List of mills in Stockport

| Wikimedia Commons has media related to Textile mills in Stockport. |

This list of mills in Stockport, lists textile factories that have existed in Stockport, Greater Manchester, England.

From the Industrial Revolution until the 20th century, Stockport was a major centre of textile manufacture, particularly cotton spinning and hat making. During this period, the valleys of the River Mersey, River Tame and their tributaries were dominated by large rectangular brick-built factories, many of which still remain today as warehouses or converted for residential or retail use.

Standing Mills in Stockport

| Name | Architect | Location | Built | Demolished | Served (Years) |

|---|---|---|---|---|---|

|

| |||||

| (Adcroft) Hat Works | Manor [1] | Standing | |||

| Aqueduct Mill | Marple North, 53°24′24″N 2°04′03″W / 53.4066°N 2.0675°W[1] | Standing | |||

| Avondale Works | Edgeley & Cheadle [1] | ||||

| Battersby Hat Works | Manor [1] | ||||

| Belmont Works | Brinnington & Central [1] | ||||

Botany Mill

|

Bredbury , 53°25′50″N 2°06′07″W / 53.4306°N 2.1019°W[2] | ||||

| Brinksway Leather Works | Edgeley & Cheadle SJ879899 53°24′21″N 2°10′53″W / 53.405970°N 2.181277°W | ||||

| Notes: three-storey hipped roof with short circular brick chimney[3] | |||||

| Brinksway Bank Mill | Edgeley & Cheadle 53°24′28″N 2°10′27″W / 53.4077°N 2.1742°W | ||||

| Notes: A 50,000-spindle three-storey mill in existence in 1872. It was run by Samuel Moorhouse: then it became part of the Fine Spinners and Doublers Association.[4] | |||||

Brinksway Mill

|

Edgeley & Cheadle SJ884899 53°24′22″N 2°10′26″W / 53.405981°N 2.173755°W | ||||

| Notes: North of the river was a four-storey mill with water tower at east corner: there was a three-storey extension. The chimney was octagonal.There are traces of a weir sluice and mill race. South of the river was a three-storey mill. The first mill north of the River Mersey was in existence in 1790.It was worked by from 1870 by J&G Waltew. It became part of the Fine Spinners and Doublers Association in 1930. [4] | |||||

| Britannia Mill | Reddish South 53°25′19″N 2°09′55″W / 53.4220°N 2.1654°W | Standing | |||

| Notes: A weaving mill in use 1870s to 1930s, manufacturing shirtings and towels. 100–200 looms. Occupied by Reuben Fildes, the Robert Atkinson & Co and McKay Mills & Co.[5] | |||||

| Broadhurst Street Hatworks | Davenport & Cale Green [1] | ||||

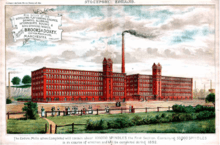

| Broadstone Mill | Reddish South SJ 892,930 53°26′02″N 2°09′50″W / 53.434°N 2.164°W | 1903 | Standing | 56 | |

| Notes: A double mill with twin chimneys, only one mill survives.[6] | |||||

| Canal Street Hat/Box Factory | Brinnington & Central [1] | ||||

| Carringtons Hat Works | Davenport & Cale Green [2] | ||||

| Chadkirk Mill | Bredbury Green & Romiley [1] | ||||

| Cheadle (Bleach) Works | Cheadle & Gatley SJ854890 53°23′53″N 2°13′16″W / 53.398°N 2.221°W | ||||

| Notes: Cheadle Lower Mill, often called Cheadle Bleachworks, and now renamed, The Bleachworks, is on a site used for this purpose since the 12th century.[1] | |||||

| Churchgate Mill | Brinnington & Central 53°24′33″N 2°09′12″W / 53.4092°N 2.1532°W | 1828 | Standing | 187 | |

| Notes: Built by 1828, later mill on site 3-storey. In 1880s spinning sewing and knitting yarn.[7] | |||||

| Compstall Bridge Works | Marple North [1] | ||||

| Compstall Mill | Marple North | ||||

| Notes: [1] | |||||

| Demmings Bleaching Works | Cheadle & Gatley [1] | ||||

| East Bank Mill | Brinnington & Central [1] | ||||

| Goyt Mill, Bredbury | Brinnington, Bredbury border SJ910910 53°24′57″N 2°08′13″W / 53.4159°N 2.1370°W | 1840 | 1981 | 141 | |

| Notes: Min building parallel to the river was a four-storey brick-built non-fireproof construction. There were 2 rows of cast-iron columns and iron roof ties. The five-storey extension was 100 ft by 120 ft with three rows of cast-iron columns. It was purchased by Isaac Pearson around 1890. Taken over by Fine Cotton Spinners and Doublers Association..[8] | |||||

| Goyt Mill, Hawk Green, Marple | Stott and Sons | Marple South 53°23′07″N 2°03′54″W / 53.3852°N 2.0651°W | 1905 | Standing | 55 |

|

Notes: Goyt Mill was built in 1905 by Jonathan Partington of Middleton for the Goyt Spinning Company, to a design by Stott and Sons. It is a six-storey with a total floor area 260,000 sq.ft. on its 6 floors. It had 82,000 mule spindles and 45,000 ring spindles, spinning 24 and 38 twist and 22 and 46 mule weft. All the machinery was by John Hetherington &Sons of Ancoats. The 165 carding engines, 25 draw frames, 26 intemediate frames, 50 roving frames were on the bottom two floors, the 30 pairs of mules were on the top three floors. It employed 480 mill staff and 12 office staff. The engine was a Carel Frères 2500 IHP condensing drop valve, cross compound ( 5ft 3in stroke, 27in and 63in bore). There were six Lancashire boilers with the firing end facing the Macclesfield Canal. The coal for its engine was supplied from the mines at Poynton and in Staffordshire.It was supplied directly to the boiler by a steam crane. The mill is now in multiple use.[1][1] | ||||

| Hallam Mill | Davenport & Cale | ||||

| Notes: aka Heaviley Mill: The former Squirrel Sweet Works. Home of a photo studio.[1] | |||||

| Hampstead Mill | Stepping Hill [1] | ||||

| Heapriding Mill | Edgeley & Cheadle SJ886902 53°24′31″N 2°10′15″W / 53.408682°N 2.170758°W | ||||

| Notes: A six-storey mill and weaving shed, that had 10,000 mule spindles in 1909. Occupied by John Greaves Son & Co in 1872 and John Edward Clegg in 1887.[4] | |||||

| Hempshaw Lane Works | Manor [1] | ||||

| Hopes Carr Hatworks | Brinnington & Central [1] | ||||

| Houldsworth Mill | Abraham Stott | Reddish North | 1865 | Standing | 150 |

| Notes: 1865 GradeII* listed.[6] | |||||

| Kershaws Tannery | Brinnington & Central [1] | ||||

| Kingston Mill | Edgeley & Cheadle 53°24′31″N 2°10′09″W / 53.4086°N 2.1692°W | ||||

| Notes: [2] | |||||

| Lancashire Hill Ropery | Reddish South 53°25′19″N 2°09′50″W / 53.4220°N 2.1638°W | Standing | |||

| Notes: Reuben Rivett used it in the 1880 to make main drive ropes, later it was occupied by the Lancashire Hill Rope & Twine Co Ltd.[1][9] | |||||

| Lincoln Bennett Hat Works | Edgeley & Cheadle [1] | ||||

| Lockside Mill | Marple North SJ926890 53°23′53″N 2°06′47″W / 53.398°N 2.113°W | 1801 | Standing | 214 | |

| Notes: Now called Lockside Mill, this canal side warehouse was built in 1801 by Samuel Oldknow. It is a three-storey 7- by 3-bay stone-built building with internal canal arm parallel to the canal, with cart entrance on the first floor. It is on the top pound of Lock 9, by lock 10.[1][10] | |||||

| Lower Carrs Mill | Brinnington & Central SJ 898902 53°24′32″N 2°09′18″W / 53.409°N 2.155°W | 1800 | |||

Notes: There were three mills built by Samuel Oldknow on Hopes Carr.

|

|||||

| Marriot Street Mill | Brinnington & Central [1] | ||||

| Meadow Mill | Brinnington & Central 53°25′04″N 2°09′09″W / 53.4177°N 2.1524°W | 1880 | Standing | 135 | |

|

Notes: Meadow Mill, Stockport. Owen Ashmore in The Industrial Archaeology of North-west England (1982) lists this as Meadow Mill (not Valley Mills). Circa 1880 built for T & J Leigh, cotton and wool spinning. Had 120,000 spindles in 1914. Twin six-storey brick built mills with ornamental engine house between. Fireproof construction. Cast-iron pillars between windows on top storey.,[2][13] | ||||

| New Mill | Reddish North [1] | ||||

| Oak Street Shed | Hazel Grove [1] | ||||

| Oakwood Mill | Bredbury Green & Romiley [1] | ||||

| Pear New Mill | A H Stott, P S Stott |

Bredbury 53°24′50″N 2°08′03″W / 53.4138°N 2.1341°W | 1912 | Standing | 66 |

|

Notes: A GradeII* listed building, Pear Mill, Stockport, was an Edwardian mill, one of the last cotton spinning mills to be built, commencing production in July 1913. The architects were A.H. Stott & Sons and the building is typical of their work. It was constructed with concrete floors, and meticulous detailing. The power was provided by a Manhattan type steam engine by George Saxon & Co. Transmission was by a rope drives. The mill had 137,312 mule spindles which remained until the 1950s when they were replaced by 33,636 ring spindles, the mill being electrified at the same time. It ceased operation as a textile mill in March 1978[2][14] | ||||

| Portwood Hatworks | Brinnington & Central [2] | ||||

| Primrose Mill | Mellor SJ 899911 53°24′03″N 2°01′55″W / 53.4009°N 2.032°W | 1780 | 1961 | 181 | |

| Notes: Was built as a Fulling Mill in 1780, enlarged in the 1820s and used as a cotton spinning mill. It was finally used eventually used for spinning and weaving gas mantles. It was burnt down in 1961, the site is used commercially by Marple Polymer Processors[1] | |||||

| Reddish Spinning Co., Victoria Mill (North mill) |

North Reddish 53°26′24″N 2°09′55″W / 53.4400°N 2.1653°W | 1870 | Standing | 145 | |

| Notes: Built by the said company in 1870, which became part of the Fine Cotton Spinners and Doublers Association in 1898. Together the mills had 133,000 mule spindles in 1909. The north mill had four storeys and with cast-iron pillars. Water and stair tower at SE corner joins the middle mill. In 2010 marketed as apartments, in Houldsworth Village development[15][16] | |||||

| Reddish Spinning Co., Elisabeth Mill (Middle mill) |

North Reddish 53°26′21″N 2°09′55″W / 53.4393°N 2.1652°W | 1870 | Standing | 145 | |

| Notes: Built by the said company in 1870, which became part of the Fine Cotton Spinners and Doublers Association in 1898. Together the mills had 133,000 mule spindles in 1909. The middle mill had four storeys and with 6 rows of cast-iron pillars, 17 pillars in a row In 2010 marketed as apartments, in Houldsworth Village development[15][16] | |||||

| Reddish Spinning Co., (South mill) |

North Reddish 53°26′20″N 2°09′57″W / 53.4390°N 2.1658°W | ||||

| Notes: A two-storey + cellar mill with 5 rows of cast-iron columns[16] | |||||

| Reynolds Mill | Brinnington & Central, Portwood 53°24′48″N 2°08′41″W / 53.4132°N 2.1448°W | ||||

| Notes: aka Cromer Street Mill | |||||

| Shaw Mill | Brinnington & Central [1] | ||||

| Sovereign Works | Edgeley & Cheadle [1] | ||||

| Springmount Mill Brinksway Bank Bleach and Pintworks |

Edgeley & Cheadle 53°24′21″N 2°10′31″W / 53.4059°N 2.1753°W | ||||

| Notes: A three-storey mill, with 2-storey extension. A five-storey mill with arched brick windows, and stair tower to south with cast-iron water tank above. Separate boiler house with round chimney. Later three-storey buildings on Brinksway. Taken over by Fine Cotton Spinners and Doublers Association.[2] | |||||

| Spur Mill | Reddish South 53°25′46″N 2°09′40″W / 53.4295°N 2.1612°W | 1907 | Standing | 65 | |

| Notes: A 1907, single-storey doubling mill with 20,000 spindles. Closed in 1972[16] | |||||

| Swallow Mill | Brinnington & Central [1] | ||||

| T W Bracher Leather | Brinnington & Central [1] | ||||

| Thorn Works | Bredbury [1] | ||||

| Throstle Grove Mill | Manor SJ 894907 53°24′47″N 2°09′40″W / 53.413°N 2.161°W | 1820 | 1870 | 50 | |

| Notes: Ralph Orrell Spinning[7] | |||||

| Unity Mill | Bredbury [1] | ||||

| Valley Mill | Hazel Grove [1] | ||||

| Vernon Mill | Brinnington & Central 53°24′51″N 2°08′45″W / 53.4143°N 2.1457°W | Standing | |||

| Notes: Graces Guide 1891 Portwood; 150,000 spindles, 45'/55' weft, 30'/42' twist. Listed building number.462281 [2] | |||||

| Victoria Dye Works | Manor SJ907895 53°24′07″N 2°08′28″W / 53.402°N 2.141°W | ||||

| Notes: Documented from the late 19th century.[1] | |||||

| Victoria Mill | South Reddish 53°25′50″N 2°09′40″W / 53.4306°N 2.1612°W | ||||

| Notes: Four-storey. | |||||

| Virginia Mill | Manor SJ 899892 53°24′00″N 2°09′11″W / 53.400°N 2.153°W | ||||

| Notes: Two-storey building on Hillgate. Documented in 1872[7] | |||||

| Waterloo Mill | Brinnington & Central [1] | ||||

Wear Mill

|

Edgeley & Cheadle 53°24′32″N 2°09′57″W / 53.4090°N 2.1658°W | Standing | |||

| Notes: [2] | |||||

| Welkin Mill | Bredbury 53°25′10″N 2°08′04″W / 53.4194°N 2.1345°W | Standing | |||

| Notes: [1] | |||||

| Wellington Mill | Brinnington & Central 53°24′31″N 2°09′44″W / 53.4085°N 2.1622°W | Standing | |||

| Notes: Wellington Mill, aka Wellington Bridge Mill, was originally an early fireproof cotton spinning mill[17][18] built in 1830–1831 before becoming a hat works in the 1890s.[19] It is a Grade II listed building[18] and is situated on the A6 Wellington Road South, between the town centre and the railway station.From 2000 it has housed the Hat Works, museum.[20] [21][22] | |||||

| Wellington Works (formally Botany Mill) | Bredbury , 53°25′50″N 2°06′07″W / 53.4306°N 2.1019°W[2] | Standing | |||

| Wood Mill, Woodley | Woodley,Stockport 53°25′57″N 2°06′08″W / 53.4324°N 2.1022°W | 1964 | |||

.jpg) |

Notes: [1] | ||||

Other Mills

| Name | Architect | Location | Built | Demolished | Served (Years) |

|---|---|---|---|---|---|

|

| |||||

| Albert | South Reddish 53°25′36″N 2°09′43″W / 53.4268°N 2.1619°W | 1845 | |||

| Notes: A four-storey mill built by Robert Hyde Greg. In 1911 it had 50,000 spindles[6] | |||||

| Hanover Mills | Reddish 53°25′41″N 2°09′41″W / 53.4280°N 2.1613°W | 1865 | |||

| Notes: Hanover Mill was built in 1865 for cotton spinning and doubling by Heywards, but in 1889 was converted to make silk, velvet, woven fur etc.[15] | |||||

Alligator

|

53°24′59″N 2°09′13″W / 53.4164°N 2.1536°W | ||||

| Notes: Occupied by the Alligator Rainwear Company until 1978 | |||||

Bankside

|

Reddish Newtown 53°25′15″N 2°09′37″W / 53.4208°N 2.1604°W | ||||

| Notes: Bankfield mill was 6-storey mill, using water from the Reddish Canal for its condensor.[23] | |||||

| Beehive | Portwood 53°24′59″N 2°09′13″W / 53.4164°N 2.1536°W | ||||

Notes: A collection of seven mills which were owned by T & J Leigh in 1872.There was an earlier mill on this site known as Brewery Mill, then

|

|||||

Brewery Street

|

53°24′59″N 2°09′13″W / 53.4164°N 2.1536°W[2] | ||||

| California | Joules Court 53°24′26″N 2°09′11″W / 53.4072°N 2.1531°W | ||||

| Notes: Brick built 2-storey, in use from 1858 to 1890s. In 1880s used for waste spinning and candlewicks.[7] | |||||

| Cataract Bridge Mill | Longhurst Lane, Mellor, Stockport 53°23′47″N 2°02′47″W / 53.3964°N 2.0464°W | Standing | |||

| Notes: In 2010 redundant, planning application pending for conversion to housing. | |||||

| Coronation | Newtown Reddish 53°25′18″N 2°09′44″W / 53.4216°N 2.1623°W | ||||

| Notes: Occupied by J&T Read in 1872 then John Whittaker & Son from 1900. Backing onto the Reddish Canal it has 35,000 spindles.[6] | |||||

| Crow Park | Portwood SJ 899911 53°25′01″N 2°09′11″W / 53.417°N 2.153°W | 1833 | |||

| Notes: A fir proof mill built of brick in 1833, it is six storeys plus basement and attic.The main rooms are 120 ft by 48 to 50 ft. The brick archeded floors are supported by cast-iron beams carried on two rows of cast-iron pillars, set 9 ft apart. Shafting was carried on brackets attached to the beams. The engine house was separate to the west of the mill. There was an earlier mill (Crow Park Wing Mill) believed to be 6 or 7 storeys that was narrower, having one row of pillars and cast-iron beams.[8][12] | |||||

| Dysart Street Shed | Great Moor SJ909882 53°23′28″N 2°08′17″W / 53.391°N 2.138°W | ||||

| Notes: Producing towelling in 1909 from 100 looms[25] | |||||

| Edgeley | |||||

| Elder | Romiley, Marple 53°24′41″N 2°05′47″W / 53.4114°N 2.0963°W | ||||

| Notes: Elder Mill was powered by a 600 hp vertical cross compound engine by Daniel Adamson, installed in 1937. It had a 3 ft stroke. It ran at 106 rpm. The flywheel was 16 ft.[26] | |||||

Faulder's

|

53°24′49″N 2°09′18″W / 53.4135°N 2.1551°W | 1989 | |||

| Notes: Rebuilt after a fire in 1871. Acquired in the 1890s by Henry Faulder & Co for use as a cocoa and chocolate factory.[27] | |||||

| Foggbrook | |||||

| Gorsey Bank | SJ878899 53°24′21″N 2°10′58″W / 53.405967°N 2.182782°W | ||||

| Notes: Main mill is two storeys plus basement, featuring 5 rows of cast-iron columns, flat roof with parapet. Second mill to the east, brick built three-storey mill with basement. It was powered by a 1908, 400 hp horizontal tandem compound engine by J & E Wood of Bolton. Lancashire boiler by Galloways of Manchester with Greens economiser and flue to octagonal chimney.[4] | |||||

| Heaton Mersey Works | |||||

| Hollins | |||||

| Hope | [2] | ||||

| India | Heaton Mersey SJ 888903 53°24′35″N 2°10′04″W / 53.409585°N 2.167752°W | ||||

| Notes: A combined mill, in 1909 it had 90,000 spindles and 1800 looms.[5] | |||||

| Logwood | 1732 | ||||

| Notes: An early silk throwing mill. It was one of the first three silk throwing mills in the UK, set up by John Guardivaglio in 1732. It was built in the park, with the blessing of Lord Warren on the site of a logwood mill, that ground logwood to creat dyestuffs. Twelve years later they dammed the Carr Brook (tin Brook) to build a further mill, and then another at the confluence of the Carr Brook and the River Mersey. There were 2000 silk throwing workers by 1760.These early silk mills built up a labour force accustomed to factory work- that was on hand for cotton in the 1780s[28] | |||||

| Mellor Mill | Marple SJ970878 53°23′13″N 2°02′49″W / 53.387°N 2.047°W | 1793 | 1892 | 99 | |

|

Notes: This was a six-storey, 42 feet wide and 210 feet long mill with additional 3-storey wings making it 400 ft in all. The mill was built for Samuel Oldknow and used to spin coarse counts. It was originally driven by the Wellington water wheel. The River Goyt, and with it the then county boundary between Derbyshire and Cheshire was diverted and a weir built, the leat fed a millpond that in later times was named the Roman Lakes. This in turn fed a second mill pond along with water from reservoir in Linnet Clough. Supplementary power was provided by a second exterior wheel known as the Waterloo wheel.The Mill reached its peak production in 1804, when 10,080 spindles were operating and around 550 people were employed. It was destroyed by fire in 1892.[29] | ||||

Middle Mill

|

Reddish SJ891937 53°26′24″N 2°09′58″W / 53.440°N 2.166°W | 1874 | |||

| Notes: Construction:1871 Patent, fireproof. Powered by a 500 hp, horizontal John Musgrave & Sons engine- produced fine to super fine counts [30] | |||||

| New Bridge Lane | [31] | ||||

| New Bridge | |||||

North Mill

|

Reddish SJ891937 53°26′24″N 2°09′58″W / 53.440°N 2.166°W | 1870 | |||

| Notes: Construction:Non fireproof on 1871 patent. The mules were supplied by Dobson & Barlow including 40 hand mules. They produced fine and super fine counts[32] | |||||

Orrell's Mill

|

Travis Street, Heaton Norris SJ 886903 53°24′32″N 2°10′23″W / 53.409°N 2.173°W | 1834 | |||

|

Notes: A historical significant mill that was used as a principal example in Andrew Ure's book. It pioneered the use of the cast-iron I-beam. It was built by William Fairbairn for Ralph Orrell. Originally a six-storey combined mill 280 ft by 50 ft, with side wings. It was designed to house 125000 throstle and 33000 mule spindles. Later in 1887 it was recorded as having 140,000 spindles and 1000 power looms. The original beam engine was replaced around 1912, and a new separate engine house built. At this time a rope race was added to the mill to replace the former fixed vertical main shaft. It was damaged by fire in the 1960s, and one storey was removed, and was demolished in the ?1980s. [9][33] | ||||

| Palmer Mills | Portwood, 53°24′52″N 2°08′48″W / 53.4144°N 2.1466°W[31] | ||||

| Reddish Mills | |||||

| Reddish Vale Printworks | Reddish Vale 53°26′11″N 2°08′39″W / 53.4363°N 2.1443°W | ||||

| Notes: Started before 1800 by James Fletcher a calico printer. In 1840,Becker Bros & Co had 4 printing machines and 118 block printing tables. Taken over by Bradshaw, Hammond & Co in 1862 and then the Calico Printers' Association in 1899. It was originally drive by water taken by a race from the River Tame. Later there was a central engine house, and a reservoir for condensing.[16] | |||||

| Rivett's | Heaton Norris 53°25′16″N 2°09′48″W / 53.4212°N 2.1632°W | ||||

| Notes: Thomas Rivett in 1887, then Joseph Rivett & Sons until taken over by the Fine Cotton Spinners and Doublers Association. It had an Octagonal Brick Chimney, was a three-storey mill with an open cast-iron water tank.[5] | |||||

| Springbank | |||||

| Springfield | SJ 897894 53°24′04″N 2°09′22″W / 53.401°N 2.156°W | ||||

| Notes: In 1897 this single-storey mill was weaving towelling on 260 looms[25] | |||||

| Squirrel Works | |||||

| Stockport Ring Mills | Heaton Norris 53°24′26″N 2°10′39″W / 53.4071°N 2.1774°W | ||||

|

Notes: Three mills 1892–1911 that ran 200,000 spindles.

|

||||

| Strines Print Works | Strines, Marple 53°22′35″N 2°02′23″W / 53.3765°N 2.0396°W | ||||

| Notes: Acquired by the Calico Printers' Association in 1899.[34] | |||||

| Top Mill | Bredbury & Woodley | ||||

Travis Brook Mill

|

Travis Street, Heaton Norris, 53°24′32″N 2°10′23″W / 53.409°N 2.173°W[9][33] | ||||

| Wards Hat Factory | |||||

| Waterloo Road Mill | [35] | ||||

References

- Notes

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10 1.11 1.12 1.13 1.14 1.15 1.16 1.17 1.18 1.19 1.20 1.21 1.22 1.23 1.24 1.25 1.26 1.27 1.28 1.29 1.30 1.31 1.32 1.33 1.34 1.35 1.36 1.37 1.38 1.39 "STANDING TEXTILE MILL BUILDINGS IN STOCKPORT". Stockport Council. Retrieved 2009-01-11.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 Ashmore 1975, p. 51

- ↑ Ashmore 1975, p. 89

- ↑ 4.0 4.1 4.2 4.3 Ashmore 1975, p. 87

- ↑ 5.0 5.1 5.2 Ashmore 1975, p. 80

- ↑ 6.0 6.1 6.2 6.3 Ashmore 1975, p. 84

- ↑ 7.0 7.1 7.2 7.3 Ashmore 1975, p. 71

- ↑ 8.0 8.1 Ashmore 1975, p. 75

- ↑ 9.0 9.1 9.2 9.3 Ashmore 1975, pp. 16–17,26,81

- ↑ Nevell & Walker 2001, p. 73

- ↑ Stockport Navigation Pitt Dixon. Retrieved 2011-01-24

- ↑ 12.0 12.1 Ashmore 1975, p. 16

- ↑ Owen Ashmore in The Industrial Archaeology of North-west England (1982)

- ↑ Holden, Roger N. (Spring 1988). "Pear New Mill, Stockport". Industrial Archaeology Review, 10 (2): 162–174. Retrieved 2010-01-06.

- ↑ 15.0 15.1 15.2 Astle 1922, p. 145|

- ↑ 16.0 16.1 16.2 16.3 16.4 16.5 Ashmore 1975, p. 85

- ↑ Fletcher & Ahmet 1994.

- ↑ 18.0 18.1 Robina McNeil; Michael Nevell (2000). A guide to the industrial archaeology of Greater Manchester. Association for Industrial Archaeology. ISBN 978-0-9528930-3-5. OCLC 45829134.

- ↑ "Spinning the Web > Home > Spinning the Web partners > Stockport Library and Information Service". Manchester City Council. Retrieved 6 March 2008.

- ↑ "Mad hatters win top award". Stockport Express (M.E.N. Media). 2 October 2002. Retrieved 6 March 2008.

- ↑ Greater Manchester Archaeological Contracts; Mark Fletcher and Koral Ahmet (1994). "Wellington Mill, Stockport.". Greater Manchester Archaeological Contracts. pp. 1–38. Retrieved 2010.

- ↑ Ashmore 1975, p. 72

- ↑ Mike Kiernan Mike Kiernan:Newtown

- ↑ Ashmore 1975, p. 74

- ↑ 25.0 25.1 Ashmore 1975, p. 90

- ↑ Roberts, A S (1921). "One guy from Barlick-Book Transcription". ARTHUR ROBERT'S BLACK BOOK. Retrieved 2009-01-11.

- ↑ http://interactive.stockport.gov.uk/edrms/onlinemvm/getimage.asp?DocumentNumber=166815

- ↑ Ashmore 1975, p. 9

- ↑ http://www.marple-uk.co.uk/Mellormillx.htm An article by Mark Whittaker in the September 2001 issue of the Community News, in our regular feature "Local History & Heritage with the Marple Website"

- ↑ Holden 1998, p. 217

- ↑ 31.0 31.1 Ashmore 1975, p. 77

- ↑ Holden 1998, p. 216

- ↑ 33.0 33.1 Ure 1836, pp. 296 et seq

- ↑ Lewis, p. 22

- ↑ Williams 1992, p. 196

- Bibliography

- Ashmore, Owen (1975), The industrial archaeology of Stockport, Dept of Extra Mural Studies Manchester University, ISBN 0-902637-17-7

- Astle (1922). Stockport Advertiser History of Stockport (PDF). Retrieved 25 February 2009.

- Lewis, Steve. "Industrial Development in New Mills". Retrieved 29 November 2009.

- Holden, Roger N. (1998). Stott & Sons : architects of the Lancashire cotton mill. Lancaster: Carnegie. ISBN 1-85936-047-5.

- Holden, Roger N (2005). Stenkamp, Hermann Josef, ed. Sidney Stott en de Engelse spinnerijen in Munsterland en Twente (PDF) (in English, Deutsch, and Nederlands). Cotton mills for the continent Sidney Stott und der englische Spinnereibau in Münsterland und Twente Sidney Stott en de Engelse spinnerijen in Munsterland en Twente. Westfalen/Lippe: Westfälische Industrie Museum. ISBN 3-89861-458-1. Retrieved 29 January 2009.

- "STANDING TEXTILE MILL BUILDINGS IN STOCKPORT". Stockport Council. Retrieved 2009-01-11.

- Ure, Andrew (1836). The cotton manufacture of Great Britain systematically investigated 1. London: Charles Knight. Retrieved 2011-01-02.