British Standard Pipe

The British Standard Pipe (BSP) is a family of standard screw thread types that has been adopted internationally for interconnecting and sealing pipe ends by mating an external (male) with an internal (female) thread and has been adopted as a standard scale used in plumbing fittings, except in the United States where NPT is the standard used.

Types

Two types of threads are distinguished:

- Parallel ('straight') threads, British Standard Pipe Parallel thread (BSPP; originally also known as[1] British Standard Pipe Fitting thread/BSPF and British Standard Pipe Mechanical thread/BSPM), which have a constant diameter; denoted by the letter G.

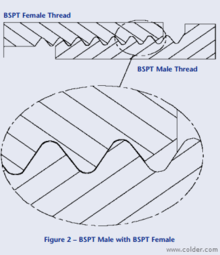

- Taper threads, British Standard Pipe Taper thread (BSPT), whose diameter increases or decreases along the length of the thread; denoted by the letter R.

These can be combined into two types of joints:

- Jointing threads: These are pipe threads where pressure-tightness is made through the mating of two threads together. They always use a taper male thread, but can have either parallel or taper female threads. (International standards require all female threads to be parallel.)

- Longscrew threads: These are parallel pipe threads used where a pressure-tight joint is achieved by the compression of a soft material (such as an o-ring seal or a washer) between the end face of the male thread and a socket or nipple face, with the tightening of a backnut.

Thread form

The thread form follows the British Standard Whitworth standard:

- Symmetrical V-thread in which the angle between the flanks is 55° (measured in an axial plane)

- One-sixth of this sharp V is truncated at the top and the bottom

- The threads are rounded equally at crests and roots by circular arcs ending tangentially with the flanks where r=0.1373P

- The theoretical depth of the thread is therefore 0.6403 times the nominal pitch

Pipe thread sizes

A list of 16 thread sizes are defined by the standards, ranging from 1⁄16 to 6. The size number was originally based on the inner diameter (measured in inches) of a steel tube for which the thread was intended, but contemporary pipes tend to use thinner walls to save material, and thus have an inner diameter larger than this nominal size. In the modern standard metric version, it is simply a size number, where listed diameter size is the major outer diameter of the external thread. For a taper thread, it is the diameter at the "gauge length" from the small end of the thread. The taper is 1 to 16, meaning that for each 16 units of measurement increase in the distance from the end, the diameter increases by 1 unit of measurement.

| Dash thread size |

BSP size (in) |

Thread pitch | Thread major diameter |

Thread minor diameter[3][4] |

A/F (mm) |

Gauge length (mm) |

Corresponding pipe | Tapping drill size (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| /in (TPI) | (mm) | (mm) | (in) | (mm) | (in) | DN (mm) |

OD (mm) |

OD (in) |

Thickness (mm) |

BSP.PL (Rp) |

BSP.F (G) | |||||

| −1 | 1⁄16 | 28 | 0.907 | 7.723 | 0.304 | 6.561 | 0.2583 | 4±0.9 | 6.60 | 6.80 | ||||||

| −2 | 1⁄8 | 28 | 0.907 | 9.728 | 0.383 | 8.565 | 0.3372 | 15 | 4±0.9 | 6 | 10.2 | 0.40 | 2 | 8.60 | 8.80 | |

| −4 | 1⁄4 | 19 | 1.337 | 13.157 | 0.518 | 11.445 | 0.4506 | 19 | 6±1.3 | 8 | 13.5 | 0.53 | 2.3 | 11.50 | 11.80 | |

| −6 | 3⁄8 | 19 | 1.337 | 16.662 | 0.656 | 14.950 | 0.5886 | 22/23 | 6.4±1.3 | 10 | 17.2 | 0.68 | 2.3 | 15.00 | 15.25 | |

| −8 | 1⁄2 | 14 | 1.814 | 20.955 | 0.825 | 18.633 | 0.7336 | 27 | 8.2±1.8 | 15 | 21.3 | 0.84 | 2.6 | 18.75 | 19.00 | |

| −10 | 5⁄8 | 14 | 1.814 | 22.911 | 0.902 | 20.589 | 0.8106 | 16 | 2.6 | - | 21.00 | |||||

| −12 | 3⁄4 | 14 | 1.814 | 26.441 | 1.041 | 24.120 | 0.9496 | 32 | 9.5±1.8 | 20 | 26.9 | 1.06 | 2.6 | 24.25 | 24.50 | |

| −16 | 1 | 11 | 2.309 | 33.249 | 1.309 | 30.292 | 1.1926 | 43 | 10.4±2.3 | 25 | 33.7 | 1.33 | 3.2 | 30.40 | 30.75 | |

| −20 | 1 1⁄4 | 11 | 2.309 | 41.910 | 1.650 | 38.953 | 1.5336 | 53 | 12.7±2.3 | 32 | 42.4 | 1.67 | 3.2 | 39.00 | 39.50 | |

| −24 | 1 1⁄2 | 11 | 2.309 | 47.803 | 1.882 | 44.846 | 1.7656 | 57 | 12.7±2.3 | 40 | 48.3 | 1.90 | 3.2 | 45.00 | 45.00 | |

| −32 | 2 | 11 | 2.309 | 59.614 | 2.347 | 56.657 | 2.2306 | 70 | 15.9±2.3 | 50 | 60.3 | 2.37 | 3.6 | 56.75 | 57.00 | |

| −40 | 2 1⁄2 | 11 | 2.309 | 75.184 | 2.960 | 72.227 | 2.8436 | 17.5±3.5 | 65 | 76.1 | 3.00 | 3.6 | ||||

| −48 | 3 | 11 | 2.309 | 87.884 | 3.460 | 84.927 | 3.3436 | 20.6±3.5 | 80 | 88.9 | 3.50 | 4 | ||||

| −64 | 4 | 11 | 2.309 | 113.030 | 4.450 | 110.073 | 4.3336 | 25.5±3.5 | 100 | 114.3 | 4.50 | 4.5 | ||||

| −80 | 5 | 11 | 2.309 | 138.430 | 5.450 | 135.472 | 5.3335 | 28.6±3.5 | 125 | 139.7 | 5.50 | 5 | ||||

| −96 | 6 | 11 | 2.309 | 163.830 | 6.450 | 160.872 | 6.3335 | 28.6±3.5 | 150 | 165.1 | 6.50 | 5 | ||||

These standard pipe threads are formally referred to by the following sequence of blocks:

- the words "Pipe thread",

- the document number of the standard (e.g., "ISO 7" or "EN 10226")

- the symbol for the pipe thread type:

- G = external + internal parallel (ISO 228)

- R = external taper (ISO 7)

- Rp = internal parallel (ISO 7/1)

- Rc = internal taper (ISO 7)

- Rs = external parallel

- the thread size

Threads are normally right-hand. For left-hand threads, the letters "LH" are appended.

Example: Pipe thread EN 10226 Rp 2½

The terminology for the use of G and R originated from Germany (G for gas, as it was originally designed for use on gas pipes; R for rohr (meaning pipe).)

See also

|

References

- ↑ "BSPM = British Standard Pipe Mechanical". Retrieved 19 November 2014.

- ↑ http://www.colder.com/Portals/0/Library/Resources/Literature/WhitePapers/Documents/NPT_whitepaper.pdf

- ↑ maryland metrics. "Maryland Metrics thread data charts". Retrieved 19 November 2014.

- ↑ "RoyMech: Pipe Threads". Retrieved 19 November 2014.

External links

- Newman Tools Inc. and J.W. WINCO, INC. show the Whitworth form BSP or ISO pipe thread.