Nickel–metal hydride battery

.jpg) Modern NiMH rechargeable cells | |

| Specific energy | 60–120 W·h/kg[citation needed] |

|---|---|

| Energy density | 140–300 W·h/L |

| Specific power | 250–1,000 W/kg |

| Charge/discharge efficiency | 66%[1] |

| Energy/consumer-price | 2.75 W·h/US$[1] |

| Cycle durability | 500–2000[2] cycles |

| Nominal cell voltage | 1.2 V |

A nickel–metal hydride battery, abbreviated NiMH or Ni–MH, is a type of rechargeable battery. Its chemical reactions are somewhat similar to the largely obsolete nickel–cadmium cell (NiCd). NiMH use positive electrodes of nickel oxyhydroxide (NiOOH), like the NiCd, but the negative electrodes use a hydrogen-absorbing alloy instead of cadmium, being in essence a practical application of nickel–hydrogen battery chemistry. A NiMH battery can have two to three times the capacity of an equivalent size NiCd, and their energy density approaches that of a lithium-ion cell.

The typical specific energy for small NiMH cells is about 100 W·h/kg, and for larger NiMH cells about 75 W·h/kg (270 kJ/kg). This is significantly better than the typical 40–60 W·h/kg for NiCd, and similar to the 100–160 W·h/kg for lithium-ion batteries. NiMH has a volumetric energy density of about 300 W·h/L (1,080 MJ/m3), significantly better than NiCd at 50–150 W·h/L, and about the same as lithium-ion at 250–360 W·h/L.

NiMH batteries have replaced NiCd for many roles, notably small rechargeable batteries. NiMH batteries are very common for AA (penlight-size) batteries, which have nominal charge capacities (C) of 1.1–2.8 A·h at 1.2 V, measured at the rate that discharges the cell in five hours. Useful discharge capacity is a decreasing function of the discharge rate, but up to a rate of around 1×C (full discharge in one hour), it does not differ significantly from the nominal capacity.[3] NiMH batteries normally operate at 1.2 V per cell, somewhat lower than conventional 1.5 V cells, but will operate most devices designed for that voltage.[citation needed]

About 22% of portable rechargeable batteries sold in Japan in 2010 were NiMH.[4] In Switzerland in 2009, the equivalent statistic was approximately 60%.[5] This percentage has fallen over time due to the increase in manufacture of lithium-ion batteries: in 2000, almost half of all portable rechargeable batteries sold in Japan were NiMH. By 2011, NiMH only represented about 22% of secondary batteries.[4]

The significant disadvantage of NiMH batteries is the high rate of self-discharge; NiMH batteries typically lose 4% of their charge per day of storage. In 2005, a low self-discharge (LSD) variant was developed. LSD NiMH batteries significantly lower self-discharge, but at the cost of lowering capacity by about 20%.

History

- Positive terminal

- Outer metal casing (also negative terminal)

- Positive electrode

- Negative electrode with current collector (metal grid, connected to metal casing)

- Separator (between electrodes)

The first consumer grade NiMH cells became commercially available in 1989.[6]

The earliest work on NiMH batteries based on sintered Ti2Ni+TiNi+x alloys and NiOOH-electrodes was conducted at the Battelle-Geneva Research Center starting after its invention in 1967. The development work was sponsored over nearly two decades by Daimler-Benz in Stuttgart, Germany, and by Volkswagen AG within the framework of Deutsche Automobilgesellschaft, now a subsidiary of Daimler AG. The batteries showed specific energy up to 50 W·h/kg (180 kJ/kg), power density up to 1000 W/kg and a life of 500 charge cycles (at 100% depth of discharge). Patent applications were filed in European countries (priority: Switzerland), the United States, and Japan, and the patents transferred to Daimler-Benz.[7]

Interest grew in the 1970s with the commercialisation of the nickel–hydrogen battery for satellite applications. Hydride technology promised an alternative much less bulky way to store the hydrogen. Research carried out by Philips Laboratories and France's CNRS developed new high-energy hybrid alloys incorporating rare earth metals for the negative electrode. However, these suffered from the instability of the alloys in alkaline electrolyte and consequently insufficient cycle life. In 1987, Willems and Buschow demonstrated a successful battery based on this approach (using a mixture of La0.8Nd0.2Ni2.5Co2.4Si0.1) which kept 84% of its charge capacity after 4000 charge–discharge cycles. More economically viable alloys using mischmetal instead of lanthanum were soon developed and modern NiMH cells are based on this design.[8]

Ovonic Battery Co. in Michigan altered and improved the Ti–Ni alloy structure and composition according to their patent[9] and licensed NiMH batteries to over 50 companies worldwide. Ovonic's NiMH variation consisted of special alloys with disordered alloy structure and specific multicomponent alloy compositions. Unfortunately, linked to their composition, the calendar and cycle life of such alloys always remains very low, and all NiMH batteries manufactured at the present time consist of AB5-type rare earth metal alloys.

A high-energy pasted electrode developed by Dr. Masahiko Oshitani from GS Yuasa Company led to the NiMH cell.

In 2008, more than 2 million hybrid cars worldwide were manufactured with NiMH batteries.[10]

In the EU and due to the Battery Directive, Nickel–metal hydride batteries have replaced Ni–Cd batteries for portable use by consumers.

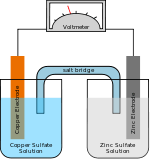

Electrochemistry

The negative electrode reaction occurring in a NiMH cell is:

- H2O + M + e−

OH− + MH

OH− + MH

The charge reaction is read left-to-right and the discharge reaction is read right-to-left.

On the positive electrode, nickel oxyhydroxide, NiO(OH), is formed:

- Ni(OH)2 + OH−

NiO(OH) + H2O + e−

NiO(OH) + H2O + e−

The "metal" M in the negative electrode of a NiMH cell is actually an intermetallic compound. Many different compounds have been developed for this application, but those in current use fall into two classes. The most common is AB5, where A is a rare earth mixture of lanthanum, cerium, neodymium, praseodymium and B is nickel, cobalt, manganese, and/or aluminium. Very few cells use higher-capacity negative electrode materials based on AB2 compounds, where A is titanium and/or vanadium and B is zirconium or nickel, modified with chromium, cobalt, iron, and/or manganese, due to the reduced life performances.[11] Any of these compounds serve the same role, reversibly forming a mixture of metal hydride compounds.

When overcharged at low rates, oxygen produced at the positive electrode passes through the separator and recombines at the surface of the negative. Hydrogen evolution is suppressed and the charging energy is converted to heat. This process allows NiMH cells to remain sealed in normal operation and to be maintenance-free.

NiMH cells have an alkaline electrolyte, usually potassium hydroxide. For separation hydrophilic polyolefin nonwovens are used.[12]

Charging

The charging voltage is in the range of 1.4–1.6 V/cell. In general, a constant-voltage charging method cannot be used for automatic charging. When fast-charging, it is advisable to charge the NiMH cells with a smart battery charger to avoid overcharging, which can damage cells and even be dangerous.[13] A NiCd charger should not be used as a substitute for an automatic NiMH charger.

Trickle charging

The simplest way to safely charge a NiMH cell is with a fixed low current, with or without a timer. Most manufacturers claim that overcharging is safe at very low currents, below 0.1 C (C/10) (where C is the current equivalent to the capacity of the battery divided by one hour).[14] The Panasonic NiMH charging manual warns that overcharging for long enough can damage a battery and suggests limiting the total charging time to 10 to 20 hours.[13]

Duracell further suggests that, for applications where the battery must be kept in a fully charged state, a trickle charge at C/300 can be used.[14] Some chargers do this after the charge cycle, to offset the natural self-discharge rate of the battery. A similar approach is suggested by Energizer[15] which indicates that the self catalysis can recombine gas formed at the anode for charge rates up to C/10, but as this leads to cell heating, recommends C/30 or C/40 for indefinite applications where long life is important. This is the approach taken in maintained emergency light fittings (which in Europe must remain on for 4 hours in the event of a power cut) where the design remains essentially the same as that used in older NiCd units, but for an increase in the trickle charging resistor value. In comparison, NiCd cells can ordinarily be charged indefinitely at C/10 without damage.

Panasonic's handbook, however, recommends that NiMH batteries on standby are kept charged by a lower duty cycle approach, where a pulse of a higher current is used whenever the battery's voltage drops below 1.3 V. This can extend battery life and use less energy.[13]

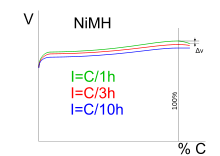

ΔV charging method

In order to charge a NiMH battery more quickly than the trickle method suggested above, a charger must stop charging before the battery is damaged. One method is to monitor the change of voltage across the battery with time. As can be seen in the charge curve diagram, when the battery is fully charged the voltage across its terminals drops slightly. The charger can detect this and stop charging. This method is often used with nickel–cadmium cells which have a large drop in voltage at full charge. However, the voltage drop is much less pronounced for NiMH and can be non-existent at low charge rates, which can make the approach unreliable.

Another option is to monitor the change of voltage with respect to time and stop when this becomes zero, but this runs the risk of premature cutoffs.[14] With this method, a much higher charging rate can be used than with a trickle charge, up to 1 C. At this charge rate, looking for a voltage drop, ΔV is approximately 5–10 mV per cell.[13] Since this method measures the voltage across the battery, a constant current (rather than a constant voltage) charging circuit must be used. This is unlike a lead–acid cell for example, which can, in theory, be more easily charged at a suitably chosen constant voltage.

ΔT temperature charging method

The ΔT temperature change method is similar in principle to the ΔV method. Because the charging voltage is nearly constant, constant-current charging delivers energy at a near-constant rate. When the cell is not fully charged, most of this energy is converted to chemical energy. However, when the cell reaches full charge, most of the charging energy is converted to heat. This increases the rate of change of battery temperature, which can be detected by a sensor such as a thermistor. Both Panasonic and Duracell suggest a maximum rate of temperature increase of 1 °C per minute. Using a temperature sensor also allows an absolute temperature cutoff, which Duracell suggests at 60 °C.[14]

With both the ΔT and the ΔV charging methods, both manufacturers recommend a further period of trickle charging to follow the initial rapid charge.

Charging at high and low temperatures

Charging temperature limits for NiMH are stricter than operational limits. Nickel-based batteries are most forgiving in accepting charge at low temperatures, however, when charging below 5 °C (41 °F), the ability to recombine oxygen and hydrogen diminishes. If NiCd and NiMH are charged too rapidly, pressure builds up in the cell that will lead to venting. Not only do escaping gases deplete the electrolyte, the hydrogen released is highly flammable. The charge current of all nickel-based batteries should be reduced to 0.1C below freezing down to −18 °C.

To enable fast-charging at all temperatures, some industrial batteries include a thermal blanket that heats the battery to an acceptable temperature; other chargers adjust the charge rate to prevailing temperatures. Consumer chargers do not have these provisions and users should make all attempts to only charge batteries at room temperatures.[16]

Safety

A good safety feature of a custom-built charger is to use a resettable fuse in series with the cell, particularly of the bimetallic strip type. This fuse will open if either the current or the temperature goes too high.[14]

Modern NiMH cells contain catalysts to immediately deal with gases developed as a result of over-charging without being harmed (2 H2 + O2 — catalyst → 2 H2O). However, this only works with overcharging currents of up to 0.1 C (nominal capacity divided by ten hours). As a result of this reaction, the batteries will heat up considerably, marking the end of the charging process.[14] Some quick chargers have a fan to keep the batteries cool.

A method for very rapid charging called in-cell charge control involves an internal pressure switch in the cell, which disconnects the charging current in the event of overpressure.

There is an inherent risk with NiMH chemistry that overcharging will cause a buildup of hydrogen, causing the cell to rupture. Therefore, cells have a vent. Hydrogen will be emitted from the vent in the event of serious overcharging.[17]

Discharging

A fully charged cell supplies an average 1.25 V/cell during discharge, down to about 1.0–1.1 V/cell (further discharge may cause permanent damage in the case of multi-cell packs, due to polarity reversal). Under a light load (0.5 ampere), the starting voltage of a freshly charged AA NiMH cell in good condition is about 1.4 volts.[18]

Over-discharging

A complete discharge of a battery can result in one or more cells going into polarity reversal, which can cause permanent damage to those cells. This situation can occur in the common arrangement of four AA cells in series in a digital camera, where one will be completely discharged before the others due to small differences in capacity among the cells. When this happens, the good cells will start to drive the discharged cell in reverse, which can cause permanent damage to that cell. Some cameras, GPS receivers and PDAs detect the safe end-of-discharge voltage of the series cells and auto-shutdown, but devices like flashlights and some toys do not. A single cell driving a load or a cell connected in parallel to other cells can't suffer from polarity reversal, because there are no other cells to reverse-charge it when it becomes discharged. (Cells parallel-connected to a discharged cell will tend to forward-charge it.)

Irreversible damage from polarity reversal is a particular danger in systems, even when a low voltage threshold cutout is employed, where cells in the battery are of different temperatures. This is because the capacity of NiMH cells significantly declines as the cells are cooled. This results in a lower voltage under load of the colder cells.[19]

Self-discharge

NiMH cells historically had a somewhat higher self-discharge rate (equivalent to internal leakage) than NiCd cells. The self-discharge rate varies greatly with temperature, where lower storage temperature leads to slower discharge rate and longer battery life. The self-discharge is 5 – 20% on the first day and stabilizes around 0.5–4% per day at room temperature.[20][21][22][23][24] But at 45 °C it is approximately 3 times as high.[14] This is not a problem in the short term but makes them unsuitable for many light-duty uses, such as clocks, remote controls, or safety devices, where the battery would normally be expected to last many months or years. The highest capacity cells on the market (>8000 mA·h) are reported to have the highest self-discharge rates.[citation needed]

Low self-discharge cells

The low self-discharge nickel–metal hydride battery(LSD NiMH) was introduced in 2005. It has a significantly lower rate of self-discharge, so holds its charge longer if left charged but unused. By using an improved electrode separator and improved positive electrode, manufacturers claim the cells retain 70% to 85% of their capacity after one year when stored at 20 °C (68 °F), compared to about half for normal NiMH batteries. They are otherwise similar to other NiMH batteries, and can be charged in the same chargers. These cells are marketed as "hybrid", "ready-to-use" or "pre-charged" rechargeables. Retention of charge depends a lot on the battery's impedance or internal resistance (the lower the better), and on the physical size of the battery as well as the charge capacity.

Low self-discharge cells have lower capacity than many standard NiMH cells due to the larger area of the separator. The highest-capacity low-self-discharge AA cells have 2000–2500 mA·h capacity, and AAA 1000 mA·h, compared to 2800 mA·h and 1300 mA·h for high-capacity AA and AAA NiMH cells.[25]

Separators keep the two electrodes apart to slow electrical discharge while also allowing the transport of ionic charge carriers that are needed to close the circuit during the passage of current.[26] High quality separators are very important for battery performance.

Thick separators provide a simple way to reduce self discharge, but take up space and reduce capacity; thin separators tend to raise the self-discharge rate. Some batteries may have overcome this tradeoff using thin separators with more precise manufacturing techniques, and by using a more advanced sulfonated polyolefin separator.

Batteries with low internal resistance waste less energy on self-heating during rapid discharge and recharge. Low self-discharge NiMH batteries typically have significantly lower internal resistance than other NiMH batteries.[citation needed]

LSD NiMH batteries were introduced in November 2005 by Sanyo,[27] marketing them under the brand "eneloop".

There are many brand names for LSD NiMH batteries. Most manufacturers produce only size AAA and AA batteries, and most low self-discharge batteries are sold in these sizes. Larger size C and D cells are available, though some are actually AA cells inside a C/D-sized case. Maha offers an LSD "D"-cell called the "Imedion" self-rated at 9500 mA·h, Accupower offers the "Acculoop" self-rated at 8500 mA·h, and Tenergy offers the "Centura" self-rated at 8000 mA·h. [citation needed] Tenergy also offers 9V cells.

Varta (USA: Rayovac) and Ansmann increased their LSD NiMH batteries' capacity to roughly 2300 mA·h. Sanyo introduced a new version of its Eneloop batteries with increased capacity and life expectancy. The "Eneloop plus" incorporates a PTC thermistor that disconnects the power if the battery overheats, in order to make it safe for use in toys for small children.

Environmental impact

Improper disposal of NiMH batteries poses less environmental hazard than that of NiCd because of the absence of toxic cadmium. However, mining and processing the various alternate metals that form the negative electrode may pose other types of environmental impact, depending on the metal, mining method, and environmental practices of the mine.

Most industrial nickel is recycled, due to the relatively easy retrieval of the magnetic element from scrap using electromagnets, and due to its high value. [citation needed]

Comparison with other battery types

NiMH cells and chargers are readily available in retail stores in the common sizes AAA and AA. Adapter sleeves are available to use the more common AA size in C and D applications. The sizes C and D cells are somewhat available, but are often just an AA core hidden in an outer shell, with a rating of about 2500 mA·h, much less than ordinary alkaline C and D batteries.[citation needed] Real NiMH C and D batteries are expensive (and the chargers are uncommon); they should be rated at least 5000 mA·h for C and 10,000 mA·h for D sizes. However, 12,000 mA·h D size batteries and 15,000 mA·h. F size batteries also exist.

PP3 (nine volt) NiMH batteries are available; these usually have an output voltage of 8.4 V (1.2 × 7) and a capacity of roughly 200 mA·h.[28] Also available are eight-cell nine volt batteries with a nominal output voltage of 9.6 V (1.2 × 8).

NiMH cells are often used in digital cameras and other high drain devices, where over the duration of single charge use they outperform primary (such as alkaline) batteries.

NiMH cells are particularly advantageous for high current drain applications, due in large part to their low internal resistance. Alkaline batteries, which might have approximately 3000 mA·h capacity at low current demand (200 mA), will have about 700 mA·h capacity with a 1000 mA load.[29] Digital cameras with LCDs and flashlights can draw over 1000 mA, quickly depleting alkaline batteries. NiMH cells can deliver these current levels without similar loss of capacity.

Certain devices that were designed to operate using primary alkaline chemistry (or zinc–carbon/chloride) cells will not function when one uses NiMH cells as substitutes. However, this is rare, as most devices compensate for the voltage drop of an alkaline as it discharges down to about 1 volt. Low internal resistance allows NiMH cells to deliver a near-constant voltage until they are almost completely discharged. This will cause a battery level indicator to overstate the remaining charge if it was designed to read only the voltage curve of alkaline cells. The voltage of alkaline cells decreases steadily during most of the discharge cycle.

Lithium-ion batteries have a higher specific energy than nickel–metal hydride batteries,[30] but they are significantly more expensive to produce.[31] In October 2009, ECD Ovonics announced that their next-generation NiMH batteries will provide specific energy and power that are comparable to those of lithium ion batteries at a cost that is significantly lower than the cost of lithium ion batteries.[31]

Applications

Applications of NiMH electric vehicle batteries include all-electric plug-in vehicles such as the General Motors EV1, Honda EV Plus, Ford Ranger EV and Vectrix scooter. Hybrid vehicles such as the Toyota Prius, Honda Insight, Ford Escape Hybrid, Chevrolet Malibu Hybrid, and Honda Civic Hybrid also use them. NiMH technology is used extensively in rechargeable batteries for consumer electronics like robotic vacuum cleaners of Neato Robotics, and it will also be used on the Alstom Citadis low floor tram ordered for Nice, France; as well as the humanoid prototype robot ASIMO designed by Honda. NiMH batteries are also commonly used in remote control cars.

Electric vehicles

Stanford R. Ovshinsky invented and patented (a popular improvement of) the NiMH battery and founded Ovonic Battery Company in 1982. General Motors purchased the patent from Ovonics in 1994. By the late 1990s, NiMH batteries were being used successfully in many fully electric vehicles, such as the General Motors EV1 and Dodge Caravan EPIC minivan. In October 2000, the patent was sold to Texaco and a week later Texaco was acquired by Chevron. Chevron's Cobasys subsidiary will only provide these batteries to large OEM orders. General Motors shut down production of the EV1 citing lack of battery availability as one of their chief obstacles. The Cobasys control of NiMH batteries has created a patent encumbrance of large automotive NiMH batteries.[32][33][34][35][36]

Telecommunications

In recent years, NiMH batteries have been deployed to provide reliable backup power to load equipment located in a network environment of a typical telecommunications service provider.

The NiMH batteries are recommended for use in the Central Office (CO), Outside Plant (OSP), and at locations such as Controlled Environmental Vaults (CEVs), Electronic Equipment Enclosures (EEEs), huts, and in uncontrolled structures such as cabinets.

To ensure conformance and product safety, the telecommunications industry has accepted a three-level compliance system, which is described in GR-3168, Generic Requirements for Nickel Metal Hydride (NiMH) Battery Systems for Telecommunications Use. The compliance system provides a common framework for evaluating and qualifying various NiMH battery technologies. The framework intends to alleviate the complexities associated with product introduction and qualification.

The service life of NiMH batteries is extremely important in a telecommunications environment. The main failure modes of lead–acid batteries are very temperature sensitive. Grid corrosion and water loss are sped up as the battery temperature increases. The service life is halved with each 8 °C (46 °F) rise in temperature. Thus, a battery designed to operate for 10 years at 25 °C (77 °F) would last approximately only 5 years at 33 °C (91 °F), and would last only 2.5 years at 42 °C (108 °F).[citation needed]

Nickel–cadmium (NiCd) batteries fail in a different manner. NiCd batteries are susceptible to failures caused by short circuiting due to dissolution/crystallization reactions occurring at the negative electrode, which can result in dendrite growth of Cd creating a short to the positive plate.

NiMH batteries do not fail in the same way as NiCd or lead–acid batteries. NiMH batteries fail in two predominant modes that are somewhat interrelated. The metal hydride material used for the negative electrode undergoes gradual corrosion in a strong alkaline environment. This corrosion results in less negative active material for hydrogen storage and also consumes water from the electrolyte.

This results in a gradual loss of power as water is consumed, increasing the cell resistance and a gradual loss in capacity as active material is converted to corrosion products. By optimization of the alloy composition, this corrosion process can be controlled at very low rates. The rate of corrosion will be impacted by various factors including temperature, State of Charge (SoC), and control of overcharge and oxygen recombination. Studies under controlled overcharge conditions predict that the service life is halved for each approximately 20 °C (68 °F) rise in temperature. Thus, a battery designed to operate for 20 years at 25 °C (77 °F) would last 10 years at 45 °C (113 °F).[citation needed] Extrapolation beyond 45 °C is not linear since other failure modes, caused by decreasing charge acceptance resulting in positive electrode swelling and thermal instability, could control the battery life.

See also

- Battery recycling

- Chevron Corporation

- Electric car

- Gas diffusion electrode

- Lithium-ion battery

- Nickel–hydrogen battery

- Nickel(II) hydroxide

- Nickel(III) oxide

- Patent encumbrance of large automotive NiMH batteries

- Power-to-weight ratio

References

- ↑ 1.0 1.1 "NiMH Battery Charging Basics".

- ↑ http://panasonic.net/energy/battery/eneloop/lineup/

- ↑ See graph, p.8 of "Ni–MH Batteries Technical Bulletin". Duracell. Retrieved 4 November 2011.

- ↑ 4.0 4.1 "Secondary battery sales statistics by volume". Battery Association of Japan. Retrieved 10 September 2011.

- ↑ "Batterien-Absatzstatistik 2008" [Battery Sales Statistics 2008] (in German). INOBAT (the Swiss interest organisation for battery disposal). p. 2. Retrieved 10 September 2011.

- ↑ In search of the perfect battery, The Economist, 6 March 2008

- ↑ The US patent is US patent 3824131A, Dr. Klaus Beccu, "Negative electrode of titanium–nickel alloy hydride phases", assigned to Battelle-Geneva R&D Center. For the performance data, see the "Examples" section.

- ↑ Nii, K.; Amano, M. (1997). "R & D of Hydrogen Absorbing Alloys in Japan". Acta Metallurgica Sinica 10 (3): 249–255. Retrieved 10 September 2011.

- ↑ US patent 6413670, "High power nickel–metal hydride batteries and high power alloys/electrodes for use therein", published July 2, 2002

- ↑ Avicenne Conf., Nice 2008, M.A. Fetcenko/ECD

- ↑ J. Kopera (25 June 2004). "Inside the Nickel Metal Hydride Battery". Cobasys. Retrieved 2011-09-10.

- ↑ Japanese Nonwoven Battery Applications

- ↑ 13.0 13.1 13.2 13.3 "Charge Methods for Nickel Metal Hydride Batteries". Nickel Metal Hydride Handbook. Panasonic.

- ↑ 14.0 14.1 14.2 14.3 14.4 14.5 14.6 "Charge Sealed Nickel–Metal Hydride Batteries". Ni–MH Technical Bulletin (Duracell).

- ↑ "Nickel–Metal Hydride Battery Handbook and application manual". energizer.

- ↑ "Charging at High and Low Temperatures".

- ↑ Mukund R. Patel (2005), "Spacecraft Power Systems" CRC Press ISBN 978-0-8493-2786-5 p. 209

- ↑ Energizer NH15-2300mAh datasheet

- ↑ Sandeep Dhameja (2002), Electric Vehicle Battery Systems, Newnes, ISBN 0-7506-9916-7, pp. 118, 123

- ↑ "Nickel–Metal Hydride (NiMH) Battery Charger and Battery Pack. User’s Manual.". Sea-Bird Electronics, Inc. Archived from the original on 2009-02-27. Retrieved 2009-07-10. "NiMH batteries self-discharge up to 20% in the first 24 hours after charging, then as much as 15% per month. Self-discharge is highly temperature dependent. NiMH batteries self discharge about three times faster at 40 °C than at 20 °C. Age also affects self-discharge. Older battery packs self-discharge faster than new ones."

- ↑ "epanorama.net: Battery Power Supply Page". Retrieved 2009-07-10. "A NiMH battery can lose up to 2% of its charge per day sitting on the shelf."

- ↑ "Battery Nurse: VCS, Voltage Control System". Retrieved 2009-07-10. "NiMh batteries tend to self-discharge at 3–4% of capacity per day."

- ↑ "Choosing the Right Battery Pack". Archived from the original on 2008-07-04. Retrieved 2009-07-10. "Nickel Metal Hydride (NiMh) Approx 1% per day if unused."

- ↑ "GP Batteries (Hong Kong) FAQ". Archived from the original on 2007-12-11. Retrieved 2009-07-10. "18. What is the self-discharge rate of NiMH batteries? In general, the rate of self-discharge ranges from 15% to 20% per month at room temperature."

- ↑ us.sanyo.com: Product information for Sanyo Eneloop XX

- ↑ Flaim, Tony, Yubao Wang, and Ramil Mercado. "High Refractive Index Polymer Coatings." SPIE Proceedings of Optical Systems Design. Web

- ↑

- ↑ Energizer type HR-22 data sheet: Actually says 175 mA·h, but that's "roughly 200 mA·h"

- ↑ Alkaline Drain Chart at greenbatteries.com

- ↑ "Mitsubishi Heavy to make lithium ion car batteries". Yahoo finance, Singapore, quoting Reuters. 23 January 2007. Retrieved July 2007.

- ↑ 31.0 31.1 http://www.ovonics.com/PDFs/Batteries2009OctoberNiceConference.pdf

- ↑ New Hybrid Reviews, News & Hybrid Mileage (MPG) Info | Hybrid Cars

- ↑ Sherry Boschert (2006). Plug-in Hybrids: The Cars that will Recharge America. New Society Publishers, Gabriola Island, Canada. ISBN 978-0-86571-571-4.

- ↑ Shnayerson, Michael (1996-08-27). The Car That Could: The Inside Story of GM’s Revolutionary Electric Vehicle. Random House. pp. 194–207, 263–264. ISBN 978-0-679-42105-4.

- ↑ Coker, M. (2003-05-15). "Dude, Wheres My Electric Car!?!". Orange County Weekly. Retrieved 2009-10-08.

- ↑ Greenberg J. (2008-10-14). "The Edison of our Age: Stan Ovshinsky and the Future of Energy (Video Interview Part 1)". The Energy Roadmap. Retrieved 2009-10-08.

External links

- "Bipolar Nickel Metal Hydride Battery" by Martin G. Klein, Michael Eskra, Robert Plivelich and Paula Ralston

- Energizer Ni-MH Battery Datasheets

- Rayovac battery Specifications and Product Guides

- Chevron/Texaco's patent on the NiMH battery