraytsberg, A.; Ein-Eli, Y. (2011). "Review on Li–air batteries—Opportunities, limitations and perspective". Journal of Power Sources 196 (3): 886. doi:10.1016/j.jpowsour.2010.09.031.

- ↑ 12.0 12.1 Abraham, K. M. (1996). "A Polymer Electrolyte-Based Rechargeable Lithium/Oxygen Battery". Journal of the Electrochemical Society 143: 1–0. doi:10.1149/1.1836378.

- ↑ K. M. Abraham and Z. Jiang, US Patent 5,510,209 (1996)

- ↑ Abraham, K. M.; H.S. Choe; D.M. Pasquariello (1998). "Polyacrylonitrile electrolyte-based Li ion batteries". Electrochimica Acta 43 (16–17): 2399–2412. doi:10.1016/S0013-4686(97)10168-2.

- ↑ Abraham, K. M.; Z. Jiang; B. Carroll (1997). "Highly Conductive PEO-like Polymer Electrolytes". Chemistry of Materials 9 (9): 1978–1988. doi:10.1021/cm970075a.

- ↑ 16.0 16.1 Xu, K. (2004). "Nonaqueous Liquid Electrolytes for Lithium-Based Rechargeable Batteries". Chemical Reviews 104 (10): 4303–417. doi:10.1021/cr030203g. PMID 15669157.

- ↑ Winter, M.; Brodd, R. J. (2004). "What Are Batteries, Fuel Cells, and Supercapacitors?". Chemical Reviews 104 (10): 4245–4269. doi:10.1021/cr020730k. PMID 15669155.

- ↑ Aurbach, D. (2000). "Review of selected electrode–solution interactions which determine the performance of Li and Li ion batteries". Journal of Power Sources 89 (2): 206–218. doi:10.1016/S0378-7753(00)00431-6.

- ↑ Whittingham, M. S. (1976). "Electrical Energy Storage and Intercalation Chemistry". Science 192 (4244): 1126–1127. doi:10.1126/science.192.4244.1126. PMID 17748676.

- ↑ 20.0 20.1 20.2 Kowalczk, I.; Read, J.; Salomon, M. (2007). "Li-air batteries: A classic example of limitations owing to solubilities". Pure and Applied Chemistry 79 (5): 851. doi:10.1351/pac200779050851.

- ↑ 21.0 21.1 Singh, M.; Gur, I.; Balsara, N. P.(2009). "Solid Electrolyte Material Manufacturable by Polymer Processing Methods", U.S. Patent Application #12271829.

- ↑ Bates, J. (2000). "Thin-film lithium and lithium-ion batteries". Solid State Ionics 135: 33–37. doi:10.1016/S0167-2738(00)00327-1.

- ↑ Visco, S.; Nimonm, Y. (2010). "Active Metal/Aqueous Electrochemical Cells and Systems", U.S.Patent #7645543.

- ↑ New Energy and Fuel. 2011. Accessed 20 Nov. 2011

- ↑ Charles P. Andersen, Han Hu, Gang Qiu, Vibha Kalra, and Ying Sun, "Pore-Scale Transport Resolved Model Incorporating Cathode Microstructure and Peroxide Growth in Lithium-Air Batteries", J. Electrochem. Soc., 162, (2015) A1135-A1145

- ↑ Read, J. (2002). "Characterization of the Lithium/Oxygen Organic Electrolyte Battery". Journal of the Electrochemical Society 149 (9): A1190–A1196. doi:10.1149/1.1498256.

- ↑ Williford, R. E.; Zhang, J. G. (2009). "Air electrode design for sustained high power operation of Li/air batteries". Journal of Power Sources 194 (2): 1164. doi:10.1016/j.jpowsour.2009.06.005.

- ↑ "Lithium-air batteries go viral for greater durability and performance". gizmag.com.

- ↑ Oh, D.; Qi, J.; Lu, Y. C.; Zhang, Y.; Shao-Horn, Y.; Belcher, A. M. (2013). "Biologically enhanced cathode design for improved capacity and cycle life for lithium-oxygen batteries". Nature Communications 4. doi:10.1038/ncomms3756.

- ↑ Li, Xianglin; Faghri (2012). "Amir". Journal of Electrochemical Society 159: A1747-A1754. doi:10.1149/2.043210jes.

- ↑ Service, Robert F. "An Electric Car That Actually Goes Far? – ScienceNOW". News.sciencemag.org. Retrieved 2012-07-20.

- ↑ 32.0 32.1 Lu, Yi-Chun (2010). "The Influence of Catalysts on Discharge and Charge Voltages of Rechargeable Li–Oxygen Batteries". Electrochemical and Solid-State Letters 13 (6): A69. doi:10.1149/1.3363047.

- ↑ Zhang, T.; Imanishi, N.; Shimonishi, Y.; Hirano, A.; Takeda, Y.; Yamamoto, O.; Sammes, N. (2010). "A novel high energy density rechargeable lithium/air battery". Chemical Communications 46 (10): 1661–1663. doi:10.1039/b920012f. PMID 20177608.

- ↑ Darren Quick (5 April 2010). "Lithium-air batteries offer three times the energy density". Retrieved 5 Oct 2011.

- ↑ Shimonishi, Y.; Zhang, T.; Imanishi, N.; Im, D.; Lee, D. J.; Hirano, A.; Takeda, Y.; Yamamoto, O.; Sammes, N. (2011). "A study on lithium/air secondary batteries—Stability of the NASICON-type lithium ion conducting solid electrolyte in alkaline aqueous solutions". Journal of Power Sources 196 (11): 5128. doi:10.1016/j.jpowsour.2011.02.023.

- ↑ Fabjan, Ch (2001). "The vanadium redox-battery: an efficient storage unit for photovoltaic systems". Electrochimica Acta 47 (5): 825–831. doi:10.1016/S0013-4686(01)00763-0.

- ↑ 37.0 37.1 DIMBERUON, PENIEL M. (October 28, 2014). "New Hybrid Solar Cell Battery Takes Aim at Solar Power’s Energy Storage Problem". Singularity Hub. Retrieved February 2015.

- A. Dobley, C. Morein, R. Roark, and K. M. Abraham, 42nd Power Sources Conference, Philadelphia, PA, June 2006

- K.M. Abraham Ph.D. at E-KEM Sciences

External links

- Argonne opens chapter in battery research – lithium air

- Argonne advanced battery research driving to displace gasoline

- The IBM Battery 500 Project

- PolyPlus battery company

- Lithion, Inc. Lithium-air battery design

| ||||||||||||||||||||