Pirani gauge

The Pirani gauge is a robust thermal conductivity gauge used for the measurement of the pressures in vacuum systems.[1] It was invented in 1906 by Marcello Pirani.[2]

Structure

The Pirani gauge consists of a metal filament (usually platinum) suspended in a tube which is connected to the system whose vacuum is to be measured. Connection is usually made either by a ground glass joint or a flanged metal connector, sealed with an o-ring. The filament is connected to an electrical circuit from which, after calibration, a pressure reading may be taken.

Mode of operation

A heated metal wire (also called a filament) suspended in a gas will lose heat to the gas as its molecules collide with the wire and remove heat. If the gas pressure is reduced the number of molecules present will fall proportionately and the wire will lose low heat more slowly. Measuring the heat loss is an indirect indication of pressure.

The electrical resistance of a wire varies with its temperature, so the resistance indicates the temperature of wire. In many systems, the wire is maintained at a constant resistance R by controlling the current I through the wire. The resistance can be set using a bridge circuit. The power delivered to the wire is I2R, and the same power is transferred to the gas.[3] The current required to achieve this balance is therefore a measure of the vacuum.

The gauge may be used for pressures between 0.5 Torr to 10−4 Torr. The thermal conductivity and heat capacity of the gas may affect the readout from the meter, and therefore the apparatus may need calibrating before accurate readings are obtainable. For lower pressure measurement other instruments such as a Penning gauge are used.

Pulsed Pirani gauge

A special form of the Pirani gauge is the pulsed Pirani vacuum gauge where the filament is not operated at a constant temperature, but is cyclically heated up to a certain temperature threshold by an increasing voltage ramp. When the threshold is reached, the heating voltage is switched-off and the filament cools down again.

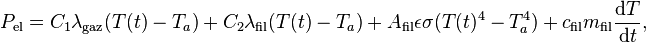

For adequately low pressure the following relation for supplied heating power and filament temperature T(t) applies:[4]

where  is the heating capacity of the filament,

is the heating capacity of the filament,  is the mass of the filament and

is the mass of the filament and  and

and  are constants.

are constants.

Advantages and disadvantages of the pulsed gauge

- Advantages

- Significantly better resolution in the range above 100 Torr. [5]

- The power consumption is drastically reduced compared to continuously operated Pirani gauges.

- The gauge's thermal influence on the real measurement is lowered considerably due to the low temperature threshold of 80°C and the ramp heating in pulsed mode.

- The pulsed mode allows for efficient implementation of modern microprocessor technology.

- Disadvantages

- Increased calibration effort

- Longer heat-up phase

References

- ↑ "Phys. Rev. 37 (1931): A. Ellett and R. M. Zabel - The Pirani Gauge for the Measurement of Small Changes of Pressure".

- ↑ von Pirani, M (1906). Deutsche Physikalische Gesellschaft, Verh. 8: 24.

- ↑ Ignoring the power lost by the electrical connections and the wire supports.

- ↑ DE 10115715, Plöchinger, Heinz, "Sensor and Method for Detecting Measurement Variables and Physical Parameters", published 2001-03-30, issued 2002-10-17, also description

- ↑ Jitschin, W.; Ludwig, S. (2004). "Gepulstes Heißdraht-Vakuummeter mit Pirani-Sensor". Vakuum in Forschung und Praxis (in German) 16: 23–29.

External links

- http://homepages.thm.de/~hg8831/vakuumlabor/litera.htm

- Jitschin, W. (2006), "100 Jahre Pirani-Vakuummeter", Vakuum in Forschung und Praxis (in German) 18 (6): 22–23

- Jitschin, W.; Ludwig, S. (2004), "Gepulstes Pirani-Vakuummeter: Berechnung von Aufheizung und Abkühlung", Vakuum in Forschung und Praxis (in German) 16: 297–301