Material flow analysis

Material flow analysis (MFA) (also referred to as substance flow analysis; SFA) is an analytical method of quantifying flows and stocks of materials or substances in a well-defined system. MFA is an important tool to assess the physical consequences of human activities and needs in the field of Industrial Ecology, where it is used on different spatial and temporal scales. Examples are accounting of material flows within certain industries and connected ecosystems, determination of indicators of material use by different societies, and development of strategies for improving the material flow systems in form of material flow management. Since 1990, research publications in the field of material flow analysis (MFA) have grown fast in the Journal of Industrial Ecology and in Ecological Economics ecological economics.

Description of the method

Motivation

Human needs such as shelter, food, transport, or communication require materials such as wood, starch, sugar, iron and steel, copper, or semiconductors. As society develops and economic activity grows, production, use, and disposal of the materials employed increases to a scale where unwanted impacts on environment and society cannot be neglected anymore, neither locally nor globally: Material flows represent the core of local environmental problems such as leaching from landfills or oil spills. Rising concern about global climate change put a previously unimportant waste flow, carbon dioxide, on the top of the political and scientific agenda. In addition the gradual shift from traditional to urban mining in developed countries requires a detailed assessment of in-use and obsolete stocks of materials within the human environment. Industries, government bodies, and other organisations therefore need a tool to complement economic accounting with systematic book-keeping of materials entering, staying, and leaving the anthroposphere. Material flow analysis is such a tool.

Basic Principles

MFA is based on two fundamental and well-established scientific principles, system approach and mass balance. While these principles are applied wide across science and technology, it is the way they are applied to the socioeconomic metabolism that makes MFA a special method. [1] [2]

System Definition:

An MFA system is a model of a process, industry sector or region of concern. Its level of detail is chosen according to the purpose of the study. An MFA system consists of the system boundary, processes, flows, and stocks. Contrary to e.g. chemical engineering where such a system would represent a specific physical setup, systems and processes in MFA can represent much larger and more abstract things as long as they are well-defined. The concept of the system is central as it allows to allocate quantitative information either as stocks within certain processes or as flows between processes. In other words an MFA system allows to graphically allocate the meaning of measurements or statistical data in form of stocks or flows that are related to certain processes in a given system.

MFA studies can be refined by disaggregating or simplified by aggregating processes.

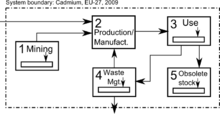

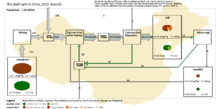

Next to the system and the arrangement of processes and flows in between, scale and scope of the system need to be specified. The spatial scale is the geographic entity that is covered by the system. A system representing a certain industrial sector can be applied to the US, China, certain world regions, or the world as a whole. The temporal scale is the point in time or time span for which the system shall be considered. A system can represent a snapshot of stocks and flows at a certain point in time or it can contain time series which describe the temporal evolution of the system variables. The material (scope) of the system is the actual physical entity that shall be quantified. This can be a certain chemical element such as cadmium or a substance such as CO2. More general things can be quantified as well as long as some kind of balance can be established. Examples are goods such as passenger cars or other physical quantities such as energy.

Unlike in daily life, MFA requires a more precise use of the terms material, substance, or good due to the way they are affected by the mass balance principle. We refer to chapter 2.1 from Brunner and Rechberger:[3]

- A chemical element is "a pure chemical substance consisting of one type of atom distinguished by its atomic number".[4]

- A substance is "any (chemical) element or compound composed of uniform units. All substances are characterized by a unique and identical constitution and are thus homogeneous." From chapter 2.1.1 in Brunner&Rechberger.[3]

- A good is defined as "economic entity of matter with a positive or negative economic value. Goods are made up of one or several substances". From chapter 2.1.2 in Brunner&Rechberger.[3]

- The term material in MFA "serves as an umbrella term for both substances and goods." From chapter 2.1.3 in Brunner&Rechberger.[3]

Process balance: One of the main purposes of MFA is to obtain a complete picture of the metabolism of certain elements or substances within the scope of the system. Such an analysis must also cover the stocks and flows that are not covered by financial accounting such as some waste flows, exhausts, or stocks of obsolete products. Mass balance or more general process balance is a first order physical principle that turns MFA into a powerful tool. The requirement for a balance to hold for each process facilitates a complete picture of the materials used, produced, and discarded within the various processes. Which balances hold for a given system depends on the specific processes that are considered: While for a process ‘oil refinery’ one can establish a mass balance for each chemical element, this is not possible for a nuclear power station. A car factory respects the balance for steel, but a steel mill doesn’t. Mass balance is a powerful and surprisingly versatile concept for the quantification of MFA systems.

When quantifying MFA systems either by measurements or from statistical data, mass balance and other process balances have to be checked to ensure the correctness of the quantification and to reveal possible data inconsistencies or even misconceptions in the system such as the omission of a flow or a process.

Applications on different spatial and temporal scales

Material flow analyses are conducted on various spatial and temporal scales, for a variety of elements, substances, and goods, and cover a wide range of process chains and material cycles. Examples are

- MFA on a national or regional scale (also referred to as Material Flow Accounting): In this type of studies the material exchanges between an economy and the natural environment are analyzed. Several indicators are calculated in order to assess the level of resource intensity of the system.

- Corporate material flow analysis, or MFA along an industrial supply chain involving a number of companies: The goal of material flow analysis within a company is to optimize the production processes in such a way that materials and energy are used in the most efficient manner (e.g. by recycling and reduction of waste). Companies that implement material flow analysis can use the results to improve their operations costs and environmental performance.

- In the life cycle of a product: The life cycle inventory as part of life cycle assessment can be considered an MFA as it involves system definition and balances.

Historic development of the discipline

- Mass balance or the conservation of matter has been postulated already in ancient Greece, and it was introduced into modern chemistry by Lavoisier (cf. chapter 2.1.3 in Brunner&Rechberger.[3]), from where it found its way to chemical engineering and finally to environmental science.

- Dennis Meadows made a wide audience aware of the physical foundation of the economy when he co-authored the bestseller Limits to Growth in 1971. Meadows et al. based their predictions on an analysis of resource stocks; see in the Glossary Glossary of environmental science#R.

- Friedrich Schmidt-Bleek is considered by many to be the father of MFA with his concept of Material Input Per Service unit (MIPS). Dr. Schmidt-Bleek is known for his work which claims that resource efficiency could be increased by a Factor 10. In the 1980s he inspired others to conduct MFA studies with him at the Wuppertal Institute[5] and to establish research groups at other academic institutions. One example is the Sustainable Europe Research Institute (SERI) in Vienna, Austria which has developed a data base called materialflows.net.[6]

- Mathis Wackernagel is known for co-developing the concept of the ecological footprint. Dr. Wackernagel founded the Global Footprint Network.

- The UNEP Resource Panel[7] was set up in 2007 by the United Nations Environment Program, and is headed by Ernst Ulrich von Weizsaecker and Ashok Khosla. In analogy to the Intergovernmental Panel on Climate Change (IPCC)[8] it brings together experts from many disciplines and institutions to review the current state of research on societal metabolism and to communicate the latest findings to policymakers and stakeholders.

Recent development

- MFA concepts have been or are being incorporated in national accounts in several countries and regions such as the EU[9] and Japan.[10]

- Several international conferences or other meetings provide a platform for researchers and policymakers to meet and exchange results and ideas. A prominent example is the World Resources Forum,[11] a bi-annual international conference on material flow analysis and sustainable development held in Davos, Switzerland. Friedrich Schmidt-Bleek, Dennis Meadows, and Ernst Ulrich von Weizsaecker from the UNEP Resource Panel were among the keynote speakers during the 2009 event.

- MFA-IO is an approach to establish an MFA system of the whole economy using monetary and physical Input-Output tables.[12]

- Dynamic MFA aims for long-term quantification of MFA systems and uses historic development patterns of physical stocks and flows to create robust scenarios for the years and decades to come.[13]

- The current centre for MFA research is Japan. The country has scarce mineral resources and is therefore dependent on imports of energy carriers, ores, and other raw materials. The Japanese government fosters research on material cycles and also inaugurated the 3-R concept.[14]

Relation to other Industrial Ecology methods

MFA is complementary to Life Cycle Assessment and Input-output models. Some overlaps between the different methods exist as they all share the system approach and to some extent the mass balance principle. The methods mainly differ in purpose, scope, and data requirements. MFA studies often cover the entire cycle (mining, production, manufacturing, use, waste handling) of a certain substance within a given geographical boundary and time frame. The level of detail of the system is adapted to the substance considered. Material stocks are considered explicitly which makes MFA suitable to tackle resource scarcity and recycling from old scrap. The common use of time series and lifetime models makes MFA a suitable forecasting tool for long-term trends in material use.

- Compared to IO analyses the number of processes considered in MFA systems is usually much lower. On the other hand mass balance ensures that flows of by-products or waste are not overlooked in MFA studies, whereas in IO tables these flows are often not listed due to their lack in economic value. In addition, physical IO models are much less common than economic ones. Material stocks are also only indirectly covered by IO analysis in form of capital accumulation. Moreover, IO models do not have an upper limit: Any given final demand can be satisfied. MFA systems on the other hand usually contain stocks of resources and hence a physical upper boundary of material turnover can be established.

- Life cycle assessments and inventories focus on the various material demands and subsequent impacts for single products, whereas MFA studies typically focus on a single material in many different products. When scaling up LCA studies to cover a whole market or sector, feedbacks on the industry, such as flows of old scrap or resource constraints should be considered, topics that are traditionally covered by MFA studies.

See also

- Material flow accounting

- Industrial ecology

- Industrial metabolism

- Anthropogenic metabolism

- Sustainability

- Energy accounting

- Material criticality

References

- ↑ Marina Fischer-Kowalski, The Intellectual History of Materials Flow Analysis, Part I, 1860-1970, Journal of Industrial Ecology 2(1), 1998, pp 61-78, doi:10.1162/jiec.1998.2.1.61.

- ↑ Marina Fischer-Kowalski, The Intellectual History of Materials Flow Analysis, Part II, 1970-1998, Journal of Industrial Ecology 2(4), 1998, pp 107-136, doi:10.1162/jiec.1998.2.4.107.

- ↑ 3.0 3.1 3.2 3.3 3.4 Brunner, P.H.; Rechberger, H. (2004). Practical Handbook of Material Flow Analysis. Lewis Publishers, New York. ISBN 1-56670-604-1.

- ↑ IUPAC, Compendium of Chemical Terminology, 2nd ed. (the "Gold Book") (1997). Online corrected version: (2006–) "chemical element".

- ↑ "Wuppertal Institute". Retrieved 3 July 2011.

- ↑ "materialflows.net". Retrieved 3 July 2011.

- ↑ "UNEP". Retrieved 3 July 2011.

- ↑ "IPCC". Retrieved 3 July 2011.

- ↑ "Accounting in the EU". Retrieved 3 July 2011.

- ↑ "Accounting in Japan". Retrieved 3 July 2011.

- ↑ "World Resources Forum". Retrieved 3 July 2011.

- ↑ Nakamura, S.; Kondo, Y. (2009). Waste Input-Output Analysis. Concepts and Application to Industrial Ecology. Springer. ISBN 978-1-4020-9901-4.

- ↑ Daniel B. Müller, Stock dynamics for forecasting material flows--Case study for housing in The Netherlands, Ecological Economics 59(1), 2006, pp 142-156, doi:10.1016/j.ecolecon.2005.09.025.

- ↑ "3R in Japan". Retrieved 3 July 2011.

Baccini, P.; Bader, H.-P. (1996). Regionaler Stoffhaushalt. Spektrum Akademischer Verlag, Heidelberg (Germany). ISBN 3-86025-235-6.

External links

- CSIRO and UNEP Material Flow and Resource Productivity Database for Asia and the Pacific

- materialflows.net

- MFA is described in great detail and published on 166 pages in the first of four paper volumes co-edited with assistance from UNEP and in online form by the *OECD

- STAN Material Flow Analysis Freeware

- Economy-wide Material Flow Analysis and Indicators

| ||||||||||||||||||||||||||