Purified water

Purified water is water that is mechanically filtered or processed to be cleaned for consumption. Distilled water and deionized (DI) water have been the most common forms of purified water, but water can also be purified by other processes including Reverse osmosis, carbon filtration, microfiltration, ultrafiltration, ultraviolet oxidation, or electrodialysis. In recent decades, a combination of the above processes have come into use to produce water of such high purity that its trace contaminants are measured in parts per billion (ppb) or parts per trillion (ppt). Purified water has many uses, largely in science and engineering laboratories and industries, and is produced in a range of purities. Purified water in colloquial English can also refer to water which has been treated ("rendered potable") to neutralize, but not necessarily remove contaminants considered harmful to humans or animals.

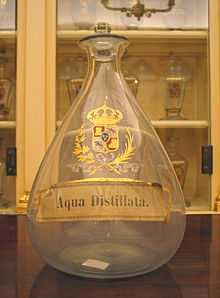

Distilled water is produced by a process of distillation and has an electrical conductivity of not more than 11 µS/cm and total dissolved solids of less than 10 mg/litre.[1] Distillation involves boiling the water and then condensing the vapor into a clean container, leaving solid contaminants behind. Distillation produces very pure water. A white or yellowish mineral scale is left in the distillation apparatus, which requires regular cleaning. Distillation alone does not guarantee the absence of bacteria in drinking water unless containers are also sterilized. For many procedures more economical alternatives are available such as deionized water and, is used in place of distilled water.

Purification methods

Double distillation

Double-distilled water (abbreviated "ddH2O", "Bidest. water" or "DDW") is prepared by double distillation of water. Historically, it was the de facto standard for highly purified laboratory water for biochemistry and, by the method of trace analysis until combination methods of purification became widespread.

Deionization

Deionized water, also known as demineralized water / DM water[2] (DI water, DIW or de-ionized water), is water that has had its mineral ions removed, such as cations like sodium, calcium, iron, and copper, and anions such as chloride and sulfate. Deionization is a chemical process that uses specially manufactured ion-exchange resins which exchange hydrogen ion and hydroxide ion for dissolved minerals, which then recombine to form water. Because the majority of water impurities are dissolved salts, deionization produces a high purity water that is generally similar to distilled water, and this process is quick and without scale buildup. However, deionization does not significantly remove uncharged organic molecules, viruses or bacteria, except by incidental trapping in the resin. Specially made strong base anion resins can remove Gram-negative bacteria. Deionization can be done continuously and inexpensively using electrodeionization.

Types of deionization

Two types of deionizations are available worldwide, co-current and counter-current.

Co-current deionization

Co-current deionization is an outdated process where chemicals for regeneration flow in the direction of service flow while regeneration takes place. Co-current deionization's operating cost is high compared to counter-current deionization. On the other hand, co-current deionization takes extra time to regenerate (up to 190 minutes) and a product quality of less than 0.998859 mg/L TDS can be achieved.

Counter-current deionization

Counter-current deionization is the most attractive method of ion exchange. Chemicals (regenerants) flow in the opposite direction of service flow. It only takes up to 40 minutes to be regenerated. The quality of the finished product can be as low as 0.00998859 mg/L TDS. The main advantage of counter-current deionization is the low operating cost, due to a low usage of regenerant during the regeneration process. However, low regenerating time saves a large quantity of water.

Other processes

Other processes are also used to purify water, including reverse osmosis, carbon filtration, microporous filtration, ultrafiltration, ultraviolet oxidation, or electrodialysis. These are used in place of, or in addition to the processes listed above. Processes rendering water potable but not necessarily closer to being pure H2O / hydroxide + hydronium ions include use of dilute sodium hypochlorite, mixed-oxidants (electro-catalyzed H2O + NaCl), and iodine; See discussion regarding potable water treatments under "Health effects" below.

Uses

Purified water is suitable for many applications, including autoclaves, hand-pieces, laboratory testing, laser cutting, and automotive use.[3] Purification removes contaminants which may interfere with processes, or leave residues upon evaporation. Although water is generally considered to be a good electrical conductor—for example domestic electrical systems are considered particularly hazardous to people if they may be in contact with wet surfaces—pure water is a poor conductor. Conductivity of sea-water is typically 5 S/m,[4] drinking water is typically in the range of 5-50 mS/m, while highly purified water can be as low as 5.5 μS/m (0,055µS/cm), a ratio of about 1,000,000:1,000:1.

Purified water is also used in the pharmaceutical industry. Water of this grade is widely used as a raw material, ingredient, and solvent in the processing, formulation, and manufacture of pharmaceutical products, active pharmaceutical ingredients (APIs) and intermediates, compendial articles, and analytical reagents. The microbiological content of the water is of importance and the water must be regularly monitored and tested to show that it remains within microbiological control. [5]

Laboratory use

Technical standards on water quality have been established by a number of professional organizations, including the American Chemical Society (ACS), ASTM International, the U.S. National Committee for Clinical Laboratory Standards (NCCLS) which is now CLSI, and the U.S. Pharmacopeia (USP). The ASTM, NCCLS, and ISO 3696 or the International Organization for Standardization classify purified water into Grade 1–3 or Types I–IV depending upon the level of purity. These organizations have similar, although not identical, parameters for highly purified water.

Note that the European Pharmacopeia uses Highly Purified Water (HPW) as a definition for water meeting the quality of Water For Injection, without however having undergone distillation. In the laboratory context highly purified water is used to denominate various qualities of water having been "highly" purified.

Regardless of which organization's water quality norm is used, even Type I water may require further purification depending upon the specific laboratory application. For example, water that is being used for molecular-biology experiments needs to be DNase or RNase-free, which requires special additional treatment or functional testing. Water for microbiology experiments needs to be completely sterile, which is usually accomplished by autoclaving. Water used to analyze trace metals may require elimination of trace metals to a standard beyond that of the Type I water norm.

| ISO 3696 (1987) | ASTM (D1193-91) | NCCLS (1988) | Pharmacopoeia | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Contaminant | Parameter | Grade 1 | Grade 2 | Grade 3 | Type I* | Type II** | Type III*** | Type IV | Type I | Type II | Type III | EP (20 °C) | USP |

| Ions | Resistivity at 25 °C [MΩ·cm] | 10 | 1 | 0.2 | 18.2 | 10.0 | 4.0 | 0.2 | >10 | >1 | >0.1 | >0.23 | >0.77 |

| Conductivity at 25 °C [μS·cm−1] | 0.1 | 1.0 | 5.0 | 0.056 | 0.1 | 0.25 | 5.0 | <0.1 | <1 | <10 | <4.3 | <1.3 | |

| Acidity/Alkalinity | pH at 25 °C | - | - | 5.0–7.5 | - | - | - | 5.0–8.0 | - | - | 5.0–8.0 | - | - |

| Organics | Total Organic Carbon/p.p.b.(μg/l) | - | - | - | 50 | 50 | 200 | - | <50 | <200 | <1000 | <500 | <500 |

| Total Solids | mg/kg | - | 1 | 2 | - | - | - | - | 0.1 | 1 | 5 | - | - |

| Colloids | Silica [μg/ml] | - | - | - | <2 | <3 | <500 | - | <0.05 | <0.1 | <1 | - | - |

| Bacteria | CFU/ml | - | - | - | \ - | - | - | - | <10 | <1000 | - | <100 | <100 |

Criticism

A member of the ASTM D19 (Water) Committee, Erich L. Gibbs, criticized ASTM Standard D1193, by saying "Type I water could be almost anything – water that meets some or all of the limits, part or all of the time, at the same or different points in the production process."[7]

Electrical Conductivity

Electrical conductivity of ultra-pure water is 5.5 × 10−6 S·m−1 (18 MΩ cm in the reciprocal terms of Electrical Resistivity) and is due only to H+ and OH- ions produced in the water dissociation equilibrium.[8][9] This low conductivity is only achieved, however, in the presence of dissolved monatomic gases. Completely de-gassed ultra-pure water has conductivity of 1.2 × 10−4 S·m−1, whereas upon equilibration to the atmosphere it is 7.5 × 10−5 S·m−1 due to dissolved CO2 in it.[8] The highest grades of ultrapure water should not be stored in glass or plastic containers because these container materials leach (release) contaminants at very low concentrations. Storage vessels made of silica are used for less demanding applications and vessels of ultrapure tin are used for the highest purity applications. It is worth noting that although electrical conductivity only indicates the presence of ions, the majority of common contaminants found naturally in water ionize to some degree. This ionization is a good measure of the efficacy of a filtration system, and more expensive systems incorporate conductivity-based alarms to indicate when filters should be refreshed or replaced. For comparison, .[10] sea water has a conductivity of perhaps 5S/m (53 mS/cm is quoted), while normal un-purified tap water may have conductivity of 5mS/m(50uS/cm) (to within an order of magnitude), which is still some 2 or 3 orders of magnitude higher than the output from a well functioning demineralizing or distillation mechanism, so low levels of contamination or declining performance are easily detected.

Non-laboratory uses

Distilled or deionized water is commonly used to top up lead-acid batteries used in cars and trucks and for other applications. The presence of foreign ions commonly found in tap water will drastically shorten the lifespan of a lead-acid battery.

Distilled or deionized water is preferable to tap water for use in automotive cooling systems.

Using deionised or distilled water in appliances which evaporate water, such as steam irons and humidifiers, can reduce the build-up of mineral scale, which shortens appliance life. Some appliance manufacturers say that deionised water is no longer necessary.[11][12]

Purified water is used in freshwater and marine aquariums. Since it does not contain impurities such as copper and chlorine, it helps to keep fish free from diseases, and avoids the build-up of algae on aquarium plants due to its lack of phosphate and silicate. Deionized water should be re-mineralized before use in aquaria, since it lacks many macro- and micro-nutrients needed by plants and fish.

Water (sometimes mixed with methanol) has been used to extend the performance of aircraft engines. In piston engines it acts to delay the onset of engine knocking. In turbine engines it allows more fuel flow for a given turbine temperature limit, and increases mass flow. As an example, it was used on early Boeing 707 models.[13] Advanced materials and engineering have since rendered such systems obsolete for new designs, however spray-cooling of incoming air-charge is still used to a limited extent with off-road turbo-charged engines (road-race track cars).

Deionized water is very often used as an "ingredient" in many cosmetics and pharmaceuticals where it is sometimes referred to as "aqua" on product ingredient labels; see International Nomenclature of Cosmetic Ingredients.

Because of its high relative dielectric constant (~80), deionized water is also used (for short durations, when the resistive losses are acceptable) as a high voltage dielectric in many pulsed power applications, such as the Sandia National Laboratories Z Machine.

Distilled water can be used in PC watercooling systems and Laser Marking Systems. The lack of impurity in the water means that the system stays clean and prevents a build up of bacteria and algae. Also, the low conductance reduces risk of electrical damage in the event of a leak.

When used as a rinse after washing cars, windows, and similar applications, purified water dries without leaving spots caused by dissolved solutes.

Deionized water is used in water-fog fire-extinguishing systems used in sensitive environments, such as where high-voltage electrical and sensitive electronic equipment is used. The 'sprinkler' nozzles use much finer spray jets than other systems, and operate at up 35 MPa (350 bar; 5,000 psi) of pressure. The extremely fine mist produced takes the heat out of a fire rapidly, and the fine droplets of water are nonconducting (when deionized) and are less likely to damage sensitive equipment. Deionized water, however, is inherently acidic and contaminants (such as copper, dust, stainless and carbon steel, and many other common materials) rapidly supply ions, thus re-ionizing the water. It is not generally considered acceptable to spray water on electrical circuits that are powered, and it is generally considered undesirable to use water in electrical contexts.[14][15][16][17]

Distilled or purified water is used in humidors to reduce cigars from collecting bacteria, mold, and contaminants, as well as to prevent residue from forming on the humidifier material.

Health effects of drinking purified water

Distillation removes all minerals from water, and the membrane methods of reverse osmosis and nanofiltration remove most, or virtually all, minerals. This results in demineralized water which has not been proven to be healthier than drinking water. The World Health Organization investigated the health effects of demineralized water in 1980, and its experiments in humans found that demineralized water increased diuresis and the elimination of electrolytes, with decreased serum potassium concentration. Magnesium, calcium and other nutrients in water can help to protect against nutritional deficiency. Recommendations for magnesium have been put at a minimum of 10 mg/L with 20–30 mg/L optimum; for calcium a 20 mg/L minimum and a 40–80 mg/L optimum, and a total water hardness (adding magnesium and calcium) of 2–4 mmol/L. At water hardness above 5 mmol/L, higher incidence of gallstones, kidney stones, urinary stones, arthrosis, and arthropathies have been observed. For fluoride the concentration recommended for dental health is 0.5–1.0 mg/L, with a maximum guideline value of 1.5 mg/L to avoid dental fluorosis.[18]

Water filtration devices are becoming increasingly common in households. Most of these devices do not distill water, though there continues to be an increase in consumer-oriented water distillers and reverse osmosis machines being sold and used. Municipal water supplies often add or have trace impurities at levels which are regulated to be safe for consumption. Much of these additional impurities, such as volatile organic compounds, fluoride, and an estimated 75,000+ other chemical compounds[19][20][21] are not removed through conventional filtration; however, distillation and reverse osmosis eliminate nearly all of these impurities.

The drinking of purified water as a replacement of drinking water has been both advocated and discouraged for health reasons. Purified water lacks minerals and ions such as calcium that play key roles in biological functions such as in nervous system homeostasis, and are normally found in potable water. The lack of naturally-occurring minerals in distilled water has raised some concerns. The Journal of General Internal Medicine[22] published a study on the mineral contents of different waters available in the US. The study found that "drinking water sources available to North Americans may contain high levels of calcium, magnesium, and sodium and may provide clinically important portions of the recommended dietary intake of these minerals". It encouraged people to "check the mineral content of their drinking water, whether tap or bottled, and choose water most appropriate for their needs". Since distilled water is devoid of minerals, supplemental mineral intake through diet is needed to maintain proper health.

The consumption of "hard" water (water with minerals) is associated with beneficial cardiovascular effects. As noted in the American Journal of Epidemiology, consumption of hard drinking water is negatively correlated with atherosclerotic heart disease.[23]

Where a public water supply contains significant fluoride, naturally or added by fluoridation, people who prefer to limit fluoride intake can install filters appropriate to reduce fluoride content.[24]

See also

- Artificial seawater

- Hydrogen production

- Ionized water

- Water ionizer

- Electrodeionization

- Atmospheric water generator

- Heavy water

- Water softening

- Milli-Q water

References

- ↑ "Frequently asked questions about bottled water". Health Canada. Retrieved 2009-05-24.

- ↑ "Deionised Water 25L". Image2output.com. 2008-12-21. Retrieved 2011-12-11.

- ↑ "Purified Water and Clinical Products". Pure Klenz. Retrieved 2011-12-11.

- ↑ "Water conductivity". Lenntech. Retrieved 2011-12-11.

- ↑ Sandle, T. (July 2004). "An approach for the reporting of microbiological results from water systems". PDA J Pharm Sci Technol 58 (4): 231–7.

- ↑ "The Importance of Water Quality is Critical".

- ↑ A Critique of ASTM Standard D1193.

- ↑ 8.0 8.1 Pashley, R. M.; Rzechowicz, M.; Pashley, L. R.; Francis, M. J. (2005). "De-Gassed Water Is a Better Cleaning Agent". J. Phys. Chem. B 109 (3): 1231–1238. doi:10.1021/jp045975a. PMID 16851085. See in particular page 1235. Note that values in this paper are given in S/cm, not S/m, which differs by a factor of 100.

- ↑ , Resistivity / Conductivity Measurement of Purified Water, Lab Manager Magazine

- ↑ http://waterfacts.net/html/conductivity.html

- ↑ "How to Buy a Steam Iron". Consumersearch.com. Retrieved 2011-12-11.

- ↑ "Steam Iron Buying Guide". Homeinstitute.com. Retrieved 2011-12-11.

- ↑ SP-4221 The Space Shuttle Decision Retrieved 25 April 2008

- ↑ "Deionized Water - Application Note - Lytron Inc". Lytron.com. Retrieved 2011-12-11.

- ↑

- ↑

- ↑ http://www.safetymgmt.com/AIGRiskTools/Knowledge_Center/General_Industry/ELECTRICAL_SAFETY.pdf

- ↑ Kozisek F (2005). "Health risks from drinking demineralised water" (PDF). Nutrients in Drinking Water. World Health Organization. pp. 148–63. ISBN 92-4-159398-9.

- ↑ "Walton International - Home". Watersystems.walton.com. 2010-11-05. Retrieved 2011-12-11.

- ↑ "Our Technology - Purification Technology". Drinkmorewater.com. Retrieved 2011-12-11.

- ↑ http://www.homeenvironmentcenter.com/10stage.htm

- ↑ Azoulay A, Garzon P, Eisenberg MJ (2001). "Comparison of the mineral content of tap water and bottled waters". J Gen Intern Med 16 (3): 168–75. doi:10.1111/j.1525-1497.2001.04189.x. PMC 1495189. PMID 11318912.

- ↑ Voors, A. W. (April 1, 1971). "Mineral in the municipal water and atherosclerotic heart death". American Journal of Epidemiology 93 (4). pp. 259–266. PMID 5550342

- ↑ Hobson WL, Knochel ML, Byington CL, Young PC, Hoff CJ, Buchi KF (2007). "Bottled, filtered, and tap water use in Latino and non-Latino children". Arch Pediatr Adolesc Med 161 (5): 457–61. doi:10.1001/archpedi.161.5.457. PMID 17485621.