Gerald R. Ford-class aircraft carrier

| Gerald R. Ford on the James River in November 2013. | |

| Class overview | |

|---|---|

| Name: | Gerald R. Ford–class aircraft carrier |

| Builders: | Newport News Shipbuilding |

| Operators: |

|

| Preceded by: | Nimitz class |

| Cost: | $12.68 billion (FY14)[1] |

| Building: | 2 |

| Planned: | 10[2] |

| Completed: | 1 (awaiting commissioning) |

| General characteristics | |

| Type: | Aircraft carrier |

| Displacement: | Approximately 100,000 long tons (110,000 short tons; 100,000 tonnes) (full load)[3] |

| Length: | 1,106 ft (337 m) |

| Beam: | 256 ft (78 m) (flight deck) 134 ft (41 m) (waterline) |

| Height: | 250 feet (76 m) |

| Draft: | 39 ft (12 m)[4] |

| Decks: | 25 |

| Installed power: | Two A1B nuclear reactors |

| Propulsion: | Four shafts |

| Speed: | In excess of 30 knots (56 km/h; 35 mph) |

| Complement: | 508 officers 3,789 enlisted[4] |

| Armament: | Anti-aircraft missiles: 2 × RIM-162 ESSM 2 × RIM-116 RAM Guns: 2 × Phalanx CIWS 4 × M2 12.7mm machine guns |

| Aircraft carried: | 75+[5] |

| Aviation facilities: | 1,092 ft × 256 ft (333 m × 78 m) flight deck |

Gerald R. Ford class (or Ford class, previously known as "CVN 21 class") is a class of supercarriers currently being built to replace some of the United States Navy's existing Nimitz-class carriers. The new vessels will have a hull similar to the Nimitz carriers, but will introduce technologies developed since the initial design of the previous class (such as the Electromagnetic Aircraft Launch System), as well as other design features intended to improve efficiency and operating costs, including reduced crew requirement.[6] The first ship of the class, the Gerald R. Ford, has hull number CVN-78.[N 1][7]

Features summary

Carriers of the Ford-class will incorporate design features including:[8]

- Advanced arresting gear.[9]

- Automation, which reduces crew requirements by several hundred from the Nimitz-class carrier.

- The updated RIM-162 Evolved Sea Sparrow missile system.[10]

- AN/SPY-3 dual-band radar (DBR), as developed for Zumwalt-class destroyers.

- An Electromagnetic Aircraft Launch System (EMALS) in place of traditional steam catapults for launching aircraft.[9]

- A new nuclear reactor design (the A1B reactor) for greater power generation.

- Stealth features to help reduce Radar cross-section.

- The ability to carry up to 90 aircraft, including the Boeing F/A-18E/F Super Hornet, Boeing EA-18G Growler, Grumman C-2 Greyhound, Northrop Grumman E-2 Hawkeye, and Lockheed Martin F-35C Lightning II, Sikorsky SH-60 Seahawk helicopters, and unmanned combat air vehicles such as the Northrop Grumman X-47B.[10][11]

The navy believes that with the addition of the most modern equipment and extensive use of automation, it will be able to reduce the crew requirement and the total cost of future aircraft carriers.[12] The primary recognition feature compared to earlier supercarriers will be the more aft location of the navigation island to make aircraft movements more efficient.[13] The Ford class are intended to sustain 160 sorties per day for 30+ days, with a surge capability of 270 sorties/day, but the Director of Operational Testing Michael Gilmore has criticised the unrealistic assumptions used in these forecasts and has indicated sortie rates similar to the 120/240 per day of the Nimitz class would be acceptable.[14]

Design and development

The Nimitz-class aircraft carrier has been an integral part of United States power projection strategy since Nimitz was first commissioned in 1975. Displacing approximately 100,000 tons when fully loaded, a Nimitz-class carrier is capable of steaming faster than thirty knots, self-sustaining for up to ninety days, and launching aircraft to strike targets hundreds of miles away.[15] The endurance of this class is exemplified by USS Theodore Roosevelt, which spent 159 days underway in support of Operation Enduring Freedom without the need to visit a port or be refueled.[16]

Over the lifespan of the class many new technologies have been successfully integrated into the design of this vessel. However, with the technical advances made in the past decade the ability of the navy to make improvements to this class of ship has become more limited. "The biggest problems facing the Nimitz class are the limited electrical power generation capability and the upgrade-driven increase in ship weight and erosion of the center-of-gravity margin needed to maintain ship stability."[17]

With these constraints in mind the navy developed what was initially known as the "CVN-21" program, which ultimately evolved into CVN-78, Gerald R. Ford. Improvements were made through developing technologies and more efficient design. Major design changes include a larger flight deck, improvements in weapons and material handling, a new propulsion plant design that requires fewer personnel to operate and maintain, and a new smaller island that has been pushed aft. Technological advances in electromagnetics have led to the development of an Electromagnetic Aircraft Launch System (EMALS), and an Advanced Arresting Gear (AAG). An integrated warfare system, the Ship Self-Defense System (SSDS), has been developed to support flexibility in adapting the infrastructure of the ship to future mission roles. The new Dual Band Radar (DBR) combines S-band and X-band radar in a single system.[18]

With new design and technology the Ford will have a 25% increase in sortie generation, threefold increase in electrical generating capacity, increased operational availability, and a number of quality-of-life improvements.[19] Requirements for a higher sortie rate of around 160 exits a day with surges to a maximum of 270 sorties a day in times of crisis and intense air warfare activity, have led to design changes in the flight deck, which enable greater aircraft launch capabilities.

Flight deck

Changes to the flight deck are the most visible of the differences between the Nimitz and Gerald R. Ford classes. Several sections have been altered from the layout of the Nimitz-class flight deck to improve aircraft handling, storage, and flow. Catapult number four on the Nimitz-class cannot launch fully loaded aircraft because of a deficiency of wing clearance along the edge of the flight deck.[20] CVN-78 will have no catapult-specific restrictions on launching aircraft, but still retains four catapults, two bow and two waist,[21] and the number of aircraft lifts from hangar deck to flight deck level was reduced from the earlier ships from four to three. The design changes to the flight deck are instrumental in the maximization of sorties launched.

The route of weapons to the aircraft stops on the flight deck has been replanned to accommodate higher rearming rates, and in turn higher potential sortie rates.

Another major change is that the smaller, redesigned island will be pushed further back relative to the older classes of carriers. Moving the island creates deck space for a centralized rearming and refueling location. This reduces the number of times that an aircraft will have to be moved after landing before it can be launched again. Fewer aircraft movements require, in turn, fewer deck hands to accomplish them, reducing the size of the ship's crew. A similar benefit is realized by altering the path and procedures for weapons movement by redshirts from storage to flight deck, again potentially allowing the new ship to support a higher sortie rate than the Nimitz-class ship while using fewer crew members than the Nimitz requires. On Nimitz-class carriers the time that it takes to launch a plane after it has landed is set by the time needed to rearm and refuel it. To minimize this time, ordnance will be moved from storage areas to the centralized rearming location via relocated, higher capacity weapons elevators, utilizing linear motors.[22] The new path that ordnance follows does not cross any areas of aircraft movement, thereby reducing traffic problems in the hangars and on the flight deck. According to Rear Admiral Dennis M. Dwyer, these changes will make it hypothetically possible to rearm the airplanes in "minutes instead of hours".[23]

Power generation

The new reactor for the CVN 21 class overcomes many of the shortfalls of the Nimitz-class reactor and is an enabler for many of the other technologies and improvements planned for the new class. Two Bechtel A1B nuclear reactors will be installed on each Ford-class carrier, with each A1B reactor capable of producing 300 MW of electricity.[24][25]

The propulsion and power plant of the Nimitz-class carriers was designed in the 1960s. Technological capabilities of that time did not require the same quantity of electrical power that modern technologies do. "New technologies added to the Nimitz-class ships have generated increased demands for electricity; the current base load leaves little margin to meet expanding demands for power."[26] Increasing the capability of the U.S. Navy to improve the technological level of the carrier fleet required a larger capacity power system.

Compared to the Nimitz-class reactor, the CVN 21 reactor will have approximately 50 percent fewer valves, piping, major pumps, condensers, and generators. The steam-generating system will use fewer than 200 valves and only 8 pipe sizes. These improvements lead to simpler construction, reduced maintenance, and lower manpower requirements as well as to a more compact system that requires less space in the ship. The new A1B reactor plant is a smaller, more efficient design that provides approximately three times the electrical power of the Nimitz-class A4W reactor plant. The modernization of the plant led to a higher core energy density, lower demands for pumping power, a simpler construction, and the use of modern electronic controls and displays. These changes resulted in a two-thirds reduction of watch standing requirements and a significant decrease of required maintenance.[27]

A larger power output is a major component to the integrated warfare system. Engineers took extra steps to ensure that integrating unforeseen technological advances onto a Gerald R. Ford-class aircraft carrier would be possible. The U.S. Navy projects that the Gerald R. Ford-class will be an integral component of the fleet for ninety years into the future (the year 2105). One lesson learned from that is that for a ship design to be successful over the course of a century, a great deal of foresight and flexibility is required. Integrating new technologies with the Nimitz-class is becoming more difficult to do without any negative consequences. To bring the Gerald R. Ford-class into dominance during the next century of naval warfare requires that the class be capable of seamlessly upgrading to more advanced systems.

EMALS launch system

The Nimitz-class aircraft carriers use steam-powered catapults to launch aircraft. Steam catapults were developed in the 1950s and have been exceptionally reliable. For over fifty years at least one of the four catapults has been able to launch an aircraft 99.5% of the time.[28] However, there are a number of drawbacks. "The foremost deficiency is that the catapult operates without feedback control. With no feedback, there often occurs large transients in tow force that can damage or reduce the life of the airframe."[29] The steam system is massive, inefficient (4–6%),[30] and hard to control.

Control problems with steam-powered aircraft launch systems on Nimitz-class carriers result in minimum and maximum weight limits. The minimum weight limit on steam-powered catapults is above the weight of all UAVs which represents a substantial shortfall in capability (an inability to launch the latest additions to the Naval air forces is a restriction on naval operations that cannot continue into the next generation of aircraft carriers).

The Electromagnetic Aircraft Launch System (EMALS) provides solutions to all these problems . An electromagnetic system is more efficient, smaller, lighter, more powerful, and easier to control. Increased control means that EMALS will be able to launch both heavier and lighter aircraft than the steam catapult. Also, the use of a controlled force will reduce the stress on airframes, resulting in less maintenance and a longer lifetime for the airframe. Unfortunately the power limitations for the Nimitz class make the installation of the recently developed EMALS impossible.

In June 2014, the Navy completed EMALS prototype testing of 450 manned aircraft launches involving every fixed-wing carrier-borne aircraft type in the USN inventory at Joint Base McGuire-Dix-Lakehurst during two Aircraft Compatibility Testing (ACT) campaigns. ACT Phase 1 concluded in late 2011 following 134 launches (aircraft types comprising the F/A-18E Super Hornet, T-45C Goshawk, C-2A Greyhound, E-2D Advanced Hawkeye, and F-35C Lightning II). On completion of ACT 1, the EMALS demonstrator was reconfigured to be more representative of the actual ship configuration on board Ford, which will use four catapults sharing several energy storage and power conversion subsystems.

ACT Phase 2 began on 25 June 2013 and concluded on 6 April 2014 after a further 310 launches (including launches of the EA-18G Growler and F/A-18C Hornet, as well as another round of testing with aircraft types previously launched during Phase 1). In Phase 2 various carrier situations were simulated, including off-centre launches and planned system faults, to demonstrate that aircraft could meet end-speed and validate launch-critical reliability.[31]

AAG landing system

Electromagnetics will also be used in the new Advanced Arresting Gear (AAG) system. The current system relies on hydraulics to slow and stop a landing aircraft. While the hydraulic system is effective, as demonstrated by more than fifty years of implementation, the AAG system offers a number of improvements. The current system is unable to capture UAVs without damaging them due to extreme stresses on the airframe. UAVs do not have the necessary mass to drive the large hydraulic piston used to trap heavier manned planes. By using electromagnetics the energy absorption is controlled by a turbo-electric engine. This makes the trap smoother and reduces shock on airframes. Even though the system will look the same from the flight deck as its predecessor, it will be more flexible, safe, and reliable, and will require less maintenance and manning.[32]

Sensors and self-defense systems

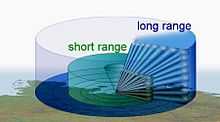

Another addition to the Gerald R. Ford-class is an integrated Active electronically scanned array search and tracking radar system. The dual-band radar (DBR) was being developed for both the Zumwalt-class guided missile destroyers and the Ford-class aircraft carriers by Raytheon. The island can be kept smaller by replacing six to ten radar antennas with a single six-faced radar. The DBR works by combining the X band AN/SPY-3 multifunction radar with the S band Volume Search Radar (VSR) emitters, distributed into three phased arrays.[33] The S-band radar was later deleted from the Zumwalt class destroyers as a cost saving measure.[34]

The three faces dedicated to the X-band radar are responsible for low altitude tracking and radar illumination, while the other three faces dedicated to the S-band are responsible for target search and tracking regardless of weather. "Operating simultaneously over two electromagnetic frequency ranges, the DBR marks the first time this functionality has been achieved using two frequencies coordinated by a single resource manager."[18]

This new system has no moving parts, therefore minimizing maintenance and manning requirements for operation. The carrier will be armed with the Raytheon evolved Sea Sparrow missile (ESSM), which defends against high-speed, highly maneuverable anti-ship missiles. The close-in weapon system is the rolling airframe missile (RAM) from Raytheon and Ramsys GmbH.

The AN/SPY-3 consists of three active arrays and the Receiver/Exciter (REX) cabinets abovedecks and the Signal and Data Processor (SDP) subsystem below-decks. The VSR has a similar architecture, with the beamforming and narrowband down-conversion functionality occurring in two additional cabinets per array. A central controller (the resource manager) resides in the Data Processor (DP). The DBR is the first radar system that uses a central controller and two active-array radars operating at different frequencies. The DBR gets its power from the Common Array Power System (CAPS), which comprises Power Conversion Units (PCUs) and Power Distribution Units (PDUs). The DBR is cooled via a closed-loop cooling system called the Common Array Cooling System (CACS).[35]

The REX consists of a digital and an analog portion. The digital portion of the REX provides system-level timing and control. The analog portion contains the exciter and the receiver. The exciter is a low-amplitude and phase noise system that uses direct frequency synthesis. The radar’s noise characteristics support the high Clutter (radar) cancellation requirements required in the broad range of maritime operating environments that DBR will likely encounter. The direct frequency synthesis allows a wide range of pulse repetition frequencies, pulse widths, and modulation schemes to be created.

The receiver has high dynamic range to support high Clutter (radar) levels caused by close returns from range-ambiguous Doppler effect waveforms. The receiver has both narrowband and wideband channels, as well as multichannel capabilities to support monopulse radar processing and sidelobe blanking. The receiver generates digital data and sends the data to the signal processors.

The DBR uses IBM commercial off-the-shelf (COTS) supercomputers to provide control and signal processing. DBR is the first radar system to use COTS systems to perform the signal processing. Using COTS systems reduces development costs and increases system reliability and maintainability.

The high-performance COTS servers perform signal analysis using radar and digital signal processing techniques, including channel equalization, Clutter (radar) filtering, Doppler processing, impulse editing, and implementation of a variety of advanced electronic protect algorithms. The IBM supercomputers are installed in cabinets that provide shock and vibration isolation. The DP contains the resource manager, the tracker, and the command and control processor, which processes commands from the combat system.

The DBR utilizes a multitier, dual-band tracker, which consists of a local X band tracker, a local S band tracker, and a central tracker. The central tracker merges the local tracker data together and directs the individual-band trackers’ updates. The X band tracker is optimized for low latency to support its mission of providing defense against fast, low-flying missiles, while the VSR tracker is optimized for throughput due to the large-volume search area coverage requirements.

The combat system develops doctrine-based response recommendations based on the current tactical situation and sends the recommendations to the DBR. The combat system also has control of which modes the radar will perform. Unlike previous-generation radars, the DBR does not require an operator and has no manned display consoles. The system uses information about the current environment and doctrine from the combat system to make automated decisions, not only reducing reaction times, but also reducing the risks associated with human error. The only human interaction is for maintenance and repair activities.

Possible upgrades

Each new technology and design feature integrated into the Ford-class aircraft carrier improves sortie generation, manning requirements, and operational capabilities. New defense systems, such as free-electron laser directed-energy weapons, dynamic armor, and tracking systems will require more power. "Only half of the electrical power-generation capability on CVN-78 is needed to run currently planned systems, including EMALS. CVN-78 will thus have the power reserves that the Nimitz-class lacks to run lasers and dynamic armor."[36] The addition of new technologies, power systems, design layout, and better control systems results in an increased sortie rate of 25% over the Nimitz-class and a 25% reduction in manpower required to operate.[37]

Breakthrough waste management technology will be deployed on Gerald R Ford. Co-developed with the Carderock Division of the Naval Surface Warfare Center, PyroGenesis Canada Inc., was in 2008 awarded the contract to outfit the ship with a Plasma Arc Waste Destruction System (PAWDS). This compact system will treat all combustible solid waste generated on board the ship. After having completed factory acceptance testing in Montreal, the system was scheduled to be shipped to the Huntington Ingalls shipyard in late 2011 for installation on the carrier.[38]

The Navy is actively developing a weapon system called the free-electron laser (FEL) to address the cruise missile threat and the swarm-boat threat against Ford-class carriers.[39][40][41][42][43] An FEL uses an electron gun to generate a stream of electrons. The electrons are then sent into a linear particle accelerator to accelerate them to near light speeds. The accelerated electrons are then sent into a device, known informally as a wiggler, that exposes the electrons to a transverse magnetic field, which causes the electrons to “wiggle” from side to side and release some of their energy in the form of light (photons). The photons are then bounced between mirrors and emitted as a coherent beam of laser light. To increase the efficiency of the system, some of the electrons are then cycled back to the front of the particle accelerator via an energy recovery loop. The cost to fire one round from an FEL is about $1 and consumes about 10 MW of electricity.

3D Computer-aided design

Newport News Shipbuilding used a full-scale three-dimensional product model developed in Dassault Systèmes CATIA V5 release 8 (which includes special features useful to shipbuilders[44]) to design and plan the construction of the Ford-class of aircraft carriers. This enables engineers and designers to test visual integration in design, engineering, planning and construction of components and subsystems. CVN 78 is the first aircraft carrier to be designed in a full-scale 3D product model. This modeling enabled the rooms within the ship to be modular, so that future upgrades can be implemented by designers simply by swapping a box in and locking it down.

This method of designing workflow also resulted in improvements to weapon handling procedures and an increase in potential sorties-per-day. Weapons-handling paths on Nimitz-class ships were designed for the potential nuclear missions of the Cold War. The current flow of weapons from storage areas in the interior of the Nimitz-class ship to loading on aircraft involves several horizontal and vertical movements to various staging and build-up locations within the ship. These movements around the ship are time-consuming and manpower-intensive and typically involve sailors manually moving weapons loaded on carts. Also, the current locations of some of the Nimitz-class weapons elevators conflict with the flow of aircraft on the flight deck, slowing down the generation of sorties or making some elevators unusable during flight operations.

The CVN 21 class was designed to have better weapons movement paths, largely eliminating horizontal movements within the ship. Current plans call for advanced weapons elevators to move from storage areas to dedicated weapons-handling areas. Sailors would use motorized carts to move the weapons from storage to the elevators at different levels of the weapons magazines. Linear motors are being considered for the advanced weapons elevators. The elevators will also be relocated such that they will not impede aircraft operations on the flight deck. The redesign of the weapons movement paths and the location of the weapons elevators on the flight deck will reduce manpower and contribute to a much higher sortie generation rate.[45]

Planned aircraft complement

The Ford-class is designed to accommodate the new Joint Strike Fighter carrier variant aircraft (F-35C), but aircraft development and testing delays have affected integration activities on CVN 78. These integration activities include testing the F-35C with CVN 78’s EMALS and advanced arresting gear system and testing the ship’s storage capabilities for the F-35C’s lithium-ion batteries (which provide start-up and back-up power), tires, and wheels. As a result of F-35C developmental delays, the Navy will not field the aircraft until at least 2017—one year after CVN 78 delivery. As a result, the Navy has deferred critical F-35C integration activities, which introduces risk of system incompatibilities and costly retrofits to the ship after it is delivered to the Navy.[46]

Crew Accommodations

Systems that reduce crew workload have allowed the ship’s company on Ford-class carriers to total only 2,600 sailors, about 600 fewer than a Nimitz-class flattop. The massive, 180-man berthing areas on the Nimitz-class are replaced by 40 racks per berthing on Ford-class carriers. The smaller berthings are quieter and the layout requires less foot traffic through other spaces.[47]

The racks are typically stacked three high, with one locker per person and extra lockers for those without storage space under their rack. The berthings, however, do not feature “sit-up” racks with more headroom (each rack can only accommodate a sailor lying down). Each berthing has an associated head, including showers, vacuum-powered septic system toilets (no urinals since the berthings are built gender-neutral), and sinks to reduce travel and traffic to access those facilities. Wifi-enabled lounges are located across the passageway in separate spaces from the berthing’s racks.

Construction

Construction began on 11 August 2005, when Northrop Grumman held a ceremonial steel cut for a 15-ton plate that will form part of a side shell unit of the carrier.[48] Construction began on components of CVN-78 in early 2007[49] and is planned to finish in 2015. It is under construction at Newport News Shipbuilding, a division of Huntington Ingalls Industries (formerly Northrop Grumman Shipbuilding) in Newport News, Virginia. This is the only shipyard in the United States capable of building nuclear-powered aircraft carriers.

In 2005, it was estimated to cost at least $8 billion excluding the $5 billion spent on research and development (though that was not expected to be representative of the cost of future members of the class).[12] A 2009 report said that the Ford would cost $14 billion including research and development, and the actual cost of the carrier itself would be $9 billion.[50] The daily operating cost of a carrier strike group is estimated at $6.5 million.[51]

A total of three carriers have been authorized for construction, but if the Nimitz-class carriers and Enterprise were to be replaced on a one-for-one basis, eleven carriers would be required over the life of the program. However, the last Nimitz-class aircraft carrier is not scheduled to be decommissioned until 2058.

In a speech on 6 April 2009, then Secretary of Defense Robert Gates announced that the program would shift to a five-year building program so as to place it on a "more fiscally sustainable path". Such a measure would result in ten carriers after 2040.[52]

In 2013 a GAO report cast doubts on the delivery schedule.[53][54] As of 2013, construction costs are estimated at $12.8 billion, 22% over the 2008 budget, plus $4.7 billion in research and development costs. Because of budget difficulties, the Chief of Naval Operations, Admiral Jonathan Greenert, has warned there may be a two-year delay beyond 2016 in completing the Ford.[55]

First-of-class type design changes

As construction of CVN-78 progresses, the shipbuilder is discovering first-of-class type design changes, which it will use to update the model prior to the follow-on ship construction. To date, several of these design changes have related to EMALS configuration changes, which have required electrical, wiring, and other changes within the ship. Although the Navy reports that these EMALS-related changes are nearing completion, it anticipates additional design changes stemming from remaining advanced arresting gear development and testing. In total, over 1,200 anticipated design changes remain to be completed (out of nearly 19,000 planned changes). According to the Navy, many of these 19,000 changes were programmed into the construction schedule early on—a result of the government’s decision at contract award to introduce improvements during construction to the ship’s warfare systems, which are heavily dependent on evolving commercial technologies.[46]

Naming

There was a movement by the USS America Carrier Veterans' Association to have CVN-78 named after America rather than after President Ford. Eventually, the amphibious assault ship LHA-6 was named America.

On 27 May 2011, the Department of Defense announced the name of CVN-79 would be USS John F. Kennedy.[56]

On 1 December 2012, Secretary of the Navy Ray Mabus announced that CVN-80 would be named USS Enterprise. The information was delivered during a prerecorded speech as part of the deactivation ceremony for the previous USS Enterprise (CVN-65). The future Enterprise (CVN-80) will be the ninth U.S. Navy ship to bear this name.[57]

Ships in class

There are expected to be ten ships of this class.[58] To date, three have been announced:

| Ship | Hull classification symbol | Laid down | Launched | Commissioned | Scheduled to replace | References |

|---|---|---|---|---|---|---|

| Gerald R. Ford | |

13 November 2009 | |

(scheduled) |

Enterprise (CVN-65) | |

| John F. Kennedy | |

(scheduled) |

(scheduled) |

(scheduled) |

Nimitz (CVN-68) | [60][61] |

| Enterprise | |

(scheduled) |

(scheduled) |

(scheduled) |

Dwight D. Eisenhower (CVN-69) | [61] |

See also

- List of aircraft carriers

- List of aircraft carrier classes of the United States Navy

- Modern United States Navy carrier air operations

- Naval aviation

- A1B reactor

- Ship class

Notes

- ↑ Before its redesignation to Ford-class (CVN-78), the new carrier was known as the CVNX carrier program ("X" meaning "in development") and then as the CVN-21 carrier program. (Here, the "21" is not a hull number, but rather it is common in "future" plans in the U.S. military, alluding to the 21st century.)

References

- ↑ Ronald O'Rourke (22 October 2013). "Navy Ford (CVN-78) Class Aircraft Carrier Program: Background and Issues for Congress" (PDF). Congressional Research Service. p. 4. Retrieved 2014-02-08. FY14 cost of CVN-79 (procured in FY13) in then-year dollars; the same budget puts the cost of CVN-78 (procured in FY08) at $12,829.3 million but that includes ~$3.3bn of development costs. CVN-80 is estimated at $13,874.2m, making the total cost of the first three Fords $38,041.9m, or $12.68bn each.

- ↑ Combat fleet of the world 2012

- ↑ "Aircraft Carriers - CVN". Fact File. United States Navy. 20 November 2013. Retrieved 19 May 2014.

- ↑ 4.0 4.1 "GERALD R FORD". Naval Vessel Register. US Navy. Retrieved 1 December 2012.

- ↑ "AIRCRAFT CARRIERS - CVN". America's Navy. Department of the Navy. Retrieved 26 October 2014.

- ↑ "CVN 78 Gerald R Ford Class". Naval technology.com. 22 December 2009. Retrieved 26 March 2010.

- ↑ "Next aircraft carrier named Gerald R. Ford". Forbes. 3 January 2007.

- ↑ Ronald O'Rourke (22 December 2009). "Navy Ford (CVN-78) Class Aircraft Carrier Program: Background and Issues for Congress" (PDF). Congressional Research Service. Retrieved 7 November 2007.

- ↑ 9.0 9.1 "Carrier Launch System Passes Initial Tests". Aviation Week.

- ↑ "Aircraft Carriers – CVN 21 Program" (PDF). US Navy (Navy Fact File). 9 February 2011. Retrieved 9 February 2011.

- ↑ 12.0 12.1 "Costing the CVN-21: A DID Primer". Defense Industry Daily. 19 December 2005. Retrieved 7 November 2007. Covers the costs of the CVN-21 program, how those are calculated, and where the $5 billion savings on operational costs is expected to come from over the ship's planned 50-year lifetime.

- ↑ Keeter, Hunter (June 2003). "New Carrier Island Is at Heart of Higher Sortie Rates for CVN 21". NavyLeague.org. Retrieved 21 August 2011.

- ↑ FY2013 Annual Report for the Office of the Director, Operational Test & Evaluation - CVN-78 Gerald R. Ford Class Nuclear Aircraft Carrier (PDF), Director, Operational Test & Evaluation

- ↑ "Ship Information". USS Nimitz Homepage. 4 March 2008.

- ↑ "Our Ship". USS Theodore Roosevelt (CVN 71) Web Page. 4 March 2008.

- ↑ Schank, John. Modernizing the U.S. Aircraft Carrier Fleet: Accelerating CVN 21 Production Versus Mid-Life Refueling. Santa Monica: Rand Corporation, 2005. p. 76.

- ↑ 18.0 18.1 Larrabee, Chuck. DDG 1000 Dual Band Radar (DBR). Raytheon. 1 March 2008.

- ↑ Aircraft Carriers - CVN 21 Program Fact File. United States Navy. 8 October 2007. 4 March 2008.

- ↑ Schank, John. Modernizing the U.S. Aircraft Carrier Fleet, p. 77.

- ↑ Navy Fact File for CVN-21 program

- ↑ "Advanced Weapons Elevators". federalequipment.com. Retrieved 1 April 2015.

- ↑ Keeter, Hunter. "New carrier island is a heart of higher sortie rates for CVN 21". BNET Business Management Network. 4 March 2008.

- ↑ http://mragheb.com/NPRE%20402%20ME%20405%20Nuclear%20Power%20Engineering/Nuclear%20Marine%20Propulsion.pdf

- ↑ "Nuclear-Powered Ships". world-nuclear.org. Retrieved 1 April 2015.

- ↑ Schank, John. Modernizing the U.S. Aircraft Carrier Fleet p. 78.

- ↑ John Schank ... [et al.] (2005). "Modernizing the U.S. aircraft carrier fleet : accelerating CVN 21 production versus mid-life refueling" (PDF). RAND. p. 78. Retrieved 2008-09-14.

- ↑ Schank, John. Modernizing the U.S. Aircraft Carrier Fleet, p. 80.

- ↑ Doyle, Michael, Douglas Samuel, Thomas Conway, and Robert Klimowski. "Electromagnetic Aircraft Launch System - EMALS". Naval Air Engineering Station Lakehurst. 1 March. p. 1.

- ↑ Doyle, Michael, "Electromagnetic Aircraft Launch System - EMALS". p. 1.

- ↑ "EMALS to start sled trials on CVN 78 in late 2015". janes.com. Retrieved 1 April 2015.

- ↑ Rodriguez, Carmelo. "Launch and Recovery Testing". ITEA-SAN. Turboelectric Arresting Gear. Mission Valley Hotel, San Diego. 16 June 2005.

- ↑ Larrabee, Chuck. "Raytheon Successfully Integrates Final Element of Dual Band Radar for DDG 1000 Zumwalt Class Destroyer". Raytheon News Release. 4 March 2008.

- ↑ https://fas.org/sgp/crs/weapons/RL32109.pdf

- ↑ http://www.navsea.navy.mil/nswc/dahlgren/Leading%20Edge/Sensors/03_Development.pdf

- ↑ Schank, John. Modernizing the US Aircraft Carrier Fleet p. 83.

- ↑ Taylor, Leslie (7 June 2006), CVN21 MS&A Overview, NDIA .

- ↑ The Plasma Arc Waste Destruction System to Reduce Waste Aboard CVN-78 (PDF), Seaframe – Carderock Division Publication, 2 008, p. 13 Check date values in:

|date=(help) - ↑ "Future is now: Navy to deploy lasers on ships in 2014", Fox news, Apr 8, 2013.

- ↑ Navi laser will…, Dvice, Mar 2011.

- ↑ "Unexpectedly, Navy’s superlaser blasts away a record", Wired, Feb 2011.

- ↑ The science of beam weapons, Extreme tech.

- ↑ Weapons (PDF), FAS.

- ↑ Dassault Systemes 3D simulation - CATIA goes virtual reality. YouTube. 15 July 2011. Retrieved 1 April 2015.

- ↑ https://www.rand.org/content/dam/rand/pubs/monographs/2006/RAND_MG289.pdf

- ↑ 46.0 46.1 http://www.gao.gov/assets/660/657412.pdf

- ↑ "Crew's ship: Sailors' comfort a centerpiece of new supercarrier Ford". Marine Corps Times. Retrieved 1 April 2015.

- ↑ ?. "Ford Reaches 50 Percent Structural Completion" (PDF). Newport News Shipbuilding. Retrieved September 2011.

- ↑ Jon W. Glass. "Construction Begins on the First Ford-class Carrier". The Virginian-Pilot. Retrieved 31 October 2008.

- ↑ "The Politician Class Carriers Evolve". strategypage.com. 12 April 2009. Retrieved 18 April 2009.

- ↑ http://www.cnas.org/files/documents/publications/CNAS%20Carrier_Hendrix_FINAL.pdf

- ↑ "Defense Budget Recommendation Statement (Arlington, VA)". US Department of Defense. 6 April 2009. Retrieved 27 March 2010.

- ↑ "U.S. GAO - Ford-Class Carriers: Lead Ship Testing and Reliability Shortfalls Will Limit Initial Fleet Capabilities". gao.gov. Retrieved 1 April 2015.

- ↑ "Newport News Shipbuilding Floods Dry Dock and Floats Aircraft Carrier Gerald R. Ford". October 11, 2013.

- ↑ "US Navy Christens Costly New Carrier, USS Ford". DefenseNews (Gannett). 10 November 2013. Retrieved 22 December 2013.

- ↑ "Navy Names Next Aircraft Carrier USS John F. Kennedy". Retrieved 29 May 2011.

- ↑ "US Navy's Ford-class aircraft carrier to be named Enterprise". Brahmand.com Defense & Aerospace News. 4 December 2012. Retrieved 4 December 2012.

- ↑ "CVN-77 Delivery Moved To December, Newport News On Track For January Commissioning". Defense Daily. 2008.

- ↑ "Aircraft Carrier Gerald R. Ford (CVN 78) Christened At Newport News Shipbuilding". November 12, 2013.

- ↑ "Navy Names Next Aircraft Carrier USS John F. Kennedy" (Press release). Secretary of the Navy Public Affairs. 29 May 2011.

- ↑ 61.0 61.1 Ronald O'Rourke (26 July 2012). "Navy Ford (CVN-78) Class Aircraft Carrier Program: Background and Issues for Congress" (PDF). Congressional Research Service. Retrieved 1 December 2012.

External links

| Wikimedia Commons has media related to Gerald R. Ford class aircraft carriers. |

- Aircraft Carriers – CVN – US Navy Fact File

- Design & Preparations Continue for the USA's New CVN-21 Super-Carrier (updated), Defense Industry Daily. Provides an extensive briefing re: the new ship class, and adds entries for many of the contracts under this program.

- Gerald R. Ford Class (CVN-78) Aircraft Carrier on Navy Recognition site

| ||||||||||