Asphaltene

Asphaltenes are molecular substances that are found in crude oil, along with resins, aromatic hydrocarbons, and saturates (i.e. saturated hydrocarbons such as alkanes).[1][2] The word "asphaltene" was coined by Boussingault in 1837 when he noticed that the distillation residue of some bitumens had asphalt-like properties. Asphaltenes in the form of asphalt or bitumen products from oil refineries are used as paving materials on roads, shingles for roofs, and waterproof coatings on building foundations.

Composition

Asphaltenes consist primarily of carbon, hydrogen, nitrogen, oxygen, and sulfur, as well as trace amounts of vanadium and nickel. The C:H ratio is approximately 1:1.2, depending on the asphaltene source. Asphaltenes are defined operationally as the n-heptane (C

7H

16)-insoluble, toluene (C

6H

5CH

3)-soluble component of a carbonaceous material such as crude oil, bitumen, or coal. Asphaltenes have been shown to have a distribution of molecular masses in the range of 400 u to 1500 u, but the average and maximum values are difficult to determine due to aggregation of the molecules in solution.[3]

Analysis

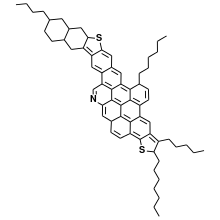

The molecular structure of asphaltenes is difficult to determine because the molecules tend to stick together in solution.[4] These materials are extremely complex mixtures containing hundreds or even thousands of individual chemical species. Asphaltenes do not have a specific chemical formula: individual molecules can vary in the number of atoms contained in the structure, and the average chemical formula can depend on the source. Although they have been subjected to modern analytical methods, including the well known SARA analysis, mass spectrometry, and nuclear magnetic resonance, the exact molecular structures are difficult to determine. Given this limitation, asphaltenes are composed mainly of polyaromatic carbon ring units with oxygen, nitrogen, and sulfur heteroatoms, combined with trace amounts of heavy metals, particularly chelated vanadium and nickel, and aliphatic side chains of various lengths.[5] Many asphaltenes from crude oils around the world contain similar ring units, which are linked together to make highly diverse large molecules.[6]

Geochemistry

Asphaltenes are today widely recognised as dispersed, chemically altered fragments of kerogen, which migrated out of the source rock for the oil, during oil catagenesis. Asphaltenes had been thought to be held in solution in oil by resins (similar structure and chemistry, but smaller), but recent data shows that this is incorrect. Indeed, it has recently been suggested that asphaltenes are nanocolloidally suspended in crude oil and in toluene solutions of sufficient concentrations. In any event, for low surface tension liquids, such as alkanes and toluene, surfactants are not necessary to maintain nanocolloidal suspensions of asphaltenes.

The nickel to vanadium contents of asphaltenes reflect the pH and Eh conditions of the paleo-depositional environment of the source rock for oil (Lewan, 1980;1984), and this ratio is, therefore, in use in the petroleum industry for oil-oil correlation and for identification of potential source rocks for oil (oil exploration).

Occurrence

Heavy oils, oil sands, bitumen and biodegraded oils (as bacteria can not assimilate asphalten[e]s, but readily consume saturated hydrocarbons and certain aromatic hydrocarbon isomers - enzymatically controlled) contain much higher proportions of asphaltenes than do medium-API oils or light oils. Condensates are virtually devoid of asphaltenes.

Measurement

Asphaltene aggregation, precipitation or deposition can be predicted by modeling or artificial intelligent methods.[7][8][9] It also can be measured using imaging methods or filtration.

Production problems

Asphaltenes impart high viscosity to crude oils, negatively impacting production, also the variable asphaltene concentration in crude oils within individual reservoirs creates a myriad of production problems.

Heat exchanger fouling

Asphaltenes are known to be one of the largest causes of fouling in the heat exchangers of the crude oil distillation preheat train. They are present within micelles in crude oil, which can be broken down by reaction with paraffins under high temperature. Once the protective micelle has been removed polar asphaltenes agglomerate and are transported to the tube walls, where they can stick and form a foulant layer.

Asphaltene removal

Chemical treatments for removing asphaltene include:

- solvents

- dispersants/solvents

- oil/dispersants/solvents

The dispersant/solvent approach is used for removing asphaltenes from formation minerals. Continuous treating may be required to inhibit asphaltene deposition in the tubing. Batch treatments are common for dehydration equipment and tank bottoms. There are also asphaltene precipitation inhibitors that can be used by continuous treatment or squeeze treatments.[10]

References

- ↑ Mullins, OC et al. Editors, Asphaltenes, Heavy Oils and Petroleomics, Springer, New York (2007) 700 pages, 23 Chapters, 46 contributing scientists.

- ↑ Asphaltene

- ↑ Podgorski, D. C., et al. (2013). "Heavy Petroleum Composition. 5. Compositional and Structural Continuum of Petroleum Revealed." Energy & Fuels 27(3): 1268-1276.

- ↑ McKenna, A. M., et al. (2013). "Heavy Petroleum Composition. 3. Asphaltene Aggregation." Energy & Fuels 27(3): 1246-1256

- ↑ Asomaning, S., 1997. Heat exchanger fouling by petroleum asphaltenes. Ph.D. Thesis, University of British Columbia

- ↑ Rueda-Velasquez, R. I., et al. (2013). "Characterization of Asphaltene Building Blocks by Cracking under Favorable Hydrogenation Conditions." Energy & Fuels 27(4): 1817-1829

- ↑ Yang, Z.; Ma, C. -F.; Lin, X. -S.; Yang, J. -T.; Guo, T. -M. (1999). "Experimental and modeling studies on the asphaltene precipitation in degassed and gas-injected reservoir oils". Fluid Phase Equilibria 157: 143. doi:10.1016/S0378-3812(99)00004-7.

- ↑ Rasuli Nokandeh, N.; Khishvand, M.; Naseri, A. (2012). "An artificial neural network approach to predict asphaltene deposition test result". Fluid Phase Equilibria 329: 32. doi:10.1016/j.fluid.2012.06.001.

- ↑ Lei, H.; Pingping, S.; Ying, J.; Jigen, Y.; Shi, L.; Aifang, B. (2010). "Prediction of asphaltene precipitation during CO2 injection". Petroleum Exploration and Development 37 (3): 349. doi:10.1016/S1876-3804(10)60038-9.

- ↑ UNDERSTANDING PARAFFIN AND ASPHALTENE PROBLEMS IN OIL AND GAS WELLS, Petroleum Technology Transfer Council, South Midcontinent Region, July 16, 2003 Workshop in Smackover, Arkansas at the Arkansas Natural Resources Museum

External links

- An in-depth article on asphaltenes from OilfieldWiki.com, the oilfield encyclopedia

- Article regarding asphaltene fouling by Irwin A. Wiehe

- Asphaltene Aggregation from Crude Oils and Model Systems Studied by High-Pressure NIR Spectroscopy (Source : American Chemical Society)

- A comprehensive website about asphaltene and its role in petroleum fouling by Prof. GA Mansoori at the Univ. of Illinois at Chicago