Radiant heating

Radiant heating is a technology for heating indoor and outdoor areas. Heating by radiant energy is observed every day, the warmth of the sunshine being the most commonly observed example. Radiant heating as a technology is more narrowly defined. It is the method of intentionally using the principles of radiant heat to transfer radiant energy from an emitting heat source to an object. Designs with radiant heating are seen as replacements for conventional convection heating as well as a way of supplying confined outdoor heating.

Indoors

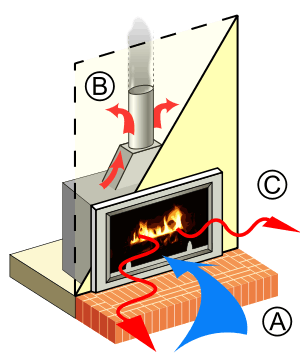

Radiant heating heats a building through radiant heat, rather than conventional methods such as radiators (mostly convection heating). The technology has existed since the Roman use of hypocaust heating. Underfloor radiant heating has long been widespread in China and Korea. Another example is the Austrian/German Kachelofen or masonry heater. The heat energy is emitted from a warm element, such as a floor, wall or overhead panel, and warms people and other objects in rooms rather than directly heating the air. The internal air temperature for radiant heated buildings may be lower than for a conventionally heated building to achieve the same level of body comfort, when adjusted so the perceived temperature is actually the same. One of the key advantages of radiant heating systems is a much decreased circulation of air inside the room and the corresponding spreading of airborne particles.

The radiant heating systems can be divided into:

- Underfloor heating systems—electric or hydronic

- Wall heating systems

- Radiant ceiling panels

Underfloor and wall heating systems often are called low-temperature systems. Since their heating surface is much larger than other systems, a much lower temperature is required to achieve the same level of heat transfer. This provides an improved room climate with healthier humidity levels. The maximum temperature of the heating surface can vary from 29–35 °C (84–95 °F) depending on the room type. Radiant overhead panels are mostly used in production and warehousing facilities or sports centers; they hang a few meters above the floor and their surface temperatures are much higher.

Outdoors

In the case of heating outdoor areas, the surrounding air is constantly moving. Relying on convection heating is in most cases impractical. The reason being, that once you heat the outside air, it will blow away with air movement. Even in a no-wind condition, the buoyance effects will carry away the hot air. Outdoor radiant heaters allow specific spaces within an outdoor area to be targeted, warming only the people and objects in their path.

The systems can be divided as:

- Trace heating- Gutter and Roof De-icing

- Snowmelt system- Electric or Hydronic

- Overhead natural gas-fired radiant heaters

.jpg)

An example of the overhead radiant heaters are the patio heaters often used with outdoor serving. The top metal disc reflects the radiant heat onto a small area. These are very inefficient and are banned in some countries because of the wasteful use of gas.

Radiant heating can also be used for snow melting and for roof and gutter de-icing applications. Snow and ice melting can be achieved on concrete, asphalt, pavers and other surfaces by placing heating units (electric heating elements or hydronic tubing) under the substrate, embedded into the substrate, or retrofit by saw-cut into the substrate of the surface to be free of snow and ice buildup. For roof de-icing, heating elements can be placed on the surface of the roofing material and some technologies can be placed underneath the roofing materials. Heating elements are used in gutters and downspouts to prevent ice buildup that can cause ice dams and icicles. Radiant heating is also used on roofs to eliminate heavy snow loads that can cause structural damage.

Electric low voltage vs. line voltage

Electric systems use fewer components and are simpler to install and commission than hydronic systems but direct heating with electricity can be more expensive than some other sources of heat. Some electric systems use line voltage technology while others use low voltage technology. Low voltage electrical radiant floor heating in respect of line voltage heating has the added complexity of the voltage regulators and transformers, so it can be more failure prone. The amount of power dissipated is, of course, equal, as all energy is given off in the form of heat.

In some cases, the cost of electric heat can be offset by other factors such as with thin film radiant heating. In this technology 99.9% of the electricity is converted to long wave infrared radiant energy, and 85% of the surface area is covered with heating element. As heat is a transfer of energy: when you increase the heated surface area, you increase the efficiency of the thermal transfer. In this way the radiant heating film warms up more area, more quickly and at lower temperatures using less energy, which can significantly increase efficiency.