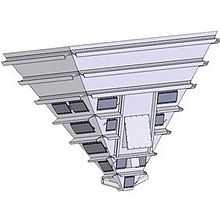

Hopper (particulate collection container)

A hopper is a large, pyramidal shaped container used in industrial processes to hold particulate matter that has been collected from expelled air. Hoppers are usually installed in groups to allow for a greater collection quantity. They are employed in industrial processes that use air pollution control devices such as dust collectors, electrostatic precipitators, and baghouses/fabric filters. Most hoppers are made of steel.

Process

Dust enters the hopper from the collection device. For example, baghouses are shaken or blown with compressed air to release caked-on dust from the bag. Precipitators use a rapping system to release the dirt. The crumbling dust falls into the hopper. Once the dust in the hopper reaches capacity, it is released through an opening in the bottom with a diameter of about 8–12 inches (20–30 cm). Hoppers are rectangular in cross section but have sides that slope at about a 60° angle. Slanted sides make it easier to remove the ash. Conveyors are sometimes used to carry away the particulate matter.[1]

Important components

Hopper walls are insulated to protect the outside environment and personnel from the discarded contents. Often, the bottom 1/4 – 1/3 of the container is heated to eliminate the possibility of condensation inside the hopper.[2]

The greatest difficulty associated with the removal of dust from the hopper is the compaction of the ash. Moisture content, particle shape and size, and vibration are all factors that contribute to compaction. Typically, vibrators are installed on the outer walls of a hopper to shake and release the dust.