Dip-coating

Dip coating is an industrial coating process which is used, for example, to manufacture coated fabrics [1] and condoms. The earliest dip-coated products may have been candles. For flexible laminar substrates such as fabrics, dip coating may be performed as a continuous roll-to-roll process. For coating a 3D object, it may simply be inserted and removed from the bath of coating. For condom-making, a former is dipped into the coating. For some products, such as early methods of making candles, the process is repeated many times, allowing a series of thin films to bulk up to a relatively thick final object.

The final product may incorporate the substrate and the coating, or the coating may be peeled off to form an object which consists solely of the dried or solidified coating, as in the case of a condom.

As a popular alternative to Spin coating, dip-coating methods are frequently employed to produce thin films from sol-gel precursors for research purposes, where it is generally used for applying films onto flat or cylindrical substrates. [2]

Process

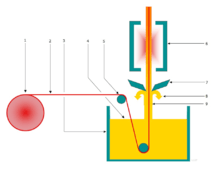

The dip coating process can be separated into five stages:[3]

- Immersion: The substrate is immersed in the solution of the coating material at a constant speed (preferably jitter-free).

- Start-up: The substrate has remained inside the solution for a while and is starting to be pulled up.

- Deposition: The thin layer deposits itself on the substrate while it is pulled up. The withdrawing is carried out at a constant speed to avoid any jitters. The speed determines the thickness of the coating (faster withdrawal gives thicker coating material).

- Drainage: Excess liquid will drain from the surface.

- Evaporation: The solvent evaporates from the liquid, forming the thin layer. For volatile solvents, such as alcohols, evaporation starts already during the deposition & drainage steps.

In the continuous process, the steps are carried out directly after each other.

References

- ↑ http://www.ntcresearch.org/pdf-rpts/AnRp03/F00-MD06-A3.pdf

- ↑ Scriven, L.E. (1988). "Physics and applications of dip coating and spin coating". Better ceramics through chemistry III. pp. 717–729.

- ↑ Rahaman, M.N. (2007). Ceramic Processing. Boca Raton: CRC Press. pp. 242–244. ISBN 0-8493-7285-2.