Hypromellose

| Hypromellose | |

|---|---|

| |

| Other names Hydroxypropyl methylcellulose; hydroxypropyl methyl cellulose; HPMC; E464 | |

| Identifiers | |

| CAS number | 9004-65-3 |

| ChemSpider | 21241863 |

| UNII | 36SFW2JZ0W |

| ATC code | S01 |

| |

| Properties | |

| Molecular formula | variable |

| Molar mass | variable |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C (77 °F), 100 kPa) | |

| Infobox references | |

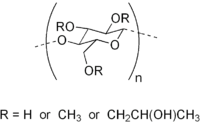

Hypromellose (INN), short for hydroxypropyl methylcellulose (HPMC), is a semisynthetic, inert, viscoelastic polymer used as an ophthalmic lubricant, as well as an excipient and controlled-delivery component in oral medicaments, found in a variety of commercial products.[1][2]

As a food additive, hypromellose is an emulsifier, thickening and suspending agent, and an alternative to animal gelatin.[3] Its Codex Alimentarius code (E number) is E464. It is Generally recognized as safe by the FDA.[4]

Chemistry

Hypromellose is a solid, and is a slightly off-white to beige powder in appearance and may be formed into granules. The compound forms colloids when dissolved in water. This non-toxic ingredient is combustible and can react vigorously with oxidising agents.[5]

Hypromellose in an aqueous solution, unlike methylcellulose, exhibits a thermal gelation property. That is, when the solution heats up to a critical temperature, the solution congeals into a non-flowable but semi-flexible mass. Typically, this critical (congealing) temperature is inversely related to both the solution concentration of HPMC and the concentration of the methoxy group within the HPMC molecule (which in turn depends on both the degree of substitution of the methoxy group and the molar substitution. That is, the higher the concentration of the methoxy group, the lower the critical temperature. The inflexibility/viscosity of the resulting mass, however, is directly related to the concentration of the methoxy group (the higher the concentration, the more viscous or less flexible the resulting mass is).

Uses

There are many fields of application for hypromellose. These are not limited to the following:[6]

- Tile adhesives

- Cement renders

- Gypsum products

- Pharmaceutical

- Paints & coatings

- Food

- Cosmetics

- Detergents & cleaners

- Eye drops

Use in whole grain breads

Agricultural Research Service scientists are investigating using the plant-derived HPMC as a substitute for gluten in making all-oat and other grain breads. Gluten, which is present in wheat, rye and barley is absent (or present only in trace quantities) in oat and other grains. Like gluten, HPMC can trap air bubbles formed by the yeast in bread dough, causing the bread to rise. Although it has not been widely studied, it is predicted that whole grain breads made with HPMC will have cholesterol-lowering effects.

Use in construction materials

HPMC is used primarily in construction materials like tile adhesives and renders[7] where it is used as a rheology modifier and water retention agent.

Functionally HPMC is very similar to HEMC (hydroxy ethyl methyl cellulose) Trade names include Methocel and Walocel. The global leading producer is Dow Wolff Cellulosics GmbH.[8]

Ophthalmic applications

Hypromellose solutions were patented as a semisynthetic substitute for tear-film.[9] Its molecular structure is predicated upon a base celluloid compound that is highly water soluble. Post-application, celluloid attributes of good water solubility reportedly aids in visual clarity. When applied, a hypromellose solution acts to swell and absorb water, thereby expanding the thickness of the tear-film. Hypromellose augmentation therefore results in extended lubricant time presence on the cornea, which theoretically results in decreased eye irritation, especially in dry climates, home, or work environments.[10] On a molecular level, this polymer contains beta-linked D-glucose units that remain metabolically intact for days to weeks. On a manufacturing note, since hypromellose is a vegetarian substitute for gelatin, it is slightly more expensive to produce due to semisynthetic manufacturing processes. Aside from its widespread commercial and retail availability over the counter in a variety of products, Hypromellose 2% solution has been documented to be used during surgery to aid in corneal protection and during orbital surgery.

Excipient/tableting ingredient

In addition to its use in ophthalmic liquids, hypromellose has been used as an excipient in oral tablet and capsule formulations, where, depending on the grade, it functions as controlled release agent to delay the release of a medicinal compound into the digestive tract.[11] It is also used as a binder[12] and as a component of tablet coatings.[13] [14]

Test Methods

Various benchmark tests are used to qualify hypromellose:

- Viscosity

- Degree of substitution (DS)

- Molar substitution (MS)

- Salt content

- Moisture

Viscosity test methods

Because hypromellose solution is a non-newtonian solution and exhibits pseudoplastic, more specifically, thixotropic behavior, various test methods are available, and the results of different methods and viscosmeters do not necessarily correspond to each other. Also, due to viscometer acceptable ranges of error, viscosity is typically given as a mean, or as a range. Typical viscosity test will specify the following:

- Solution concentration (1%, 2%, 1.9% bone dry, etc.)

- Viscometer (Brookfield LV or RV, Höppler falling ball, Haake Rotovisco, etc.)

- Viscometer spindle number (1 ~ 4 for Brookfield LV, 1 ~ 7 for Brookfield RV, etc.)

- Solution Temperature (20 °C, 25 °C, etc.)

Degree of substitution

Degree of substitution is the average level of methoxy substitution on the cellulose chain. Since there are maximum three possible sites of substitution with each cellulose molecule, this average value is a real number between 0 and 3. However, degree of substitution is often expressed in percentages.

Molar substitution

Molar substitution is the average level of hydroxypropoxy substitution on the cellulose chain. Since hydroxypropoxy base can be attached to each other on side chains and does not each require a base substitution site on the cellulose molecule, this number can be higher than 3. However, molar substitution is also often expressed in percentages.

Moisture

Since all cellulose ethers are hygroscopic, they will absorb moisture from surroundings if left exposed from original packaging. Thus, moisture must be tested and weight corrected to ensure adequate amount of dry active material are aportioned for usage. Moisture is tested by weighing a sample of X grams on an analytic scale, and drying the sample in an oven at 105 °C for 2 hours, then weighing the sample again on the same scale.

See also

References

- ↑ de Silva DJ, Olver JM (July 2005). "Hydroxypropyl methylcellulose (HPMC) lubricant facilitates insertion of porous spherical orbital implants". Ophthal Plast Reconstr Surg 21 (4): 301–2. PMID 16052145.

- ↑ Williams RO, Sykora MA, Mahaguna V (2001). "Method to recover a lipophilic drug from hydroxypropyl methylcellulose matrix tablets". AAPS PharmSciTech 2 (2): E8. doi:10.1208/pt020208. PMID 14727883.

- ↑ NOSB TAP Review Compiled by OMRI: Hydroxypropyl Methylcellulose

- ↑ Agency Response Letter GRAS Notice No. GRN 000213

- ↑ Safety data for hydroxypropyl methyl cellulose

- ↑ Example properties and applications of hydroxypropyl methyl cellulose

- ↑

- ↑ "About Us". Dow.com. Retrieved 2013-01-01.

- ↑ US Pat. No. 5,679,713

- ↑ Koroloff N, Boots R, Lipman J, Thomas P, Rickard C, Coyer F (June 2004). "A randomised controlled study of the efficacy of hypromellose and Lacri-Lube combination versus polyethylene/Cling wrap to prevent corneal epithelial breakdown in the semiconscious intensive care patient". Intensive Care Med 30 (6): 1122–6. doi:10.1007/s00134-004-2203-y10.1007/s00134-004-2203-y. PMID 15014864.

- ↑

- ↑ Weiner, Myra L.; Lois A. Kotkoskie (1999). Excipient Toxicity and Safety. p. 8. ISBN 9780824782108.

- ↑ Reddy, Indra K.; Riz̤ā Miḥvar (2004). Chirality in Drug Design and Development. p. 21. ISBN 9780824750626.

- ↑ Niazi, Sarfaraz (2004). Handbook of Pharmaceutical Manufacturing Formulations. pp. 275–276. ISBN 9780849317460.