Cook stove

In cooking, a cook stove is heated by burning wood, charcoal, animal dung or crop residue. Cook stoves are commonly used for cooking and heating food in developing countries.

Developing countries consume little energy compared to developed nations; however, over 50% of the energy that they do use goes into cooking food. The average rural family spends 20% or more of its income purchasing wood or charcoal for cooking. Living in the city provides no refuge either as the urban poor frequently spend a significant portion of their income on the purchase of wood or charcoal.

Besides the high expense, another problem of cooking over an open fire is the increased health problems brought on from the smoke, particularly lung and eye ailments, but also birth defects. Replacing the traditional 3-rock cook stove with an improved one and venting the smoke out of the house through a chimney can dramatically improve a family’s health.

Deforestation and erosion are often the end result of harvesting wood for cooking fuel. The main goal of most improved cooking stoves is to reduce the pressure placed on local forests by reducing the amount of wood the stoves consume. Additionally, the money a family spends on wood or charcoal translates into less money being available to be spent on food, education, and medical care; so an improved cooking stove is seen as a way of boosting a family's income.

Three-stone cooking fire

The traditional method of cooking is on a three-stone cooking fire. It is the cheapest stove to produce, requiring only three suitable stones of the same height on which a cooking pot can be balanced over a fire. However, this cooking method also has many problems:

- Smoke is vented into the home, instead of outdoors, causing health problems. According to the World Health Organization, "4.3 million people a year die prematurely from illness attributable to the household air pollution caused by the inefficient use of solid fuels (2012 data)."[1]

- Fuel is wasted, as heat is allowed to escape into the open air. This requires more labor on the part of the user to gather fuel and may result in increased deforestation if wood is used for fuel.

- Only one cooking pot can be used at a time.

- The use of an open fire creates a risk of burns and scalds.[2] Especially when the stove is used indoors, cramped conditions make adults and particularly children susceptible to falling or stepping into the fire and receiving burns. Additionally, accidental spills of boiling water may result in scalding, and blowing on the fire to supply oxygen may discharge burning embers and cause eye injuries.

Improved stoves and other measures

The World Health Organization has documented the significant number of deaths caused by smoke from home fires.[3] The negative impacts can be reduced by using improved cook stoves, improved fuels (e.g. biogas, or kerosene instead of dung), changes to the environment (e.g. use of a chimney), and changes to user behavior (e.g. drying fuel wood before use, using a lid during cooking)."[1] Improved stoves are more efficient, meaning that the stove's users spend less time gathering wood or other fuels, suffer less emphysema and other lung diseases prevalent in smoke-filled homes, while reducing deforestation and air pollution. However, a closed stove may result in production of more soot and ultra-fine particles than an open fire would.[4]

For instance, an improvement of the energy efficiency from 25% for the traditional Lao stove (wood and charcoal fired) to 29% efficiency for an improved Lao stove, results in 21% less wood fuel being needed, and saves 182000 ton CO2eq emissions, as reported in this GHG-compensation project.[5] The traditional Lao stove needs an average of 385 kilograms of charcoal and 450 kilograms of wood per year as fuel. For making a kilogram of charcoal about seven kilograms of wood is needed. The report also indicates that in Cambodia 369000 ton of non-renewable biomass wood fuel is consumed yearly for charcoal production for these stoves, destroying 45 km² of deciduous forests. This is not sustainable, as only 4% of the forests regrows.

Some designs also make the stove safer, preventing burns that often occur when children stumble into open fires. Some of the new stove designs are discussed below.

Brick and mortar stove

A variety of new brick and mortar stoves have emerged. Most of the new designs incorporate a combustion chamber found in a rocket stove. By confining combustion to an insulated and enclosed area, the stoves increase the core temperature and thereby achieve more complete combustion. This allows a smaller amount of fuel to burn hotter, while producing less ash and smoke.[6] Several stoves with similar features have emerged, often varying only slightly from one another. The Justa Stove is a simple biomass stove built around an insulated, elbow-shaped combustion chamber which provides more intense heat and cleaner combustion than an open fire, meaning that it consumes less fuel than a three-stone stove.

An improved Justa Stove jointly developed by the non-profit Proyecto Mirador and the Aprovecho Research Center called the "Dos por Tres" is being disseminated in Honduras with more than 20,000 stoves installed as of 2011. The Dos por Tres has been registered as Project 690 and certified by the Gold Standard Foundation to reduce greenhouse gas emissions by 2.7 tons per year. All Proyecto Mirador documentation related to proof of these reductions can be viewed on the Gold Standard Project registry . The co-benefits of the "Dos por Tres" are highlighted in this video [7] and construction of a Dos por Tres can be seen here [8]

The Justa Stove[9] has been deployed in Honduras by Trees, Water & People and AHDESA, for which they jointly won an Ashden Award in 2005.[10] The Eco Stove and the Patsari stove share common benefits with the Justa Stove, and are also used in Central America. Their proponents claim that these stoves use approximately 1/3 of the fuel required by traditional three stone stoves, lessening the daily labor devoted to gathering wood and also preventing deforestation. At the same time, it employs a stove pipe flue to vent fumes through the roof.[11] This almost eliminates cooking smoke within the home, preventing respiratory problems for the users. Various groups have run programs to provide such stoves, or encourage production of stove making facilities, including certain Rotary Clubs; Trees, Water and People;[12] and organizations aimed at preserving wildlife by preventing deforestation.

Lorena adobe stove

A predecessor to the Justa/Eco/Patsari Stoves was the Lorena adobe Stove. It was designed as a simple-to-build cook stove for use in Central America, one that could be manufactured locally of materials. The name of Lorena Stove comes from the combination of the two Spanish words lodo and arena (meaning mud and sand) as the stoves are basically a mix of the two. It became very popular in Central America, with anecdotal evidence suggesting that it is the most popular improved cooking stove in the region. The Lorena Stove is an enclosed stove of rammed earth construction, with a chimney built onto it.[13]

The Lorena Stove was designed with the mistaken belief that rammed earth would act as insulation; there was a basic misunderstanding of the difference between mass and insulation. Good insulation resists the passage of heat; thermal mass does the opposite, it absorbs heat. Testing has shown that the rammed earth used in the Lorena stove absorbs heat that should be directed toward cooking.

The designers, Aprovecho, now state: "The Lorena has been tested over the years by many researchers and has generally been found to use more firewood than an indoor open fire. The stove has other attributes. Its chimney takes smoke out of the kitchen and it is well liked. It is pretty and a nice addition to the house. It is low cost and can be repaired and even built by the home owner. But, it is not a fuel saving or low emission stove". In later designs, the rammed earth has been replaced with thermal insulation, such as pumice or ash.

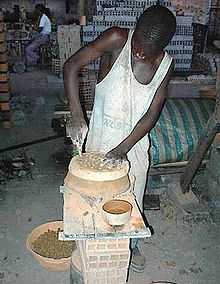

Kenya Ceramic Jiko

From the beginning of the appropriate technology movement, one of the principal goals has been to create an affordable stove that was more efficient than the universally used three stone cooking fire. Of all the improved stoves, the Kenya Ceramic Jiko (KCJ) has been the most widely accepted to date, having become a standard item in most homes in Kenya and neighboring countries in East and Central Africa.

Charcoal is the standard cooking fuel in East Africa. Traditionally it was burned in a metal stove or “Jiko” as stoves are called in the Swahili language. The KCJ is simply the traditional Jiko mated to a ceramic liner, producing a stove that is at least one fourth (and up to 50%) more efficient than traditional all-metal alternatives, costing only $2 to $5. The initial model has a distinctive shape, differing from the traditional cylindrical jiko, with the top and bottom the same diameter, tapering at about 30 degrees to a waist.

There are many variations on the same theme that can be found in Kenya and other areas of East Africa. Some are designed to be more robust than the original KCJ, and some such as the Upisi are designed to burn wood instead of charcoal, while others are built into the home, and remain stationary. The Energy Efficient Charcoal Oven is a new innovation that has been developed and marketed by one of the initial disseminators of the KCJ; Dr. Max Kinyanjui, they are sold in supermarket chains around east Africa and allow people without access to electricity or gas to bake bread on a commercial or domestic scale using very little charcoal. Improved stoves also reduce the amount of forest cover lost and are a viable greenhouse gas reducer in addition to providing employment to a large number of sheet metal artisans.

Sanjha Chulha/Earth Stove/Surya Stove

Since 1999, an engineering company named Nishant Bioenergy (P) Limited in North India is conceiving, designing, fabricating and selling patent pending biomass briquette cook stoves. These are commercial cook stoves and are designed to burn biomass briquette. Biomass briquettes can be made from any farm or forest residues with or without binders.

The advantages of the stoves include sturdiness for heavy cooking utensils, lower cost of operation, ease of use, safe operation and the fact that they are carbon neutral. They manufacture many models like Sanjha Chulha and Earth Stove. Capacities are from 16000 KCal/Hr to 200000 KCal/hr. Earth Stoves are being used by a variety of people cooking food for 50 people to 50,000 people per day. As of January, 2010, they have installed around 355 stoves (total installed capacity is more than 13 MWh). Projects under execution are worth 3.5 Million Kcal/hr. They also have five franchises in western and southern states of India and are planning two more to spread the technology. Earth Stove based NISHANT STEAMER is also a great hit with college/school hostels. At some places savings are more than 75%.

The company has won national and international recognition for their unique efforts. Awards include the Ashden Award in 2005,[14] PCRA Award-2001, and UN promising practices-2006.

The Sanjha Chulha (community-cooking stove) is an "Institutional Cook Stove" for use with multiple pot combined cooking. The stove name is derived from a village tradition where women would cook all their rotis (bread) on a "Sanjha Chulha", which was a communal earthen cook stove used by everyone. The stove was designed by Ramesh K. Nibhoria who also designed the Earth Stove for use with a single pot.

The Surya Stove by Nishant Bioenergy runs on powdered biomass such as saw dust or any other biomass that has a moisture content level of 10% or less and is also pulverized fine enough to pass through an 8 mm mesh. The stove has an automated fuel feed and ash cleansing system. It has a temperature controller to pre-set the temperature of the cooking/frying medium. It is especially designed for the frying needs of the ready-to-eat food industry. The company plans on launching a nationwide project of 1000 such stoves duly linked with a fuel supply chain based on the assistance of a local village based bio refinery.

Project Surya

Project Surya, by Scripps Institute of Oceanography at UCSD, field tested a number of improved cook stoves and modifications during its pilot phase which is now complete and the results have been posted online. [15] Project Surya has also launched the Carbon Credit Pilot Project (C2P2) to explore if rewarding women directly with funds from carbon markets, for using improved stoves, will significantly enhance adoption of the field tested stoves.

Prefab stoves

The Ecocina stove was designed by StoveTeam International and is manufactured at a central location from cement, pumice, and ceramic tiles. It resembles a large flower pot, with a steel cooking surface which can also receive a pot.[16] It is the creation of a volunteer worker who noticed the high number of respiratory illnesses and burns on patients in Guatemala. It is actively produced in several countries, including Guatemala, El Salvador, Honduras, Nicaragua and Mexico. Unlike its brick and mortar counterparts, the Ecocina stoves have no flue and are manufactured in a backyard factory. They are then placed in a home on top of a table or similar raised surface. Again, as with its brick and mortar counterpart, the Ecocina stove employs a rocket stove combustion chamber and promises the same reduction in consumption of firewood and reduction in fumes emitted into the home. It also remains cool to the touch, preventing burns.

Baker stoves

The Baker cook stove was developed by Top Third Ventures and designed by Claesson Koivisto Rune. The Baker cook stove is designed to emphasize aesthetic appeal, usability, and cultural conformity. Rural households in Kenya are the target consumer group for the product. The Baker cook stove is made up entirely of metal components. Thermal insulation and a forced air flow mechanism result in a higher combustion temperature and safer and cleaner cooking compared to the traditional three-stone cooking fire.[17]

Turbo stoves

Some new metal stoves employ turbo-charging features such that air pressed into the stove or swirled, will then dramatically increase the efficiency of combustion.

The Lucia Stove developed by World Stove employs swirling air patterns to change combustion and has been economically produced. It is marketed by World Stove as one part of a larger environmental solution because it captures carbon and thereby reduces the amount of carbon in the atmosphere from cooking. It produces Biocarb that is then recycled back to the soil.[18]

The Turbococina Stove was developed in El Salvador by René M. N. Suarez'[19] the name is derived from the term “Turbocombustión” which is a new combustion method as follows: it is desirable, when dealing with the combustion of fuel, to maintain temperatures as low as possible to inhibit the formation of pollutants like NOx; an alternative is to reduce the concentration of oxygen below the stoichiometric requirement. The Turbococina promised dramatic results by employing higher pressures to lower combustion temperatures, but its high cost of production (stainless steel) and its use of electricity have prevented it from going into production. At present, it does not appear to be economically viable.

The BioLite Stoves

The BioLite HomeStove was made to replace open cooking fires. Its design converts the heat into usable electricity to power a fan, which reduces fuel needs by 50%, toxic smoke by about 95%, and black carbon emissions by 91%. Additionally, the amount of CO2 saved per year by one stove equals the amount that’s saved by buying a hybrid car.[20] The effects of deforestation are lessened and time is regained by women and children who spend hours gathering wood for open fires. The remaining off-grid energy that does not power the fan can then be used to charge portable devices through a USB port, such as cell phones and LED lights.[21][22]

Solar Stoves

Simple solar stoves use the following basic principles:

- Concentrating sunlight: A reflective mirror of polished glass, metal or metallised film concentrates light and heat from the sun on a small cooking area, making the energy more concentrated and increasing its heating power.

- Converting light to heat: A black or low reflectivity surface on a food container or the inside of a solar cooker improves the effectiveness of turning light into heat. Light absorption converts the sun's visible light into heat, substantially improving the effectiveness of the cooker.

- Trapping heat: It is important to reduce convection by isolating the air inside the cooker from the air outside the cooker. A plastic bag or tightly sealed glass cover traps the hot air inside. This makes it possible to reach temperatures on cold and windy days similar to those possible on hot days.

See also: Solar cooker

Alcohol Fueled Stoves

The use of alcohol as stove fuel has been pioneered by Project Gaia. Alcohol fuels, such as ethanol, burn cleanly, and fast and are renewable. Project Gaia works with the CleanCook, a clean-burning stove that use absorption technology to burn the ethanol safely and efficiently.

Standard approaches to conserving cooking fuel

Almost all rural and many urban families in Latin America rely solely on wood for their cooking needs. In most of Africa charcoal is the standard cooking fuel. In other places it can be a mix of the two, or alternatively like families on the Great Plains during the 1800s animal dung may be in common use if it is the only thing available.

There are three places in the cooking process where fuel can be conserved; the fuel, the stove, and the cooking pot. The greatest gains come not from the stove itself, but from how the heat the stove produces is used; paying attention to the pot rather than the stove results in the greatest fuel savings. In fact, fuel efficiency in a stove is usually much more affected by heat transfer to the pot than it is by improving combustion efficiency.

- The first way to reduce the amount of fuel a family consumes is simply to use a cooking lid while cooking, which by itself reduces fuel consumption by 40%. This simple change will normally save more fuel by itself than switching to an improved stove.

- The second strategy is similar to the first; use a larger cooking pot. Larger pots are more energy efficient than smaller ones and wide shallow pots are more efficient than tall narrow ones.

- Last, when cooking for a family, switching from a stove that has room for only one pot to cook at a time, to a stove where two or more pots can cook at once will often raise efficiencies by up to 40%.

In developing countries, families who rely upon wood for cooking have three ways of obtaining it. They can scavenge the areas where they live for firewood, purchase it from a firewood dealer, or grow their own. In most villages there is a lack of harvestable firewood in the surrounding area, and so most of the wood used is brought into the village and sold through a dealer. Those who cannot afford to buy firewood are often forced to travel several miles to acquire wood. Some families have obtained self-sufficiency by maintaining a living fence, or growing a woodlot near the family home.

Improved Cook Stoves

Improved Cook Stoves (ICS) are designed to reduce the fuel consumption per meal and to curb smoke emissions from open fires inside dwellings. They are designed for developing country settings as a low cost bridging technology. It is generally claimed that the new designs burn the wood (or other fuel) more efficiently. Evidence refers to significant reductions on firewood consumption, time consuming wood extraction and respiratory diseases. Important features may include a pipe (chimney) to vent the smoke and a different chamber design.

There are various designs, such as the ONIL Stove which uses mortar-less concrete blocks in its construction and costs $150 USD per stove.[24] Another design is the Berkeley-Darfur stove that reduces smoke and is twice as efficient as a clay stove, with the goal of reducing the need for women to leave the camps in search of wood.[25]

The Save80[26] is a portable stove plus an integral 8-liter pot (both made of stainless steel) and weighs about 4 kg. It has a nominal effective thermal power of 1.5 kW and needs only 250 g of small dry wood sticks to bring 6 liters of water to the boil, which is 80% less than a traditional cooking fire. This efficiency can only be achieved when using the 8-liter pot that is design-optimized for this stove. On one side near the upper rim there is a small port for feeding additional fuel into the already burning stove. The stove design ensures pre-heating of the air supply from the bottom inlet and a complete combustion with no visible smoke and only small amounts of ash. Exhaust air outlets are on the side opposite the fuel feed port.

The Save80-Wonderbox is made of expanded polypropylene, which is unbreakable, stackable, lightweight, and is specifically designed to contain the 8-liter pot of the Save80 stove. It will keep a near boiling temperature for a long time. After 2 hours the temperature decreases from 100° C to about 90°C, after 12 hours it is still 65°C. After reaching the boiling temperature, food – for instance rice – can be transferred to the Wonderbox, a retained heat cooking device. There it will continue to simmer until it is well cooked. The Wonderbox thus allows important energy savings in addition to the fuel savings of the Save80 stove.

The most fuel-efficient type of cooker is the solar cooker, which uses no fuels of any kind. These devices of course require clear sunlight, but they are practical in many of the sunny regions of the world.[27]

The Energy and Resources Institute cookstove model SPT-610 has an efficiency of 37%[28] and has been developed in collaboration with Indian Institute of Technology Delhi.

Advanced biomass cookstoves

There are two primary types of advanced biomass stoves[29] that can achieve high levels of performance; forced air stoves and gasifier stoves, both of which can run on processed or raw biomass.

- Forced air stoves have a fan powered either by a battery, an external source of electricity, or a thermoelectric generator. This fan blows high velocity, low volume jets of air into the combustion chamber, which when optimized results in much more complete combustion of the fuel. In some cases these stoves appear to be more robust to variations in how users cook, as well.

- Gasifier stoves force the gases and smoke that result from incomplete combustion of fuels such as biomass back into the cookstove's flame, where the heat of the flame then continues to combust the particles in the smoke until almost complete combustion has occurred, resulting in very few if any emissions. Typical gasifier stoves are known as Top Lit Updraft (TLUD) stoves because some fuel is lit on top of the stove, forcing combustible products to pass through the flame front before being emitted into the air. In a gasifier stove with a fan, the jets of air create superior mixing of flame, gas, and smoke and can be extremely clean. However, testing needs to confirm how robust these stoves are in field conditions.

Biomass

Approximately half of the world's population still depend on coal and biomass fuels, (mainly wood, charcoal, dung, and crop residues), for their home cooking and heating. Biomass is the oldest source of renewable energy known to humans and is used for household energy production either through growing energy crops, plants specifically grown for energy use, or by using biomass residues from plants with other applications. Wood is still the largest biomass energy resource today, though other sources of biomass include food crops, grassy and woody plants, residues from agriculture or forestry, and the organic component of municipal and industrial wastes.

Classification of cookstoves

Classification of cookstoves[30][31]

- 1. Three-stone fire

- 2. Early “ICS” “Improved Cook Stoves” to 1990s (clay/ceramic/buckets)

- 3. Fuel-controlled stoves (mainly Rocket stoves)

- a. Simple (portable) b. Stationary (w/ chimney) c. Forced-air (FA)

- 4. Semi-gasifiers (mainly China and Vesto) w/ some air control

- 5. Gasifiers (“micro-” for cooking), some with FA (Fan Assistance)

- a. Top-lit updraft (known as TLUDs) w/ migrating pyrolytic zone (batch)

- b. Updrafts and downdrafts w/ stationary gasification zones (continuous)

- c. Other drafts, including cross and opposite/opposing drafts

- 6. “Fan-jet” with very strong air currents into the fuel (3 known examples):

- a. Philips-FA

- b. Lucia-FA

- c. Turbococina

- 7. Non-biomass. Stoves not using raw dry biomass fuels:

- Charcoal; alcohol; refined fossils; coal; biogas; electric; solar.

Note that multi-mode capable stoves can be used only in one way at any one time.

See also

- BioLite

- Hobo stove

- Envirofit

- Indoor air pollution in developing nations

- List of stoves

- Lo Trau

- Multifuel stove

- Portable stove

- Rocket stove

- Shichirin

References

- ↑ 1.0 1.1 Indoor air pollution and health - World Health Organization fact sheet.

- ↑ "Health Benefits". The ONIL Stove. Retrieved 2007-04-13.

- ↑ Indoor air risks; World Health Organization

- ↑ Umair Irfan (April 5, 2013). "Study finds improved cookstoves solve one emissions problem, but create another". ClimateWire E & E Publishing. Retrieved April 5, 2013.

- ↑ Fuel wood saving with improved cookstoves in Cambodia

- ↑ Design Principles for Wood Burning Cookstoves

- ↑ YouTube Video on Carbon Offsets Plus

- ↑ Proyecto Mirador: Building an Estufa Dos por Tres

- ↑ YouTube Video on Justa Stove

- ↑ Justa stove wins Ashden Award

- ↑ Diagrams and Plans for Justa Stove

- ↑ Trees, Water and People

- ↑ Household stoves construction manual; bioenergylists.org

- ↑ Ashden Award for Nishant Bioenergy

- ↑ Aprovecho Research Center Test-Results-Cookstove-Performance.pdf

- ↑ YouTube Video on Ecocina Stove

- ↑ http://www.fastcoexist.com/1681925/a-simple-elegant-stove-to-make-cooking-safer-in-africa

- ↑ YouTube Video on Lucia Stove

- ↑ René M. N. Suarez, US Patent 6651645

- ↑ "BioLite Home Stove". Design To Improve Life.

- ↑ "MICROGRID ENERGY RULES THE SUSTAINABLE BRANDS INNOVATION OPEN". Fast Company. 11 June 2010.

- ↑ "OWPG Derryck Draper Award goes to BioLite Campstove". OWPG. 18 October 2012.

- ↑ Solar Cooking Atlas Website about solar stoves and solar cookers

- ↑ "The ONIL Stove". HELPS International. Retrieved 2007-04-14.

Each stove costs only $150...

- ↑ "What is a Darfur Stove - Darfur Stoves Project". Retrieved 2008-07-14.

- ↑ Highly efficient stove: Save80

- ↑ "Solar Household Energy". Retrieved 2011-07-27.

- ↑ http://www.worldstainless.org/Files/ISSF/non-image-files/PDF/Protection_of_the_Environment/About_TERI_model_Stove.pdf

- ↑ The Global Alliance For Clean Cookstoves - Cookstove technology

- ↑ Paul S. Anderson

- ↑ Paul S. Anderson, 2011.Classification.pdf

External links

- BioLite's Official Website

- Improved stoves at Appropedia, an anti-poverty and appropriate technology wiki.

- Partnership for Clean Indoor Air

- StoveTeam International

- Biomass cooking stoves

- Aprovecho stove research

- Rethinking the Latin American Cookstove by Dean Still. A critical assessment of Lorena stoves & other new "improvements", and a discussion of how to improve the design.

- Final Report for "Lorena Stoves to Protect Lungs and Forests" - The Virtual Foundation

- Onil Stove - Community of Christ Health Ministries Association.

- Burning Issues - A project of Clean Air Revival, Inc.. Promotes awareness of the negative health impacts of wood smoke.

- BioEnergy Lists: Biomass Cooking Stoves

- Holey Briquette Gassifier Stove Development - Richard Stanley, Kobus Venter 14 August 2003, on BioEnergy Lists

- Asia Regional Cookstove Program (ARECOP)

- What Makes People Cook With Improved Stoves

- Ashden Awards case studies on fuel-efficient stoves in developing countries

- The Gold Standard Foundation (Certification of Carbon Offsets)

- IDcook Solar Stoves - An alternative to fuel, coal and electricity.