Turbo-compound engine

A turbo-compound engine is a reciprocating engine that employs a blowdown turbine to recover energy from the exhaust gases. The turbine is usually mechanically connected to the crankshaft, as on the DC-7B and the Super Constellation,[1] but electric and hydraulic systems have been investigated as well. The turbine increases the output of the engine without increasing its fuel consumption, thus reducing the specific fuel consumption. The turbine is referred to as a "blowdown turbine" (or power-recovery turbine), as it recovers the energy developed in the exhaust manifold during blowdown, that is the first period of the exhaust process when the piston still is on its expansion stroke (this is possible since the exhaust valves open before bottom dead center).

Conventional turbines extract energy from the exhaust stream by lowering its pressure as it expands though the turbine. This has the undesirable side-effect of increasing the back-pressure in the engine, which decreases scavenging of the exhaust gas from the cylinders and thereby lowers the efficiency of the piston portion of a compound engine. In order to avoid this problem, turbo-compound engines used the "blowdown turbine", which extract energy only from the momentum of the rapidly moving exhaust gasses. This is less efficient, but has almost no effect on the operation of the piston side of the system.[2] The exhaust restriction imparted by the three blowdown turbines used on the Wright R-3350 is equal to a well-designed jet stack system used on a conventional radial engine. However, the blowdown turbines recover about 550 hp (410 kW) at METO (maximum continuous except for take-off) power.[3]

The first aircraft engine to be tested with a power-recovery turbine was the Rolls-Royce Crecy, during WWII. This was used primarily to drive a geared centrifugal supercharger, although it was also coupled to the crankshaft and gave an extra 15 to 35 percent fuel economy.[4]

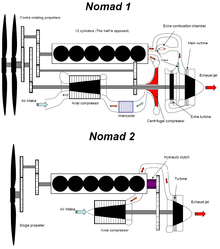

Turbo-compounding was used on on several airplane engines after World War II, including the Napier Nomad[5][6] and the Wright R-3350[7][8] being examples. In the case of the R-3350, maintenance crews sometimes nicknamed the turbine the parts recovery turbine due to its negative effect on engine reliability. Turbo-compound versions of the Napier Deltic, Rolls-Royce Crecy, and Allison V-1710 were constructed but none was developed beyond the prototype stage. It was realized in many cases the power produced by the simple turbine was approaching that of the enormously complex and maintenance-intensive piston engine to which it was attached. As a result, turbo-compound aero engines were soon supplanted by turboprop and turbojet engines.

Some modern heavy truck diesel manufacturers have incorporated turbo-compounding into their designs. Examples include the Detroit Diesel DD15[9][10] and Scania[11] in production from 1991.[12]

Starting with the 2014 season, Formula 1 will be switching to a new 1.6 liter turbocharged V6 formula that uses turbo-compounding. The engines will use a single turbocharger that's connected to an electric motor/generator called the MGU-H. On deceleration, the MGU-H acts as a generator, converting wasted mechanical energy from the turbine into electrical energy that's stored in a battery. When the car accelerate, the MGU-H acts as a motor, using the stored electrical energy to spool up the turbine, eliminating lag.

Turbo-compound engines

- Detroit Diesel

- DD15[13]

- Wright Aeronautical

- Wright R-3350 - The turbo-compound version was the only turbo-compound aero-engine to see mass production and widespread usage.

- Dobrynin

- Zvezda

- Zvezda M503 - Soviet-built 42 cylinder diesel naval engine used in the Osa-class missile boat

- Renault

- Renault Energy F1-2014 - 1.6 liter turbocharged V6 engine built for Formula 1. Unlike it's contemporaries, still uses a wastegate as an emergency measure to control boost pressure in case the turbo-compounding with the MGU-H fails.

- Ferrari

- Ferrari 059/3 - 1.6 liter turbocharged V6 engine built for Formula 1 for the Ferrari F14 T as well as the Sauber C33.

See also

- Sequential twin-turbo

- Motorjet

- Turbosteamer

- Cogeneration

- Turbocharger

- Gas turbine

References

- ↑ "The Race of the Airliners", Popular Mechanics, February 1956, pp. 113-118, see p. 114.

- ↑ "Facts about the Wright Turbo Compound", Wright Aircraft Engines, October 1956, p. 7.

- ↑ "Facts about the Wright Turbo Compound", Wright Aircraft Engines, October 1956, p. 25.

- ↑ "Rolls-Royce and the Sleeve Valve". New Zealand Rolls-Royce & Bentley Club Inc (07-3): 15. 2007.

- ↑ Gunston, Bill (30 April 1954). "Napier Nomad: An engine of outstanding efficiency" (PDF). Flight: 543–551. Retrieved 19 February 2010.

- ↑ E.E. Chatterton (22 April 1954). "Napier diesels: An RAeS lecture" (PDF). Flight: 552. Retrieved 19 February 2010.

- ↑ "Ten ideas that failed: 2 Turbo-compound piston engine" (PDF). Flight. 16 December 2003. Retrieved 19 February 2010.

- ↑ "Super survivor" (PDF). Flight. 18 June 1997. Retrieved 19 February 2010. "in its hey-day, the Connie was often called the world's best tri-motor"

- ↑ "DD15" (video). Detroit Diesel.

- ↑ "DD15 Brochure" (pdf). Detroit Diesel.

- ↑ "Scania Turbocompound". Scania Group.

- ↑ "Scania produces 4 ECO-point engine from Oct 2001". Scania Group. "With 440 hp, the new version of Scania's 12-litre turbocompound engine is suitable for Alpine terrain, as well as normal European long-haul and construction operations."

- ↑ "The Turbo Compounding Boost". 2007.

| |||||||||||||||||||||||||||||||||||||||||||||