Tantalum capacitor

A tantalum capacitor is a type of electrolytic capacitor, a component of electronic circuits. It typically consists of a pellet of tantalum metal as anode, covered by an insulating oxide layer that forms the dielectric, surrounded by conductive material as a cathode. Tantalum capacitors are the main use of the element tantalum.

The tantalum capacitor distinguishes itself from other capacitors in having high capacitance per volume and weight. Tantalum capacitors have lower equivalent series resistance (ESR), lower leakage, and higher operating temperature than other electrolytic capacitors, although other types of capacitors are even better in these regards.

Tantalum capacitors are considerably more expensive than any other commonly used type of capacitor, so they are used only in applications where the small size or better performance are important.[citation needed]

Description

Tantalum electrolytic capacitors exploit the tendency of tantalum to form a non-conductive protective oxide surface layer. A tantalum capacitor consists of tantalum powder pressed into a pellet shape as one "plate" of the capacitor, with the oxide as a dielectric, and an electrolytic solution or conductive solid as the other "plate". The dielectric layer thus can be very thin (thinner than the similar layer in, for instance, an aluminum electrolytic capacitor).

The capacitor typically consists of a sintered tantalum metallic sponge acting as the anode, a manganese dioxide cathode, and a dielectric layer of tantalum pentoxide created on the tantalum sponge surface by anodizing.

Characteristics

Because of its thin dielectric, a tantalum capacitor can have high capacitance in a small volume (high volumetric efficiency). The size and weight advantages make tantalum capacitors attractive for portable telephones, compact personal computers, and automotive electronics.

The steady-state and dynamic reliability of a tantalum capacitor are influenced by several factors under the control of the circuit design engineer. These factors are voltage derating, ripple current and voltage conditions, maximum operating temperature, and circuit impedance. Tantalum capacitors have very low electrical leakage (high leakage resistance), so will retain a charge for a long time. They tolerate hot operating environments up to 125 °C, unlike most aluminum electrolytic capacitors.

Tantalum capacitors have lower equivalent series resistance (ESR) than aluminum electrolytic capacitors of the same capacitance, which is a significant advantage in many designs. However, care must be taken when designing a circuit using tantalum capacitors, to limit charge and discharge currents (particularly those of a repetitive nature) to a level that does not overstress other circuit components.

Tantalum capacitors are relatively expensive, particularly in the mil-spec grades.

Tantalum capacitors are extremely reliable. However, their failure mode tends to be a short-circuit, due to the extremely thin dielectric; designs using these capacitors need to take into account the consequences of this possible failure mode. There is also a possibility of catastrophic thermal runaway failure (see below).

Because most tantalum capacitors being made as of 2012 are solid (no liquid electrolyte), there is no known wear-out mechanism. Solid-bodied tantalum electrolytic capacitors are less prone to "drying out" than aluminum capacitors, which tend to decrease in capacitance (and increase in ESR) particularly when used in hot environments. When operated within their design limits, tantalum capacitors can maintain their designed capacitance under such conditions for decades.

Polarity

Most tantalum capacitors are polarized devices, with distinctly marked positive and negative terminals. When subjected to reversed polarity (even briefly), the capacitor depolarizes and the dielectric oxide layer breaks down, which can cause it to fail even when later operated with correct polarity. If the failure is a short circuit (the most common occurrence), and current is not limited to a safe value, catastrophic thermal runaway may occur (see below).

Tantalum capacitors usually have their positive terminal marked, while aluminum electrolytic capacitors are often marked on the negative terminal, which can cause dangerous confusion.

Thermal runaway and self-destruction

Tantalum capacitors are, under some conditions, prone to self-destruction by thermal runaway. The tantalum oxide layer may have weak spots that undergo dielectric breakdown during a voltage spike. The tantalum anode then comes in direct contact with the manganese dioxide cathode, and the leakage current causes localized heating; a chemical reaction then produces manganese(III) oxide and regenerates (self-heals) the tantalum oxide layer.

However, if the energy dissipated at the failure point is high enough, a new self-sustaining exothermic reaction may initiate, similar to the thermite reaction, with tantalum as fuel and manganese dioxide as oxidizer. This can destroy the capacitor, and occasionally produces smoke and possibly flame.[1] To prevent catastrophic thermal runaway failure, auxiliary protective devices (e.g. thermal fuses, circuit breakers, or current limiters) may be used to limit fault currents.

Uses

The low leakage and high capacity of tantalum capacitors favor their use in sample and hold circuits to achieve long hold duration, and some long duration timing circuits where precise timing is not critical. They are also often used for power supply rail decoupling in parallel with film or ceramic capacitors which provide low ESR and low reactance at high frequency. Tantalum capacitors can replace aluminum electrolytic capacitors in situations where the external environment or dense component packing results in a sustained hot internal environment and where high reliability is important. Equipment such as medical electronics and space equipment that require high quality and reliability makes use of tantalum capacitors.

An especially common application for low-voltage tantalum capacitors is power supply filtering on computer motherboards and in peripherals, due to their small size and long-term reliability.[2][3]

When applying tantalum capacitors, the possibility of thermal runaway (see above) or spontaneous short-circuiting must be considered. In many cases, a failed capacitor will only make the circuit stop functioning normally. However, if sufficient power is available, catastrophic thermal runaway may cause a fire or small explosion. A design can prevent this by using external current limiting (e.g. thermal fuse, circuit breaker).

Construction

Anode

Tantalum capacitors are manufactured from a powder of relatively pure elemental tantalum metal. A common figure of merit for comparing volumetric efficiency of powders is expressed in capacitance (C) in microfarads (µF) times voltage (V) in volts (V) per gram (CV/g). The typical particle size is between 2 and 10 μm. Figure 1 shows powders of successively finer grain, resulting in greater surface area per unit volume. Note the very great difference in particle size between the powders.

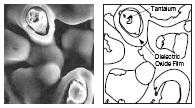

The powder is compressed around a tantalum wire (known as the riser wire) to form a “pellet”.[4] The riser wire ultimately becomes the anode connection to the capacitor. This pellet/wire combination is subsequently vacuum sintered at high temperature (typically 1200 to 1800 °C) which produces a mechanically strong pellet and drives off many impurities within the powder. During sintering, the powder takes on a sponge-like structure, with all the particles interconnected into a monolithic spatial lattice. This structure is of predictable mechanical strength and density, but is also highly porous, producing a large internal surface area (see Figure 2).

Larger surface area produces higher capacitance; thus high CV/g powders, which have a lower average particle size, are used for low voltage, high capacitance parts. By choosing the correct powder type and sintering temperature, a specific capacitance/voltage rating can be designed. For example, a 220μF 6V capacitor will have a surface area close to 346 cm2, or 80% of the size of a sheet of paper (US Letter, 8.5×11 inch paper has area ~413 cm2), although the total volume of the pellet is only about 0.0016 cm3.

Dielectric

The dielectric is then formed over all the tantalum particle surfaces by the electrochemical process of anodization. To achieve this, the “pellet” is submerged into a very weak solution of acid and DC voltage is applied. The total dielectric thickness is determined by the final voltage applied during the forming process. Initially the power supply is kept in a constant current mode until the correct voltage (i.e. dielectric thickness) has been reached; it then holds this voltage and the current decays to close to zero to provide a uniform thickness throughout the device and production lot. The chemical equations describing the dielectric formation process at the anode are as follows:

- 2 Ta → 2 Ta5+ + 10 e−

- 2 Ta5+ + 10 OH− → Ta2O5 + 5 H2O

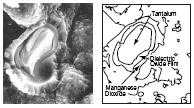

The oxide forms on the surface of the tantalum but it also grows into the material. For each unit of oxide, one third grows out and two thirds grows in. It is for this reason that there is a limit on the maximum voltage rating of tantalum oxide for each of the presently available tantalum powders (see Figure 3).

Cathode

The next stage for solid tantalum capacitors is the application of the cathode plate (wet tantalum capacitors use a liquid electrolyte as a cathode in conjunction with their casing). This is achieved by pyrolysis of manganese nitrate into manganese dioxide. The “pellet” is dipped into an aqueous solution of nitrate and then baked in an oven at approximately 250 °C to produce the dioxide coat. The chemical equation is:

- Mn(NO3)2 → MnO2 + 2 NO2

This process is repeated several times through varying specific gravities of nitrate solution, to build up a thick coat over all internal and external surfaces of the “pellet”, as shown in Figure 4.

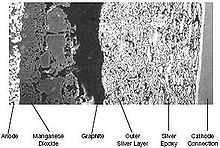

In traditional construction, the “pellet” is successively dipped into graphite and then silver to provide a good connection to the manganese dioxide cathode plate. Electrical contact is first established by deposition of graphitic carbon onto the surface of the cathode. The carbon is then coated with a conductive material to facilitate connection to the external cathode termination (see Figure 5).

In the newer tantalum polymer capacitor process, conductive polymers are used as cathode material.[5]

Packaging

Once fabricated, finished capacitor pellets are packaged into four basic forms: chip, resin-dipped, molded, or axial-leaded.[6]

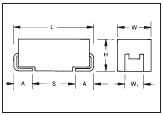

Package dimensions

The following are standard dimensions for surface-mount tantalum components. In recent years, the common case types are: A, B, C, D, and T.

| EIA Code (imperial) |

IEC Code (metric) |

Case Code | L (mm) |

W (mm) |

H (mm) |

W1 (mm) |

A (mm) |

|---|---|---|---|---|---|---|---|

| 0805 | 2012-12 | R | 2.0 | 1.2 | ? | ? | ? |

| 1206 | 3216-10 | I, K | 3.2 | 1.6 | 1.0 (max) | 1.2 | 0.8 |

| 1206 | 3216-12 | S | 3.2 | 1.6 | 1.2 (max) | 1.2 | 0.8 |

| 1206 | 3216-18 | A | 3.2 | 1.6 | 1.6 | 1.2 | 0.8 |

| 1411 | 3528-12 | T | 3.5 | 2.8 | 1.2 (max) | 2.2 | 0.8 |

| 1411 | 3528-15 | M, H | 3.5 | 2.8 | 1.5 (max) | 2.2 | 0.8 |

| 1411 | 3528-21 | B | 3.5 | 2.8 | 1.9 | 2.2 | 0.8 |

| 2412 | 6032-15 | U, W | 6.0 | 3.2 | 1.5 (max) | 2.2 | 1.3 |

| 2412 | 6032-28 | C | 6.0 | 3.2 | 2.6 | 2.2 | 1.3 |

| 2917 | 7343-20 | V, Y | 7.3 | 4.3 | 2.0 (max) | 2.4 | 1.3 |

| 2917 | 7343-31 | D | 7.3 | 4.3 | 2.9 | 2.4 | 1.3 |

| 2917 | 7343-43 | X, E | 7.3 | 4.3 | 4.1 | 2.4 | 1.3 |

| Tolerance | +0.2/–0.2 | +0.2/–0.1 | +0.2/–0.1 | +0.2/–0.0 | +0.3/–0.2 | ||

L: package length, W: package width, H: package height,

W1: contact plate width, A: contact plate length.[7]

Case Code: Kemet, AVX.

See also

|

References

- ↑ AVX - Failure Modes of Tantalum Capacitors

- ↑ Prymak, J.D. (1998). "New tantalum capacitors in power supply applications". Industry Applications Conference, 1998 2: 1129–1137. doi:10.1109/IAS.1998.730289. ISBN 0-7803-4943-1.

- ↑ Tamara Schmitz and Mike Wong Choosing and Using Bypass Capacitors

- ↑ Vishay

- ↑

- ↑ AVX - Basic Tantalum Capacitor Technology

- ↑ Vishay