Critical speed

In solid mechanics, in the field of rotordynamics, the critical speed is the theoretical angular velocity that excites the natural frequency of a rotating object, such as a shaft, propeller, leadscrew, or gear. As the speed of rotation approaches the object's natural frequency, the object begins to resonate, which dramatically increases system vibration. The resulting resonance occurs regardless of orientation. When the rotational speed is equal to the numerical value of the natural vibration, then that speed is referred to as critical speed.

Critical speed of shafts

All rotating shafts, even in the absence of external load, will deflect during rotation. The unbalanced mass of the rotating object causes deflection that will create resonant vibration at certain speeds, known as the critical speeds. The magnitude of deflection depends upon the following:

- (a) stiffness of the shaft and its support

- (b) total mass of shaft and attached parts

- (c) unbalance of the mass with respect to the axis of rotation

- (d) the amount of damping in the system

In general, it is necessary to calculate the critical speed of a rotating shaft, such as a fan shaft, in order to avoid issues with noise and vibration.

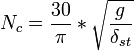

Critical speed equation (Nc)

There are two main methods used to calculate critical speed—the Rayleigh–Ritz method and Dunkerley's method. Both calculate an approximation of the first natural frequency of vibration, which is assumed to be nearly equal to the critical speed of rotation. In general, the Rayleigh–Ritz equation overestimates and the Dunkerley equation underestimates the natural frequency. The equation illustrated below is the Rayleigh–Ritz method applied to a shaft. The static deflection expresses the relationship between rigidity of the shaft and inertial forces; it includes all the loads applied to the shaft when placed horizontally.[1] However, the relationship is valid no matter what the orientation of the shaft is.

- Critical speed,

where:

- g = gravitational acceleration (≈ 9.81 m⁄s²)

- δst = vertical static deflection of the shaft when placed horizontally

- Nc is in rpm

Critical speed depends upon the magnitude and location of the shaft unbalance, the length of the shaft, its diameter, and the kind of bearing support. Many practical applications suggest as good practice that the maximum operating speed should not exceed 75% of the critical speed; however, there are cases that require speeds above the critical speed to work correctly.

See also

References

- ↑ Technical Bulletin, "Critical Speed of Shafts", Krueger. Retrieved on 4 September 2012.