Concrete slab

A concrete slab is common structural element of modern buildings. Horizontal slabs of steel reinforced concrete, typically between 4 and 20 inches (100 and 500 millimeters) thick, are most often used to construct floors and ceilings, while thinner slabs are also used for exterior paving. Sometimes these thinner slabs, ranging from 2 inches (5.1 cm) to 6 inches (15 cm) thick, are called mud slabs, particularly when used under the main floor slabs[1] or in crawl spaces.[2]

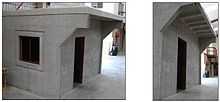

In many domestic and industrial buildings a thick concrete slab, supported on foundations or directly on the subsoil, is used to construct the ground floor of a building. These can either be "ground-bearing" or "suspended" slabs. In high rise buildings and skyscrapers, thinner, pre-cast concrete slabs are slung between the steel frames to form the floors and ceilings on each level.

On the technical drawings, reinforced concrete slabs are often abbreviated to "r.c.c.slab" or simply "r.c.".

Thermal performance

There are two main thermal considerations. The first is the question of insulating a floor slab. In older buildings, concrete slabs cast directly on the ground can drain heat from a room. In modern construction, concrete slabs are usually cast above a layer of insulation such as expanded polystyrene, and the slab may contain underfloor heating pipes. However, there are still uses for an uninsulated slab, typically in outbuildings which are not heated or cooled to room temperature. In those cases, casting the slab directly onto a rocky substrate will maintain the slab at or near the temperature of the substrate throughout the year, and can prevent both freezing and overheating.

The second consideration is the high thermal mass, which applies to walls and floors, or wherever the concrete is used within the thermal envelope. It is a disadvantage where the rooms are heated intermittently and require a quick response, as the concrete takes time to warm up, causing a delay in warming the building. But it is an advantage in climates with large daily temperature swings, where the slab acts as a regulator, keeping the building cool by day and warm by night.

Design

For a suspended slab, there are a number of designs to improve the strength-to-weight ratio. In all cases the top surface remains flat, and the underside is modulated:

- Corrugated, usually where the concrete is poured into a corrugated steel tray. This improves strength and prevents the slab bending under its own weight. The corrugations run across the short dimension, from side to side.

- A ribbed slab, giving considerable extra strength on one direction.

- A waffle slab, giving added strength in both directions and it look hollow from bottom .

Ribbed and waffle slabs provide a lighter and stiffer slab than an equivalent flat slab, reducing the extent of foundations. They provide a very good form where slab vibration is a problem, such as laboratories and hospitals.

Ribbed slabs are made up of wide band beams running between columns with equal depth narrow ribs spanning the orthogonal direction. A thick top slab completes the system.

Waffle slabs tend to be deeper than the equivalent ribbed slab. Waffle slabs have a thin topping slab and narrow ribs spanning in both directions between column heads or band beams. The column heads or band beams are the same depth as the ribs.

Reinforcement design

- A one-way slab needs moment resisting reinforcement only in its short-direction because the moment along long axes is so small that it can be neglected. When the ratio of the length of long direction to short direction of a slab is greater than 2 it can be considered as a one way slab.

- A two-way slab needs moment resisting reinforcement in both directions. If the ratio of the lengths of long and short side is less than two then movement in both direction should be considered in design.

Construction

A concrete slab may be prefabricated or in situ. Prefabricated concrete slabs are built in a factory and transported to the site, ready to be lowered into place between steel or concrete beams. They may be pre-stressed (in the factory), post-stressed (on site), or unstressed. It is vital that the supporting structure is built to the correct dimensions, or the slabs may not fit.

In situ concrete slabs are built on the building site using formwork - a type of boxing into which the wet concrete is poured. If the slab is to be reinforced, the rebars are positioned within the formwork before the concrete is poured in. Plastic tipped metal, or plastic bar chairs are used to hold the rebar away from the bottom and sides of the form-work, so that when the concrete sets it completely envelops the reinforcement. For a ground slab, the form-work may consist only of sidewalls pushed into the ground. For a suspended slab, the form-work is shaped like a tray, often supported by a temporary scaffold until the concrete sets.

The formwork is commonly built from wooden planks and boards, plastic, or steel. On commercial building sites today, plastic and steel are more common as they save labour. On low-budget sites, for instance when laying a concrete garden path, wooden planks are very common. After the concrete has set the wood may be removed, or left there permanently.

In some cases formwork is not necessary - for instance, a ground slab surrounded by brick or block foundation walls, where the walls act as the sides of the tray and hardcore acts as the base.

See also

- Concrete cover

- Formwork

- Hollow core slab (Voided slab, one-way spanning)

- paving stone

- Plattenbau

- Precast concrete

- Rebar

- Reinforced concrete

- Slab-on-grade foundations

- Voided biaxial slab (Voided slab, two-way spanning)