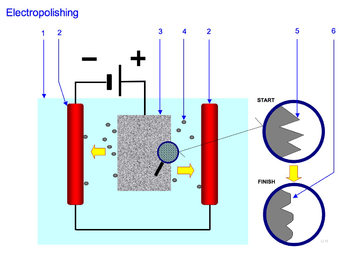

Electropolishing

Electropolishing, also known as electrochemical polishing or electrolytic polishing (especially in the metallography field), is an electrochemical process that removes material from a metallic workpiece. It is used to polish, passivate, and deburr metal parts. It is often described as the reverse of electroplating. It may be used in lieu of abrasive fine polishing in microstructural preparation.[1]

Mechanism

1. Electrolyte

2. Cathode

3. Workpiece to polish (Anode)

4. Particle moving from the workpiece to the cathode

5. Surface before polishing

6. Surface after polishing

Typically, the workpiece is immersed in a temperature-controlled bath of electrolyte and serves as the anode; it is connected to the positive terminal of a DC power supply, the negative terminal being attached to the cathode. A current passes from the anode, where metal on the surface is oxidized and dissolved in the electrolyte, to the cathode. At the cathode, a reduction reaction occurs, which normally produces hydrogen. Electrolytes used for electropolishing are most often concentrated acid solutions having a high viscosity, such as mixtures of sulfuric acid and phosphoric acid. Other electropolishing electrolytes reported in the literature include mixtures of perchlorates with acetic anhydride and methanolic solutions of sulfuric acid.

To achieve electropolishing of a rough surface, the protruding parts of a surface profile must dissolve faster than the recesses. This process, referred to as anodic leveling, is achieved by a mass transport limited dissolution reaction. Anodic dissolution under electropolishing conditions deburrs metal objects due to increased current density on corners and burrs.

Applications

Electropolishing has many applications in the metal finishing industry because of its simplicity and it can be applied to objects of complex shape. Typical examples are electropolished stainless steel drums of washing machines and stainless steel surgical devices. Electropolishing is also commonly applied to the preparation of thin metal samples for transmission electron microscopy because electropolishing does not cause mechanical deformation of surface layers usually observed when mechanical polishing is used. Ultra high vacuum (UHV) components are typically electropolished in order to have a smoother surface for improved vacuum pressures, outgassing rates, and pumping speed.

Standards

- ASME BPE Standards for Electropolishing Bioprocessing Equipment

- SEMI F19, Electropolishing Specifications for Semiconductor Applications

- ASTM B 912-02 (2008), Passivation of Stainless Steels Using Electropolishing

- ASTM E1558, Standard Guide for Electrolytic Polishing of Metallographic Specimens

Benefits of electropolishing (stainless steel)

- Removes iron from the surface and enhances the chromium/nickel content providing the most superior form of passivation for stainless steel.

- Provides a clean and smooth surface that is easier to sterilize.

- Polishes areas inaccessible by other polishing methods.

- Improves the surface finish by leveling micro-peaks and valleys.

- Removes a small amount of material from the surface of the parts, also removing small burrs.

- Can be used to reduce the size of some parts when necessary.

- Results are seen by many as aesthetically pleasing.[2]

References

- ↑ G.F. Vander Voort, ed., "Chemical and Electrolytic Polishing," ASM Handbook, Vol. 9: Metallography and Microstructures, ASM International, 2004, p 281-293, ISBN 978-0-87170-706-2.

- ↑ Stainless Steel Electropolishing. Arrow Cryogenics http://www.arrowcryogenics.com/stainless-steel-electropolishing.htm. Retrieved 28 February 2014. Missing or empty

|title=(help)