Polybenzimidazole fiber

Polybenzimidazole (PBI) fiber is a synthetic fiber with a very high melting point that also does not readily ignite, because of its exceptional thermal and chemical stability. The U.S. Federal Trade Commission definition for PBI fiber is "A manufactured fiber in which the fiber-forming substance is a long chain aromatic polymer having recurring imidazole groups as an integral part of the polymer chain". Kermel, a polyamide-imide, is a related "high performance polymer."

PBI is used to fabricate high-performance protective apparel such as firefighter turnout coats and suits, astronaut space suits, high temperature protective gloves, welders' apparel, race driver suits, braided packings, and aircraft wall fabrics.[1]

Production

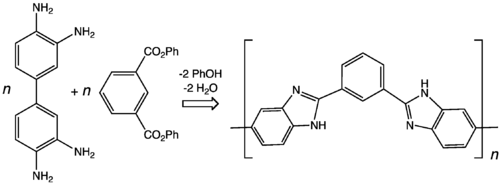

PBI is prepared by step-growth polymerization from 3,3',4,4'-tetraaminobiphenyl and diphenyl isophthalate (an ester of Isophthalic acid and phenol). The resulting polymer is processed into a solution using dimethyl acetamide, then fibered via a dry spinning process.

The first U.S. commercial PBI fiber was produced by Celanese. HOS-Technik GmbH, which is a small European chemical company can also produce PBI in powdery and liquid form.

See also

References

- ↑ Hiroshi Mera, Tadahiko Takata "High-Performance Fibers" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2005. doi:10.1002/14356007.a13_001

Appendix of properties

PBI fiber characteristics

The chemical formula of poly[2,2’-(m-phenylen)-5,5’ bibenzimidazol] (PBI) is believed to be: ([NH-C=CH-C=CH-CH=C-N=C-]2-[C=CH-C=CH-CH=CH-])n OR (C20N4H12)n of Molar mass 308.336 ± 0.018 g/mol.[citation needed]

Chemical resistance

| Chemical Resistance | Grade |

|---|---|

| Acids - concentrated | Poor |

| Acids - dilute | Fair-Poor |

| Alcohols | Good |

| Alkalis | Good-Poor |

| Aromatic hydrocarbons | Good |

| Greases and Oils | Good |

| Halogenated Hydrocarbons | Good |

| Ketones | Good |

It is dyeable to dark shades with basic dyes following caustic pretreatment and resistant to most chemicals.

Electrical Properties

| Electrical | Properties |

|---|---|

| Dielectric constant @ 1 MHz | 3.2 |

| Dielectric strength | 21 kV·mm−1 |

| Volume resistivity | 8x1014 Ω·cm |

Features low electrical conductivity and low static electricity buildup.

Mechanical Properties

| Mechanical | Properties |

|---|---|

| Coefficient of friction | 0.19-0.27 |

| Compressive modulus | 6.2 GPa |

| Compressive strength | 400 MPa |

| Elongation at break | 3% |

| Hardness - Rockwell | K115 |

| Izod impact strength | 590 J·m−1 unnotched |

| Poisson's ratio | 0.34 |

| Tensile modulus | 5.9 GPa |

| Tensile strength | 160 MPa |

Features abrasion resistance.

Physical Properties

| Physical | Properties |

|---|---|

| Char Yield (under pyrolysis) | High |

| Density | 1.3 g/cm³ |

| Flammability | Does not burn |

| Limiting oxygen index | 58% |

| Radiation resistance | Good |

| Water absorption - over 24 hours | 0.4% |

Additional features: will not ignite or smolder (burn slowly without flame), mildew- and age-resistant, resistant to sparks and welding spatter.

Thermal Properties

| Thermal | Properties | Grade |

|---|---|---|

| Coefficient of thermal expansion | 23×10−6·K−1 | Low |

| Heat-deflection temperature - 0.45 MPa | 435 °C (815 °F) | High |

| Thermal conductivity @ 23 °C (73 °F) | 0.41 W·m−1·K−1 | Low |

| Upper working temperature | 260–400 °C (500–752 °F) | High |

Other features: continuous temperature: 540 °C (1,004 °F), does not melt but degrades around the temperature: 760 °C (1,400 °F) under pyrolysis, retains fiber integrity and suppleness up to 540 °C (1,004 °F).