Operations management

Operations management is an area of management concerned with overseeing, designing, and controlling the process of production and redesigning business operations in the production of goods or services. It involves the responsibility of ensuring that business operations are efficient in terms of using as few resources as needed, and effective in terms of meeting customer requirements. It is concerned with managing the process that converts inputs (in the forms of materials, labor, and energy) into outputs (in the form of goods and/or services). The relationship of operations management to senior management in commercial contexts can be compared to the relationship of line officers to highest-level senior officers in military science. The highest-level officers shape the strategy and revise it over time, while the line officers make tactical decisions in support of carrying out the strategy. In business as in military affairs, the boundaries between levels are not always distinct; tactical information dynamically informs strategy, and individual people often move between roles over time.

According to the U.S. Department of Education, operations management is the field concerned with managing and directing the physical and/or technical functions of a firm or organization, particularly those relating to development, production, and manufacturing. Operations management programs typically include instruction in principles of general management, manufacturing and production systems, factory management, equipment maintenance management, production control, industrial labor relations and skilled trades supervision, strategic manufacturing policy, systems analysis, productivity analysis and cost control, and materials planning.[3][4] Management, including operations management, is like engineering in that it blends art with applied science. People skills, creativity, rational analysis, and knowledge of technology are all required for success.

History

Industrial Revolution

Before the First industrial revolution work was mainly done through two systems: domestic system and craft guilds. In the domestic system merchants took materials to homes where artisans performed the necessary work, craft guilds on the other hand were associations of artisans which passed work from one shop to another, for example: leather was tanned by a tanner, passed to curriers, and finally arrived at shoemakers and saddlers. The beginning of the industrial revolution is usually associated with 18th century English textile industry, with the invention of flying shuttle by John Kay in 1733, the spinning jenny by James Hargreaves in 1765, the water frame by Richard Arkwright in 1769 and the steam engine by James Watt in 1765. In 1851 at the Crystal Palace Exhibition the term American system of manufacturing was used to describe the new approach that was evolving in the United States of America which centered on two central features: interchangeable parts and extensive use of mechanization to produce them.

In 1913 Henry Ford first used the concept of the assembly line in Highland Park, he characterized it as follows:

"The thing is to keep everything in motion and take the work to the man and not the man to the work. That is the real principle of our production, and conveyors are only one of many means to an end"[5]

This became one the central ideas that led to mass production, one of the main elements of the Second Industrial Revolution, along with emergence of the electrical industry and petroleum industry.

Operations Management

In 1911 Frederick Taylor published his "The Principles of Scientific Management",[6] in which he characterized scientific management as:

- The development of a true science;

- The scientific selection of the worker;

- The scientific education and development of the worker;

- Intimate friendly cooperation between the management and the workers.

Taylor is also credited for developing stopwatch time study, this combined with Frank and Lillian Gilbreth motion study gave way to time and motion study which is centered on the concepts of standard method and standard time. Other contemporaries of Taylor worth remembering are Morris Cooke (rural electrification in 1920s) and Henry Gantt (Gantt chart). Also in 1910 Hugo Diemer published the first industrial engineering book: Factory Organization and Administration.

In 1913 Ford W. Harris published his "How Many parts to make at once" in which he presented the idea of the economic order quantity model. He described the problem as follows:

"Interest on capital tied up in wages, material and overhead sets a maximum limit to the quantity of parts which can be profitably manufactured at one time; "set-up" costs on the job fix the minimum. Experience has shown one manager a way to determine the economical size of lots"[7]

In 1931 Walter Shewhart published his Economic Control of Quality of Manufactured Product, the first systematic treatment [8] of the subject of Statistical Process Control.

In 1943, in Japan, Taiichi Ohno arrived at Toyota Motor company. Toyota evolved a unique manufacturing system centered on two complementary notions: just in time (produce only what is needed) and autonomation (automation with a human touch). Regarding JIT, Ohno was inspired by American supermarkets: workstations functioned like a supermarket shelf where the customer can get products they need, at the time they need and in the amount needed, the workstation (shelf) is then restocked. Autonomation was developed by Toyoda Sakichi in Toyoda Spinning and Weaving: an automatically activated loom that was also foolproof, that is automatically detected problems. In 1983 J.N Edwards published his "MRP and Kanban-American style" in which he described JIT goals in terms of seven zeros:[9] zero defects, zero (excess) lot size, zero setups, zero breakdowns, zero handling, zero lead time and zero surging. This period also marks the spread of Total Quality Management in Japan, ideas initially developed by American authors such as Deming, Juran and Armand V. Feigenbaum. Schnonberger[10] identified seven fundamentals principles essential to the Japanese approach:

- Process control: SPC and worker responsibility over quality

- Easy-to-see quality: boards, gauges, meters, etc. and poka-yoke

- Insistence on compliance: "quality first"

- Line stop: stop the line to correct quality problems

- Correcting one's own errors: worker fixed a defective part if he produced it

- The 100% check: automated inspection techniques and foolproof machines

- Continual improvement: ideally zero defects

In 1987 the International Organization for Standardization (ISO), recognizing the growing importance of quality, issued the ISO 9000, a family of standards related to quality management systems. There has been some controversy thought regarding the proper procedures to follow and the amount of paperwork involved.

Meanwhile in 1964, a different approach was developed by Joseph Orlicky as a response to the TOYOTA Manufacturing Program: Material Requirements Planning (MRP) at IBM, latter gaining momentum in 1972 when the American Production and Inventory Control Society launched the "MRP Crusade". One of the key insights of this management system was the distinction between dependent demand and independent demand.

Recent trends in the field revolve around concepts such as Business Process Re-engineering (launched by Michael Hammer in 1993[11]), Lean Manufacturing, Six Sigma (an approach to quality developed at Motorola between 1985-1987) and Reconfigurable Manufacturing Systems.

The term lean manufacturing was coined in the book The Machine that Changed the World.[12] Six Sigma refers to control limits placed at six (6) standard deviations from the mean of a normal distribution, this became very famous after Jack Welch of General Electric launched a company-wide initiative in 1995 to adopt this set of methods. More recently, Six Sigma has included DMAIC (for improving processes) and DFSS (for designing new products and new processes)

Topics

Production Systems

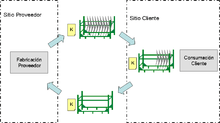

A production system comprises both the technological elements (machines and tools) and organizational behavior (division of labor and information flow). An individual production system is usually analyzed in the literature referring to a single business, therefore it's usually improper to include in a given production system the operations necessary to process goods that are obtained by purchasing or the operations carried by the customer on the sold products, the reason being simply that since businesses need to design their own production systems this then becomes the focus of analysis, modeling and decision making (also called "configuring" a production system) .

A first possible distinction in production systems (technological classification) is between process production and part production.

- Process production means that the product undergoes physical -chemical transformations and lacks assembly operations, therefore raw materials can easily be obtained from the final product, examples include: paper, cement and nylon.

- Part production (ex:cars and ovens) comprises both manufacturing systems and assembly systems. In the first category we find job shops, manufacturing cells, flexible manufacturing systems and transfer lines, in the assembly category we have fixed position systems, assembly lines and assembly shops (both manual and/or automated operations).[13]

Another possible classification[14] is one based on Lead Time (manufacturing lead time vs delivery lead time): Engineer to Order, Purchase to Order, Make to Order, Assemble to Order and Make to Stock. According to this classification different kinds of systems will have different customer order decoupling points (CODP), meaning that Work in Progress cycle stock levels are practically nonexistent regarding operations located after the CODP (except for WIP due to queues).

The concept of production systems can be expanded to the service sector world keeping in mind that services have some fundamental differences in respect to material goods: intangibility, client always present during transformation processes, no stocks for "finished goods". Services can be classified according to a service process matrix:[15] degree of labor intensity (volume) vs degree of customization (variety). With a high degree of labor intensity there are Mass Services (e.g., commercial banking bill payments and state schools) and Professional Services (e.g., personal physicians and lawyers), while with a low degree of labor intensity there are Service Factories (e.g., airlines and hotels) and Service Shops (e.g., hospitals and auto mechanics).

The systems described above are ideal types: real systems may present themselves as hybrids of those categories. Consider, for example, that the production of jeans involves initially carding, spinning, dyeing and weaving, then cutting the fabric in different shapes and assembling the parts in pants or jackets by combining the fabric with thread, zippers and buttons, finally finishing and distressing the pants/jackets before being shipped to stores.[16] The beginning can be seen as process production, the middle as part production and the end again as process production: it's unlikely that a single company will keep all the stages of production under a single roof, therefore the problem of vertical integration and outsourcing arises. Most products require, from a supply chain perspective, both process production and part production.

Metrics: efficiency and effectiveness

Operations strategy concerns policies and plans of use of the firm productive resources with the aim of supporting long term competitive strategy. Metrics in operations management can be broadly classified into efficiency metrics and effectiveness metrics. Effectiveness metrics involve:

- Price (actually fixed by marketing, but lower bounded by production cost): purchase price, use costs, maintenance costs, upgrade costs, disposal costs

- Quality: specification and compliance

- Time: productive lead time, information lead time, punctuality

- Flexibility: mix, volume, gamma

- Stock availability

A more recent approach, introduced by Terry Hill,[17] involves distinguishing competitive variables in order winner and order qualifiers when defining operations strategy. Order winners are variables which permit differentiating the company from competitors, while order qualifiers are prerequisites for engaging in a transaction. This view can be seen as a unifying approach between operations management and marketing (see segmentation and positioning).

Productivity is a standard efficiency metric for evaluation of production systems, broadly speaking a ratio between outputs and inputs, and can assume many specific forms, for example: machine productivity, workforce productivity, raw material productivity, warehouse productivity (=inventory turnover). It is also useful to break up productivity in use U (productive percentage of total time) and yield η (ratio between produced volume and productive time) to better evaluate production systems performances. Cycle times can be modeled through manufacturing engineering if the individual operations are heavily automated, if the manual component is the prevalent one, methods used include: time and motion study, predetermined motion time systems and work sampling.

ABC analysis is a method for analyzing inventory based on Pareto distribution, it posits that since revenue from items on inventory will be power law distributed then it makes sense to manage items differently based on their position on a revenue-inventory level matrix, 3 classes are constructed (A,B and C) from cumulative item revenues, so in a matrix each item will have a letter (A,B or C) assigned for revenue and inventory. This method posits that items away from the diagonal should be managed differently: items in the upper part are subject to risk of obsolescence, items in the lower part are subject to risk of stockout.

Throughput is a variable which quantifies the number of parts produced in the unit of time. Although estimating throughput for a single process maybe fairly simple, doing so for an entire production system involves an additional difficulty due to the presence of queues which can come from: machine breakdowns, processing time variability, scraps, setups, maintenance time, lack of orders, lack of materials, strikes, bad coordination between resources, mix variability, plus all these inefficiencies tend to compound depending on the nature of the production system. One important example of how system throughput is tied to system design are bottlenecks: in job shops bottlenecks are typically dynamic and dependent on scheduling while on transfer lines it makes sense to speak of "the bottleneck" since it can be univocally associated with a specific station on the line. This leads to the problem of how to define capacity measures, that is an estimation of the maximum output of a given production system, and capacity utilization.

Overall Equipment Effectiveness (OEE) is defined as the product between system availability, cycle time efficiency and quality rate. OEE is typically used as key performance indicator (KPI) in conjunction with the lean manufacturing approach.

Configuration and Management

Designing the configuration of production systems involves both technological and organizational variables. Choices in production technology involve: dimensioning capacity, fractioning capacity, capacity location, outsourcing processes, process technology, automation of operations, tradeoff between volume and variety (see Hayes-Wheelwright matrix). Choices in the organizational area involve: defining worker skills and responsibilities, team coordination, worker incentives and information flow.

Regarding the planning of production there is a basic distinction between the push approach and the pull approach, with the later including the singular approach of Just in Time. Regarding the traditional pull approach a number of techniques have been developed based on the work of Ford W. Harris[7] (1913) which came to be know as the Economic Order Quantity Model (EOQ), which formed the basis of subsequent techniques as the Wagner-Within Procedure, the News Vendor Model, Base Stock Model and the Fixed Time Period Model. These models usually involve the calculation of cycle stocks and buffer stocks, the latter usually modeled as a function of demand variability. The Economic Production Quantity[18] (EPQ) differs from the EOQ model only in that it assumes a constant fill rate for the part being produced, instead of the instantaneous refilling of the EOQ model.

Joseph Orlickly and others developed Material Requirement Planning (MRP) at IBM, essentially a push approach to inventory control and production planning, which takes as input both the Master Production Schedule (MPS) and the Bill of Materials (BOM) and gives as output a schedule for the materials needed in the production process. The MPS can be seen as a kind of aggregate planning for production coming in two fundamentally opposing varieties: plans which try to chase demand and level plans which try to keep uniform capacity utilization. Many models have been proposed to solve MPS problems:

- Analytical models (e.g. Magee Boodman model)

- Exact optimization algorithmic models (e.g. LP and ILP)

- Heuristic models (e.g. Aucamp model).

MRP can be briefly described as a 3s procedure: sum (different orders), split (in lots), shift (in time according to item lead time) To avoid an "explosion" of data processing in MRP (number of BOMs required in input) planning bills (such as family bills or super bills) can be useful since they allow a rationalization of input data into common codes. MRP had some notorious problems such as infinite capacity and fixed lead times, giving way later on to modifications of original software implementation in the form of MRP II and ERP. In this context problems of scheduling (sequencing of production), loading (tools to use), part type selection (parts to work on) and applications of operations research have a significant role to play.

Lean Manufacturing is an approach to production which arose in Toyota between the end of World War II and the seventies. It comes mainly from the ideas of Taiichi Ohno and Toyoda Sakichi which are centered on the complementary notions of Just in Time and Autonomation (jidoka), all aimed at reducing waste (usually applied in PDCA style). Some additional elements are also fundamental:[19] production smoothing (Heijunka), capacity buffers, setup reduction, cross-training and plant layout.

- Heijunka: production smoothing presupposes a level strategy for the MPS and a final assembly schedule developed from the MPS by smoothing aggregate production requirements in smaller time buckets and sequencing final assembly to achieve repetitive manufacturing. In this case throughput can be equaled to takt time. Besides volume, heijunka also means attaining mixed model production, which however may only be feasible trough set-up reduction. A standard tool for achieving this is the Heijunka box

- Capacity buffers: ideally a JIT system would work with zero breakdowns, this however is very hard to achieve in practice, nonetheless Toyota favors acquiring extra capacity over extra WIP to deal with starvation.

- Set-up reduction: typically necessary to achieve mixed model production, a key distinction can be made between internal and external setup. Internal setups (ex:removing a die) refers to tasks when the machine is not working, while external setups can be completed while the machine is running (ex:transporting dies).

- Cross training: important as an element of Autonomation, Toyota cross trained their employees through rotation, this served as an element of production flexibility, reducing boredom and holistic thinking.

- Layout: U-shaped lines or cells are common in the lean approach since they allow for minimum walking, greater worker efficiency and flexible capacity.

A series of tools have been developed mainly with the objective of replicating Toyota success: a very common implementation involves small cards known as kanbans, these also come in some varieties: reorder kanbans, allarm kanbans, triangle kanbans, etc. In the classic kanban procedure with one card:

- Parts are kept in containers with their respective kanbans

- The downstream station moves the kanban to the upstream station and starts producing the part at the downstream station

- The upstream operator takes the most urgent kanban from his list (compare to queue discipline from queue theory) and produces it and attach its respective kanban

The two-card kanban procedure differs a bit:

- The downstream operator takes the production kanban from his list

- If required parts are available he removes the move kanban and places them in another box, otherwise he chooses another production card

- He produces the part and attach its respective production kanban

- Periodically a mover picks up the move kanbans in upstream stations and search for the respective parts, when found he exchanges production kanbans for move kanbans and move the parts to downstream stations

Since the number of kanbans in the production system is set by managers as a constant number, the kanban procedure works as WIP controlling device, which for a given arrival rate, per Little's Law, works as lead time controlling device.

In Toyota the TPS represented more of a philosophy of production than a set of specific tools, the latter would include: SMED, Value Stream Mapping, 5S, poka-yoke, elimination of time batching, lot-size reduction, Rank Order Clustering, single point scheduling, multi-process handling and backflush accounting.

Seen more broadly JIT can include methods such as: product standardization and modularity, group technology, total productive maintenance, job enlargement, job enrichment, flat organization and vendor rating (JIT production is very sensitive to replenishment conditions).

Modeling

There are also fields of mathematical theory which have found applications in the field of operations management such as operations research, mainly mathematical optimization problems and queue theory. Queue theory is employed in modeling queue and processing times in production systems while mathematical optimization draws heavily from multivariate calculus and linear algebra. Queue theory is based on markov chains and stochastic processes. It also worth noticing that computations of safety stocks are usually based on modeling demand as a normal distribution.

When analytical models are not enough, managers may resort to using simulation. Simulation has been traditionally done thought the Discrete event simulation paradigm, where the simulation model possesses a state which can only change when a discrete event happens, which consists of a clock and list of events. The more recent Transaction-level modeling paradigm consists of a set of resources and a set of transactions: transactions move thought a network of resources (nodes) according to a code, called process.

Since real production processes are always affected by disturbances in both inputs and outputs, many companies implement some form of Quality management or quality control. Quality control tools include check sheets, pareto charts, Ishikawa diagrams, control charts, which are used in approaches like Total quality management and Six Sigma. Keeping quality under control is relevant to both increasing customer satisfaction and reducing processing waste.

Operations management textbooks usually cover demand forecasting, even though it is not strictly speaking an operations problem, because demand is related to some production systems variables. For example, a classic approach in dimensioning safety stocks requires calculating standard deviation of forecast errors. Demand forecasting is also a critical part of push systems, since order releases have to be planned ahead of actual clients orders. Also any serious discussion of capacity planning involves adjusting company outputs with market demands.

Safety, Risk and Maintenance

Other important management problems involve maintenance policies (see also reliability engineering and maintenance philosophy), safety management systems (see also safety engineering and Risk management), facility management and supply chain integration.

Organizations

The following organizations support and promote operations management:

- Association for Operations Management (APICS) which supports the Production and Inventory Management Journal

- European Operations Management Association (EurOMA) which supports the International Journal of Operations & Production Management

- Production and Operations Management Society (POMS) which supports the journal: Production and Operations Management

- Institute for Operations Research and the Management Sciences (INFORMS)

- The Manufacturing and Service Operations Management Society (MSOM) which supports the journal: Manufacturing & Service Operations Management

- Institute of Operations Management (UK)

- Association of Technology, Management, and Applied Engineering (ATMAE)

Journals

The following high-ranked[20] academic journals are concerned with Operations Management issues:

- Management Science

- Manufacturing & Service Operations Management

- Operations Research

- Journal of Operations Management

- International Journal of Operations & Production Management

- Production and Operations Management

See also

|

|

References

- ↑ R. B. Chase et all, Operations Management, McGraw-Hill 2007

- ↑ A. Portioli, A.Pozzetti, Progettazione dei sistemi produttivi, Hoepli 2003

- ↑ U.S. Department of Education Institute of Education Sciences: Classification of Instructional Programs (CIP). Retrieved on October 26, 2009 from CIP 2000 - CIP Lookup to Occupational Crosswalks

- ↑ ATMAE Membership Venn Diagram

- ↑ H. Ford, Today and Tomorrow, New York, 1926

- ↑ Taylor, Frederick Winslow (1911). The Principles of Scientific Management. New York, NY, US and London, UK: Harper & Brothers. LCCN 11010339. OCLC 233134. Also available from Project Gutenberg.

- ↑ 7.0 7.1 Harris, Ford W. (1990) [Reprint from 1913]. "How Many Parts to Make at Once". Operations Research (INFORMS) 38 (6): 947–950. JSTOR 170962. Retrieved Nov 21, 2012.

- ↑ Shewhart, Walter A[ndrew]. (1931). Economic control of quality of manufactured product. New York: D. Van Nostrand Company. pp. 501 p.. ISBN 0-87389-076-0 (edition ??). LCCN 3132090. OCLC 1045408. LCC TS155 .S47.

- ↑ J. N. Edwards, MRP and Kanban-American style, APICS 26th Conference Proceedings,pp586-603 1983

- ↑ Japanese Manufacturing Techniques:Nine Hidden Lessons in Simplicity, New York 1982

- ↑ M.Hammer, J.Champy, Reengineering the Corporation: A Manifesto for Business Revolution, Harper Business 1993

- ↑ Womack, Jones, Roos, The Machine that Changed the World, Free Press, 1990

- ↑ A. Portioli, A.Pozzetti, Progettazione dei sistemi produttivi, Hoepli 2003 Note: this classification is very old but it has been subject to update as production systems have evolved over the 20th century, for a complete picture consult recent texts

- ↑ J.C. Wortmann, Chapter: "A classification scheme for master production schedule", in Efficiency of Manufacturing Systems, C. Berg, D. French and B. Wilson (eds) New York, Plenum Press 1983

- ↑ Roger W. Schmenner, How Can Service Businesses Survive and Prosper?, Sloan Management Review, vol. 27, no. 3, Spring 1986 http://umairbali.ekalaam.com/Business%20Process%20Workflow%20Analysis/Week6/SMR-ServiceBusiness.pdf

- ↑ http://www.madehow.com/Volume-1/Blue-Jeans.html

- ↑ T. Hill, Manufacturing Strategy-Text and Cases, 3rd ed. Mc-Graw Hill 2000

- ↑ Taft, E. W. "The most economical production lot." Iron Age 101.18 (1918): 1410-1412.

- ↑ W. Hopp, M. Spearman, Factory Physics, 3rd ed. Waveland Press, 2011

- ↑ http://vhbonline.org/uploads/media/Ranking_Gesamt_2.1.pdf

Further reading

- D. Wren, The Evolution of Management Thought, 3rd ed. New York Wiley 1987

- W. Hopp, M. Spearman, Factory Physics, 3rd ed. Waveland Press, 2011 (Part 1 contains both description and critical evaluation of the historical development of the field)

- R. B. Chase, F.R. Jacobs, N.J.Aquilano, Operations Management for Competitive Advantage, 11th ed McGraw-Hill 2007

- Askin, R. G., C.R. Stanridge, Modeling & Analysis Of Manufacturing Systems, John Wiley and Sons, New York 1993

- J.A. Buzacott, J.G. Shanthikumar, Stochastic models of manufacturing systems, Prentice Hall, 1993

- D.C. Montgomery, Statistical Quality Control: A Modern Introduction, 7th edition 2012